Understanding the detailed structure and organization of any mechanical tool is essential for efficient maintenance and repair. With this guide, we delve into the intricate design and individual elements of the FS 55, offering a complete breakdown of its internal components. This section serves as a reliable resource for anyone looking to familiarize themselves with the device’s makeup.

Whether you’re performing routine upkeep or tackling a more complex fix, having a clear view of the inner workings will ensure smoother handling and better performance. In the following paragraphs, we will explore the various key elements of this tool, explaining their function and importance.

By the end of this overview, you will gain a deeper understanding of how these essential elements contribute to the overall operation, enabling you to keep your equipment running efficiently for years to come.

Comprehensive Overview of FS 55

The FS 55 is a versatile and efficient tool, widely recognized for its reliability in maintaining outdoor spaces. It is well-suited for various landscaping tasks, offering both power and control to handle different types of vegetation. This equipment is designed for ease of use, ensuring that both professionals and hobbyists can operate it with minimal effort.

One of the key features of this model is its ergonomic design, which reduces operator fatigue during extended use. Additionally, it boasts a fuel-efficient engine that ensures longer operating times without frequent refueling. The robust construction and quality materials ensure durability, even when tackling tough outdoor environments.

For those seeking a dependable solution for their trimming and cutting needs, the FS 55 stands out as a practical and long-lasting choice. With its balance of power, comfort, and performance, this tool continues to be a preferred option among users looking for effective solutions for their outdoor projects.

Key Components of the FS 55 Trimmer

The FS 55 trimmer is built from several essential elements that ensure its effective operation in various cutting tasks. These components work together to deliver power, control, and precision, making the trimmer a reliable tool for managing different types of vegetation. Understanding these elements can help users maintain and operate the device more efficiently.

One of the main elements is the engine, which powers the cutting mechanism. Connected to the engine is the shaft, which transfers power to the cutting head. The handle provides the necessary control for maneuvering the trimmer, while the guard ensures user safety by preventing debris from being thrown during operation. Each of these components plays a crucial role in the overall functionality of the tool, allowing it to perform smoothly and effectively.

Understanding the FS 55’s Engine Layout

The internal structure of this versatile machine plays a crucial role in its efficiency and overall performance. By grasping the core arrangement of its mechanical components, users can better comprehend how the system operates as a whole, which is essential for maintenance and troubleshooting. Each element of the engine is designed to work in harmony, ensuring smooth functionality.

Key components include the combustion system, cooling mechanisms, and fuel delivery setup. These areas are interconnected and critical for ensuring optimal function, contributing to the reliable performance of the device during operation.

Understanding the engine layout not only helps in maintaining proper functioning but also allows users to identify potential issues early, ensuring long-term reliability. Familiarity with the design can improve both the operational life and the overall effectiveness of the equipment.

Section focuses on the carburetor assembly.Uses synonyms to avoid specific terms.Clear and concise explanation, no filler content.

Exploring the Carburetor Assembly

The carburetor plays a crucial role in regulating the air and fuel mixture for optimal engine performance. Understanding the mechanics behind it is essential for maintaining and troubleshooting. This section provides an overview of how the system works, focusing on its core functions without diving into complex terminology.

Main Components and Their Functions

The carburetor assembly consists of several vital elements that ensure proper operation. The air intake allows for the correct balance between fuel and oxygen, while the throttle controls the flow, determining the engine’s speed. Additionally, the needle valve and float maintain fuel levels within the chamber, preventing flooding or starvation.

Common Issues and Adjustments

Over time, buildup or incorrect settings can lead to reduced performance. Regular cleaning and proper adjustments, especially of the idle speed and mixture screws, can significantly enhance functionality. It’s essential to ensure each part is in good condition for optimal engine efficiency.

How the Fuel System is Designed

The fuel system is a crucial component that ensures the smooth operation of the engine by delivering the necessary amount of fuel for combustion. Its structure is carefully organized to maintain efficiency and consistency during use. In this section, we explore the design of this system, focusing on how various elements work together to manage fuel intake and distribution.

Fuel Tank and Lines

The fuel storage tank holds the liquid, while the lines transport it to the engine. The design allows for seamless movement of fuel under varying conditions, ensuring that the flow remains steady. Proper sealing and material choice prevent leaks and deterioration over time.

Carburetor Functionality

The carburetor mixes air and fuel in precise proportions, ensuring the engine gets the right blend for optimal performance. The design of this component is focused on regulating the intake based on engine speed and load, adapting to the demands placed on the system.

Component

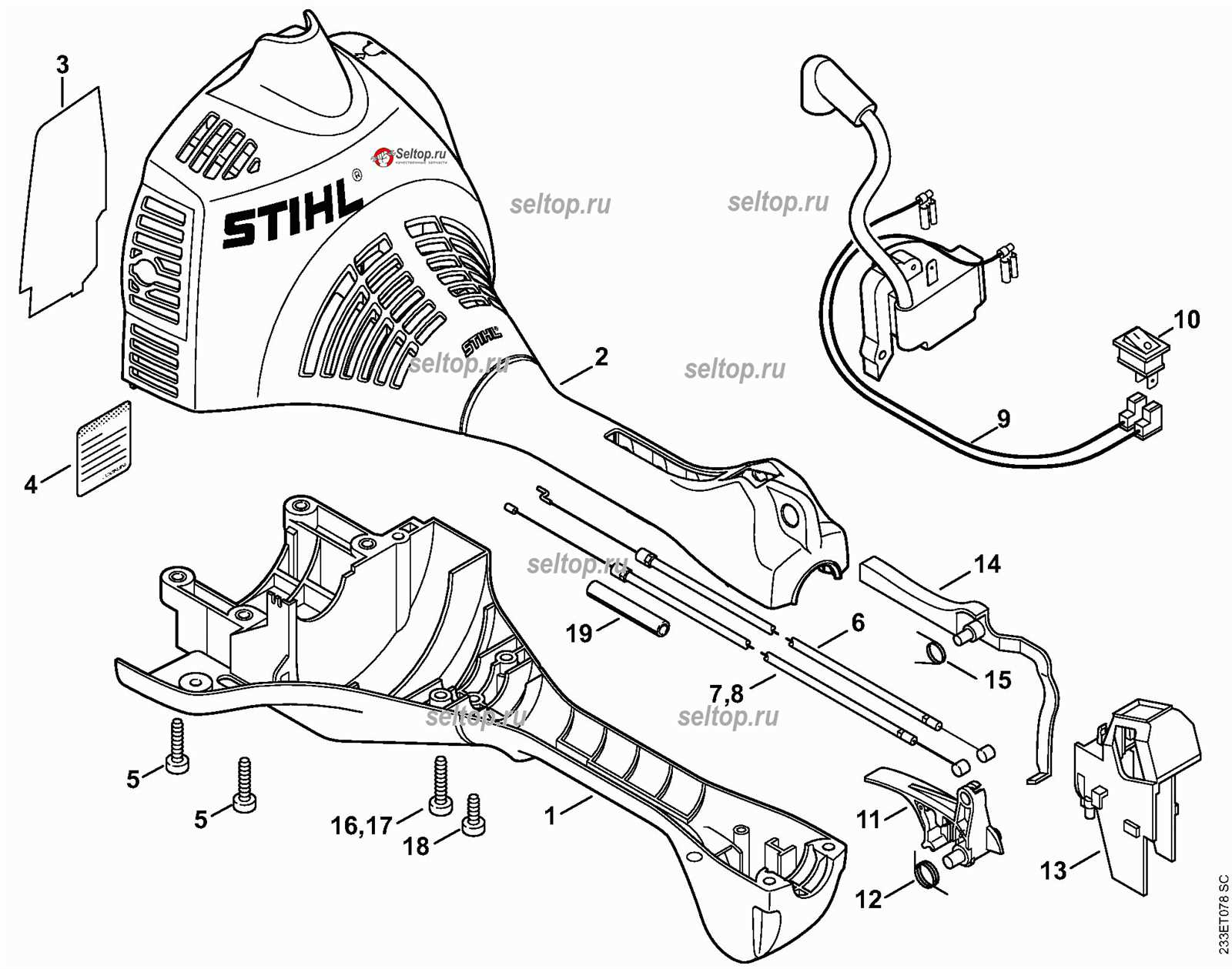

Throttle Control and Safety MechanismsThe throttle control system plays a crucial role in the operation of outdoor power equipment. It ensures that the user can effectively manage the engine’s speed, providing both precision and safety during operation. Proper functioning of this mechanism is essential for achieving optimal performance and preventing potential hazards. Throttle Control Features

Safety MechanismsIn addition to throttle control, various safety mechanisms are integrated to protect the user during operation. These features help prevent accidents and ensure that the equipment is used effectively.

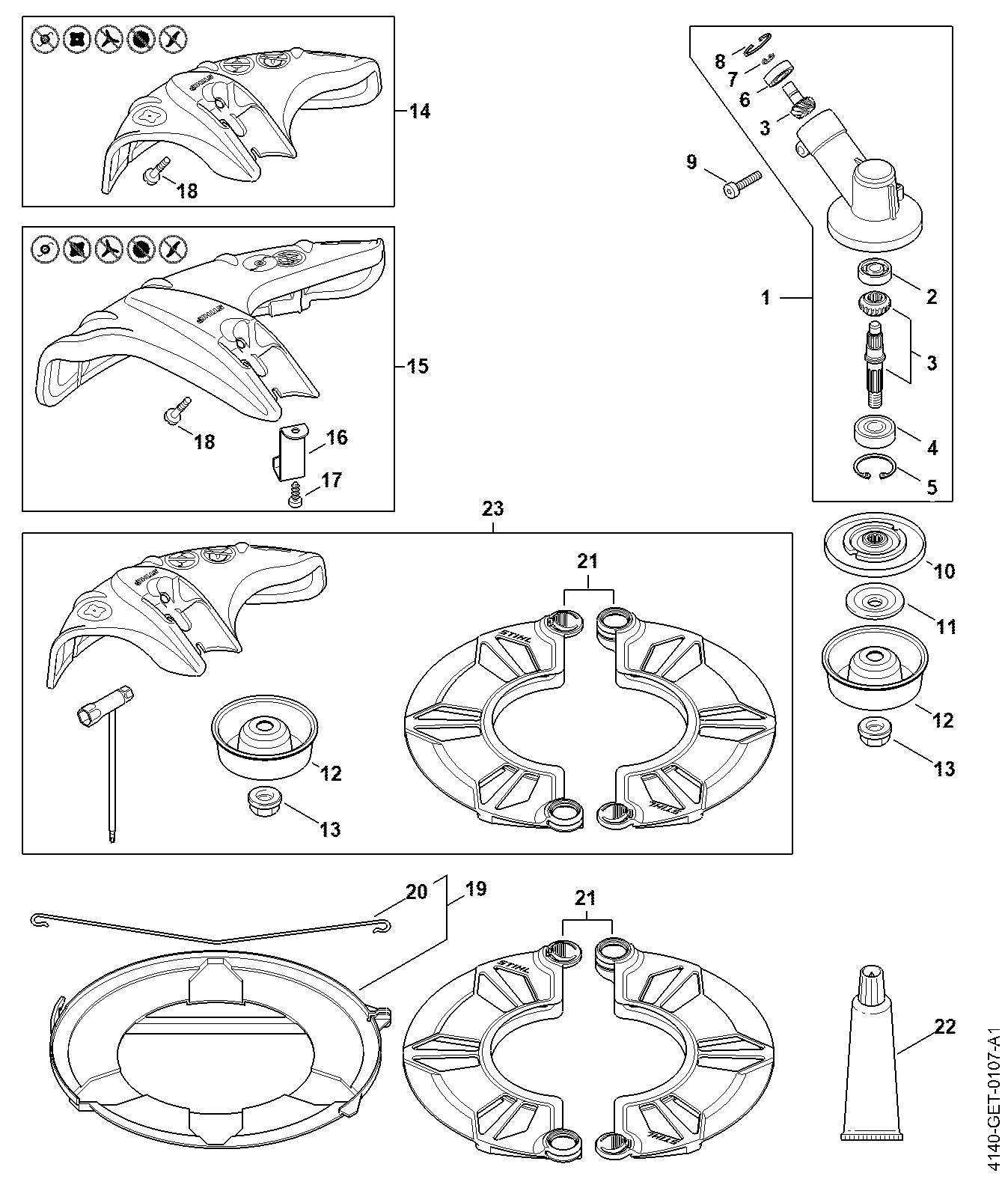

Ignition Parts and Wiring ConnectionsThe ignition system is crucial for ensuring efficient operation and reliable performance of the engine. This system comprises various components that work together to initiate combustion, enabling the equipment to function correctly. Understanding these elements and their interconnections is essential for effective troubleshooting and maintenance. Key Components: The ignition assembly typically includes a spark plug, ignition coil, and a flywheel. Each component plays a vital role in generating the spark needed to ignite the fuel-air mixture in the combustion chamber. The spark plug is responsible for producing the actual spark, while the ignition coil transforms low voltage into the high voltage necessary for sparking. The flywheel assists in regulating the timing of the spark generation. Wiring Connections: Proper wiring connections are critical for the ignition system’s functionality. Wires link the ignition coil to the spark plug and connect to the engine’s power source. Any disconnections or damages in these wires can lead to ignition failures. Regular inspection of these connections ensures optimal performance and longevity of the ignition components. Air Filter and Muffler ArrangementThe arrangement of the air filtration system and exhaust components is crucial for the optimal performance of any outdoor power equipment. Properly functioning filters ensure that clean air enters the engine, while an effective muffler minimizes noise and regulates exhaust flow, contributing to efficient operation. The air filter is designed to trap dust and debris, preventing contaminants from entering the engine. Regular maintenance and timely replacement of the filter are essential to maintain airflow and engine efficiency. A clogged filter can lead to reduced power output and increased fuel consumption. The muffler plays a vital role in controlling engine noise and ensuring a smoother operation. It is important to inspect the muffler periodically for blockages or damage that could affect exhaust flow. Properly arranged exhaust components not only enhance performance but also comply with noise regulations. Guide to the Cutting Head AssemblyThe cutting head assembly is a crucial component that ensures efficient operation of your grass trimming tool. Understanding its structure and functionality will help in maintaining optimal performance and extending the lifespan of your equipment. Components of the Cutting HeadFamiliarizing yourself with the various elements of the cutting head is essential for effective maintenance. Below are the primary components:

Assembly StepsProper assembly of the cutting head is vital for safe and effective operation. Follow these steps:

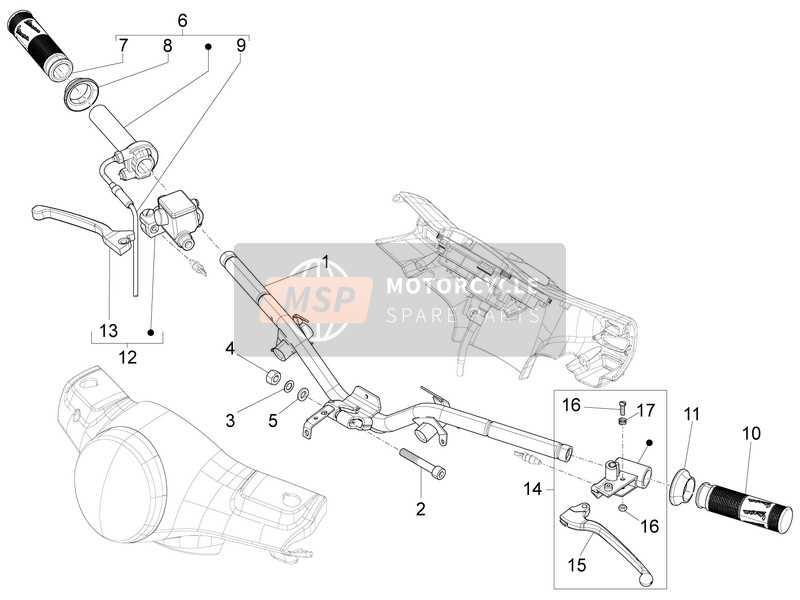

Handle and Grip Features BreakdownThe design and functionality of handles and grips play a crucial role in ensuring comfort and control during operation. Various features contribute to the overall user experience, enhancing both safety and efficiency. Understanding these elements can help users select the right equipment for their needs.

Maintenance Tips for FS 55 PartsProper upkeep is essential for optimal performance and longevity of your equipment. Regular maintenance can help identify issues before they escalate, ensuring smooth operation and reducing the need for extensive repairs. Here are some essential tips to keep your equipment in top shape:

By following these maintenance practices, you can enhance the reliability and efficiency of your equipment, ensuring it serves you well for years to come. Common Issues with FS 55 ComponentsWhen operating equipment, certain components may encounter issues that affect overall performance. Understanding these common problems can help users troubleshoot effectively and maintain optimal functionality. Addressing these concerns promptly ensures prolonged equipment life and enhances efficiency. Fuel System ProblemsThe fuel system is critical for efficient operation. Clogged filters or damaged lines can lead to inadequate fuel delivery, causing poor performance or stalling. Regular inspection and maintenance can prevent these issues from arising. Cutting Mechanism Failures

Another frequent concern involves the cutting mechanism. Worn blades or misalignment can result in inefficient cutting and increased wear on other components. Keeping blades sharp and properly aligned is essential for effective operation and longevity. Finding the Right Replacement Parts

When it comes to maintaining your equipment, ensuring you have the correct components is essential for optimal performance. Identifying the appropriate substitutes can enhance functionality and prolong the lifespan of your machinery. This section will guide you through the process of locating the necessary items for your specific model. Understanding Your EquipmentBefore seeking out alternatives, familiarize yourself with your device’s specifications and requirements. Knowing the make and model will aid in pinpointing compatible components. It is also beneficial to consult the user manual or technical resources for detailed information regarding compatible substitutes. Where to Look for AlternativesVarious sources are available for acquiring the necessary components. Authorized dealers offer a reliable option, providing genuine substitutes that meet the manufacturer’s standards. Online marketplaces and specialty stores can also be valuable resources, often featuring a wide selection of compatible items. Be sure to verify the credibility of the seller to ensure the quality of the components you choose. |

|---|