The intricate design of a garden tool reveals the essential elements that contribute to its functionality and performance. By comprehending how each piece interacts, users can optimize their experience and ensure longevity. This section will explore the various elements that make up this specific model, highlighting their roles and importance.

Each component serves a unique purpose, working in harmony to deliver the ultimate results for your landscaping tasks. From the motor to the cutting mechanism, knowing the specifics of these features enables more effective maintenance and troubleshooting. Dive deeper into the structure and you’ll uncover how to enhance your gardening routine.

With an understanding of these crucial elements, you can make informed decisions about repairs and upgrades. This knowledge empowers you to tackle challenges confidently, ensuring your tool operates at peak efficiency. Let’s embark on this journey to unveil the specifics behind this essential gardening equipment.

Understanding Stihl FS 40 C Overview

This section provides an insight into a popular model of handheld outdoor equipment designed for cutting grass and clearing brush. It combines efficiency and user-friendly features, making it suitable for both residential and light commercial use.

The device is characterized by its lightweight construction, powerful engine, and ergonomic design, which contribute to ease of use during extended periods. Here are some key aspects to consider:

- Engine Performance: The motor is designed to deliver reliable power, allowing users to tackle various tasks effectively.

- Weight: Its lightweight nature minimizes user fatigue, making it ideal for prolonged operation.

- Fuel Efficiency: The engine is optimized for lower fuel consumption, which not only reduces costs but also minimizes environmental impact.

- User Comfort: An ergonomic handle and adjustable features enhance comfort, ensuring better control and maneuverability.

Understanding these aspects will help users maximize the potential of this versatile tool, making yard maintenance and landscaping tasks more manageable and enjoyable.

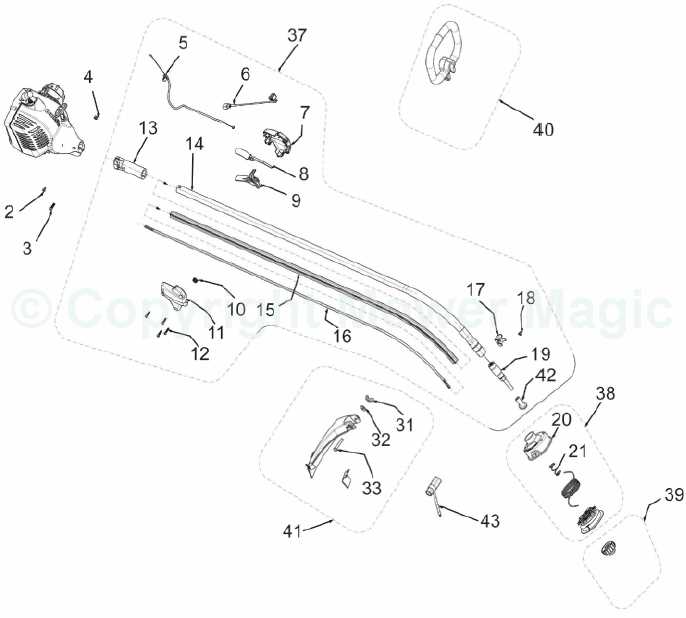

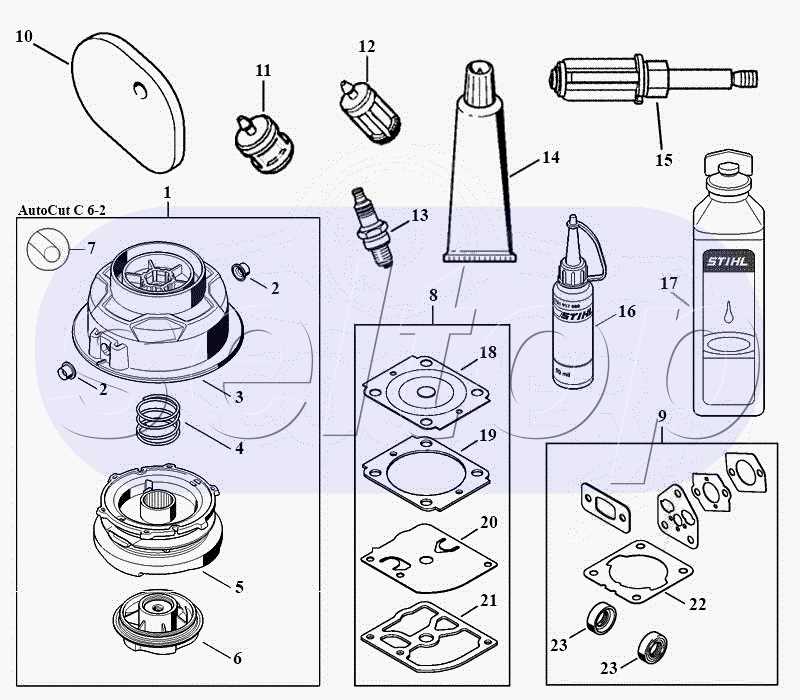

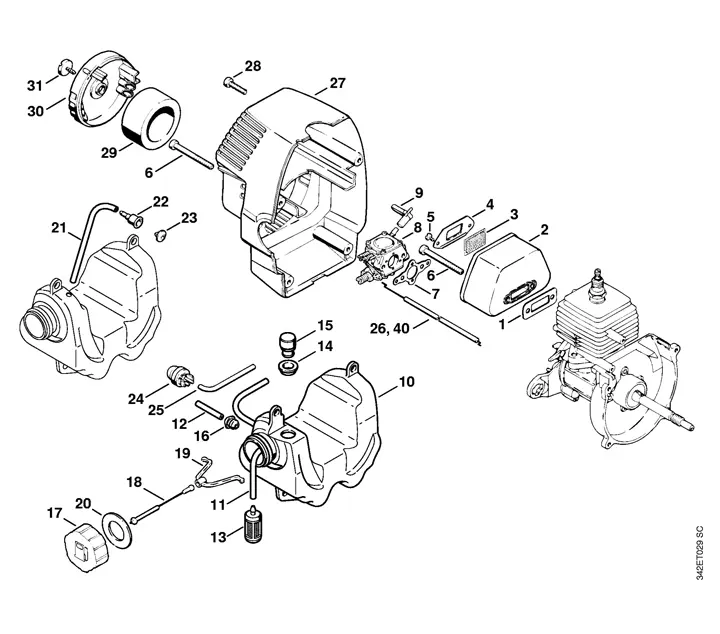

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for effective maintenance and repairs. Visual representations serve as essential tools that simplify the identification and organization of various elements. They enable users to quickly grasp the structure and relationships among components, enhancing both efficiency and accuracy during servicing.

Moreover, these illustrations provide valuable guidance for troubleshooting, allowing operators to pinpoint issues with precision. By referencing these visuals, one can reduce the likelihood of errors, streamline the repair process, and ensure that each element is reassembled correctly. This ultimately leads to prolonged equipment life and optimal performance.

In addition, familiarity with these resources fosters a deeper understanding of the machinery itself, empowering users to take proactive measures in maintenance. By investing time in studying these representations, one can cultivate a sense of confidence and competence, making future repairs less daunting.

Main Components of the FS 40 C

The FS 40 C consists of several essential elements that work together to ensure optimal performance. Each component plays a vital role in the overall functionality and efficiency of the equipment, contributing to its effectiveness in various tasks.

At the core is the engine, which provides the necessary power. The cutting mechanism, typically featuring a line or blade, is crucial for executing precise cuts. The handle and control system offer user-friendly operation, allowing for comfortable maneuverability.

Additionally, the fuel system ensures proper operation, while the safety features enhance user protection. Understanding these key components is essential for effective maintenance and troubleshooting, ensuring longevity and peak performance of the equipment.

Identifying Replacement Parts Easily

When it comes to maintaining your outdoor equipment, knowing how to find the right components can save you time and effort. Understanding the structure and functionality of each element will help you quickly identify what you need for replacements. A systematic approach can streamline your search and ensure you acquire the correct items efficiently.

| Component | Description | Common Issues |

|---|---|---|

| Engine | Core unit that powers the machine. | Hard starting, loss of power. |

| Cutting Head | Rotating part that does the trimming. | Worn lines, uneven cuts. |

| Fuel Tank | Container for the fuel supply. | Leaks, cracks. |

| Handle | Grip area for maneuvering. | Looseness, cracks. |

Common Issues with Stihl FS 40 C

This section addresses frequent problems encountered with a particular type of gardening equipment. Users may experience various challenges that affect performance, efficiency, and overall satisfaction. Understanding these issues can help in troubleshooting and maintenance, ensuring optimal operation.

Engine Starting Difficulties

One of the most prevalent issues is difficulty in starting the engine. This can stem from several factors, such as fuel quality, spark plug condition, or air filter blockage. Regular maintenance can prevent these issues, but if they arise, diagnosing the root cause is essential for effective resolution.

Power Loss During Operation

Another common complaint is a noticeable loss of power during use. This can be attributed to problems like clogged fuel lines, worn-out components, or improper fuel-to-oil ratio. Regular inspections and adhering to manufacturer guidelines can help maintain consistent power output.

| Issue | Possible Cause | Solution |

|---|---|---|

| Engine won’t start | Poor fuel quality | Use fresh, high-quality fuel |

| Engine stalls | Clogged air filter | Clean or replace air filter |

| Loss of power | Worn spark plug | Replace spark plug |

| Vibration issues | Loose components | Tighten all screws and bolts |

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires regular care and attention. By implementing a systematic maintenance routine, you can extend the life of your tools and enhance their performance. Here are some essential practices to keep your machine running smoothly.

- Regular Cleaning: After each use, clean the exterior and any accessible components to remove dirt and debris. This helps prevent wear and maintains optimal functionality.

- Check Fuel and Oil: Use the recommended fuel mixture and regularly check oil levels. Fresh fuel prevents clogging, while adequate lubrication reduces friction.

- Inspect Blades and Attachments: Regularly examine cutting tools for damage or dullness. Sharpen or replace them as needed to ensure effective operation.

- Tighten Fasteners: Over time, screws and bolts can loosen. Periodically check and tighten all connections to maintain stability.

- Store Properly: Keep the equipment in a dry, protected area when not in use. This prevents rust and other environmental damage.

By following these straightforward tips, you can significantly enhance the longevity and reliability of your equipment, ensuring it remains in top condition for years to come.

Tools Required for Disassembly

When undertaking the process of taking apart your equipment, having the right instruments is essential for a smooth and efficient experience. A well-equipped toolkit not only facilitates the disassembly but also ensures that components are handled carefully, minimizing the risk of damage.

Begin with basic hand tools such as screwdrivers and wrenches, which are fundamental for loosening screws and bolts. Depending on the design, you may also need specialized tools like pliers or socket sets to reach difficult areas. Additionally, a utility knife can prove useful for cutting through any protective coverings or seals.

For those more intricate tasks, consider having a set of torque wrenches to ensure that components are reassembled with the correct tightness. Lastly, organization tools, like trays or magnets, can help keep small parts in order, preventing loss and making reassembly more straightforward.

Exploring Aftermarket Part Options

When maintaining outdoor power equipment, considering alternative components can enhance performance and reduce costs. Aftermarket alternatives often provide a balance of quality and affordability, making them an attractive choice for many users. This section delves into the various options available for those looking to replace or upgrade their machinery.

Benefits of Aftermarket Alternatives

- Cost-Effectiveness: Typically more affordable than original manufacturer offerings.

- Variety: A wider range of options allows for customization and upgrades.

- Availability: Often easier to find, especially for older models or discontinued items.

Factors to Consider

- Quality: Research the reputation of manufacturers to ensure reliability.

- Compatibility: Verify that the components are suitable for your specific model.

- Warranty: Check if the alternatives come with a guarantee or warranty for added security.

By weighing these benefits and factors, users can make informed decisions when selecting replacement components, ensuring optimal functionality and longevity of their equipment.

Original Parts vs. Aftermarket Choices

When it comes to maintaining and repairing outdoor power equipment, users often face the decision between genuine components and alternatives. Each option has its own set of advantages and drawbacks, impacting performance, longevity, and overall satisfaction. Understanding these differences can help users make informed choices that best suit their needs.

Benefits of Genuine Components

- Quality Assurance: Original components are designed specifically for compatibility and optimal performance.

- Warranty Protection: Using genuine parts often ensures that the manufacturer’s warranty remains intact.

- Reliability: These components undergo rigorous testing, providing peace of mind in terms of durability and safety.

Considerations for Aftermarket Options

- Cost-Effectiveness: Alternatives can be more budget-friendly, making them appealing for users looking to save money.

- Variety: Aftermarket options may offer a broader selection, catering to specific preferences or unique needs.

- Availability: These components can often be found in a wider range of locations, providing convenience for quick repairs.

Ultimately, the choice between original and alternative components will depend on individual priorities such as budget, performance expectations, and the specific requirements of the equipment in question.

How to Access Parts Diagrams Online

Finding visual guides for machinery components can greatly simplify repair and maintenance tasks. These resources often provide clear illustrations and detailed information about individual elements, ensuring you can identify and replace necessary pieces efficiently.

Utilizing Manufacturer Websites

One of the most reliable methods is to visit the official website of the equipment maker. Here, you can typically navigate to a section dedicated to support or resources, where you may find comprehensive breakdowns of various models.

Exploring Online Forums and Communities

Joining relevant online communities or forums can also be beneficial. Members often share links to useful resources, including schematics, making it easier for you to obtain the information you need quickly.

Step-by-Step Repair Process

When it comes to restoring outdoor power equipment, a systematic approach can make all the difference. This guide outlines a clear, step-by-step method to efficiently diagnose and fix issues, ensuring your device operates smoothly once again.

Preparation and Safety

Before starting any repairs, it’s crucial to gather all necessary tools and ensure a safe working environment. Wear appropriate safety gear, including gloves and goggles. Disconnect the device from any power source to avoid accidental activation during the repair process.

Diagnosis and Repair

Begin by carefully examining the equipment for visible signs of damage or wear. Listen for unusual sounds and pay attention to any performance issues. Once identified, refer to the manufacturer’s guidelines for specific troubleshooting steps. Replace or adjust components as needed, ensuring all connections are secure. After completing the repairs, reassemble the unit and test its functionality to confirm that the problem has been resolved.

Cost Considerations for Parts Replacement

When it comes to maintaining outdoor equipment, budgeting for component replacements is essential for ensuring longevity and optimal performance. Understanding the financial implications of swapping out worn or damaged elements can greatly affect overall maintenance costs and the decision-making process regarding repairs or upgrades.

Several factors influence the expenses associated with component replacement. The type and quality of the items required can vary significantly, with premium options often offering better durability but at a higher price. Additionally, labor costs should be taken into account, especially if professional assistance is needed for installation. Evaluating whether to perform repairs independently or seek professional help can lead to significant savings or unforeseen expenses.

It’s also important to consider the frequency of replacements. Some components may need to be changed more often than others, affecting long-term budgeting. Regular maintenance can extend the lifespan of certain elements, potentially reducing the need for frequent replacements and thus lowering overall costs.

Lastly, exploring alternative sources for components, such as aftermarket suppliers, can provide opportunities for savings. However, ensuring compatibility and quality should remain a priority to avoid future expenses related to subpar items. Careful planning and research can lead to more informed decisions and better financial outcomes in maintaining outdoor equipment.

Where to Purchase Stihl Parts

Finding the right components for your equipment can greatly enhance its performance and longevity. With a variety of sources available, it’s essential to know where to look for genuine items to ensure quality and compatibility. This guide highlights the best options for acquiring what you need.

Authorized Dealers

Visiting an authorized retailer is one of the most reliable methods for obtaining authentic items. These dealers are certified to sell original components and often provide expert advice on installation and maintenance. Additionally, they may offer warranties on their products, giving you added peace of mind.

Online Marketplaces

The internet offers a plethora of options for purchasing necessary components. Reputable online platforms feature a wide selection, often at competitive prices. When shopping online, it’s crucial to verify the credibility of the seller and check for customer reviews to ensure a satisfactory experience. Make sure to look for options that guarantee authenticity and offer easy returns.