The exploration of a telescopic pruner’s structure provides valuable insights into its functionality and maintenance. A clear visualization of its elements can enhance the user experience and facilitate effective repairs and upgrades.

In this section, we will delve into the intricate assembly of this gardening tool, highlighting key components and their roles. Understanding how these pieces fit together is crucial for anyone looking to optimize their equipment.

Moreover, familiarizing oneself with the ultimate layout can lead to better decision-making when it comes to servicing and selecting replacements. Equipped with this knowledge, users can ensure their tools remain efficient and reliable over time.

Understanding Stihl HT 105 Components

Exploring the intricate elements of a pole pruner reveals a complex system designed for optimal performance and efficiency. Each component plays a crucial role, contributing to the overall functionality and ease of use. Understanding these parts can enhance maintenance practices and improve operational effectiveness.

Key Elements of the Pruner

The core structure includes a robust engine, designed to provide reliable power for cutting through various types of branches. An essential aspect is the cutting head, which houses the blade and is engineered for precision. Additionally, the extending shaft allows for reach, enabling users to tackle high branches without compromising safety.

Maintenance and Care

Regular upkeep is vital for prolonging the lifespan of the tool. Ensuring that the engine is clean and well-oiled can prevent unnecessary wear. Moreover, inspecting the cutting head and replacing any dull blades ensures efficient performance. Proper knowledge of these components not only aids in maintenance but also empowers users to troubleshoot common issues effectively.

Key Features of Stihl HT 105

This powerful tool is designed to excel in pruning and cutting tasks, combining performance with user-friendly features. Its engineering ensures efficiency and ease of handling, making it suitable for both professionals and home gardeners.

Performance and Efficiency

Equipped with a robust engine, this equipment offers impressive cutting power, enabling users to tackle thick branches with ease. The advanced design minimizes fuel consumption while maximizing output, making it a reliable choice for extended use.

User-Friendly Design

Lightweight and ergonomically designed, this tool provides comfort during operation. The adjustable telescoping shaft allows users to reach high branches without the need for ladders, enhancing safety and convenience.

| Feature | Description |

|---|---|

| Engine Type | Powerful, efficient engine for enhanced performance |

| Weight | Lightweight design for easy handling |

| Telescoping Shaft | Adjustable length for high reach |

| Fuel Efficiency | Optimized fuel consumption for longer use |

Common Issues and Solutions

When working with outdoor power tools, users often encounter various challenges that can hinder performance and efficiency. Understanding these common problems and their solutions can significantly improve the longevity and functionality of the equipment.

One frequent issue is difficulty starting the machine. This can often be attributed to fuel-related problems, such as old or contaminated fuel. To resolve this, ensure you use fresh, clean fuel and check the fuel lines for any blockages. Additionally, inspecting the spark plug for wear or deposits can help restore starting efficiency.

Another common concern is overheating during operation. This may result from inadequate cooling or excessive strain on the engine. To prevent this, regularly clean the air filter and check for obstructions around the cooling fins. Allowing the tool to cool down between uses can also help mitigate this problem.

Vibration is another issue that can affect both comfort and control while using the equipment. Excessive vibration often indicates loose or worn components. Conducting a thorough inspection and tightening any loose screws or replacing damaged parts can enhance stability and user experience.

Lastly, reduced cutting performance is a sign that maintenance is needed. Dull blades or worn chains can significantly impact efficiency. Regularly sharpening or replacing cutting components ensures optimal performance and reduces the risk of injury during use.

Importance of Maintenance and Care

Proper upkeep of equipment is essential for ensuring longevity and optimal performance. Regular attention not only enhances functionality but also prevents unexpected failures and costly repairs. This commitment to maintenance reflects a proactive approach that can significantly extend the lifespan of your tools.

Benefits of Regular Maintenance

Routine care can lead to improved efficiency and safety. By regularly inspecting and servicing components, users can identify potential issues before they escalate, ensuring a smoother operation. Additionally, a well-maintained tool delivers superior results, allowing for more effective work.

Best Practices for Care

Establishing a consistent maintenance schedule is vital. Cleaning, lubricating, and checking vital components should become habitual. Investing time in care not only preserves the equipment but also enhances user satisfaction and performance, making it a worthwhile endeavor.

Where to Find Replacement Parts

Locating suitable components for your outdoor equipment can significantly enhance its performance and longevity. Whether you are looking to replace a worn-out item or upgrade your tool, understanding where to search is essential for successful maintenance and repair.

Authorized Dealers: One of the most reliable sources for finding high-quality replacements is through authorized retailers. These dealers offer genuine components that are specifically designed for compatibility with your equipment, ensuring optimal performance.

Online Marketplaces: Various online platforms provide a vast selection of components at competitive prices. Websites such as e-commerce giants or specialized retailers often feature customer reviews and ratings, assisting you in making informed decisions.

Local Repair Shops: Visiting a nearby repair facility can also be beneficial. Experienced technicians may not only sell replacement items but can also offer valuable advice on installation and maintenance.

Manufacturer’s Website: Checking the official website of the manufacturer is another great option. Many manufacturers list available components and accessories, along with helpful resources such as installation guides and maintenance tips.

Online Forums and Communities: Engaging with online groups focused on outdoor equipment can provide insights and recommendations on where to find specific components. Members often share their experiences, which can lead you to lesser-known sources.

By exploring these various avenues, you can ensure that your equipment remains in top condition and continues to serve you effectively for years to come.

Step-by-Step Assembly Instructions

This section provides a comprehensive guide for assembling your equipment with precision. Following these instructions carefully will ensure optimal performance and longevity of your tool.

Preparation

Before starting the assembly, gather all necessary components and tools. Ensure you have a clean workspace to avoid losing any small parts. Familiarize yourself with each piece to understand how they fit together.

Assembly Process

Begin by connecting the main sections according to the provided layout. Secure all screws and bolts firmly, checking for stability after each connection. Follow each step methodically to achieve the best results, ensuring everything aligns correctly for ultimate functionality.

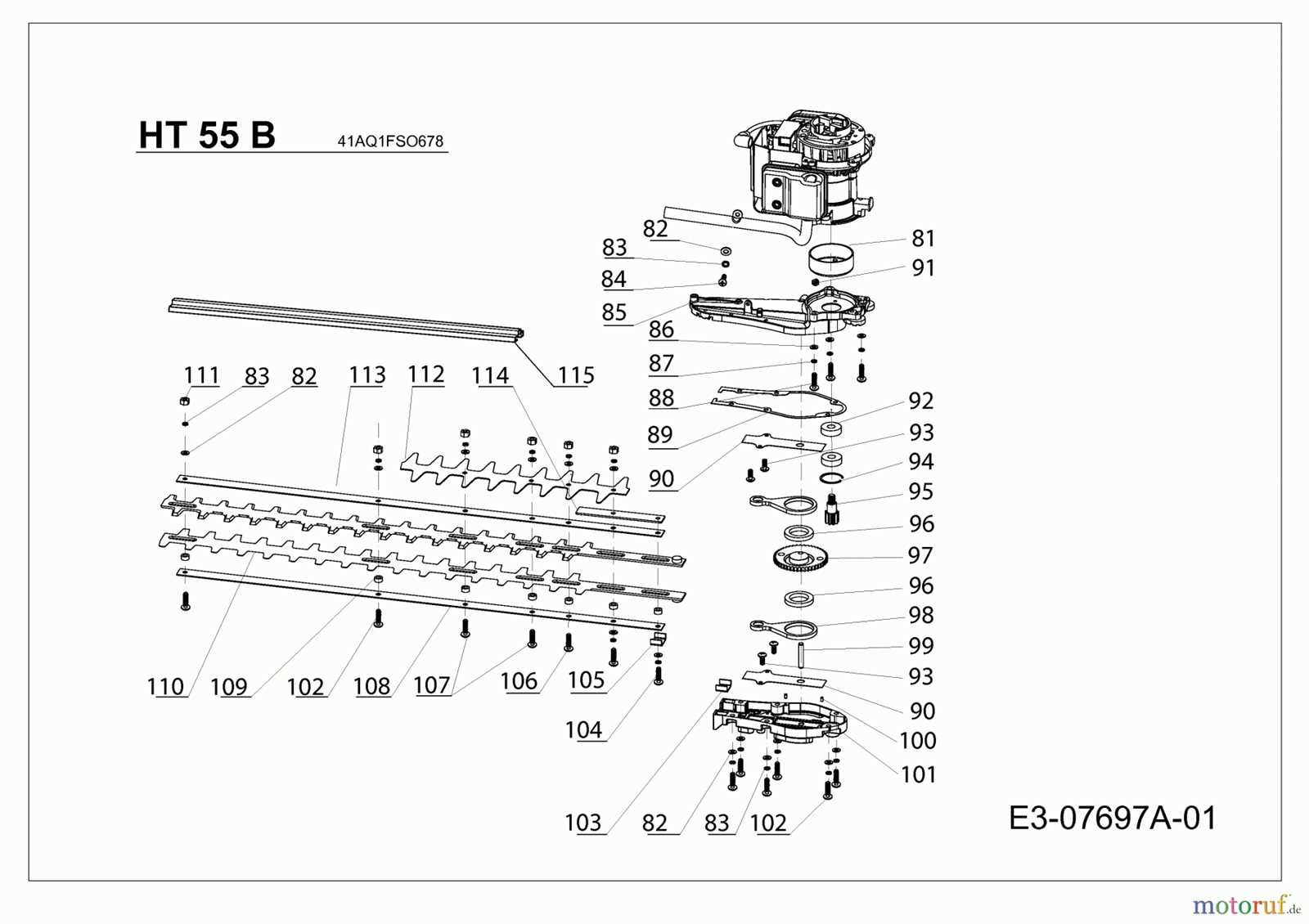

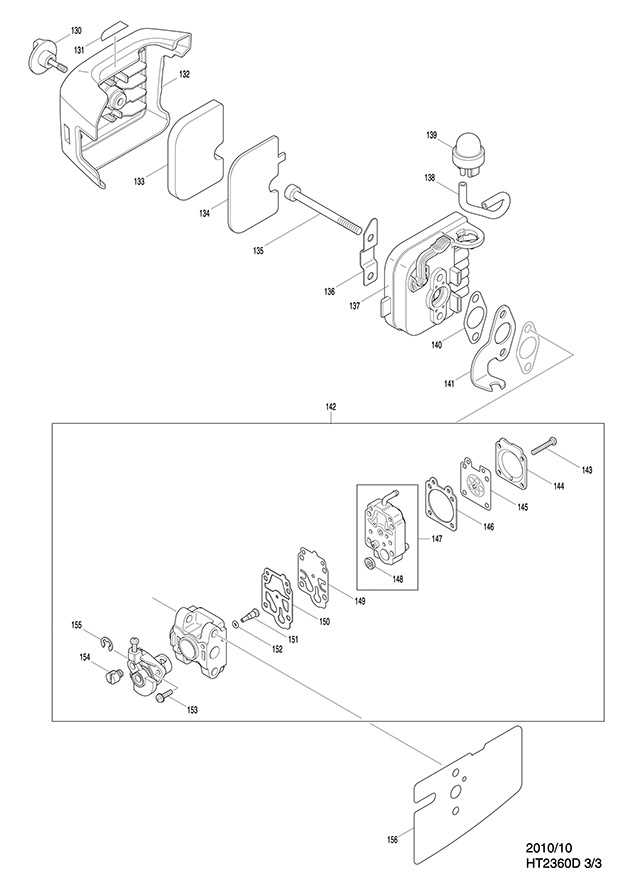

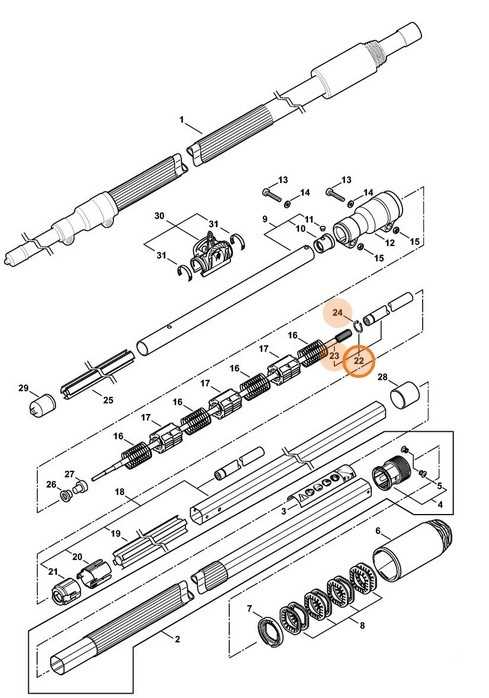

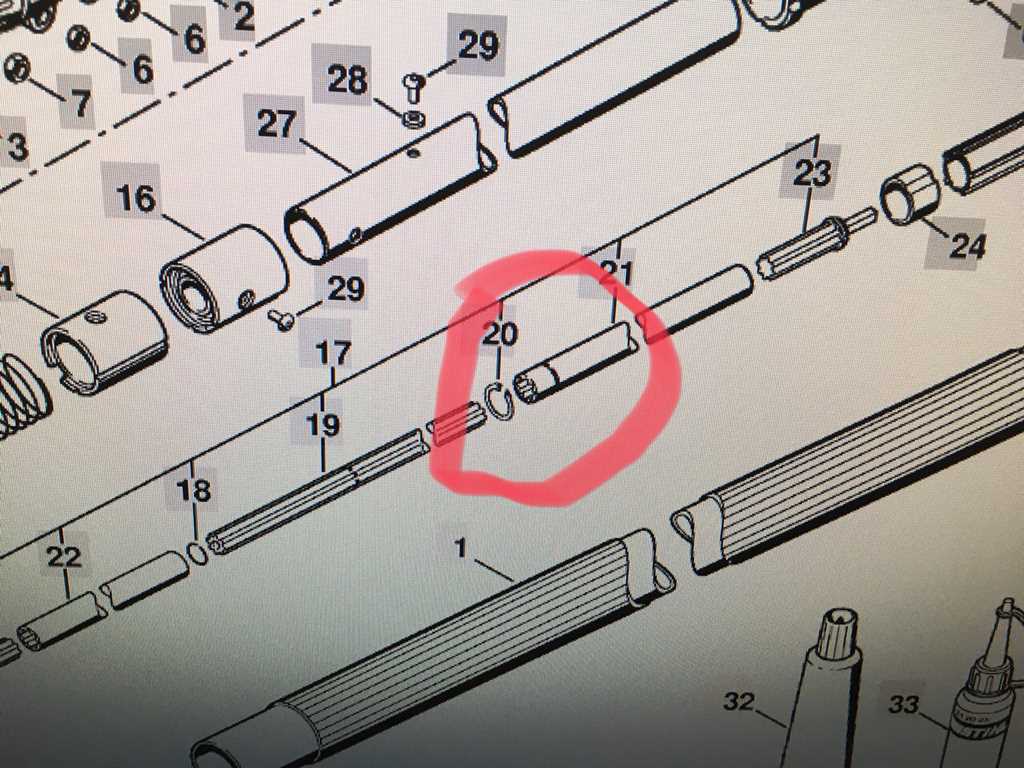

Using the Parts Diagram Effectively

Understanding the layout of components within a machine can significantly enhance your maintenance and repair skills. A visual representation of the various elements serves as a vital tool for both novices and experienced users. By referring to this illustration, you can identify specific sections and their respective roles, facilitating a more efficient troubleshooting process.

Begin by familiarizing yourself with the overall structure depicted in the illustration. Each section is typically labeled, allowing for easy navigation. Pay attention to the numbers or letters associated with each component, as these will be crucial when ordering replacements or seeking assistance from service professionals.

When performing maintenance, refer back to this visual guide to ensure you have disassembled or reassembled the equipment correctly. Double-checking against the illustration can help prevent mistakes that might lead to further complications. Additionally, using the representation as a reference point can aid in recognizing worn or damaged parts that require attention.

Overall, leveraging this visual tool effectively can streamline your repair processes, minimize downtime, and enhance your understanding of the equipment’s functionality.

Tips for Troubleshooting Problems

Tackling issues with your equipment can be daunting, but a systematic approach can lead to effective solutions. Understanding common malfunctions and their potential causes allows for quicker resolutions and less frustration.

Identify the Symptoms

Begin by observing any unusual behavior. Note specific symptoms like unusual noises, difficulty starting, or performance drops. This information is crucial for narrowing down potential problems.

Check Common Components

Inspect frequently problematic areas such as the fuel system, spark plug, and air filter. Ensuring these components are clean and functional can resolve many issues without further intervention.

Comparing with Other Stihl Models

This section explores the distinctions and similarities among various models from a renowned brand, focusing on their functionality and design aspects. By examining these variations, users can better understand which machine suits their specific needs and preferences.

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Weight | 8.5 lbs | 7.8 lbs | 9.2 lbs |

| Power | 1.5 kW | 1.3 kW | 1.6 kW |

| Bar Length | 10 inches | 12 inches | 14 inches |

| Fuel Capacity | 0.5 liters | 0.4 liters | 0.6 liters |

Understanding these differences can ultimately guide users in making informed decisions tailored to their specific applications and preferences.

Safety Precautions During Repairs

When undertaking maintenance or repair tasks on any equipment, it is crucial to prioritize safety to prevent accidents and injuries. Understanding the potential hazards associated with the tools and machinery being serviced can significantly reduce risks. This section outlines essential precautions to consider before, during, and after repair activities.

Always wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and ear protection. This gear helps shield against flying debris and sharp objects, ensuring a safer working environment.

Before starting any repair, ensure the equipment is powered off and disconnected from any power source. This simple step can prevent accidental starts that may cause harm to the technician or damage to the equipment.

Work in a well-ventilated area to avoid inhaling harmful fumes or dust, especially when using chemicals or power tools. Adequate airflow is vital for maintaining a safe workspace.

Additionally, organize your workspace to keep tools and parts easily accessible, minimizing the chances of tripping or misplacing items. A clutter-free environment enhances focus and efficiency during repair work.

Stay alert and focused while working. Distractions can lead to mistakes that may result in injuries. Take regular breaks to maintain concentration and avoid fatigue.

By adhering to these safety measures, individuals can create a secure environment that allows for effective and responsible repairs, ultimately protecting both the technician and the equipment being serviced.

Enhancing Performance with Upgrades

Improving efficiency and functionality can significantly elevate the user experience of any tool. By focusing on key enhancements, one can achieve greater reliability and effectiveness, ensuring that tasks are completed with optimal precision and speed. Investing in superior components not only boosts performance but also extends the lifespan of the equipment.

Upgrading specific features can lead to remarkable changes. For instance, enhancing the power source or refining the cutting mechanism can result in smoother operation and reduced wear. These modifications allow users to tackle more demanding tasks with ease and confidence.

Additionally, considering ergonomic improvements can transform usability. Upgrades that promote better grip and balance can reduce fatigue, enabling longer, more productive work sessions. Ultimately, a combination of performance and comfort upgrades delivers the best results for both professional and casual users.

FAQs about Stihl HT 105 Parts

This section addresses common inquiries regarding components of a specific model, providing clarity and assistance for users. Understanding these aspects can enhance maintenance and functionality.

- What types of components are available for this model?

Several categories include engines, cutting tools, and maintenance items.

- How can I identify the correct component for my device?

Refer to the model number and consult the manufacturer’s resources or authorized dealers.

- Are there any compatible aftermarket components?

Yes, many third-party manufacturers offer compatible options; however, verify quality and fit.

- What is the best way to maintain these components?

Regular cleaning, lubrication, and timely replacement of worn parts are essential for longevity.

- Where can I purchase original components?

Authorized retailers and the manufacturer’s official website are reliable sources.