In the world of outdoor maintenance, having a clear understanding of the assembly of your machinery is essential. This section delves into the intricate components of a specific model, shedding light on its structure and functionality. By exploring the various elements that come together to create a well-oiled machine, users can ensure optimal performance and longevity.

Each segment plays a crucial role in the overall operation, and recognizing these parts can facilitate better maintenance practices. Through a detailed overview, enthusiasts will gain insights into how these pieces interact, allowing for informed decision-making during repairs or upgrades. With this knowledge, users can confidently tackle any challenges that may arise while using their equipment.

Stihl FS 360 C Overview

This section provides an insightful look into a particular model known for its efficiency and reliability in outdoor maintenance tasks. Designed for various applications, this equipment has become a preferred choice among professionals and enthusiasts alike.

The unit is characterized by:

- Robust construction ensuring longevity.

- Powerful engine performance for demanding tasks.

- Ergonomic design for user comfort during extended use.

Its versatility makes it suitable for:

- Clearing grass and weeds.

- Managing overgrown areas with ease.

- Performing precision trimming in various environments.

Overall, this equipment stands out in its category, making it an invaluable tool for anyone involved in land management and gardening activities.

Key Components of FS 360 C

The effective functioning of a gardening tool hinges on its essential elements. Understanding these components is vital for maintenance, repair, and optimal performance. Each part plays a specific role, contributing to the overall efficiency of the equipment.

Essential Elements

The following are the primary components that ensure the reliable operation of the device:

| Component | Description |

|---|---|

| Engine | Provides the power needed for operation, converting fuel into mechanical energy. |

| Cutting Head | The part that houses the blade or line, responsible for cutting through grass and weeds. |

| Handle | Offers control and maneuverability, allowing the user to navigate various terrains. |

| Fuel Tank | Stores the fuel necessary for the engine to function efficiently. |

| Starter Mechanism | Initiates the engine’s operation, enabling the user to start the tool with ease. |

Importance of Regular Maintenance

Regular upkeep of these components is essential to extend the lifespan and functionality of the device. Periodic checks and timely replacements can prevent common issues and enhance performance.

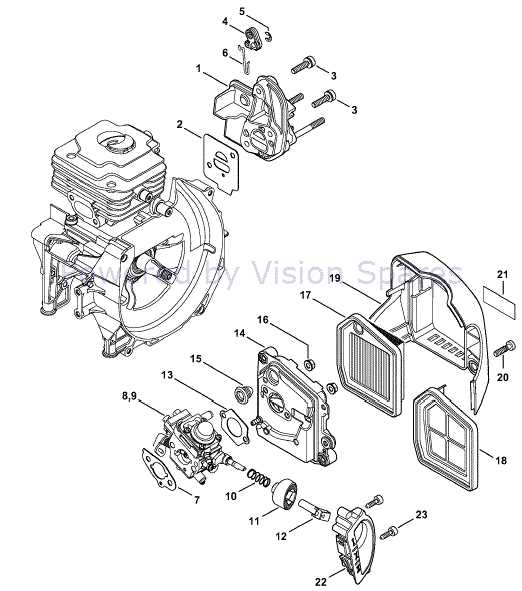

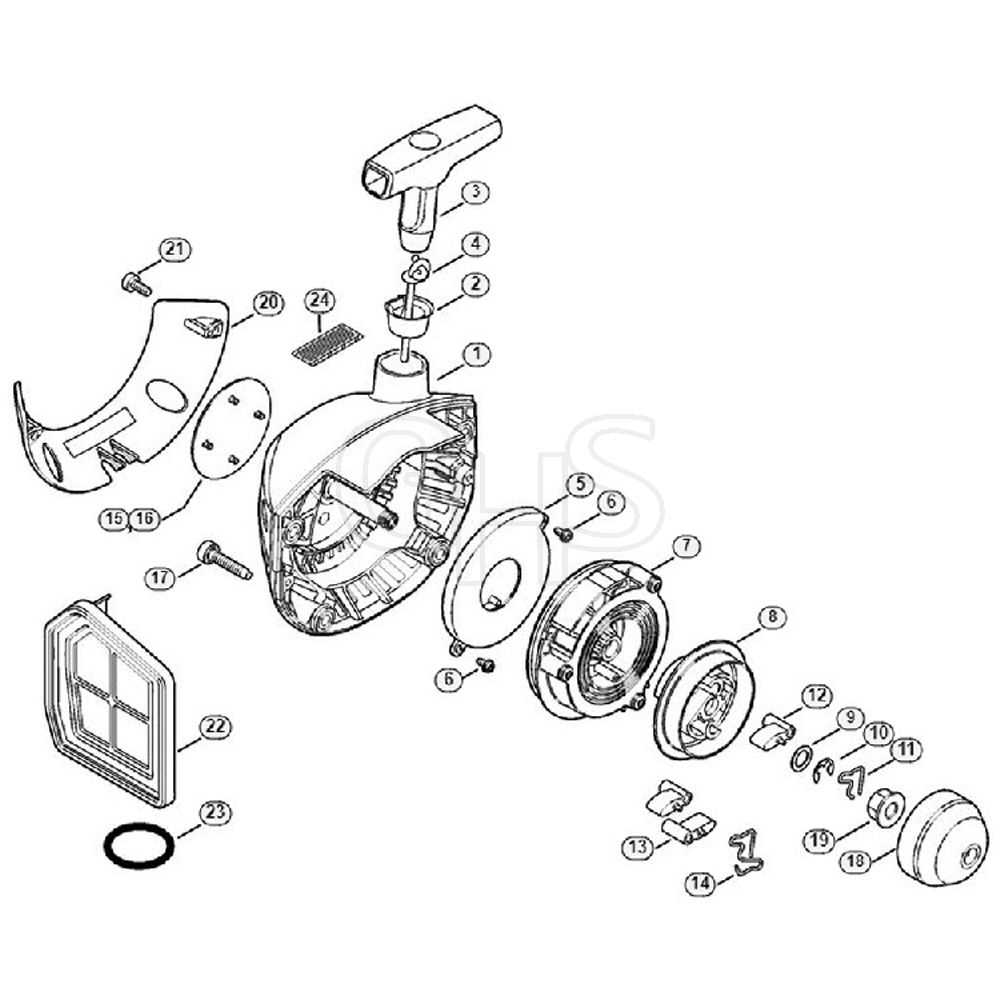

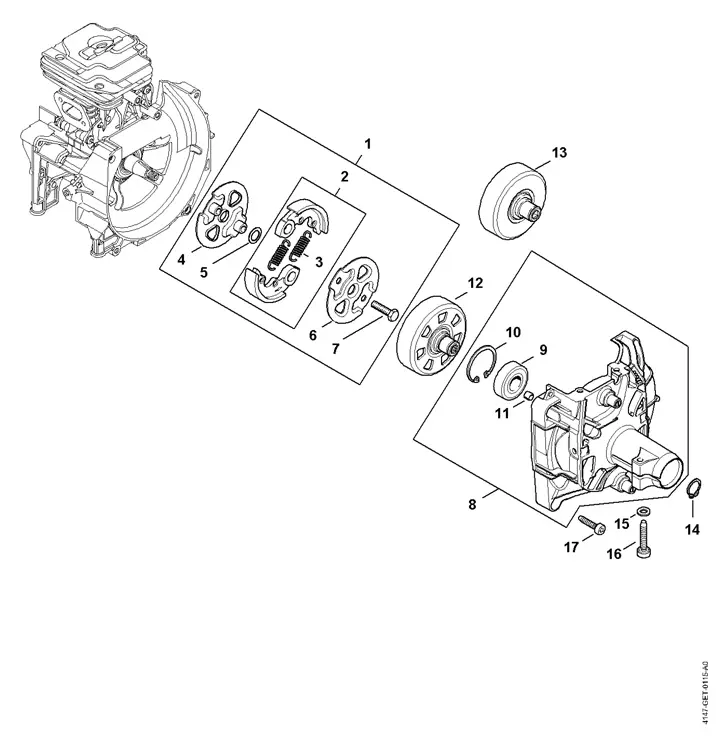

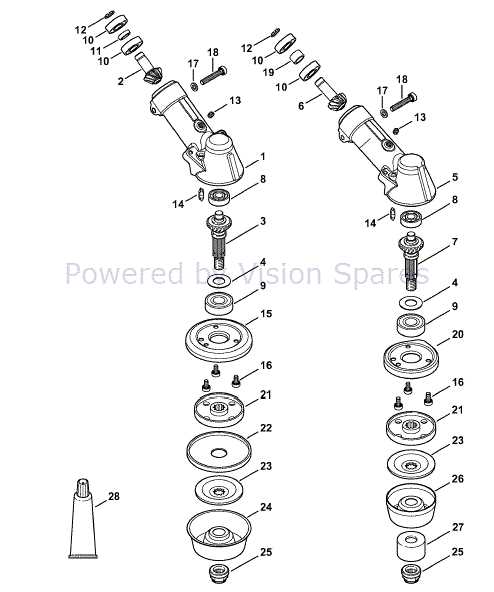

Understanding the Parts Diagram

The illustration of components is essential for grasping the functionality of a machine. It provides a visual representation that aids users in identifying various elements and understanding how they interact with one another. This knowledge is crucial for effective maintenance and troubleshooting.

Key Elements of the Illustration

Familiarizing oneself with the main features of the visual aid can enhance operational efficiency. Here are some vital aspects to consider:

- Labels: Each section is usually marked to indicate specific components.

- Connections: Understanding how parts link together is critical for assembly and disassembly.

- Color Coding: Often, different colors may signify various categories or functions.

Benefits of Using the Component Illustration

Utilizing this visual representation offers several advantages:

- Facilitates quick identification of components during repairs.

- Enhances comprehension of the machine’s structure and function.

- Streamlines the ordering of replacement items by providing clear references.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your equipment involves regular upkeep and attention to detail. Implementing a few simple practices can significantly enhance performance and durability.

Regularly clean the exterior to remove dirt and debris, as buildup can lead to overheating and reduced efficiency. Additionally, checking and replacing filters at recommended intervals helps maintain optimal airflow and functionality.

Lubricate moving parts as needed, using appropriate oils to prevent friction and wear. Furthermore, inspecting components for signs of damage or excessive wear enables timely repairs, preventing further complications.

Lastly, store the equipment in a dry and sheltered location to protect it from environmental factors that may cause deterioration. Following these tips will contribute to sustained performance and reliability over time.

Common Issues and Solutions

In any machinery, certain challenges may arise during operation that can hinder performance. Understanding these frequent problems and their respective remedies can enhance the longevity and efficiency of the equipment.

1. Engine Failure to Start: One prevalent issue is the inability of the engine to start. This can often be traced to a clogged fuel line or a dirty air filter. Regular maintenance of these components ensures optimal functionality.

2. Overheating: Overheating is another common concern that can lead to severe damage. This may result from inadequate cooling or an obstructed exhaust system. Ensuring proper airflow and checking for blockages can prevent this issue.

3. Vibration and Noise: Excessive vibration or unusual noises can indicate loose parts or wear in components. Regularly inspecting bolts and connections helps maintain stability and reduces operational noise.

4. Poor Cutting Performance: When the machinery fails to perform cutting tasks effectively, it may be due to dull blades or incorrect tension. Regular sharpening and tension adjustments are essential for optimal performance.

How to Order Replacement Parts

When your outdoor equipment requires new components, understanding the process of acquiring these items is essential. Ensuring you have the correct replacements can prolong the lifespan of your device and maintain its efficiency. This guide outlines the steps to successfully obtain the necessary items for your machine.

Identify the Required Components

Start by determining which elements need replacement. Consult your user manual or online resources to locate the specific identifiers for the components you need. Make a list to streamline the ordering process.

Choose a Reliable Supplier

Select a trusted vendor, whether online or at a local store, that specializes in outdoor machinery. Verify their inventory and ensure they carry the items you require. Many suppliers offer detailed catalogs to assist you in finding the right components.

Tools Needed for Assembly

Assembling equipment requires specific instruments to ensure efficiency and accuracy. Having the right tools on hand can significantly streamline the process and enhance the overall performance of the machine.

| Tool | Purpose |

|---|---|

| Wrench Set | For tightening and loosening fasteners. |

| Screwdriver Set | Essential for securing screws in place. |

| Pliers | Useful for gripping and twisting components. |

| Torque Wrench | To apply precise torque to bolts and nuts. |

| Safety Goggles | To protect eyes during assembly tasks. |

Safety Precautions During Repair

When undertaking maintenance on equipment, ensuring safety is of utmost importance. Proper precautions help prevent accidents and injuries, creating a secure environment for both the individual performing the task and those nearby.

Wear appropriate personal protective equipment, such as gloves, safety goggles, and hearing protection, to shield against potential hazards. Ensure that the workspace is well-ventilated and free of clutter to minimize risks.

Before beginning any repair, disconnect the power source to avoid accidental start-ups. Familiarize yourself with the equipment’s manual to understand specific safety recommendations and maintenance procedures. Keeping tools in good condition is also essential for safe operation.

Maintain focus during the repair process; distractions can lead to mistakes. If you feel fatigued, take a break to recharge before continuing. Always work with a clear mind to ensure careful handling of components.

By adhering to these guidelines, you can create a safer atmosphere while working on your machinery, ultimately leading to successful repairs and enhanced equipment longevity.

Comparing Models in the Series

In the realm of outdoor power equipment, understanding the differences among various models is essential for making informed decisions. Each variant brings its own unique features, specifications, and advantages, catering to a wide range of user needs.

When evaluating models in this particular series, consider the following aspects:

- Engine Power: Variations in horsepower can impact performance significantly, affecting cutting efficiency and overall productivity.

- Weight: The weight of each model plays a crucial role in maneuverability and ease of use, especially during extended tasks.

- Fuel Efficiency: Different designs can lead to variations in fuel consumption, influencing operating costs over time.

- Attachment Compatibility: Certain models may offer greater flexibility with attachments, enhancing versatility for diverse tasks.

Ultimately, understanding these differences allows users to choose the most suitable model for their specific requirements, optimizing performance and satisfaction in their outdoor endeavors.

Installation Steps for Key Parts

Proper installation of essential components is crucial for optimal performance and longevity of your equipment. Understanding each step involved in this process ensures that the assembly is both secure and efficient, minimizing the risk of malfunctions.

Below are the key steps to follow when installing vital components:

| Step | Description |

|---|---|

| 1 | Gather all necessary tools and components required for the installation. |

| 2 | Refer to the user manual to familiarize yourself with the layout and positioning of each part. |

| 3 | Start with the main assembly; align it properly to ensure a snug fit. |

| 4 | Secure each component using the recommended fasteners, making sure they are tightened to specifications. |

| 5 | Conduct a thorough inspection to verify that all parts are installed correctly and securely. |

| 6 | Perform a test run to ensure everything operates smoothly before full use. |

Following these steps will help guarantee that your equipment functions efficiently, extending its operational life and enhancing your overall experience.

Benefits of Regular Maintenance

Consistent upkeep of machinery plays a crucial role in ensuring optimal performance and longevity. By adhering to a structured maintenance routine, users can prevent potential issues, enhance efficiency, and ultimately save on costs associated with repairs or replacements.

Enhanced Performance

Regular maintenance helps to maintain the efficiency of equipment. This ensures that it operates smoothly and effectively, resulting in higher productivity levels.

Cost Savings

Investing time in routine checks can lead to significant cost reductions. Preventive measures often minimize the likelihood of major breakdowns, which can be expensive to fix.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Inspect and clean air filters | Every month | Improves airflow and performance |

| Check and tighten bolts | Monthly | Ensures stability and safety |

| Sharpen cutting blades | Every 25 hours of use | Enhances cutting efficiency |

Where to Find User Manuals

Accessing user manuals is essential for understanding and effectively operating various equipment. These guides provide detailed information on maintenance, functionality, and troubleshooting, ensuring users can maximize the performance of their devices.

Official Manufacturer Websites

One of the most reliable sources for user manuals is the official website of the manufacturer. These sites typically offer:

- A dedicated section for product documentation

- Search functionality to locate specific manuals by model

- Downloadable PDF versions for convenience

Online Retailers and Third-Party Websites

In addition to official resources, many online retailers and third-party sites provide access to user manuals. Consider the following:

- Retailer product pages often include links to manuals

- Specialized websites may aggregate manuals for various brands and models

- Forums and user communities can offer links to hard-to-find documents

Customer Reviews and Feedback

This section highlights user experiences and opinions regarding a particular model of outdoor power equipment. Understanding customer insights can provide valuable guidance for potential buyers, showcasing both strengths and areas for improvement.

Positive Experiences

- Many users appreciate the machine’s reliability and durability, making it suitable for demanding tasks.

- Customers often mention the ease of use, particularly for those new to similar equipment.

- Efficient performance is frequently noted, with users expressing satisfaction in achieving desired results quickly.

Areas for Improvement

- Some feedback points to the weight of the device as a consideration for extended use.

- A few customers have suggested enhancements in the user manual for better clarity.

- Minor complaints about noise levels have been mentioned, particularly in residential areas.