In any mechanical device, understanding the various elements that contribute to its functionality is essential. This section delves into the intricate layout of an essential tool, highlighting its critical components and how they interact with one another. By exploring these elements, users can gain valuable insights into maintenance and repairs.

Knowledge of the arrangement and role of each segment empowers users to troubleshoot issues effectively. This understanding fosters a more profound appreciation for the engineering behind the tool, ensuring optimal performance and longevity. Furthermore, familiarity with the structure aids in identifying replacement items when needed.

As we explore the various sections of the tool, each component’s function will be elucidated, emphasizing the importance of every part in the overall operation. With this information, users will be better equipped to manage their equipment, ensuring it remains in peak condition for all tasks ahead.

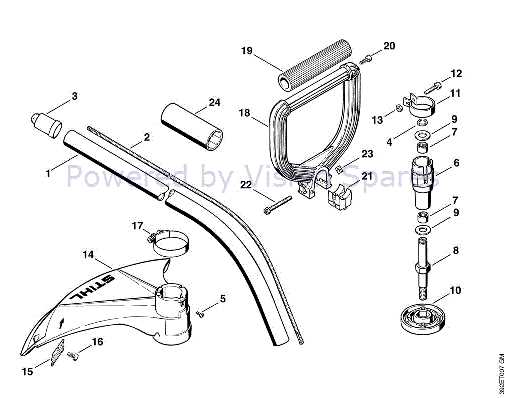

Overview of Stihl FS 75

The FS 75 is a versatile tool designed for efficient landscaping and yard maintenance. Its robust build and powerful engine make it suitable for tackling various tasks, from trimming grass to cutting through thick brush.

Equipped with advanced features, this equipment ensures user comfort and optimal performance. Lightweight design allows for extended usage without excessive fatigue, while ergonomic handles enhance control during operation.

Whether for professional landscapers or home garden enthusiasts, this model provides reliability and effectiveness in every task.

Key Components of FS 75

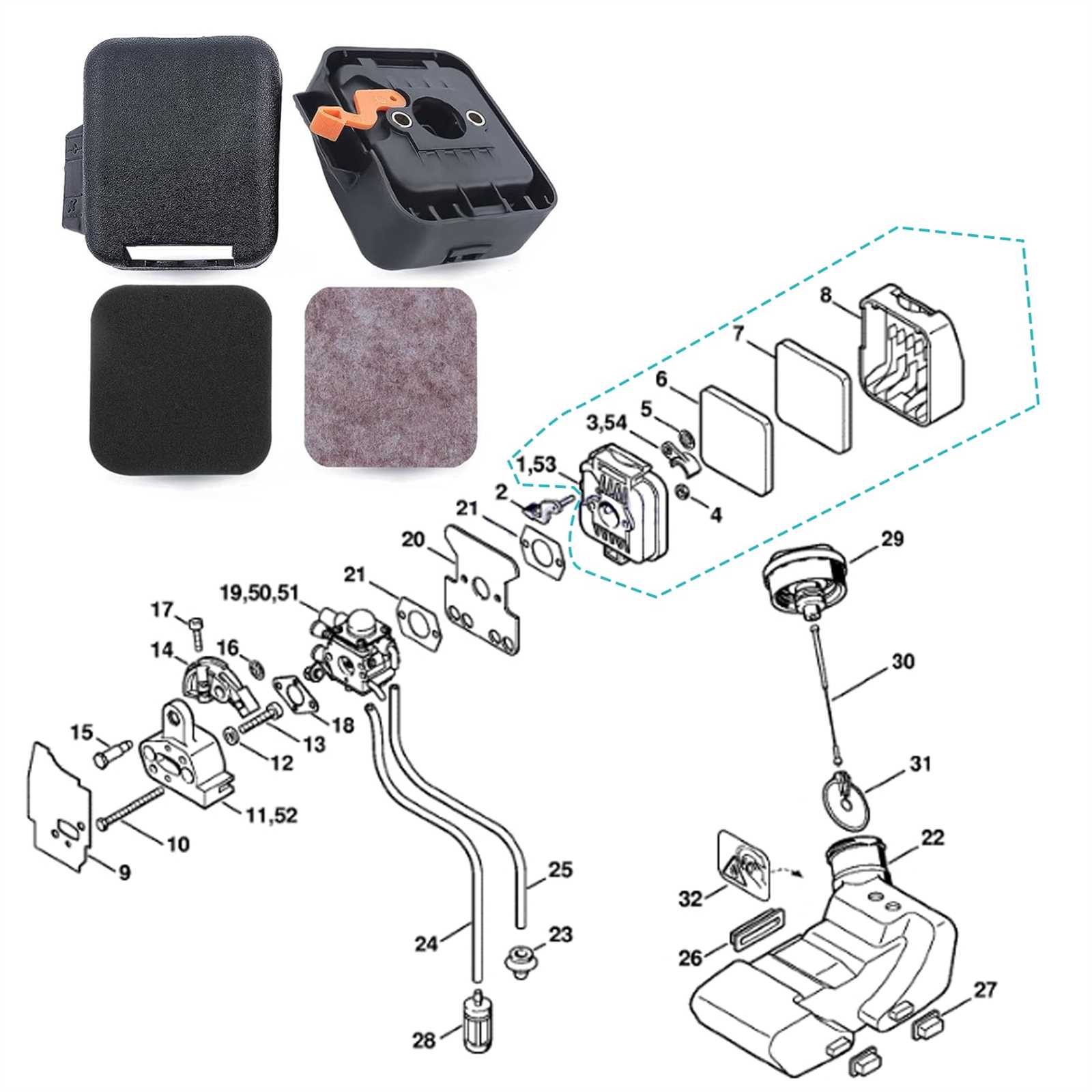

This section focuses on the essential elements that contribute to the efficient operation of a specific cutting tool. Understanding these components can enhance maintenance and performance, ensuring longevity and reliability.

- Engine: The heart of the tool, providing the necessary power for operation.

- Fuel Tank: Holds the mixture required for combustion, influencing run time and efficiency.

- Handle: Designed for comfort and control, allowing the user to maneuver the tool easily.

- Cutter Head: The component responsible for cutting grass and weeds, available in various styles.

- Throttle Control: Regulates the engine speed, enabling the user to adjust performance as needed.

- Safety Guard: Protects the user from debris and enhances overall safety during operation.

These key elements work together harmoniously to deliver effective performance and user satisfaction. Regular inspection and maintenance of each component can lead to optimal functionality.

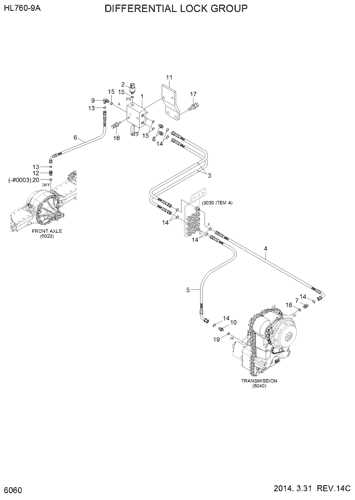

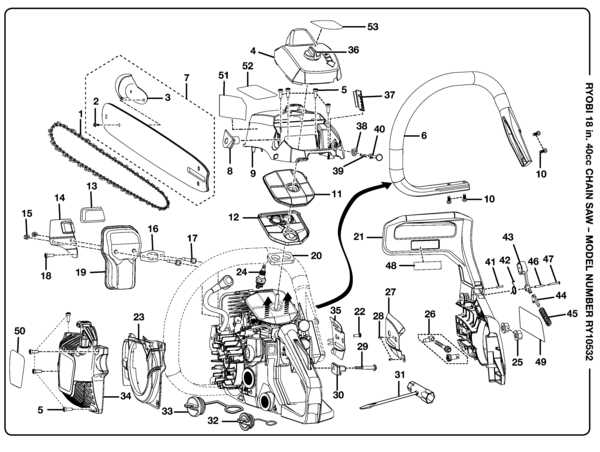

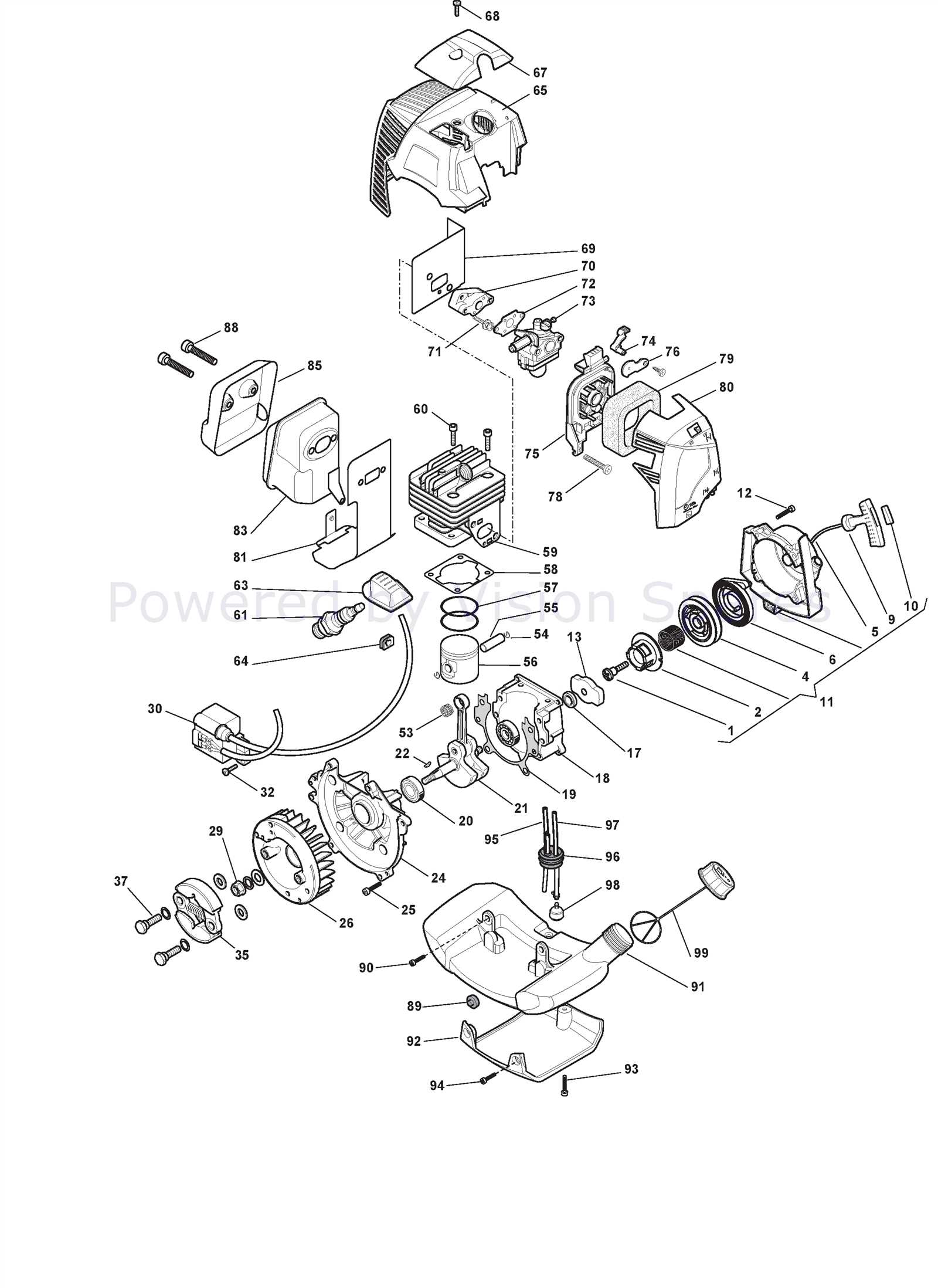

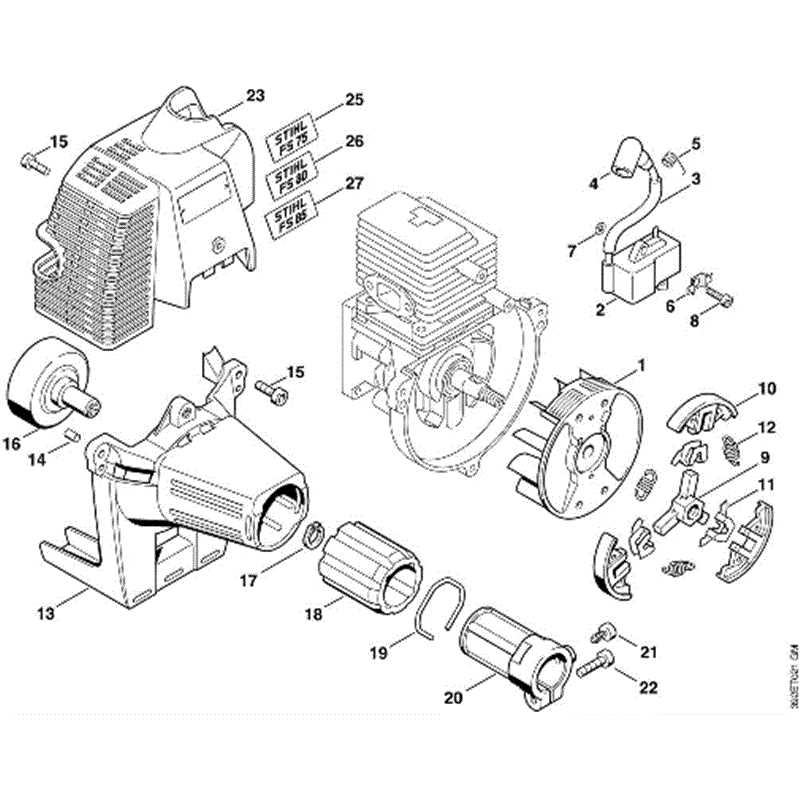

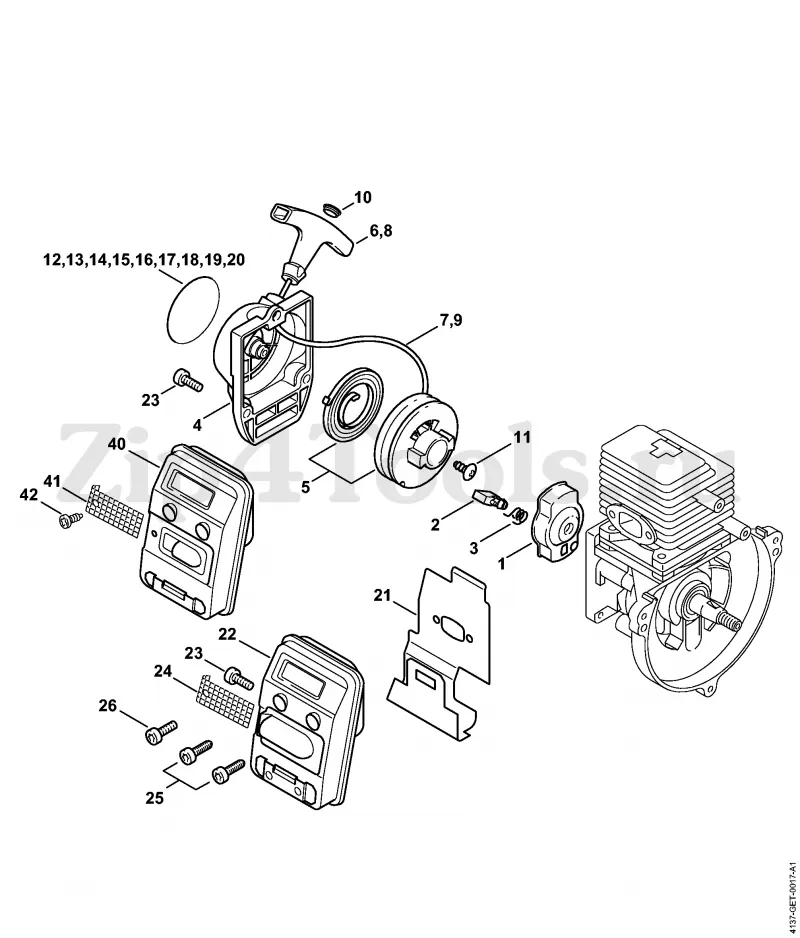

Understanding the Parts Diagram

Comprehending the visual representation of components is essential for effective maintenance and repair tasks. This illustration serves as a guide, showcasing the relationship and arrangement of various elements within the device.

Recognizing the key elements allows users to identify each component’s function, making troubleshooting simpler. For instance, observing how different sections interact can reveal potential issues that may arise during operation.

Utilizing this visual aid not only enhances understanding but also empowers users to perform repairs confidently. A clear representation aids in pinpointing the exact location of each item, facilitating efficient assembly or disassembly processes.

Maintenance Tips for FS 75

Regular upkeep of your trimming equipment is essential for optimal performance and longevity. Implementing simple maintenance practices can greatly enhance efficiency and reduce the likelihood of repairs.

Routine Checks

- Inspect the cutting head for wear and tear.

- Ensure the air filter is clean and unobstructed.

- Check fuel lines for cracks or leaks.

- Examine the spark plug for proper function.

Cleaning and Lubrication

- Clean the exterior of the equipment after each use.

- Lubricate moving parts to prevent rust and ensure smooth operation.

- Clear debris from the cooling vents to avoid overheating.

Common Issues and Solutions

This section addresses typical challenges faced by users of similar outdoor equipment, along with effective solutions to enhance performance and longevity.

Frequent Challenges

- Engine Starting Problems

- Inconsistent Power Output

- Overheating Issues

- Excessive Vibration

Effective Solutions

- Ensure proper fuel mixture is used for optimal combustion.

- Check and replace the air filter to maintain airflow.

- Inspect spark plug condition and clean or replace as necessary.

- Regularly tighten bolts and screws to minimize vibration.

How to Replace Parts

Maintaining equipment in optimal condition is crucial for efficiency and longevity. This section outlines the steps necessary to ensure a smooth replacement process for various components, enhancing performance and functionality.

Preparation Steps

- Gather necessary tools, such as screwdrivers and pliers.

- Ensure the device is powered off and disconnected from any power source.

- Consult the manual for specific instructions related to the component being replaced.

Replacement Process

- Carefully remove the old component, taking note of its placement and any fasteners.

- Inspect the area for any debris or damage that may affect the new part’s installation.

- Install the new component, ensuring it is securely fastened.

- Test the equipment to verify proper functionality after the replacement.

Tools Required for Repair

When undertaking maintenance or restoration tasks on a brush cutting device, having the right tools is essential for ensuring efficiency and safety. The following section outlines the necessary instruments to facilitate the repair process effectively.

Basic Hand Tools

- Screwdrivers (Flathead and Phillips)

- Wrenches (Adjustable and Socket)

- Pliers (Needle Nose and Regular)

- Hex Key Set

Specialized Equipment

- Torque Wrench

- Compression Tester

- Fuel Line Pliers

- Multi-Meter

Identifying Each Component

This section focuses on recognizing the various elements that make up a specific outdoor power tool. Understanding the functionality and arrangement of these components is essential for effective maintenance and operation.

Key Elements Overview

Each component plays a vital role in the overall performance of the equipment. From the engine to the cutting mechanism, familiarizing oneself with these elements allows for better troubleshooting and efficient repairs.

Importance of Component Recognition

Proper identification not only enhances the user experience but also prolongs the life of the tool. Knowing each part helps in diagnosing issues quickly and ensures that the correct replacements are utilized when needed. Awareness of these elements is key to achieving optimal performance and durability.

Safety Precautions During Repairs

When undertaking maintenance on outdoor equipment, it is essential to prioritize safety to prevent accidents and injuries. Proper precautions can ensure a smooth repair process and safeguard the individual working on the machine.

- Always wear appropriate personal protective equipment, including gloves, safety goggles, and sturdy footwear.

- Ensure the equipment is turned off and disconnected from any power source before starting any work.

- Work in a well-ventilated area to avoid inhaling harmful fumes or dust.

- Keep a first aid kit nearby in case of minor injuries.

- Familiarize yourself with the specific equipment and its components to avoid mishandling.

Taking these precautions not only enhances safety but also contributes to more efficient and effective repairs.

Upgrades for Improved Performance

Enhancing the efficiency of your equipment can lead to better results and prolonged lifespan. There are several modifications that can be implemented to achieve superior functionality and overall performance. By investing in quality components and optimizing existing systems, users can experience significant benefits in their operations.

Engine Modifications: Upgrading the engine can provide a noticeable boost in power. Consider installing a high-performance air filter and a suitable exhaust system to improve airflow, which can enhance combustion efficiency.

Blade Enhancements: Utilizing advanced cutting tools can increase precision and reduce workload. Opt for blades designed for specific tasks, ensuring they are sharp and well-maintained for optimal results.

Weight Reduction: Reducing excess weight can improve maneuverability. Explore options for lighter materials or components that do not compromise strength, allowing for easier handling and increased operational comfort.

Regular Maintenance: Consistent upkeep is crucial for maintaining peak performance. Regularly check and replace worn parts, and keep all mechanisms clean and lubricated to ensure smooth operation.

Implementing these enhancements can transform your equipment, enabling it to meet demanding tasks more efficiently and effectively.