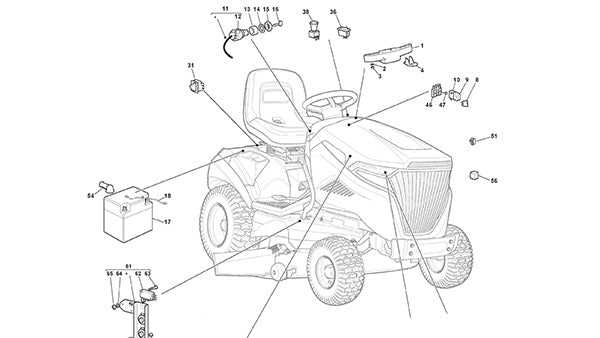

Understanding the layout and arrangement of crucial tool elements is vital for efficient maintenance and repair. Proper identification of these components ensures smooth operation and helps prevent issues that could arise from wear or damage.

In this guide, we will delve into the structure and placement of key elements, offering a clear and organized view. This information is essential for anyone looking to maintain or restore optimal functionality, ensuring long-lasting performance.

Through a detailed breakdown, users will gain valuable insights into how the different pieces fit together, enhancing their ability to troubleshoot and replace necessary parts efficiently.

Understanding the Stihl HL 145 Components

Every machine is composed of various essential elements that work together to deliver reliable performance. By identifying and becoming familiar with the main elements, you can ensure proper maintenance and efficient operation. Knowing how each section functions will help prevent potential issues and extend the overall lifespan of the equipment.

Main Sections of the Equipment

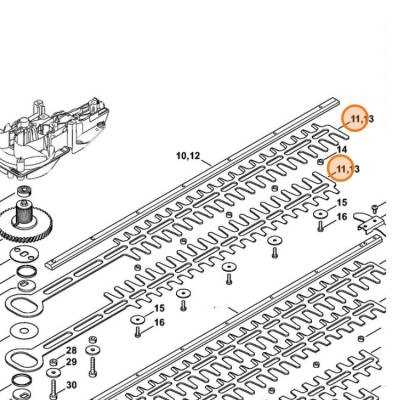

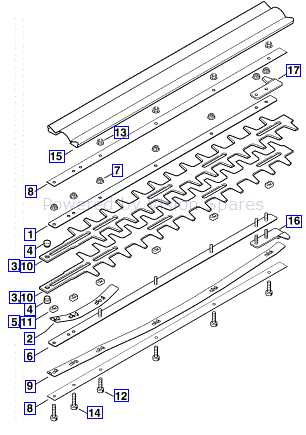

The tool consists of multiple areas that each serve a specific purpose. The power unit is the heart, providing the necessary energy to operate, while the cutting mechanism is designed for precision work. Together, these sections work seamlessly to achieve desired results.

Importance of Regular Maintenance

Proper upkeep is crucial for maintaining the effectiveness of any tool. Regularly checking key areas like the drive system and cutting components ensures smooth

Main Features of the Stihl HL 145

This model offers impressive functionality, focusing on performance, versatility, and ease of use. Designed for demanding tasks, it excels in precision and durability, making it an excellent tool for both professional and home use. The innovative features allow for superior results in a variety of cutting conditions, enhancing the overall efficiency of any project.

| Feature | Benefit |

|---|---|

| Adjustable Cutting Head | Allows for flexible angle adjustments, improving reach in difficult areas. |

| Ergonomic Design | Reduces strain during extended use, ensuring user comfort. |

High

How to Identify Different PartsUnderstanding the various components of a machine is crucial for proper maintenance and repairs. Each element plays a unique role, and recognizing them helps ensure the equipment functions effectively. By familiarizing yourself with the core features, you can easily identify what requires attention or replacement during regular check-ups. Recognizing Key ComponentsTo start, focus on the main sections of the machine, such as the engine, cutting mechanism, and handles. These areas house essential elements that contribute to the tool’s performance. Pay attention to distinct shapes and connections that distinguish one component from another. Identifying these features allows for smoother repairs and better handling of the device. Checking for Wear and TearOver time, some parts may show signs of wear. It’s important to examine frequently used sections for visible damage or irregularities. Common Issues with HL Trimmer ComponentsWhen using a motorized hedge cutter, various mechanical challenges may arise during its operation. Over time, frequent usage and exposure to tough conditions can lead to certain malfunctions in the tool’s components. Understanding these potential problems helps in preventing breakdowns and ensures efficient performance. Wear and Tear on Cutting BladesThe most frequent issue with hedge cutting machines involves the degradation of the cutting edges. Regular contact with thick branches and dense vegetation gradually dulls the blades, reducing cutting efficiency. Periodic sharpening or replacement may be required to maintain optimal performance. Motor Overheating

Another common problem users face is engine overheating, especially during prolonged periods of heavy use. Inadequate cooling or blocked ventilation can cause the motor to overheat, leading to performance issues or even permanent damage if left unaddressed.

|