Understanding how various components of a frequently used garden tool come together is essential for anyone looking to maintain or repair it. This guide provides an in-depth look into the essential elements that make this machine function, helping you keep it in top working order. Whether you’re a DIY enthusiast or simply curious about its construction, knowing how the individual sections fit together can be incredibly valuable.

Each section of this tool serves a unique purpose, contributing to its overall efficiency. From the smallest connectors to

Understanding FS 76 Trimmer Components

The FS 76 model is a precision tool designed to maintain outdoor spaces efficiently. It’s built from various essential components, each contributing to its reliable performance. Familiarity with these elements is crucial for anyone looking to maintain, troubleshoot, or optimize the device’s usage. By learning the key features of the mechanical structure, users can ensure longevity and proper function.

Engine and Power Delivery

The core of this equipment is its motor, responsible for delivering the necessary force. Proper care of the engine ensures smooth and consistent operation. Key areas include regular cleaning, fuel management, and checking for wear in the combustion system to keep the machine running smoothly.

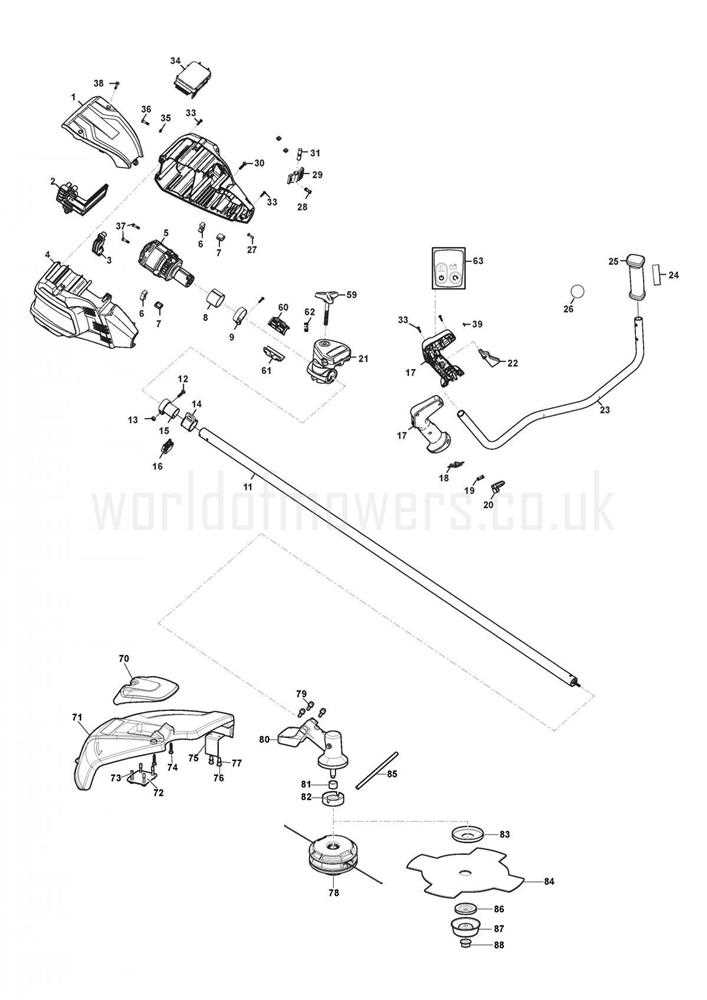

Cutting Mechanism and Guard

Another vital section is the cutting system, which includes the rotating blade or string. This part is supported by a protective guard to ensure safe operation. Keeping the cutting mechanism sharp and balanc

How to Identify Key Parts of FS 76

Understanding the essential components of the FS 76 is crucial for maintaining and optimizing its performance. Familiarizing yourself with these elements allows for easier troubleshooting and upkeep, ensuring a longer lifespan and better efficiency.

Main Engine Section

The core of the FS 76 is its power unit. This section includes the mechanism responsible for generating the necessary force to operate. Regular inspection of this area is vital to detect any early signs of wear or malfunction. It houses several critical elements that work together to keep everything running smoothly.

Cutting Assembly

This is where the operational work happens. The cutting system is responsible for efficient performance and should be checked regularly for sharpness and overall condition. Paying attention to this part can make a significant difference in the unit’s effectiveness and ease of use. Proper care of the cutting ele

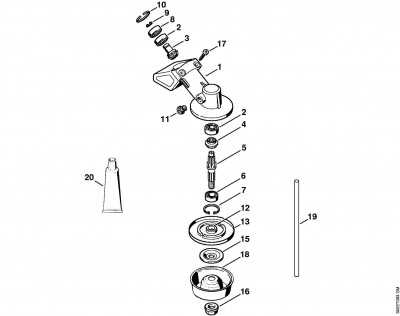

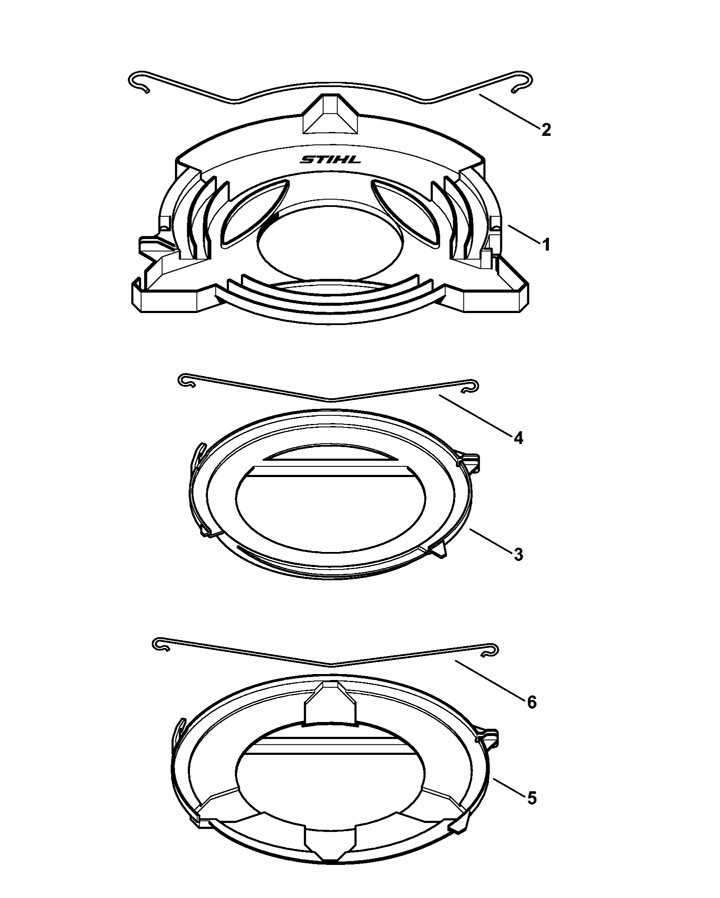

Replacing the Trimmer Head on FS 76

Over time, the cutting head of your FS 76 may wear out or require replacement for optimal performance. A new cutting attachment ensures efficient cutting and smooth operation. Below is a step-by-step guide to help you replace the cutting component quickly and easily.

Follow these steps to complete the replacement:

- First, ensure the tool is powered off and the engine has cooled down before handling any components.

- Hold the shaft steady by securing it, either with a locking pin or similar device, to prevent any movement while removing the old component.

- Unscrew the retaining nut or bolt at the base of the old cutting head by turning it counterclockwise. You may need a wrench or socket for this step.

- Once

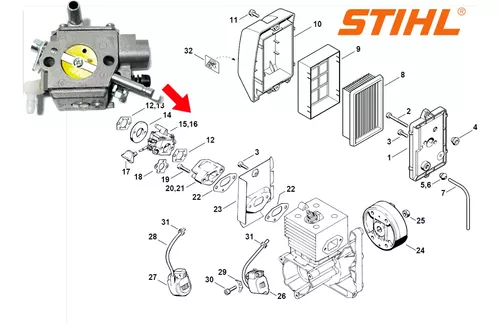

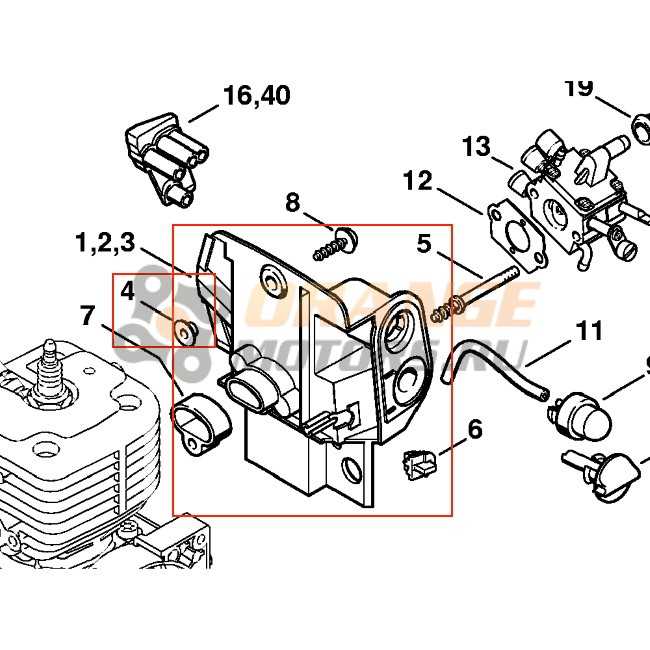

Guide to FS 76 Carburetor Maintenance

Proper care of the fuel system in outdoor equipment is essential for optimal performance. Ensuring the main fuel component functions smoothly can prevent common issues like starting difficulties or irregular engine behavior. Regular upkeep of this key element helps maintain efficiency and prolong the life of your device.

To maintain the fuel system, it’s crucial to check for debris, clean sensitive areas, and ensure all components are in good working order. Disassembly should be done with care, paying close attention to the arrangement of parts to ensure proper reassembly. Regular cleaning of fuel passages and adjusting flow settings can prevent clogs and maintain a steady fuel supply.

In addition to cleaning, inspecting key seals and connections for wear or damage can prevent air leaks, which are a common cause of performance problems. If any parts show signs of wear, replace them promptly to avoid further complications. Proper tuning of the fuel system will ensure that your equipment runs at its best.

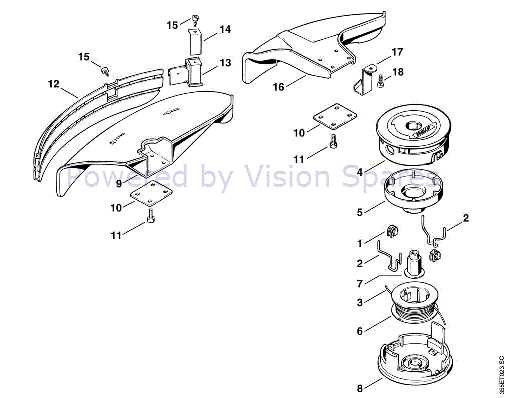

Locating FS 76 Gearbox Components

The gearbox is a critical mechanism that ensures the smooth operation of your equipment. When this component requires attention or replacement, it’s important to understand how to identify the necessary elements for repair or maintenance. With the right approach, you can easily find the right components and ensure proper functionality.

Step-by-step identification process starts with a clear understanding of how the gearbox is structured. Each element plays a role in the overall performance, so careful attention is needed when seeking out specific parts.

Reference guides, detailed breakdowns, and clear labeling can significantly simplify the process of locating individual components. Make sure to consult

Stihl FS 76 Ignition System Overview

The ignition system is a crucial component in any small engine, playing a vital role in initiating combustion and ensuring optimal performance. This system comprises various elements that work in harmony to generate the necessary spark for igniting the fuel-air mixture within the combustion chamber. Understanding the intricacies of the ignition mechanism can help in troubleshooting and maintaining the equipment efficiently.

Components of the Ignition System

The ignition assembly typically includes essential parts such as the spark plug, ignition coil, and flywheel. The spark plug serves as the point where the spark occurs, igniting the fuel mixture. The ignition coil transforms the battery’s voltage into a high-voltage spark that travels through the ignition lead to the spark plug. The flywheel, often connected to the engine’s crankshaft, plays a dual role, aiding in engine timing while also helping to generate electricity for the ignition system.

Functionality and Maintenance

Proper functionality of the ignition assembly is paramount for reliable engine operation. Regular maintenance, including checking the spark plug’s condition and ensuring the ignition coil is functioning correctly, is essential to prevent performance issues. Any irregularities in the spark generation can lead to starting difficulties or engine misfires, making routine inspections crucial for longevity and efficiency.

FS 76 Trimmer Throttle Assembly Breakdown

The throttle assembly is a crucial component that regulates the engine’s power output. Understanding its structure and function is essential for maintaining optimal performance and ensuring smooth operation. This section will delve into the key elements of the throttle assembly, highlighting their roles and interconnections.

Key Components

The assembly consists of several vital parts, including the throttle trigger, return spring, and cable. The throttle trigger allows the user to control the speed of the engine by adjusting the airflow. The return spring ensures that the trigger returns to its original position when released, providing stability and safety during operation. The cable connects the trigger to the carburetor, transmitting the user’s input to adjust the engine’s performance.

Maintenance Tips

Regular maintenance of the throttle assembly is essential for longevity and efficiency. It is advisable to periodically check the integrity of the cable and trigger, ensuring there are no signs of wear or damage. Lubrication of moving parts can enhance performance and prevent sticking. Additionally, keeping the assembly clean will help avoid obstructions that may hinder operation.

Air Filter Replacement for Stihl FS 76

Maintaining optimal performance of your outdoor power equipment is essential for its longevity and efficiency. One critical aspect of this maintenance involves the timely replacement of the air filtration system. A clean air filter ensures that the engine receives the right amount of air, which is vital for effective combustion and overall functionality.

Steps for Replacing the Air Filter

To begin the replacement process, first, gather the necessary tools, including a screwdriver and a new filter. Start by turning off the engine and allowing it to cool completely. Locate the air filter cover and carefully remove the screws holding it in place. Once the cover is off, take out the old filter, ensuring that no debris falls into the intake.

Installing the New Filter

Next, position the new filter into the designated area, making sure it fits snugly. Reattach the air filter cover, tightening the screws securely. Finally, check for any gaps or loose parts to ensure everything is properly sealed. Regularly replacing the air filter not only enhances performance but also prolongs the lifespan of your equipment.

Regular maintenance is key to ensuring that your outdoor tools operate at their best, so don’t neglect this simple yet vital task.

Troubleshooting Common Issues with FS 76

Encountering problems with your gardening equipment can be frustrating, but many issues can be resolved with some basic troubleshooting techniques. Understanding the common challenges and their potential solutions can help you get back to maintaining your garden efficiently. This section will cover several typical complications and offer practical advice for addressing them effectively.

Engine Won’t Start

If the engine fails to ignite, first check the fuel level and quality. Stale or contaminated fuel can lead to starting issues. Ensure that the fuel mix is fresh and correctly prepared. Additionally, inspect the spark plug for wear or damage, as a faulty plug may prevent ignition. Cleaning or replacing the spark plug can often resolve this problem.

Uneven Cutting Performance

When the equipment struggles with an inconsistent cutting performance, the cutting mechanism may be dull or damaged. Regularly sharpening or replacing the cutting tool is essential for optimal performance. Furthermore, ensure that the unit is operating at the correct speed, as improper throttle settings can lead to uneven results. Lastly, check for any obstructions in the cutting area that might impede functionality.

How to Install a New Spark Plug on FS 76

Replacing the ignition component in your outdoor equipment is essential for maintaining optimal performance. This process not only ensures efficient operation but also extends the life of your machine. A properly functioning ignition element allows the engine to start smoothly and run reliably. Follow the steps below to successfully replace the component.

Required Tools and Materials

Before you begin, gather the necessary tools and materials. You will need a spark plug socket, a ratchet wrench, and a new ignition element compatible with your equipment. Having a gap gauge on hand can also be useful to ensure the correct spacing for optimal performance.

Installation Steps

1. Disconnect the Power: Start by ensuring your equipment is turned off and disconnected from any power source to prevent accidents.

2. Remove the Old Component: Use the spark plug socket to carefully unscrew the old ignition element. Turn it counterclockwise until it is free. If it’s stuck, gently tap the socket to loosen it.

3. Prepare the New Ignition Element: Before installing the new part, check the gap using the gap gauge. Adjust as necessary according to the manufacturer’s specifications to ensure proper functioning.

4. Install the New Component: Carefully place the new ignition element into the socket and screw it in by hand initially. Once it is secure, use the ratchet wrench to tighten it further, ensuring it is snug but not overly tight.

5. Reconnect the Power: Finally, reattach any power sources and check that everything is in place. Your equipment is now ready to use!

By following these steps, you will have effectively replaced the ignition component, ensuring your equipment runs smoothly and efficiently.

Cleaning and Lubricating FS 76 Drive Shaft

Maintaining the drive shaft of your equipment is essential for optimal performance and longevity. Regular cleaning and lubrication ensure that all components function smoothly, reducing wear and tear while enhancing efficiency. This section outlines the necessary steps to effectively care for the drive shaft, keeping it in peak condition.

Begin by disconnecting the power source and inspecting the drive shaft for any visible debris or buildup. Use a soft brush or cloth to gently remove any dirt or grime. Pay special attention to any areas where residue may accumulate, as this can hinder functionality.

After cleaning, it’s crucial to apply a suitable lubricant to ensure smooth operation. Select a high-quality grease that is compatible with the materials of the drive shaft. Apply the lubricant evenly to all moving parts, ensuring that it penetrates thoroughly for maximum effectiveness.

Finally, reassemble any components that were removed for cleaning, ensuring everything is securely in place. Regular attention to this maintenance routine will contribute significantly to the longevity and reliability of your equipment.