When it comes to maintaining outdoor machinery, having a clear overview of its components is essential. A thorough understanding of how each element fits together can enhance both the performance and longevity of your device. Whether you’re a seasoned user or a newcomer, grasping the intricacies of these assemblies can greatly aid in effective upkeep.

Comprehending the layout of individual components allows for easier identification of wear and tear, ultimately preventing unexpected breakdowns. This knowledge can empower users to make informed decisions regarding repairs and replacements, ensuring that the machine operates smoothly and efficiently.

Moreover, a well-structured visual reference can serve as a valuable tool during the disassembly and reassembly processes. This aids in not only simplifying repairs but also in enhancing the user’s confidence when tackling maintenance tasks. Embracing this level of understanding fosters a more rewarding experience when working with your outdoor equipment.

Understanding Stihl FS 80 R

The FS 80 R is a versatile tool designed for various landscaping tasks, combining power and efficiency to meet the needs of both professionals and enthusiasts. Its robust construction allows it to tackle a range of vegetation, making it an essential addition to any gardening toolkit.

This equipment features a reliable engine that ensures optimal performance, enabling users to work for extended periods without compromising on effectiveness. The ergonomic design enhances user comfort, reducing fatigue during prolonged use.

Maintenance is crucial for longevity, and familiarizing oneself with the essential components can significantly improve operational efficiency. Understanding how each part functions will help users make informed decisions about repairs and replacements.

By exploring the functionality and capabilities of this machine, users can better appreciate its role in maintaining a well-groomed outdoor space. Whether used for trimming, edging, or clearing, it proves to be a dependable companion in various landscaping endeavors.

Parts Overview and Functions

This section provides a comprehensive examination of the various components that contribute to the efficient operation of a particular outdoor power tool. Each element plays a crucial role in ensuring optimal performance, durability, and ease of use, making it essential to understand their functions and interrelationships.

| Component | Function |

|---|---|

| Engine | Generates power to drive the tool and perform cutting tasks. |

| Trimmer Head | Holds the cutting line and allows for adjustment of line length. |

| Shaft | Connects the engine to the cutting head, transmitting power. |

| Handle | Provides a grip for the operator, enhancing control and maneuverability. |

| Throttle Control | Regulates engine speed and power output during operation. |

| Fuel Tank | Stores fuel required for engine operation, ensuring uninterrupted performance. |

| Guard | Protects the user from debris and enhances safety during use. |

Understanding these components and their respective roles is vital for effective maintenance and troubleshooting, ensuring the longevity and reliability of the equipment.

Importance of Maintenance for Longevity

Regular upkeep is crucial for ensuring the extended lifespan of any equipment. Consistent care not only enhances performance but also minimizes the risk of unexpected failures. By implementing a structured maintenance routine, users can significantly improve efficiency and reliability, leading to a better overall experience.

Neglecting maintenance can result in various issues that compromise functionality. Accumulation of debris, wear and tear, and fluid degradation can all contribute to decreased performance and potential breakdowns. To avoid these pitfalls, a proactive approach is essential.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Cleaning | After each use | Prevents debris buildup and ensures optimal operation |

| Inspection | Monthly | Identifies wear and potential issues before they escalate |

| Lubrication | Every 20 hours of use | Reduces friction and prolongs component life |

| Filter Replacement | Every season | Maintains air quality and engine efficiency |

By adhering to a maintenance schedule, users can ensure their equipment remains in peak condition, thus maximizing both performance and longevity. This diligence not only protects the investment but also enhances productivity and safety during use.

Common Issues and Solutions

When operating a motorized tool, users may encounter various challenges that can affect performance and efficiency. Understanding these common problems and their corresponding solutions can significantly enhance the user experience and prolong the life of the equipment.

1. Engine Won’t Start: This is a frequent issue that can stem from multiple sources, such as an empty fuel tank, a clogged air filter, or faulty spark plugs. Solution: Check the fuel level and replace old fuel with fresh, ensure the air filter is clean, and inspect the spark plug for wear or damage.

2. Poor Cutting Performance: If the tool struggles to cut effectively, it may be due to dull blades or incorrect line length. Solution: Regularly sharpen the cutting edges and ensure the line is the appropriate length for optimal performance.

3. Excessive Vibration: Excessive shaking during operation can indicate loose components or wear on the engine mounts. Solution: Inspect all bolts and fasteners, tightening as necessary, and check the condition of the mounts for any signs of deterioration.

4. Overheating: Overheating can lead to serious damage if not addressed promptly. This issue may arise from inadequate lubrication or clogged cooling fins. Solution: Ensure that lubrication levels are sufficient and clear any debris from cooling areas to promote better airflow.

5. Fuel Leaks: Leaking fuel is a safety hazard and can lead to decreased efficiency. Common causes include damaged fuel lines or loose connections. Solution: Inspect all fuel lines for cracks or damage and tighten any loose fittings to prevent leaks.

By addressing these common challenges proactively, users can maintain their equipment in optimal condition, ensuring reliable performance for years to come.

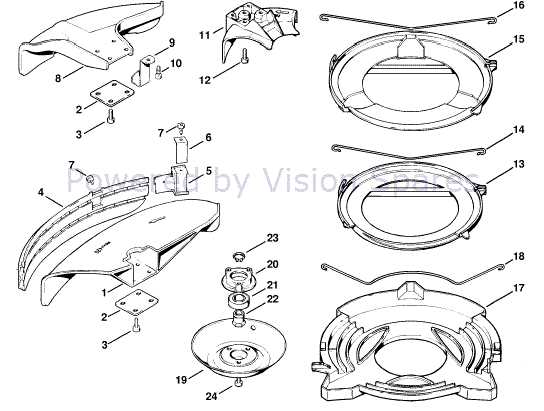

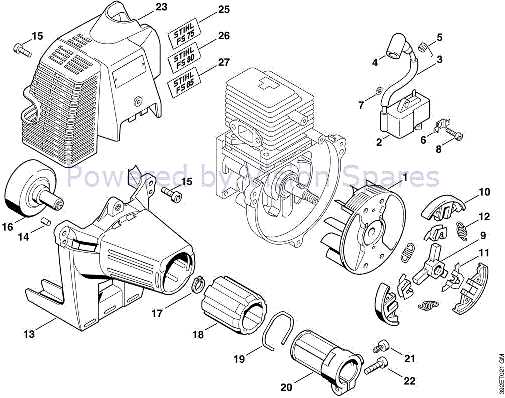

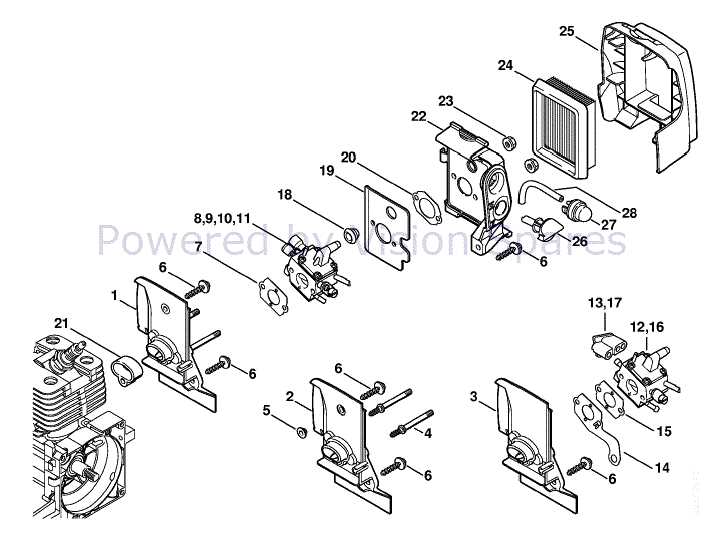

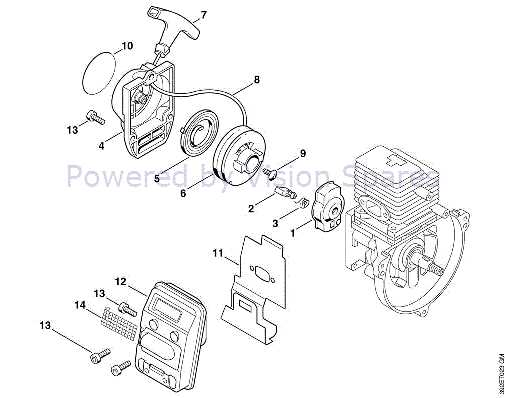

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations provide a detailed view of individual elements and their relationships within a system, enabling users to identify and locate specific items efficiently.

Key Elements to Identify

- Labels: Look for clear annotations that indicate the name or number of each item.

- Connections: Observe lines or arrows showing how components fit together.

- Grouping: Note sections that cluster similar parts for easier navigation.

Tips for Effective Reading

- Start by familiarizing yourself with the overall layout.

- Focus on one section at a time to avoid confusion.

- Cross-reference with the corresponding list of items for clarification.

Essential Tools for Repairs

When tackling maintenance and fixes, having the right equipment at hand can make all the difference. The right tools not only streamline the process but also ensure that tasks are completed efficiently and effectively. Below is a list of indispensable tools that every repair enthusiast should consider for optimal performance.

| Tool | Description |

|---|---|

| Wrench Set | Ideal for loosening and tightening various fasteners. |

| Screwdriver Set | Essential for assembling and disassembling components with precision. |

| Pliers | Great for gripping, bending, and cutting wires and small parts. |

| Torque Wrench | Ensures proper tension is applied to nuts and bolts. |

| Utility Knife | Versatile for cutting materials during repairs. |

| Multimeter | Useful for diagnosing electrical issues and measuring voltage. |

Identifying OEM vs. Aftermarket Parts

Understanding the distinction between original equipment and alternative components is crucial for ensuring optimal performance and longevity of your equipment. Each category has its own advantages and disadvantages, which can significantly affect functionality and reliability.

OEM components are produced by the original manufacturer, ensuring a perfect fit and compatibility with your equipment. These items typically meet stringent quality standards, which can lead to enhanced performance and reduced risk of malfunction.

On the other hand, aftermarket alternatives are created by third-party companies. They may offer cost savings and availability, but quality can vary widely. It’s essential to delve into the reputation of the manufacturer and customer reviews before making a choice.

Ultimately, the decision between OEM and aftermarket options should align with your needs for quality, budget, and long-term reliability. Making an informed choice can lead to improved satisfaction with your equipment’s performance.

Step-by-Step Repair Process

This section outlines a systematic approach to restore functionality to your equipment. By following these stages, you can effectively address common issues and ensure optimal performance. Careful attention to detail is crucial throughout the entire procedure.

Preparation and Safety Measures

Before starting, gather the necessary tools and ensure a safe working environment. Wear protective gear, such as gloves and goggles, to minimize risks.

Disassembly and Inspection

Begin by carefully disassembling the unit, taking note of the arrangement of components. Inspect each part for wear or damage, which may require replacement.

| Component | Condition | Action |

|---|---|---|

| Fuel System | Worn | Replace Filters |

| Cutter Head | Damaged | Replace Assembly |

| Housing | Intact | Clean Thoroughly |

After assessing each component, proceed with the necessary repairs or replacements to restore the unit to its ultimate condition.

Where to Find Replacement Parts

Finding suitable components for your equipment can be a straightforward task if you know where to look. There are numerous resources available that cater to the needs of users seeking to maintain or repair their machinery effectively. These sources provide a range of options, from online retailers to local stores, ensuring that you can find what you need without hassle.

Online Marketplaces: Websites dedicated to selling equipment components often have extensive catalogs. These platforms allow you to search by model or part type, making it easier to locate specific items. Customer reviews can also help you gauge the reliability of the seller and the quality of the components.

Authorized Dealers: Visiting a licensed distributor can be beneficial. They often have access to genuine components and can provide expert advice on compatibility and installation. Establishing a relationship with a dealer can also offer advantages, such as notifications about new arrivals or special promotions.

Local Hardware Stores: Many local retailers carry a selection of essential components. While the variety may be limited compared to online options, you can often get immediate assistance and sometimes even helpful installation tips from knowledgeable staff.

Community Forums: Online communities and forums dedicated to equipment enthusiasts can be valuable resources. Users often share their experiences and recommendations for where to find specific components, as well as tips for sourcing hard-to-find items.

By exploring these avenues, you can efficiently locate the components necessary for your equipment, ensuring it remains in optimal working condition.

Cost Considerations for Repairs

Understanding the financial aspects of maintenance and repair can significantly impact decision-making. This section explores various elements that influence the overall expenditure associated with upkeep.

- Labor Costs: The expense of hiring professionals versus DIY efforts.

- Component Prices: Variability in cost based on brand and quality.

- Frequency of Repairs: The cumulative effect of recurring issues over time.

- Warranty Considerations: Potential savings through existing guarantees.

By evaluating these factors, one can make informed choices to ensure longevity and efficiency without breaking the bank.

User Experiences and Reviews

This section captures the insights and opinions of individuals who have utilized this particular piece of equipment. Their feedback reflects various aspects, such as performance, reliability, and ease of use, providing potential users with valuable perspectives.

Many users appreciate the efficiency and durability of the device. Common themes in their reviews include:

- Impressive power for tackling tough tasks

- Lightweight design contributing to ease of handling

- Low maintenance requirements over time

However, some users highlight areas for improvement:

- Initial setup can be challenging for beginners

- Noise levels may be higher than expected

- Cost of replacement components can be significant

Overall, feedback indicates that while there are minor drawbacks, many find the experience to be rewarding and effective for their needs.

Tips for Effective Troubleshooting

When faced with equipment issues, a systematic approach can significantly enhance your problem-solving efficiency. By breaking down the situation and examining various components, you can identify the root cause of the malfunction. This section provides essential strategies for diagnosing problems effectively, ensuring your tools remain in optimal working condition.

Identify Symptoms Clearly

The first step in troubleshooting is to clearly define the symptoms of the issue. Listen for unusual sounds, observe any irregular behavior, and note performance drops. Documenting these details will help you establish a clearer picture of the problem, making it easier to pinpoint the source.