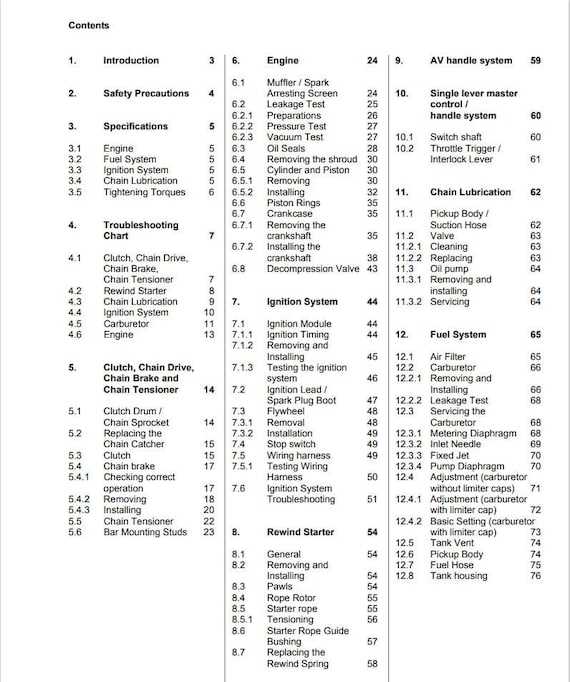

Understanding the structure and functionality of outdoor equipment is crucial for maintaining its efficiency and prolonging its lifespan. By gaining a clearer picture of how various elements fit together, you can effectively troubleshoot issues and replace necessary items when needed. This guide provides an overview of the essential elements that make up the core functionality of your tool, ensuring you can perform maintenance tasks with ease.

The layout of mechanical systems is often intricate, consisting of interconnected components that work in harmony. Knowing the proper configuration of these elements is vital for ensuring optimal performance. Whether you’re replacing worn-out components or performing routine checks, having a clear understanding of the connections will make the process smoother and more efficient.

Stihl FS56RC Components Overview

The machine is built from several key elements that work together to ensure optimal functionality and performance. This section provides an overview of its essential elements, helping to understand how each contributes to the smooth operation of the device.

Power System

- Engine: The core component, designed to provide the necessary force for the tool’s operation.

- Fuel Tank: A container that stores the energy source, allowing the engine to run for extended periods without frequent refills.

Cutting Mechanism

- Cutting Head: The part responsible for trimming, equipped with a durable cutting line or blade.

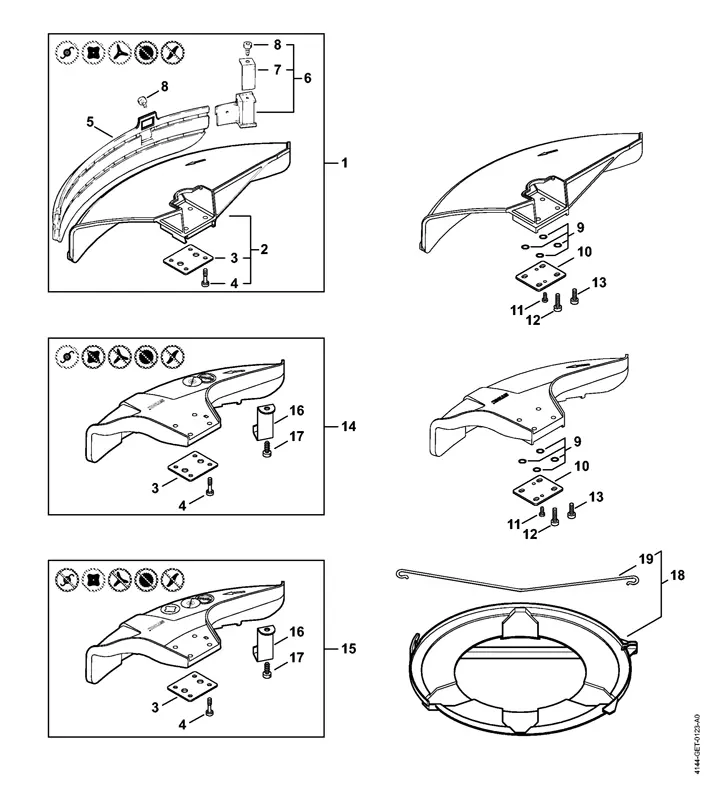

- Shield:

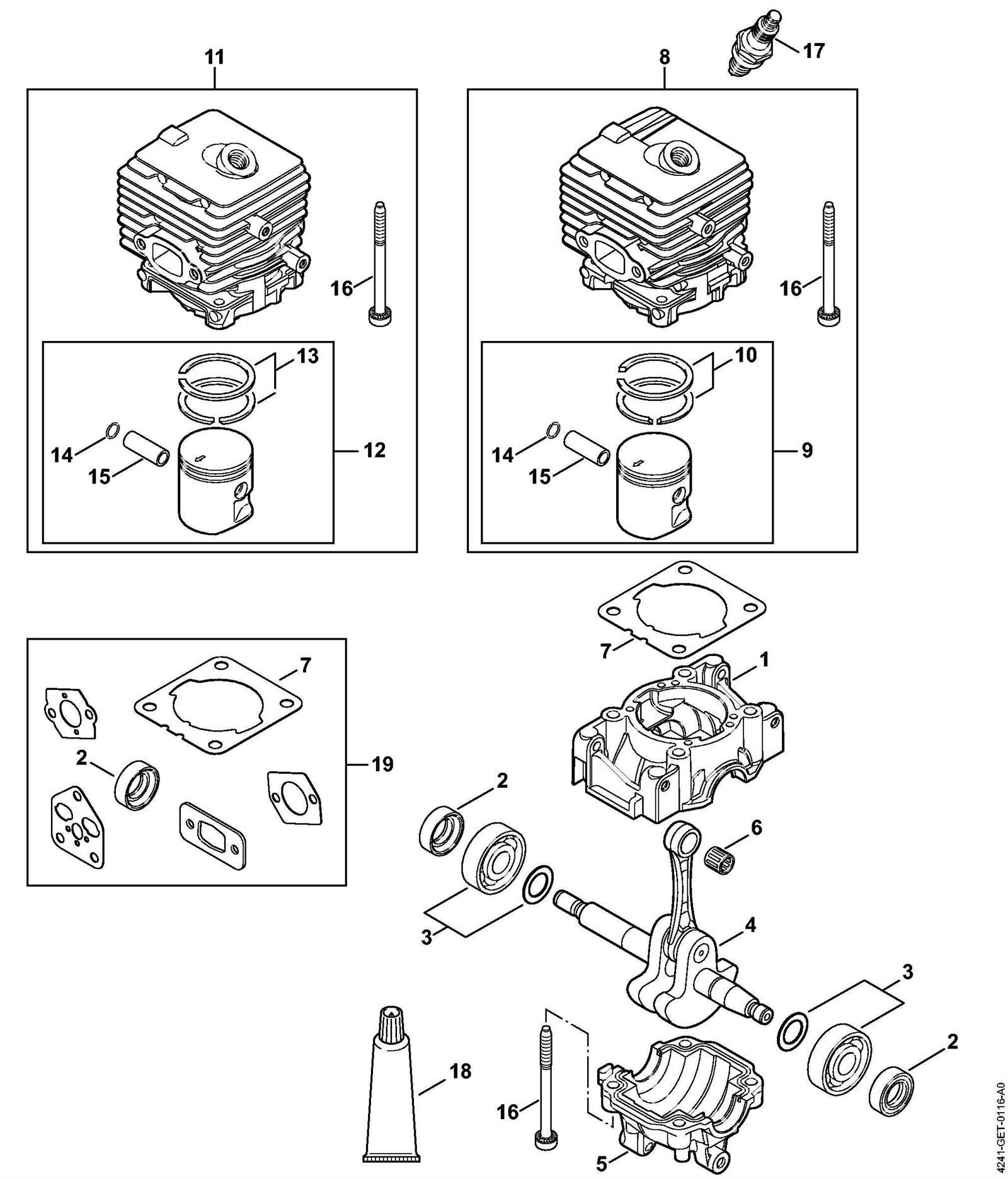

Exploring the Engine Assembly

The engine assembly is a critical component, responsible for converting energy into mechanical motion. Understanding how this intricate system operates can greatly assist in its maintenance and repair. By examining each section of the engine, you can gain insights into its functionality and ensure long-term reliability.

Main Engine Components

The assembly consists of several interconnected elements that work together to produce power efficiently. Below are the key parts that form the foundation of the engine:

- Cylinder: The core area where combustion occurs, transforming fuel into power.

- Piston: Moves within the cylinder to convert combustion energy into mechanical action.

- Crankshaft: Converts the linear motion of the piston into rotational energy, driving other mechanisms.

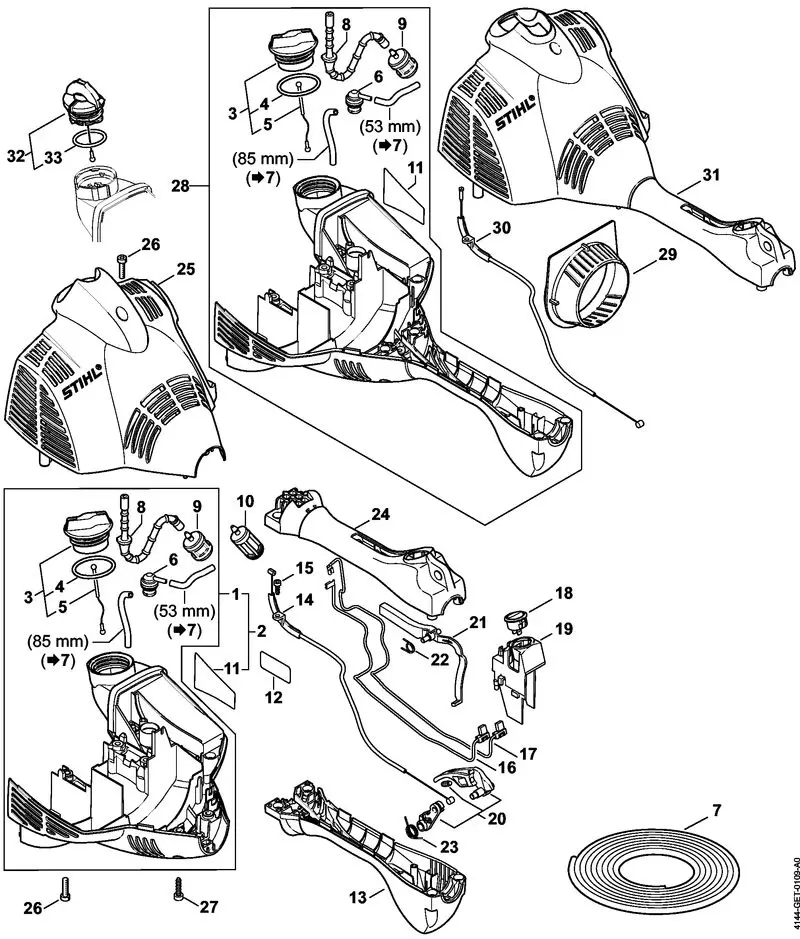

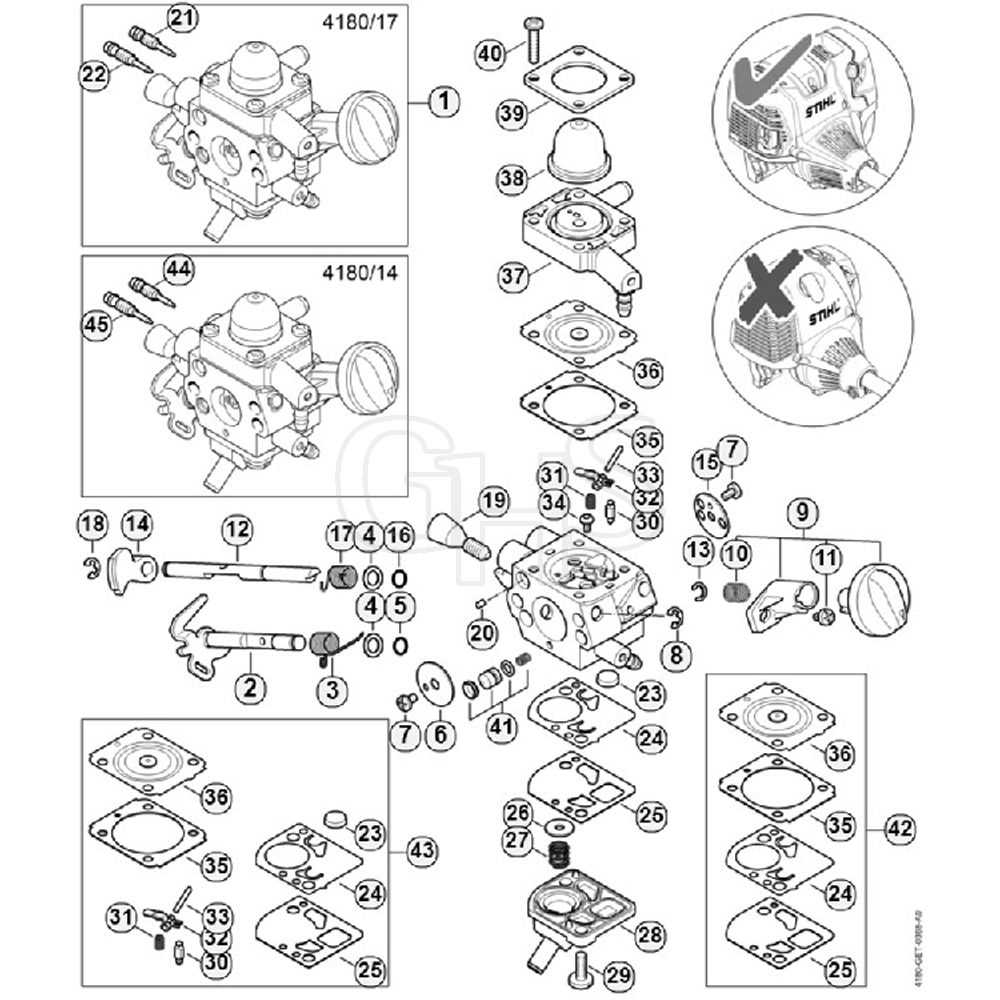

Understanding the Fuel System The fuel system is a critical component that ensures smooth engine operation by delivering the right mixture of air and fuel. Proper maintenance and understanding of its components help to keep the machine running efficiently and avoid common issues related to poor fuel supply.

Main Components of the Fuel System

The fuel system typically includes a tank, filter, lines, and a carburetor. These elements work together to store, filter, and deliver fuel to the engine. The tank holds the fuel, the filter ensures no debris enters the engine, and the carburetor mixes the air and fuel for combustion. Regular checks and cleaning of these components will prolong the machine’s life and performance.

Fuel System Troubleshooting

If the engine fails to start or

Key Features of the Cutting Head

The cutting head is a vital component of any grass trimmer, ensuring smooth and efficient operation when trimming and edging. Designed for durability and ease of use, the cutting head allows for quick line adjustments and replacement, offering users a practical solution for maintaining clean cuts. Its construction balances robustness with user-friendly mechanisms to reduce wear and tear during extended use.

Durability and Construction

The cutting head is built with strong materials that can withstand the demands of frequent use. Its reinforced housing helps protect the internal mechanisms, while the cutting line is designed to endure various conditions, from thick grass to light brush. This construction ensures long-term performance without compromising precision.

Throttle and Control Mechanism

The throttle and control system plays a crucial role in regulating engine speed and ensuring smooth operation of the equipment. This system consists of interconnected components that allow the operator to easily adjust power output, providing optimal performance during various tasks.

Main Components

The primary elements of the throttle system include the trigger, cable, and linkage, all of which work in harmony to manage engine speed. The trigger serves as the operator’s interface, while the cable transfers motion from the trigger to the engine. A properly adjusted cable and linkage ensure responsive and efficient control.

Operation and Adjustment

Correct operation of the throttle mechanism involves smooth, precise movements of the trigger.

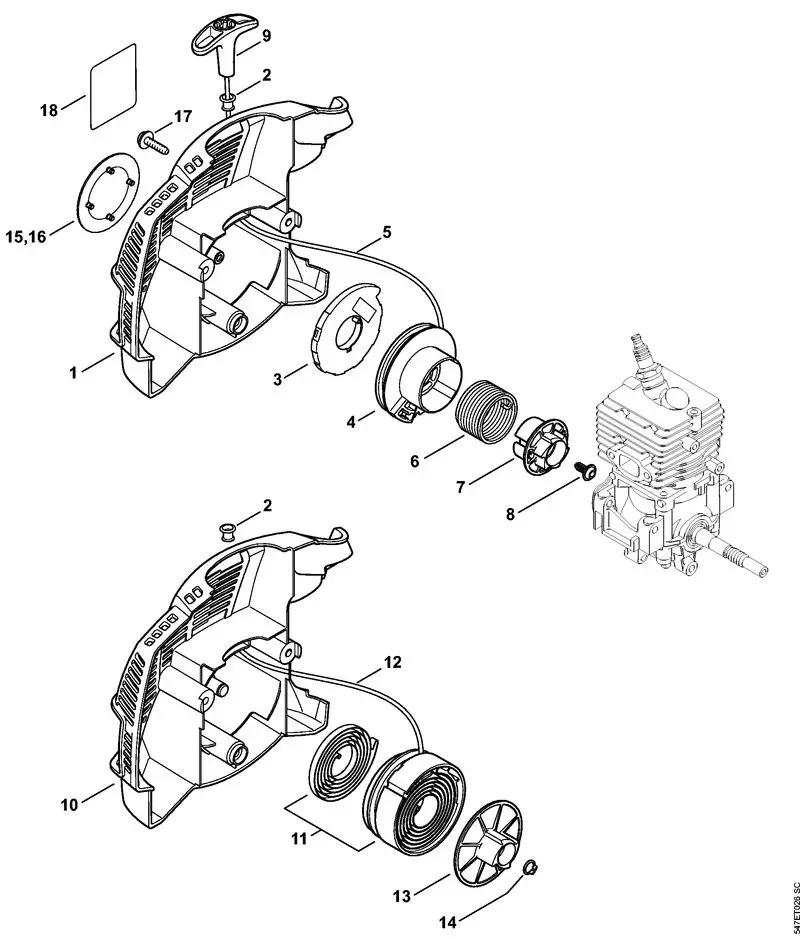

Air Filter and Maintenance Guide

Proper upkeep of your outdoor power equipment is essential for optimal performance and longevity. One of the most critical components to maintain is the air filtration system, which ensures that the engine receives clean air for combustion. Neglecting this part can lead to decreased efficiency and potential engine damage.

Importance of the Air Filter

The air filter plays a vital role in keeping debris, dust, and contaminants out of the engine. A clean filter promotes better airflow, improving fuel efficiency and power output. Conversely, a clogged filter restricts airflow, which can cause the engine to overheat and perform poorly.

Maintenance Schedule

Regular inspection and cleaning of the air filter are crucial. Depending on usage, it is advisable to check the filter every 10 to 20 hours of operation. In dusty conditions, more frequent checks may be necessary. Cleaning can typically be done by gently tapping the filter to remove loose debris or washing it with soap and water, allowing it to dry completely before reinstalling.

Replacement Guidelines

When cleaning is no longer effective, replacing the air filter is essential. A new filter should be installed every 25 to 50 hours of operation or at least once per season. Consult the equipment manual for the correct replacement part number and installation instructions.

Conclusion

Maintaining the air filtration system is a straightforward yet critical aspect of equipment care. By adhering to a regular maintenance routine, you can ensure your machinery operates smoothly and efficiently, prolonging its lifespan and enhancing its performance.

Vibration Reduction System Components

The vibration reduction system plays a crucial role in enhancing user comfort and tool control during operation. This system is designed to minimize the transmission of vibrations from the engine and cutting equipment to the operator’s hands. By effectively managing these vibrations, users can operate the equipment for extended periods with reduced fatigue and a lower risk of injury.

Main Elements of the Vibration Reduction System

- Anti-Vibration Mounts: These components absorb and dampen vibrations, preventing them from reaching the operator. They are typically made of rubber or other resilient materials.

- Handle Design: Ergonomically designed handles help to distribute vibrations more evenly, allowing for better grip and control during use.

- Counterweights: Added weight to specific parts of the equipment can counterbalance vibrations, contributing to a smoother operation.

Maintenance Tips for Optimal Performance

- Regularly inspect anti-vibration mounts for wear and replace them as needed to maintain their effectiveness.

- Ensure that all handle attachments are secure and in good condition to promote stability during use.

- Clean and lubricate moving parts periodically to prevent excess wear and enhance vibration control.

Ignition System and Spark Plug Setup

The ignition mechanism is a crucial component in ensuring the effective operation of small engine equipment. It plays a vital role in initiating the combustion process by creating the spark necessary for igniting the fuel-air mixture. Proper setup and maintenance of this system are essential for optimal engine performance and longevity.

The spark plug is a key element within this system, serving as the point where the electrical energy from the ignition coil is transformed into a spark. This spark ignites the compressed fuel-air mixture within the combustion chamber. Selecting the right type of spark plug, as well as ensuring it is correctly gapped, can significantly affect engine efficiency and reliability.

Regular inspection and replacement of the ignition components, including the spark plug, contribute to maintaining engine health. It is important to check for signs of wear, such as carbon buildup or electrode erosion, as these can impede performance. Following the manufacturer’s specifications regarding spark plug type and maintenance intervals can lead to improved starting, reduced emissions, and enhanced overall operation.

Drive Shaft Assembly Breakdown

The drive shaft assembly is a critical component that transmits power from the engine to the cutting tool. Understanding its structure and functionality is essential for effective maintenance and repair. This section delves into the individual elements that comprise the drive shaft assembly, detailing their roles and interconnections to enhance your knowledge of this vital assembly.

Component Description Function Drive Shaft A long, cylindrical part that connects the engine to the cutting head. Transmits rotational energy from the engine to the cutter. Coupling A connecting piece that joins the drive shaft to the engine. Ensures a secure connection while allowing for flexibility during operation. Flexible Shaft A section that can bend without breaking, accommodating movement and vibration. Allows for the alignment of the drive shaft with the engine and cutting tool. Support Bearing A bearing that stabilizes the drive shaft and reduces friction. Provides support and minimizes wear on the shaft during operation. Output Shaft The end section that connects to the cutting tool. Transfers the rotational motion to the cutting attachment. Each of these components plays a significant role in ensuring the efficiency and longevity of the assembly. Regular inspection and maintenance of the drive shaft assembly can prevent potential issues, ensuring optimal performance of the equipment.

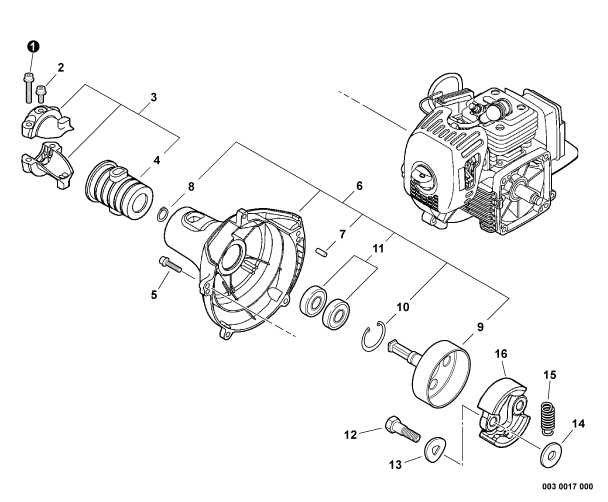

Understanding the Gearbox Assembly

The gearbox assembly plays a crucial role in the efficient functioning of outdoor power equipment. It is responsible for transmitting power from the engine to the cutting tools, ensuring optimal performance. Understanding its components and their interactions is essential for effective maintenance and troubleshooting.

The gearbox typically consists of several key elements that work together to facilitate smooth operation. Each component has a specific function that contributes to the overall efficiency and reliability of the machine.

Component Function Gear Set Transmits power and adjusts torque to the cutting attachment. Bearings Reduces friction and supports rotating parts for smooth movement. Shaft Connects the engine to the gear set, transferring rotational energy. Housing Encloses the gearbox components, providing protection and stability. Seals Prevents dirt and debris from entering the gearbox, maintaining integrity. Regular inspection and maintenance of the gearbox assembly are vital for prolonging the lifespan of the equipment. Familiarity with each component’s role will aid in identifying issues and ensuring optimal functionality.

Exploring the Handlebar Components

The handlebar assembly is a critical aspect of any outdoor power tool, providing both control and comfort during operation. Understanding its various elements can enhance user experience and improve overall functionality. This section delves into the key components that make up the handlebar, highlighting their roles and significance.

Key Elements of the Handlebar Assembly

At the core of the handlebar structure is the main frame, designed to support the weight of the machine while allowing for ease of maneuverability. Grip covers are attached to ensure a secure hold, often made from materials that resist wear and provide cushioning. Control levers are integrated into the handle, enabling the user to adjust speed and activate the tool seamlessly. Additionally, mounting brackets play a vital role in connecting the handlebar to the engine, ensuring stability and durability during use.

Adjustability and Comfort Features

Many modern handlebar designs incorporate adjustable features, allowing users to customize the height and angle according to their comfort. This adaptability not only reduces strain on the operator but also enhances control over the equipment. Some models may even include vibration dampening systems to minimize fatigue during extended periods of operation. By understanding these components and their functions, users can better appreciate the ergonomic considerations in outdoor machinery.

Proper Blade Guard Installation

Ensuring the correct attachment of the blade shield is crucial for safe and efficient operation. A well-installed guard protects the user from potential injuries while enhancing the performance of the cutting tool. This guide outlines the essential steps and considerations for effectively securing the blade cover.

Follow these key steps for proper installation:

- Gather Required Tools: Before beginning, collect the necessary tools such as a screwdriver and any specific fasteners that may be needed for your model.

- Examine the Blade Guard: Inspect the shield for any damage or wear. A compromised guard may not provide adequate protection.

- Align the Guard: Position the blade cover so that it aligns with the designated mounting points on the tool. Ensure that all holes match up correctly.

- Secure Fasteners: Using the appropriate fasteners, attach the guard firmly to the cutting device. Avoid over-tightening, as this can lead to damage.

- Check for Stability: Once installed, gently shake the blade cover to confirm it is secure and does not move. This step is essential for ensuring safety during operation.

By following these steps, you can achieve a proper blade guard installation, significantly enhancing safety and performance. Regularly inspect the installation for any signs of loosening or wear and maintain the equipment for optimal use.

Understanding the Trimmer Line Mechanism

The trimmer line mechanism is a crucial component of a lawn care tool, designed to efficiently manage grass and weeds. This system allows the user to achieve a clean cut while navigating around obstacles, ensuring a well-manicured landscape. Understanding its functionality helps in effective maintenance and optimal performance.

The mechanism primarily operates through a few key elements:

- Line Feed System: This system allows for the automatic release of new line as it wears down, ensuring continuous cutting capability.

- Spool: The spool holds the cutting line and is designed to unwind as needed, facilitating ease of use.

- Drive Shaft: This component connects the motor to the spool, transferring power and enabling the line to rotate at high speeds.

- Cutting Head: The cutting head is where the line exits and engages with the grass, providing the primary cutting action.

Maintenance of the trimmer line mechanism is essential for its longevity. Key maintenance tips include:

- Regularly check and replace worn lines to maintain cutting efficiency.

- Ensure the spool is properly loaded and secured to prevent line jams.

- Clean the cutting head to remove debris that may affect performance.

- Inspect the drive shaft for any signs of wear or damage.

By understanding the trimmer line mechanism and adhering to these maintenance practices, users can ensure their equipment operates smoothly and effectively, leading to a well-groomed outdoor space.