When it comes to maintaining and enhancing the functionality of outdoor equipment, a comprehensive grasp of its components is essential. This knowledge not only facilitates repairs but also empowers users to optimize performance for various tasks. Exploring the intricate arrangement of parts reveals how each element contributes to the overall efficiency of the machine.

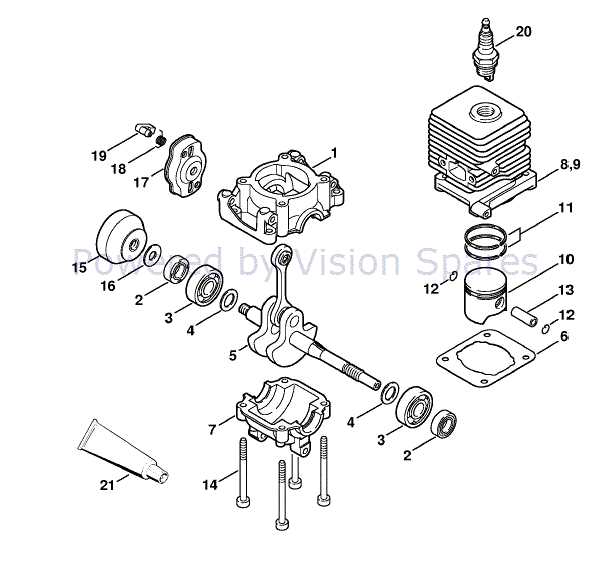

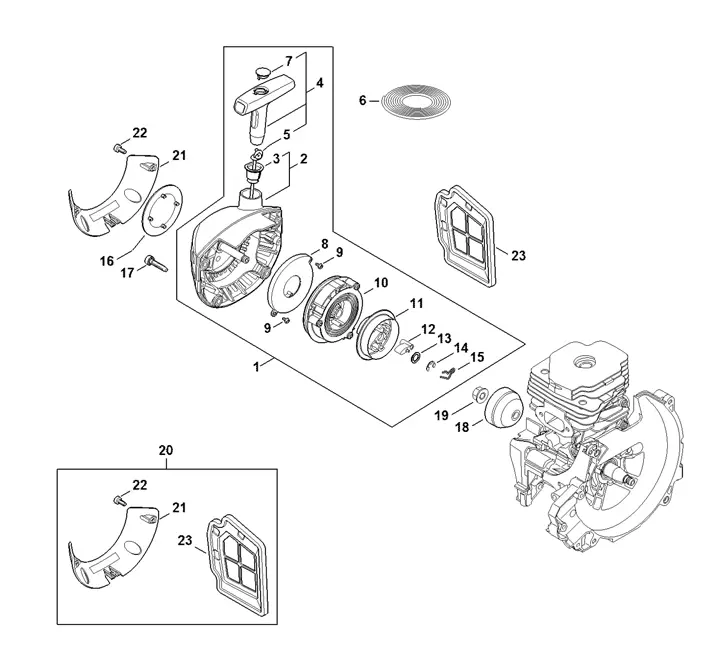

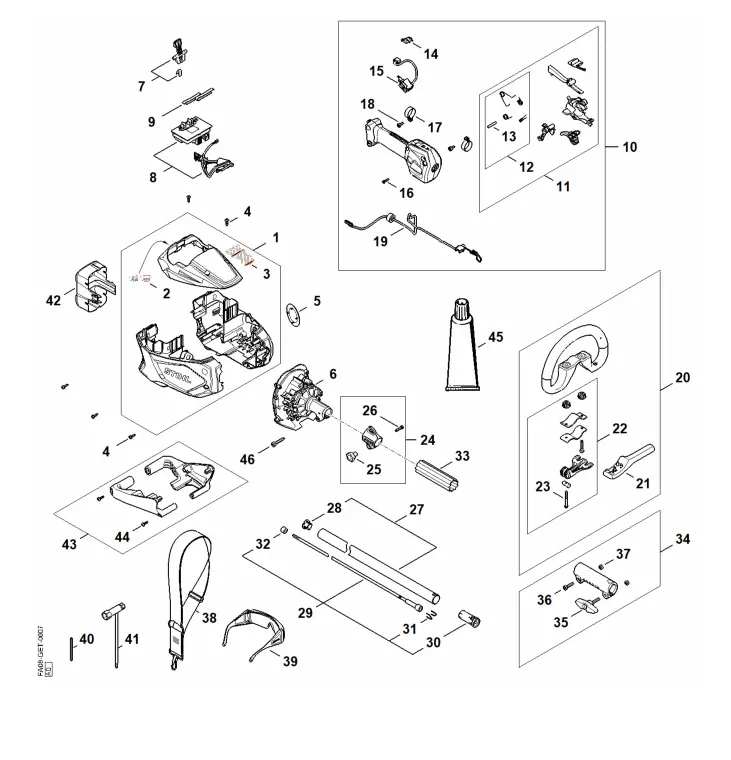

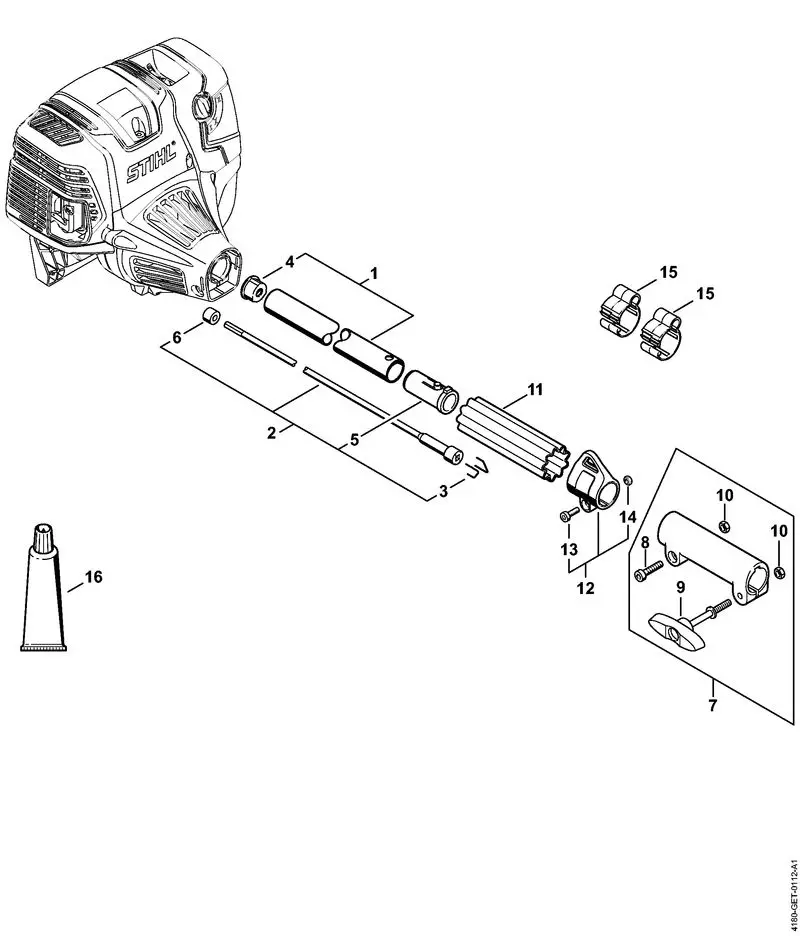

Visualizing the configuration of these elements provides a clearer understanding of how they interact and function together. From the engine to the attachments, each component plays a pivotal role in ensuring smooth operation. Analyzing these relationships can ultimately lead to better maintenance practices and increased longevity of the device.

By delving into the specific arrangements and functions of individual pieces, users can uncover the ultimate potential of their equipment. Whether you’re a seasoned professional or a casual user, this exploration can enhance your expertise and confidence in managing your tool effectively.

Understanding Stihl KM55R Parts

In the world of outdoor power equipment, comprehending the components of your tools is essential for optimal performance and longevity. Each machine comprises various elements that work in harmony to ensure efficiency and effectiveness in tasks such as gardening, landscaping, and maintenance. A thorough understanding of these elements can aid in maintenance, repairs, and upgrades, ultimately enhancing the user experience.

Key Components and Their Functions

Familiarity with the essential elements can greatly improve your interaction with the equipment. Each section plays a unique role, contributing to the overall functionality. Here are some vital components:

| Component | Function |

|---|---|

| Engine | Powers the unit and drives the performance. |

| Fuel Tank | Holds the fuel necessary for operation. |

| Cutting Head | Handles the trimming and cutting tasks. |

| Handlebar | Provides control and maneuverability. |

| Throttle Control | Regulates the speed and power output. |

Maintenance Tips

Proper upkeep of each component is crucial for sustaining performance. Regular checks and timely replacements of worn parts can prevent costly repairs and extend the lifespan of your equipment. Always refer to the user manual for specific guidelines on maintenance and replacement intervals.

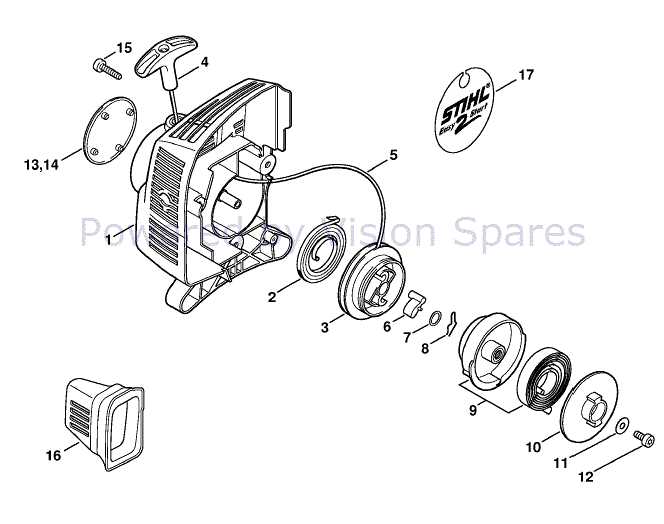

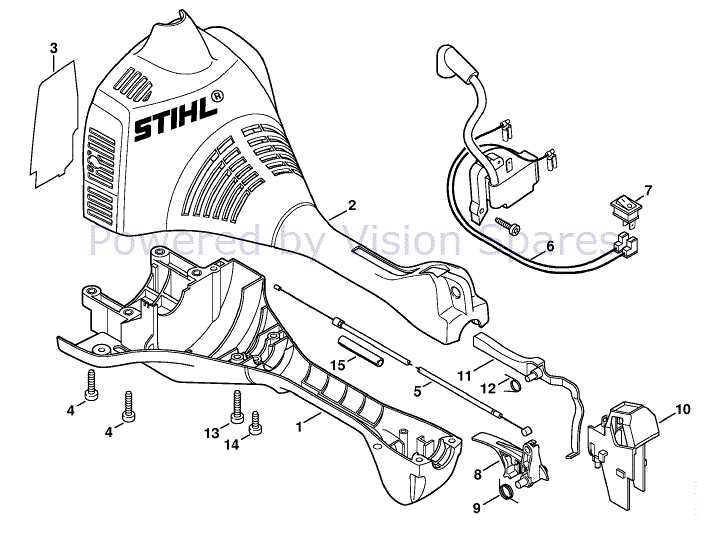

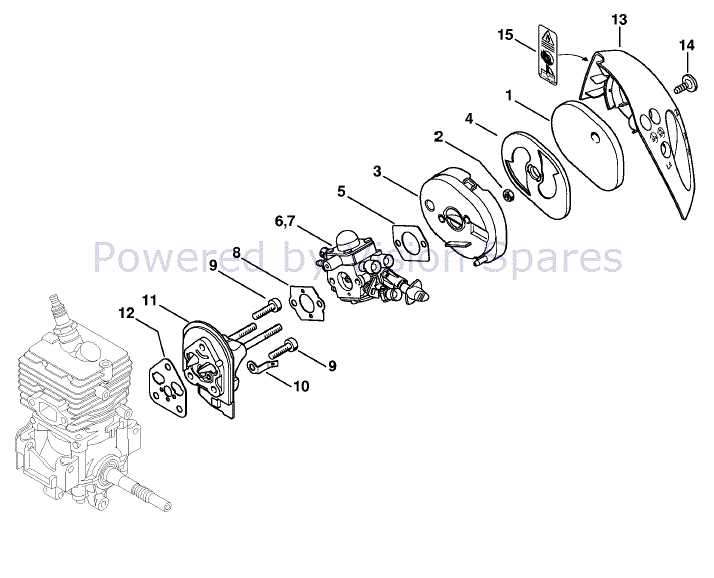

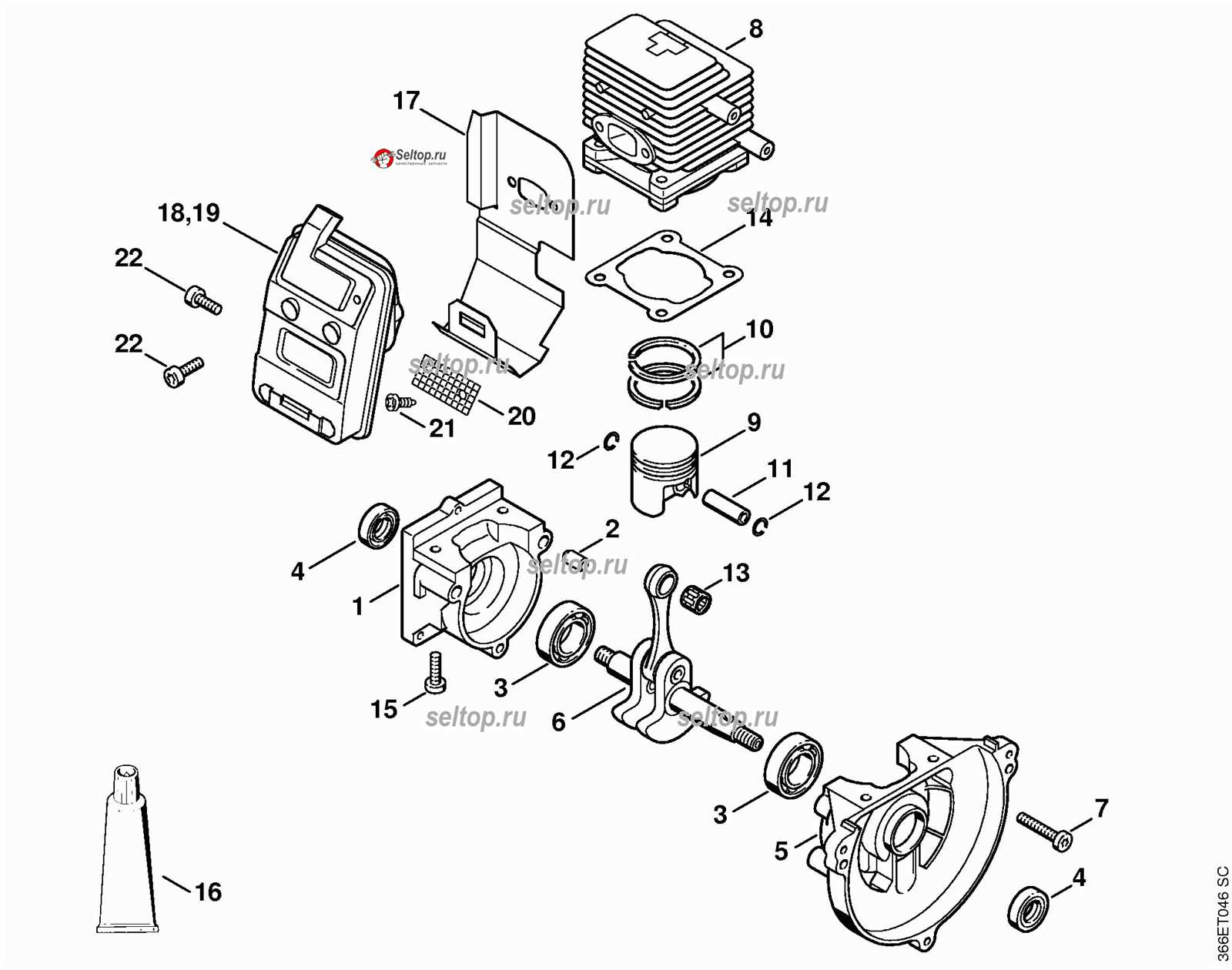

Importance of Parts Diagrams

Understanding the components of a machine is crucial for effective maintenance and repair. Visual representations of the individual elements help users identify each part’s role and relationship within the overall system. This knowledge is essential for ensuring longevity and optimal performance.

Benefits of Visual Guides

- Enhanced Understanding: Visual aids clarify complex structures, making it easier to comprehend how different elements interact.

- Efficient Repairs: With a clear view of all components, identifying the source of a problem becomes quicker and more straightforward.

- Reduced Errors: Accurate visuals minimize the risk of misplacing or incorrectly assembling parts during maintenance tasks.

- Improved Safety: Knowing how components fit together can prevent accidents that arise from improper handling or assembly.

Utilizing Visual References

When undertaking repairs or maintenance, consulting these guides can lead to better outcomes. They serve as valuable resources for both novice and experienced users, ensuring that all necessary elements are accounted for. Additionally, having a visual reference encourages a more organized approach, which can save time and reduce frustration.

Identifying Key Components

Understanding the essential elements of a tool is crucial for effective operation and maintenance. Each component plays a significant role in ensuring optimal performance and longevity. By familiarizing yourself with these parts, you can enhance your user experience and troubleshoot issues more efficiently.

Main Parts Overview

Below are the primary components commonly found in outdoor power equipment, along with their functions:

| Component | Function |

|---|---|

| Engine | Powers the machine and drives its various functions. |

| Fuel Tank | Holds the fuel necessary for the engine operation. |

| Handle | Provides grip and control during operation. |

| Cutting Head | Delivers cutting action through blades or trimmer line. |

Maintenance Importance

Regular checks and maintenance of these components are vital. Proper care ensures peak functionality and can prevent potential failures, extending the tool’s lifespan.

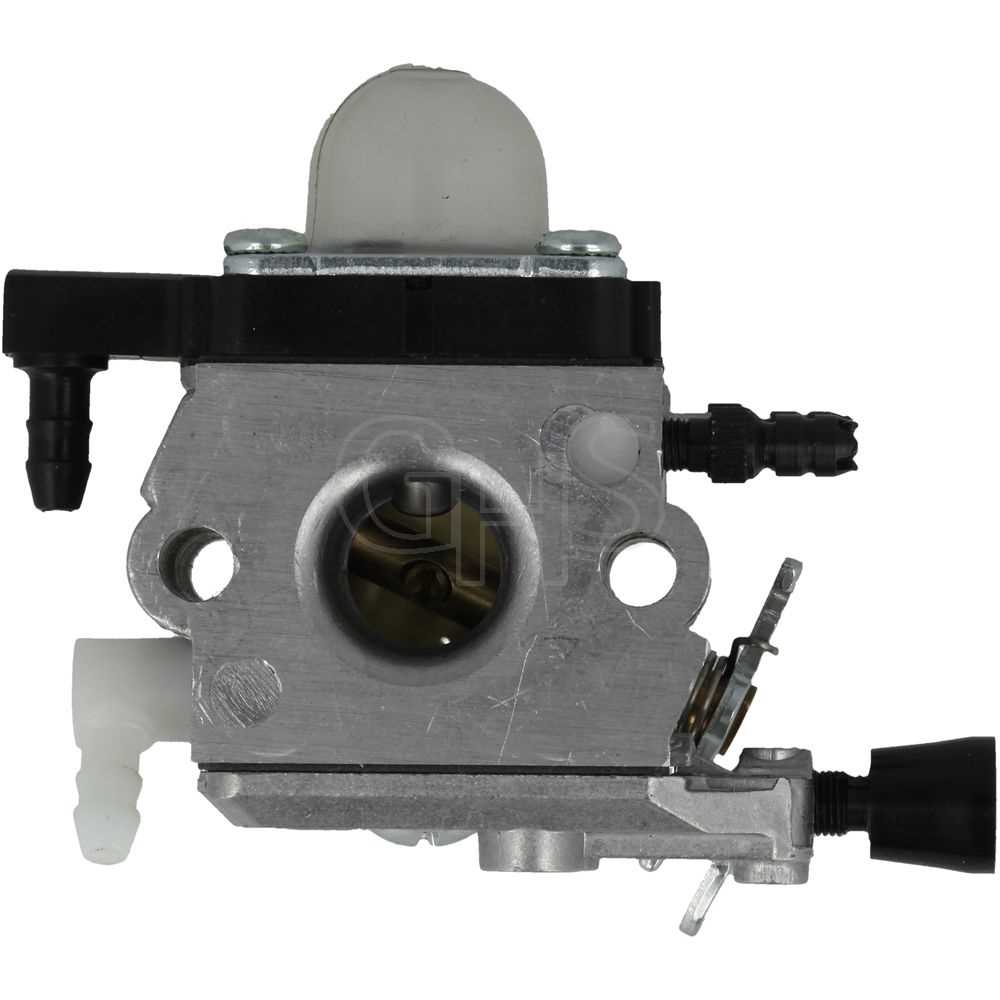

Common Issues with KM55R Parts

When operating outdoor power tools, users often encounter various challenges related to components. Understanding these common issues can significantly enhance maintenance and performance, ensuring the machine operates smoothly and efficiently.

Wear and Tear

Frequent use can lead to significant deterioration of critical elements. Components like the cutting head and drive shaft are particularly susceptible to damage, which may result in reduced effectiveness and increased strain on the engine.

Fuel and Ignition Problems

Fuel delivery and ignition issues are prevalent concerns that can affect overall functionality. Clogs in fuel lines or malfunctioning spark plugs often hinder proper operation, necessitating regular inspection and replacement to maintain optimal performance.

How to Access the Diagram

Understanding the layout of components for your equipment can significantly enhance maintenance and repair efforts. Accessing a visual representation of the parts is essential for anyone looking to perform repairs or upgrades effectively. This guide will walk you through the steps to locate and utilize these resources efficiently.

Finding the Right Resources

- Visit the official website of the manufacturer.

- Look for a section dedicated to customer support or product manuals.

- Utilize search features to input the model number or name of the equipment.

Downloading and Viewing the Layout

- Once you locate the appropriate section, download the available documentation.

- Open the file using a PDF reader or similar application.

- Zoom in on the sections that pertain to your needs for a clearer view.

With the correct representation in hand, you’ll be better equipped to identify and troubleshoot issues, ensuring your equipment remains in optimal condition.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and efficiency of your outdoor power equipment. By adhering to a few fundamental practices, you can significantly enhance the lifespan of your machine and maintain optimal performance.

Regular Cleaning: Keep your equipment free from dirt and debris. Regularly cleaning the exterior prevents buildup that can lead to overheating and wear.

Inspect Components: Routinely examine essential parts for signs of wear or damage. Addressing small issues before they escalate can save time and money in the long run.

Lubrication: Ensure that moving parts are properly lubricated to minimize friction. Regular application of suitable oils helps maintain smooth operation.

Fuel Quality: Use high-quality fuel to prevent clogging and other issues. Stale or contaminated fuel can adversely affect performance and lead to unnecessary repairs.

Storage Practices: When not in use, store your equipment in a dry, sheltered place. Protecting it from harsh weather conditions can prevent rust and degradation.

Follow Manufacturer Guidelines: Always adhere to the manufacturer’s recommendations for maintenance schedules and procedures. These guidelines are designed to optimize performance and longevity.

Replacing Worn Out Parts

Over time, essential components of any outdoor power equipment can degrade, affecting performance and efficiency. Timely replacement of these elements is crucial to maintaining optimal functionality and extending the lifespan of the machine. Understanding how to identify and replace these items is key for any user looking to ensure reliable operation.

Identifying Worn Components

Recognizing the signs of wear is the first step towards effective maintenance. Common indicators include:

- Decreased performance during operation

- Unusual noises or vibrations

- Difficulty starting or maintaining power

- Visible damage or wear on parts

Steps for Replacement

Once you have identified the worn components, follow these steps for replacement:

- Gather necessary tools and replacement items.

- Consult the user manual for specific instructions on disassembly.

- Carefully remove the worn part, ensuring not to damage surrounding components.

- Install the new part, following the manufacturer’s guidelines.

- Reassemble the equipment and conduct a thorough check before use.

By staying vigilant about the condition of your equipment and proactively replacing worn components, you can enhance its performance and reliability for many years to come.

Where to Find Genuine Parts

Locating authentic components for your outdoor equipment is essential for maintaining optimal performance and longevity. Using original items ensures compatibility and reliability, allowing you to get the most out of your machinery.

Authorized Dealers

One of the most reliable sources for genuine items is through authorized distributors. These retailers often carry a full inventory and can provide expert advice tailored to your needs.

Online Resources

Many websites specialize in offering genuine replacements. Look for platforms that guarantee authenticity and have positive customer reviews.

| Source Type | Advantages |

|---|---|

| Authorized Dealers | Expert advice and full inventory |

| Online Retailers | Convenience and wide selection |

| Manufacturer’s Website | Direct access to original components |

DIY Repairs Using the Diagram

Understanding the assembly and components of your equipment can significantly enhance your repair capabilities. Utilizing a visual reference allows you to identify parts easily, making it simpler to perform maintenance tasks. This section will guide you through the essential steps for executing repairs effectively by leveraging the available illustrations.

Essential Tools for Repairs

Before diving into the repair process, it’s crucial to gather the necessary tools. Here’s a quick overview of what you’ll need:

| Tool | Purpose |

|---|---|

| Screwdriver Set | To remove and secure screws in various components. |

| Wrench | For loosening and tightening nuts and bolts. |

| Pliers | To grip and manipulate small parts. |

| Safety Goggles | To protect your eyes during repairs. |

Step-by-Step Repair Process

Once you have your tools ready, follow these steps for a smooth repair experience:

1. Identify the malfunctioning part using the visual guide to locate it on the equipment.

2. Gather your tools and prepare your workspace for easy access.

3. Carefully disassemble the relevant components, taking care to keep screws and small parts organized.

4. Inspect each part for wear and damage, replacing any that are not functioning properly.

5. Reassemble the equipment in the reverse order, ensuring all parts are securely fastened.

By following these guidelines, you can effectively carry out repairs and keep your equipment in optimal condition.

Understanding Part Numbers

Part numbers serve as a vital reference system in the world of machinery and equipment. They allow users to identify, locate, and acquire specific components efficiently. By deciphering these alphanumeric codes, one can ensure compatibility and quality in replacements.

Typically, a part number contains a combination of letters and digits that convey essential information about the item. Here are some key elements often found within these codes:

- Manufacturer Code: Often the first segment, indicating the company responsible for the part.

- Category Identifier: This portion may specify the type of component, such as engine or transmission parts.

- Unique Identifier: A distinct series of numbers that differentiate similar items from one another.

- Revision Number: Indicates any updates or changes made to the component design.

Understanding these elements can significantly enhance the process of sourcing replacements. Here are a few tips to consider:

- Always check the manufacturer’s website or official documentation for accurate numbers.

- Cross-reference multiple sources to ensure the part’s compatibility.

- Consult with knowledgeable dealers or repair professionals when in doubt.

By becoming familiar with part numbering systems, users can streamline maintenance and repair tasks, ultimately leading to improved performance and longevity of their equipment.

Tools Needed for Repairs

When tackling maintenance tasks on outdoor power equipment, having the right instruments is essential for efficiency and safety. A well-equipped toolbox can make the difference between a successful repair and a frustrating experience. Understanding which tools are necessary not only streamlines the process but also ensures that all components are handled properly.

Basic Hand Tools: A set of screwdrivers, wrenches, and pliers should be the foundation of any repair kit. These tools are indispensable for loosening or tightening fasteners and making adjustments. Be sure to include both metric and standard sizes, as various parts may require different measurements.

Specialized Tools: Depending on the model, certain repairs may necessitate specific tools, such as socket sets or torque wrenches. These items allow for more precise work, ensuring that components are secured to the manufacturer’s specifications.

Cleaning Supplies: Keeping equipment in good condition involves regular cleaning. Brushes, cloths, and degreasers are crucial for removing debris and buildup that can affect performance. A clean workspace is also vital for conducting repairs effectively.

Safety Gear: Don’t overlook personal protective equipment. Safety goggles, gloves, and ear protection are important to safeguard against potential hazards during repair work. Prioritizing safety ensures a smooth repair experience.

In summary, equipping yourself with the right tools not only simplifies the repair process but also enhances the overall longevity and performance of your outdoor equipment.

Expert Advice for Troubleshooting

Tackling mechanical issues can often feel daunting, but with the right approach, solutions become clearer. Understanding the core elements of your equipment and identifying common problems are crucial steps in resolving issues effectively. By following a systematic method, you can enhance performance and extend the lifespan of your tools.

1. Identify the Symptoms: Begin by observing any unusual sounds, vibrations, or operational inconsistencies. Document these symptoms, as they can provide invaluable clues for diagnosis.

2. Consult the Manual: Referencing the user guide can clarify the intended operation and highlight potential pitfalls. This resource often includes troubleshooting sections tailored to common concerns.

3. Inspect Key Components: Delve into checking vital parts such as filters, spark plugs, and fuel lines. Regular maintenance of these elements can prevent many problems from escalating.

4. Test for Blockages: Ensure there are no obstructions in air or fuel pathways. Clearing these blockages can restore normal function and improve efficiency.

5. Seek Professional Help: If troubleshooting efforts are unfruitful, consulting a qualified technician may provide the ultimate solution. Their expertise can help identify underlying issues that may not be immediately apparent.