For enthusiasts of garden maintenance, knowing the intricacies of your equipment is crucial for optimal performance. Each machine consists of various elements that contribute to its efficiency and longevity. Familiarizing yourself with these components can enhance your ability to manage outdoor spaces effectively.

In this section, we will explore the essential features and mechanisms of a specific type of pruning tool. By examining its structure, users can gain valuable insights into maintenance, troubleshooting, and potential upgrades. Understanding how each element functions ultimately leads to a more productive gardening experience.

Moreover, recognizing the unique aspects of your device can help in identifying the right replacements and enhancements when needed. This knowledge not only empowers you as a user but also ensures that your gardening tasks are completed with precision and ease.

Understanding Stihl Hedge Trimmer Design

The construction of these gardening tools is a blend of functionality and innovation, aimed at providing users with efficient and precise cutting experiences. Recognizing the various components and their roles can enhance the overall understanding and usability of these devices.

Key Components of the Tool

Each model is built with several essential elements that contribute to its performance:

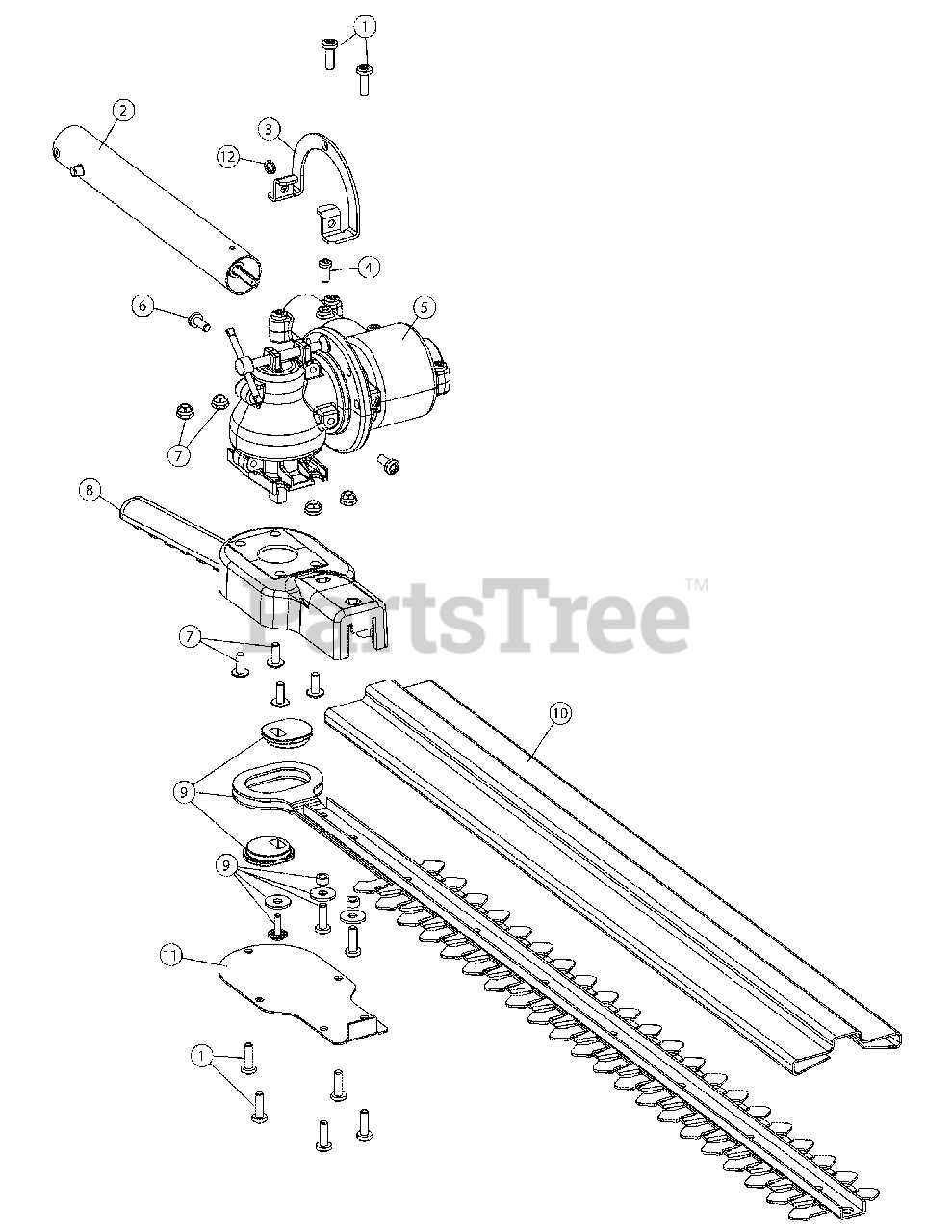

- Blade Assembly: The cutting edge is crucial for achieving clean cuts, and its design varies based on the intended use.

- Motor: This component provides the necessary power, influencing the tool’s efficiency and cutting speed.

- Handle: Ergonomically designed for comfort, the handle allows for better maneuverability during operation.

- Gearbox: This part transmits power from the motor to the blades, affecting overall performance.

Understanding Performance Features

Several features enhance the effectiveness of these devices:

- Weight Distribution: A well-balanced tool reduces fatigue, allowing for longer usage without strain.

- Blade Spacing: The distance between blades affects the type of vegetation that can be handled.

- Safety Mechanisms: Built-in features to protect users during operation are vital for safe handling.

By familiarizing oneself with these aspects, users can make informed decisions regarding maintenance and operation, ultimately leading to better results in their gardening tasks.

Key Components of Hedge Trimmers

Understanding the essential elements of these garden tools enhances their efficiency and longevity. Each component plays a vital role in performance, ensuring clean and precise cutting of foliage.

| Component | Description |

|---|---|

| Blade | The cutting edge that determines the quality of cuts, available in various shapes and sizes. |

| Motor | Drives the blades and is crucial for power; can be electric or gas-powered. |

| Handle | Provides grip and control, often designed ergonomically for comfort during use. |

| Gearbox | Transmits power from the motor to the blades, influencing cutting efficiency. |

| Safety Guard | A protective feature that ensures user safety by covering sharp edges. |

Importance of Maintenance Parts

Ensuring the longevity and efficiency of your equipment heavily relies on the timely replacement of essential components. Regular attention to these elements not only prevents unexpected breakdowns but also enhances overall performance, making tasks smoother and more effective.

Prolonging Equipment Lifespan

By regularly servicing crucial components, users can significantly extend the operational life of their machinery. Timely interventions allow for early detection of wear and tear, ultimately saving costs in the long run.

Optimizing Performance

Well-maintained machinery operates at peak efficiency, providing better results in less time. Consistent upkeep of vital elements ensures that the equipment runs smoothly, reducing energy consumption and improving output quality.

Common Issues with Hedge Trimmer Parts

Maintaining garden equipment can often reveal various challenges that affect performance and longevity. Understanding these issues is crucial for ensuring optimal functioning and preventing costly repairs. Here, we explore frequent problems associated with garden cutting tools.

Wear and Tear

Regular usage can lead to deterioration of components, such as blades and motors. Signs of wear include dull cutting edges and unusual vibrations during operation. Regular inspections and timely replacements can mitigate these effects.

Fuel and Lubrication Problems

Insufficient fuel or improper lubrication can result in poor performance or even engine failure. It’s essential to check fuel levels and use the correct type of oil to ensure smooth operation and prevent overheating.

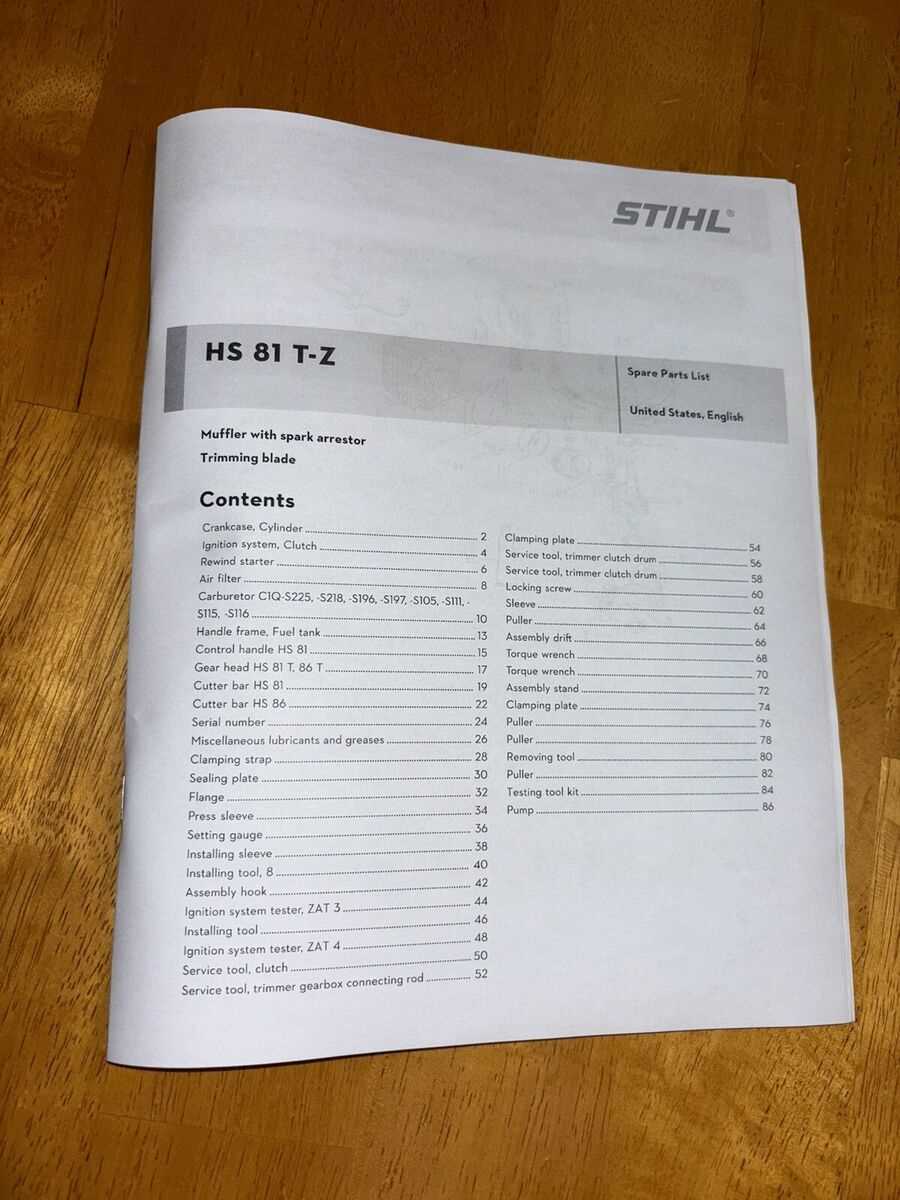

How to Identify Stihl Parts

Recognizing components of outdoor equipment can significantly enhance maintenance and repair processes. Familiarity with individual elements not only ensures better performance but also aids in effective troubleshooting. Understanding how to pinpoint these pieces is essential for optimal functioning.

To effectively identify the necessary components, follow these steps:

| Step | Description |

|---|---|

| 1 | Consult the user manual to locate part numbers and diagrams. |

| 2 | Inspect the machine for model information typically found on a label. |

| 3 | Utilize online resources or manufacturer websites for detailed visuals. |

| 4 | Join community forums for insights from experienced users. |

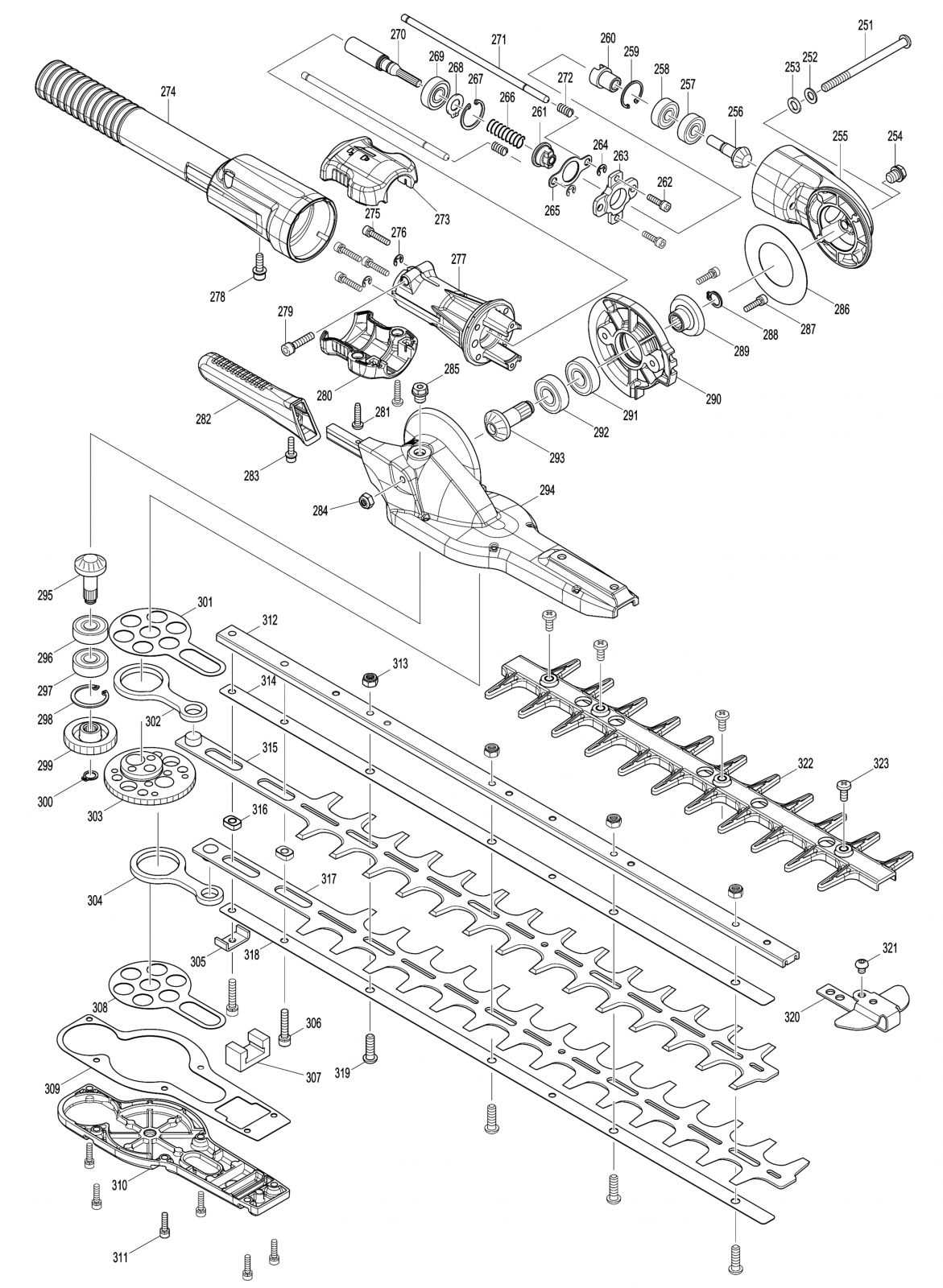

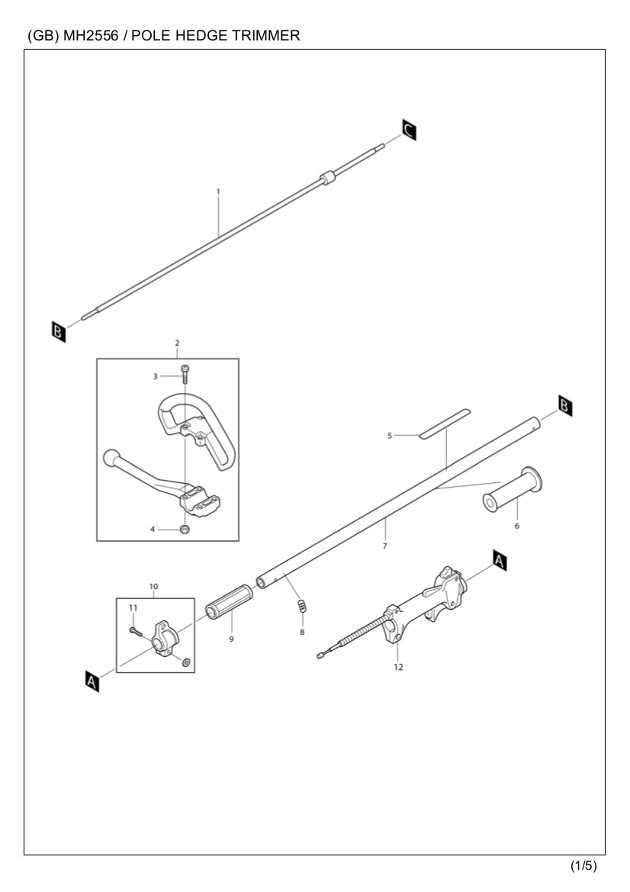

Parts Diagram Overview Explained

The visual representation of component layouts serves as a vital resource for understanding how different elements interact within machinery. These illustrations not only provide clarity on assembly but also aid in identifying specific pieces for maintenance or replacement. By examining such visuals, users can gain insights into the functionality and organization of various components, enhancing their ability to perform repairs effectively.

Understanding the structure of each section is essential for troubleshooting and ensuring optimal performance. An accurate depiction allows operators to delve into the mechanics, enabling them to locate the ultimate components needed for efficient operation. This knowledge fosters a deeper appreciation for the design and engineering behind the equipment.

Utilizing these resources empowers individuals to make informed decisions when faced with repairs or upgrades, ultimately prolonging the lifespan of the machine. Engaging with the visual guides transforms complex tasks into manageable steps, enhancing both confidence and capability in maintenance activities.

Replacing Blades: A Step-by-Step Guide

Maintaining sharp blades is crucial for achieving optimal performance in your cutting tool. This guide will help you replace the blades effectively, ensuring your equipment remains in top condition for efficient use.

- Gather Necessary Tools:

- Replacement blades

- Screwdriver

- Wrench

- Safety gloves

- Protective eyewear

- Prepare the Equipment:

- Disconnect from power source.

- Ensure the unit is stable.

- Remove the Old Blades:

- Locate screws or fasteners securing the blades.

- Carefully unscrew and remove the old blades.

- Install the New Blades:

- Align new blades with the mounting points.

- Securely fasten with screws or fasteners.

- Final Check:

- Ensure all screws are tight.

- Reconnect power source and test functionality.

Following these steps will ensure your cutting tool is equipped with fresh blades, enhancing its efficiency and performance.

Choosing Quality Replacement Parts

Selecting superior components is crucial for ensuring optimal performance and longevity of your outdoor equipment. Quality replacements can significantly impact efficiency and reliability, making it essential to make informed choices.

Why Quality Matters

Investing in high-quality components provides numerous benefits:

- Enhanced durability and lifespan

- Improved performance and efficiency

- Reduced risk of breakdowns

- Better compatibility with existing machinery

Tips for Selecting Quality Components

Consider the following guidelines when choosing replacements:

- Research reputable brands known for reliability.

- Check for certifications and warranties that assure quality.

- Read customer reviews to gauge performance experiences.

- Compare prices but prioritize quality over cost.

Tools Needed for Repair Work

When undertaking maintenance tasks, having the right equipment is crucial for effective repairs. This ensures efficiency and safety during the process. Below is a list of essential tools to consider.

Essential Tools

- Wrenches

- Screwdrivers (flathead and Phillips)

- Pliers

- Socket set

- Torque wrench

Additional Supplies

- Replacement fasteners

- Lubricants

- Cleaning cloths

- Safety goggles

- Work gloves

Gathering these tools will facilitate a smoother repair process and help achieve the ultimate results in maintaining your equipment.

Safety Precautions When Repairing

When undertaking maintenance or repairs on gardening equipment, it is crucial to prioritize safety to prevent accidents and injuries. Proper preparation and adherence to guidelines can ensure a secure environment while working.

First and foremost, always disconnect the power source before beginning any repair tasks. This simple step can significantly reduce the risk of accidental starts. Additionally, wear appropriate protective gear, such as gloves and goggles, to shield yourself from debris and sharp components.

Ensure your workspace is organized and free of hazards. Having the right tools within reach and a clear area to work can help maintain focus and efficiency. Lastly, consult the manufacturer’s guidelines for specific safety recommendations related to your equipment, as they provide valuable insights into safe practices.

Where to Purchase Stihl Parts

Finding quality components for outdoor equipment is essential for maintaining performance and longevity. Several reliable sources offer a variety of items that can enhance your tools and ensure they operate efficiently.

Online Retailers: Numerous e-commerce platforms specialize in equipment accessories. These websites often provide a vast selection and competitive prices, making it convenient to find what you need from the comfort of your home.

Local Dealers: Authorized dealers are a great option for personalized service. They can help you identify the correct components and may offer installation assistance, ensuring you get the right fit for your machinery.

Repair Shops: Local repair specialists often have access to a range of components. They can recommend high-quality options and sometimes even carry inventory, which can save time and effort.

Manufacturer’s Website: Directly visiting the official website can provide you with the most accurate information about the available items and any specific offerings. This route often ensures you are purchasing genuine products.

Forums and Community Groups: Engaging with fellow enthusiasts in online forums or social media groups can yield valuable recommendations. Members often share their experiences with various suppliers, helping you find trustworthy sources.

Benefits of Using Original Parts

Utilizing authentic components for your equipment enhances performance and longevity. These original pieces are designed to fit seamlessly, ensuring optimal functionality and safety.

Quality Assurance

- Manufactured to strict standards.

- Guaranteed durability and reliability.

- Reduces the risk of malfunctions.

Enhanced Performance

- Ensures compatibility with existing machinery.

- Maintains efficiency and power output.

- Offers better overall results in operation.

Tips for Long-lasting Equipment Performance

Maintaining your tools in optimal condition is essential for ensuring their efficiency and longevity. Proper care not only enhances performance but also reduces the need for frequent replacements and repairs. Here are some effective strategies to keep your equipment running smoothly.

Regular Maintenance

Perform routine checks and cleaning to prevent buildup of debris and grime. Lubricate moving parts regularly to minimize wear and tear, ensuring that everything operates seamlessly. Scheduling maintenance during off-peak seasons can also extend the lifespan of your devices.

Proper Storage

When not in use, store your equipment in a dry, protected environment. Using protective covers can shield against dust and moisture. Additionally, ensure that tools are kept out of direct sunlight to avoid material degradation, which is vital for preserving functionality over time.