The efficient functioning of any outdoor machinery relies heavily on the precise arrangement and understanding of its various elements. Knowing how these components interact and work together can enhance performance and ensure longevity. This section aims to provide a comprehensive overview of the intricate structure involved in operating such machines.

By exploring the relationships between different sections, users can gain valuable insights into maintenance and troubleshooting. A clear visualization of how each segment fits into the whole allows for better decision-making when it comes to repairs and upgrades. This knowledge not only empowers users but also fosters a deeper appreciation for the engineering behind these tools.

Moreover, familiarizing oneself with the specific features of each component can significantly simplify the process of diagnosing issues. Understanding where each part is located and its function aids in streamlining maintenance tasks, ensuring that equipment remains in optimal condition for years to come. This exploration serves as a guide for enthusiasts and professionals alike, promoting a hands-on approach to machinery care.

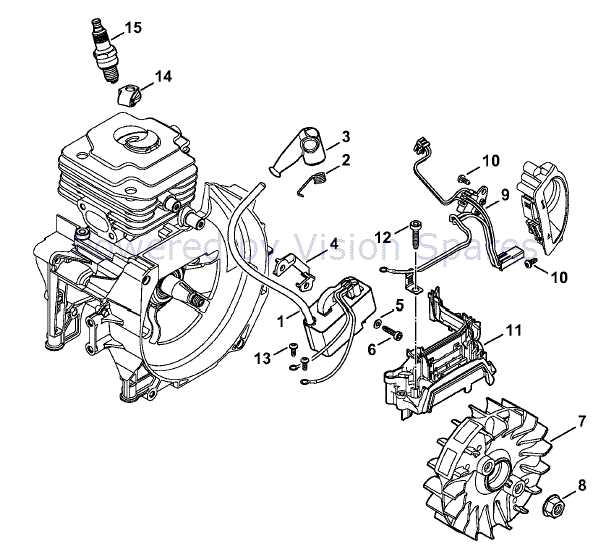

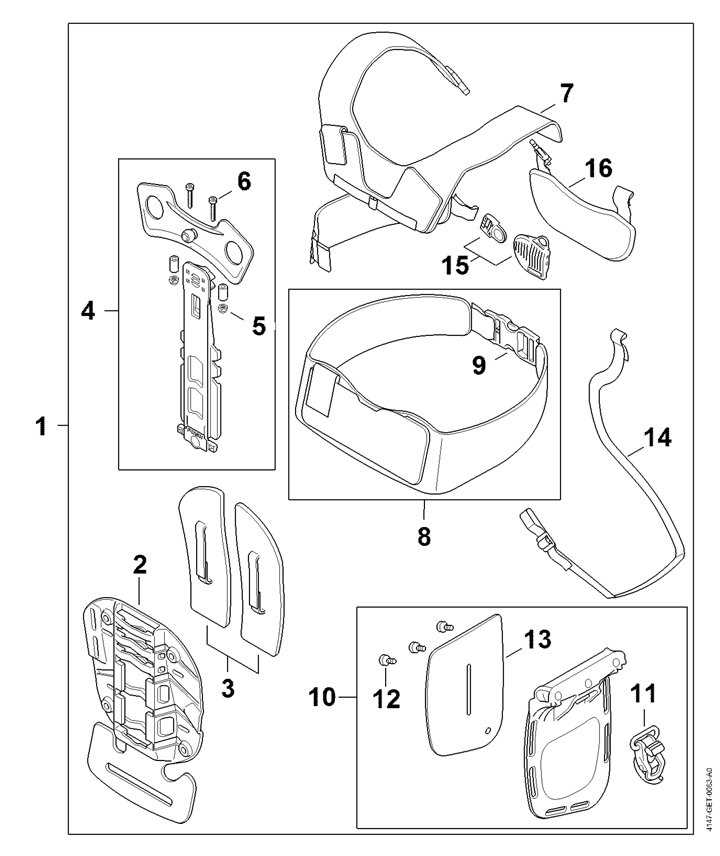

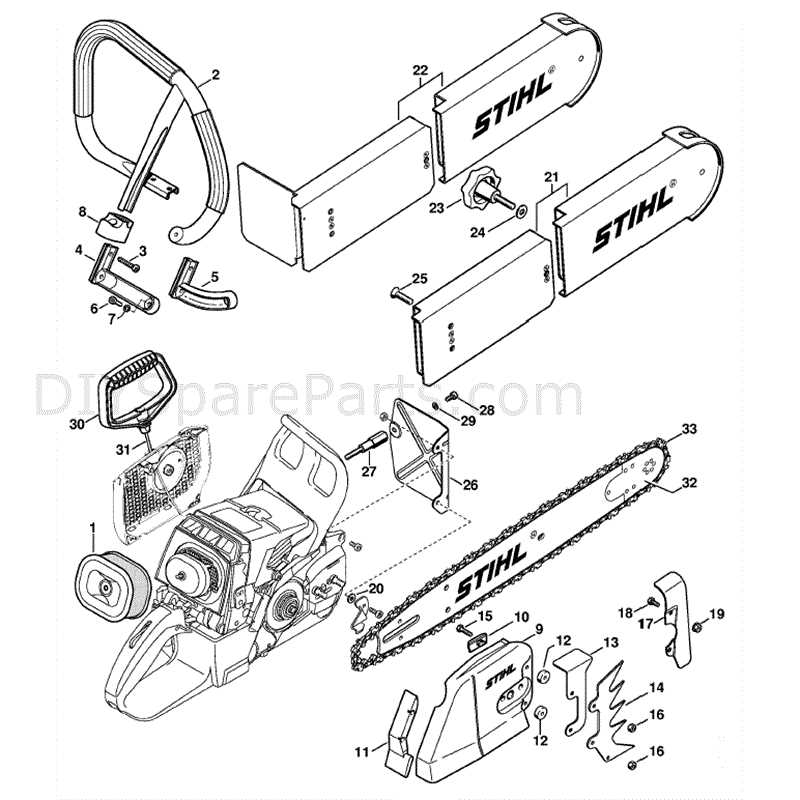

This section will provide a comprehensive overview of the brushcutter, focusing on its key components and functionality. Understanding the assembly and structure of this equipment is essential for proper maintenance and effective use.

- Engine: The heart of the device, responsible for powering the cutting mechanism.

- Handle: Designed for comfort and control during operation.

- Cutting Head: The part that houses the blade or line used for trimming.

- Fuel Tank: Stores the mixture needed for the engine to operate efficiently.

- Air Filter: Ensures clean air intake for optimal engine performance.

- Guard: Provides protection from debris while operating the machine.

Each component plays a vital role in the overall functionality of the tool, making it crucial to familiarize oneself with them for enhanced performance and longevity.

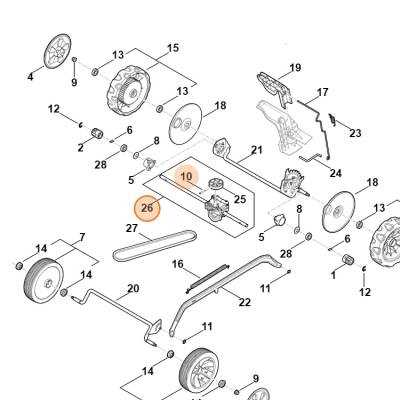

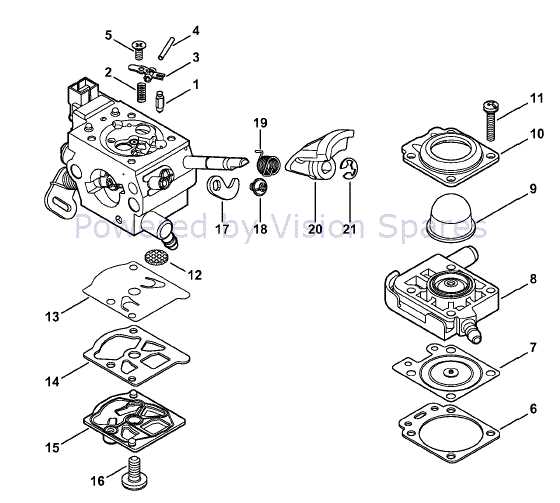

Understanding the Parts Diagram

The illustration of components serves as a crucial resource for anyone looking to familiarize themselves with the assembly and functionality of a machine. This visual guide not only highlights the individual elements but also showcases how they interact within the overall structure. By comprehending this schematic, users can better appreciate the intricacies of their equipment and facilitate effective maintenance or repairs.

Components Overview

This section provides a brief summary of the main elements depicted in the schematic. Each part plays a vital role in ensuring the proper operation of the machinery, contributing to its efficiency and longevity. Below is a table summarizing the key features of the components:

| Component Name | Description | Functionality |

|---|---|---|

| Engine | The core unit that powers the machine. | Generates energy to drive the equipment. |

| Fuel Tank | Reservoir for the operating fluid. | Holds the necessary liquid to keep the engine running. |

| Cutting Head | Attachment designed for trimming or cutting. | Executes the primary function of the machinery. |

| Handle | Part used for maneuvering the device. | Provides control and stability during operation. |

Benefits of Understanding the Schematic

Familiarizing oneself with the layout of the components offers several advantages. First, it aids in troubleshooting issues by allowing users to identify specific elements that may require attention. Additionally, a clear understanding promotes safer operation practices, as users become more aware of the machinery’s capabilities and limitations. Ultimately, this knowledge can lead to more efficient and effective usage.

Key Components of the Trimmer

Understanding the essential elements of a cutting device is crucial for effective operation and maintenance. Each component plays a significant role in ensuring the equipment performs optimally, contributing to its overall efficiency and longevity.

| Component | Description |

|---|---|

| Engine | The power source of the tool, responsible for generating the necessary force to drive the cutting mechanism. |

| Cutting Head | The part that houses the cutting line or blade, designed to efficiently trim grass and vegetation. |

| Throttle Control | A mechanism that allows the operator to regulate the engine speed and power output, enhancing control during use. |

| Shaft | The connecting element between the engine and the cutting head, transmitting power from one to the other. |

| Handle | Provides grip and maneuverability, allowing the user to direct the tool accurately while in operation. |

Importance of Regular Maintenance

Routine upkeep is essential for ensuring the longevity and optimal performance of any outdoor equipment. By dedicating time to regular care, users can prevent potential issues that could lead to costly repairs or replacements. This proactive approach not only enhances efficiency but also promotes safety during operation.

Consistent maintenance allows for the early detection of wear and tear, enabling users to address minor concerns before they escalate into major problems. Additionally, maintaining the equipment as per recommended guidelines can significantly improve its operational efficiency, reducing fuel consumption and enhancing overall productivity.

Furthermore, regular servicing helps to preserve the equipment’s resale value. A well-maintained machine is likely to attract more interest from potential buyers, as it reflects a history of care and reliability. In summary, establishing a routine maintenance schedule is a wise investment that pays off in terms of performance, safety, and value retention.

How to Identify Each Part

Understanding the components of your machine is essential for effective maintenance and repair. By familiarizing yourself with each individual element, you can ensure optimal performance and longevity. This section will guide you through the identification process, making it easier to recognize the different elements of your equipment.

Start by consulting the manufacturer’s guide, which typically includes labeled illustrations or descriptions. These resources serve as a valuable reference point when trying to distinguish between similar components. Pay attention to unique features such as shape, size, and color that can help differentiate one piece from another.

Another useful method is to categorize the components based on their function. For instance, separating cutting tools from support structures can simplify identification. You can also consider using a checklist to track which elements you have identified and which ones require further examination.

Finally, if you encounter any uncertainty, online forums and communities can provide additional insights. Engaging with fellow users who have experience with the same equipment can offer practical tips and clarifications. Remember, a well-informed operator is key to maintaining equipment effectively.

Replacement Components and Their Functions

In the realm of machinery maintenance, understanding the various elements that can be exchanged is essential for optimal performance. Each component serves a specific role, contributing to the overall efficiency and functionality of the equipment. Knowledge of these components enables operators to make informed decisions when it comes to repairs and upgrades.

Key Elements and Their Roles

Engine components play a crucial role in powering the device. These include elements responsible for ignition, fuel delivery, and combustion, ensuring that the machine operates smoothly and effectively.

Wearable Accessories

Cutting tools are among the most frequently replaced items due to their exposure to wear and tear. These attachments are designed to handle various tasks, and selecting the right type is essential for achieving desired results. Regular inspection and timely replacement of these accessories enhance performance and prolong the life of the machinery.

Troubleshooting Common Issues

Maintaining optimal performance of your outdoor power equipment is essential for efficient operation. This section aims to address frequent problems that users may encounter, providing insights and solutions to enhance functionality and reliability.

Engine Fails to Start

If the engine refuses to start, check the fuel supply, ensuring it is fresh and properly mixed. Examine the spark plug for wear or damage, as a faulty plug can impede ignition. Additionally, inspect the air filter for clogs, which may restrict airflow and affect performance.

Reduced Cutting Power

A noticeable decrease in cutting efficiency may indicate that the cutting attachment is dull or damaged. Regularly sharpen or replace blades to maintain optimal cutting performance. Furthermore, verify that the throttle is functioning correctly, as any obstructions or malfunctions may limit engine power and effectiveness.

Step-by-Step Repair Guide

This guide provides a detailed approach to performing repairs on your outdoor power equipment, ensuring it operates efficiently. Following these steps will help you troubleshoot common issues and perform necessary maintenance tasks effectively.

Preparation and Safety

Before beginning any repair process, it’s essential to prepare adequately. Start by gathering the necessary tools and protective gear. Ensure your equipment is turned off and disconnected from any power source to prevent accidents. A clean workspace will facilitate easier access to components and enhance safety.

Identifying Issues

Begin by diagnosing the specific problems with your machine. Look for symptoms such as unusual noises, poor performance, or difficulty starting. Consult the user manual for troubleshooting tips related to your particular model. Document your observations to track what has been checked or replaced during the repair process.

Where to Buy Authentic Parts

Ensuring the longevity and efficiency of your equipment hinges on sourcing genuine components. Authentic items guarantee compatibility, reliability, and optimal performance, making them essential for maintenance and repairs.

Here are some reliable options for acquiring original replacements:

- Authorized Dealers: These vendors are licensed to sell genuine merchandise and can provide expert advice on selection and installation.

- Official Online Retailers: Many manufacturers have dedicated websites where you can purchase authentic goods directly. Ensure you are on the official site to avoid counterfeit items.

- Local Hardware Stores: Some local shops specialize in high-quality equipment and may stock original components or be able to order them for you.

- Specialty Online Marketplaces: Reputable platforms that focus on tool and equipment sales often feature sections for authentic replacements, ensuring quality assurance.

When purchasing, always verify the authenticity of the seller and inspect the items for any signs of tampering or discrepancies. Investing in genuine replacements is crucial for maintaining your machinery’s performance and durability.

Comparing OEM and Aftermarket Options

When it comes to selecting replacement components for your outdoor equipment, the choice between original equipment manufacturer (OEM) items and aftermarket alternatives is crucial. Each option has its distinct advantages and drawbacks, making it essential to understand the implications of your decision.

Advantages of OEM Components

- Quality Assurance: OEM items are designed and manufactured to the original specifications, ensuring compatibility and reliability.

- Longevity: Generally, these components tend to last longer due to higher manufacturing standards.

- Warranty Coverage: Using OEM parts often ensures that the warranty on your equipment remains intact.

Benefits of Aftermarket Alternatives

- Cost-Effectiveness: Aftermarket options typically offer significant savings compared to OEM equivalents.

- Variety: The aftermarket often provides a wider selection, allowing for potential upgrades or unique features.

- Accessibility: These alternatives may be more readily available, making repairs quicker and easier.

Ultimately, the decision between OEM and aftermarket options hinges on individual preferences, budget constraints, and the specific requirements of your equipment. Careful consideration will help you make an informed choice that best suits your needs.

Safety Tips for Repairs

When undertaking maintenance tasks on your equipment, prioritizing safety is essential to prevent accidents and ensure a successful repair process. By adhering to specific guidelines, you can significantly reduce the risk of injuries while working.

Always wear appropriate personal protective equipment (PPE), such as gloves, safety goggles, and sturdy footwear. This gear provides a barrier against potential hazards and enhances your overall safety. Additionally, ensure that your workspace is well-lit and free of clutter to minimize the chances of mishaps.

Before beginning any repair, disconnect the power source or fuel supply to prevent accidental activation. Familiarize yourself with the equipment’s components and consult relevant documentation for guidance. It’s important to work methodically, keeping your tools organized and within reach to avoid distractions.

Never rush through repairs; take your time to ensure each step is completed correctly. If you encounter difficulties, don’t hesitate to seek assistance from a knowledgeable person or professional. This approach not only ensures a safer working environment but also contributes to a more efficient repair process.

Frequently Asked Questions

This section addresses common inquiries related to the maintenance and components of a specific outdoor power tool. Here, you will find valuable information that can assist users in understanding the essential features and operational aspects of their equipment.

| Question | Answer |

|---|---|

| What should I do if my equipment won’t start? | Ensure the fuel is fresh and properly mixed, check the spark plug for damage, and inspect the air filter for blockages. |

| How often should I replace the cutting line? | It is recommended to replace the cutting line after every 1-2 hours of use, depending on the type of vegetation being trimmed. |

| Where can I find replacement components? | Replacement components can typically be purchased from authorized retailers, online marketplaces, or directly from manufacturers. |

| What is the correct maintenance schedule for my device? | Regular maintenance should include checking the fuel system, cleaning the air filter, and inspecting the cutting tools at least once a month. |

| Can I use aftermarket accessories? | While some aftermarket accessories may be compatible, it is advised to use original equipment manufacturer components to ensure optimal performance. |