When working with complex machines, it’s essential to have a clear view of how different elements are connected and interact with each other. Knowing the arrangement of various mechanical components helps in maintaining, repairing, and optimizing performance. This guide offers a detailed breakdown of the individual elements and their placement, ensuring clarity for anyone needing to engage with the equipment.

Each section focuses on specific mechanical areas, highlighting key connections and placements that contribute to the overall operation. Whether you’re new to working with this type of equipment or simply need a refresher, the visual representation of these elements provides valuable insight into the system’s inner workings. This structured approach simplifies understanding and aids in successful troubleshooting.

Overview of Stihl MM 56 Components

Understanding the key elements of this versatile tool helps in maintaining its functionality and ensuring long-lasting performance. Each component plays a vital role in delivering efficient operation, making it essential to know the purpose and interaction of these elements.

- Power Source: The engine serves as the heart, generating the energy required for smooth operation.

- Transmission System: Transfers energy from the power source to other components, allowing for movement and control.

- Cutting Attachments: These interchangeable parts offer various functions, such as trimming, cultivating, and edging, depending on the task at hand.

- Handle Assembly: Provides stability and ease of use, ensuring a comfortable grip while operating the tool.

- Wheels: Offer mobility, allowing easy maneuverability over different surfaces during use.

Each of these elements works in harmony to ensure effective performance and to adapt to various outdoor tasks. Regular upkeep and proper handling o

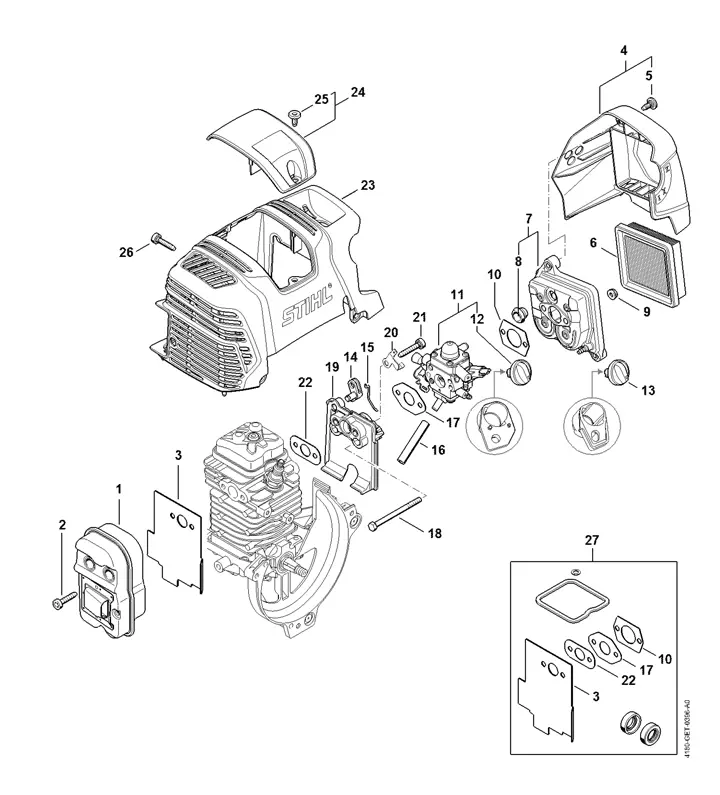

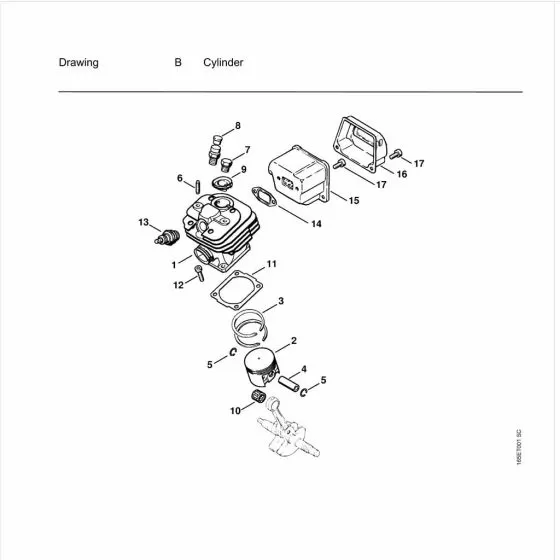

Engine Parts Breakdown

The internal components of the motor are crucial for ensuring smooth operation and optimal performance. By understanding the arrangement and function of each element, it becomes easier to identify potential issues and maintain the system effectively.

Below is an overview of the key sections of the motor:

- Cylinder: The core of the motor, where energy conversion occurs, driving the overall mechanism.

- Piston: Moves inside the cylinder to generate power and facilitate motion.

- Crankshaft: Converts the up-and-down motion of the piston into rotational force.

- Flywheel: Helps to maintain consistent speed by storing energy and providing balance to the system.

- Spark Plug: Ignites the fuel mixture, initiating the combustion process.

- Carburetor: Regulates the air-fuel mixture to ensure the proper combustion ratio.

Each of these components works in

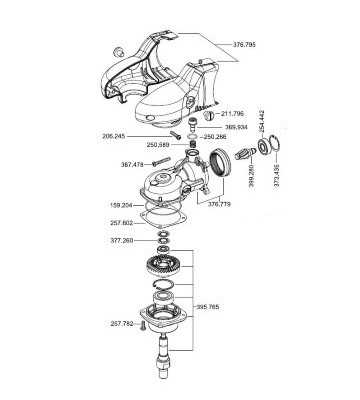

Transmission Assembly Structure

The transmission system plays a key role in ensuring smooth operation by transferring power effectively. Understanding the internal structure is crucial for maintaining optimal performance, as every component contributes to the overall efficiency. Proper alignment and connectivity within the system are essential to avoid unnecessary wear and ensure long-lasting functionality.

At the heart of the assembly lies a series of interconnected mechanisms that manage the flow of power. These elements must work in harmony to regulate movement and control, translating energy into the desired output. Keeping each section in check allows the system to handle varying demands with ease, providing consistent and reliable results.

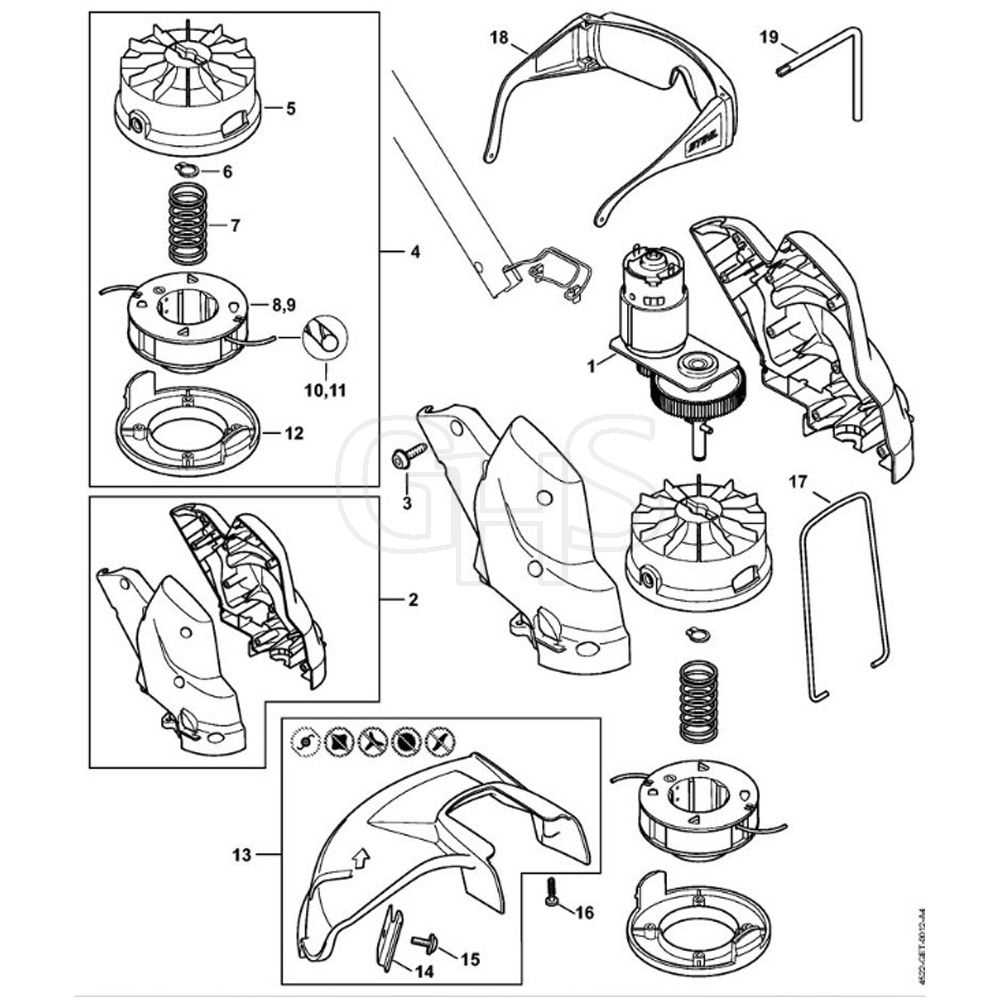

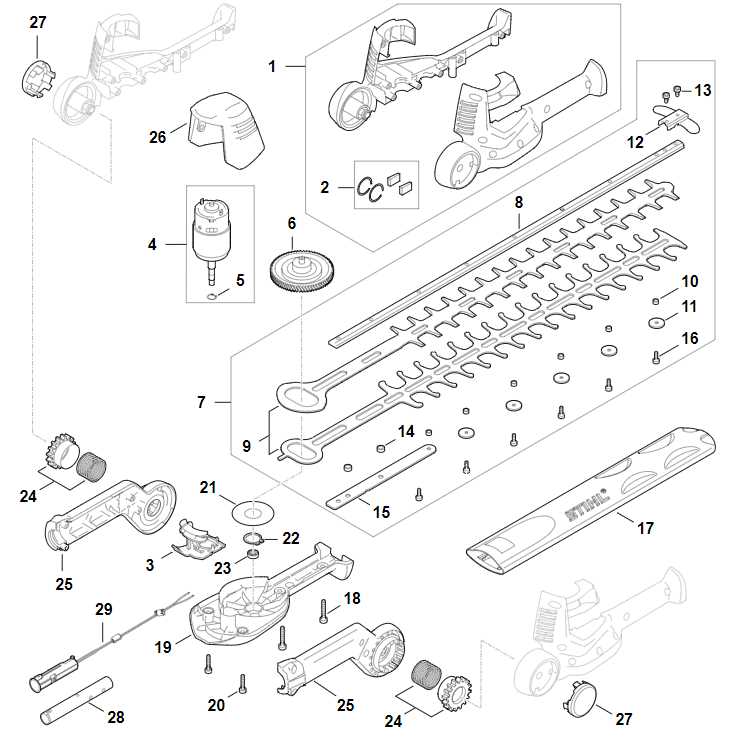

Understanding the Blade Mechanism

The blade system is essential for ensuring smooth operation and efficient performance. By focusing on the structure and function of this component, one can grasp how it contributes to overall efficiency and durability. The arrangement of the cutting element, combined with supporting components, plays a key role in achieving precise movement and action.

Key Components of the Cutting System

- Rotating element: Provides the primary cutting motion.

- Mounting structure: Secures the blade and allows for adjustable positioning.

- Control linkage: Ensures the blade responds correctly to user input.

Maintaining Efficiency and Performance

To maintain peak efficiency, it’s essential to regularly check the alignment and sharpness of the cutting mechanism. Ensuring all connections are tight and well-lubricated will help prevent wear and prolong the lifespan of the entire system.

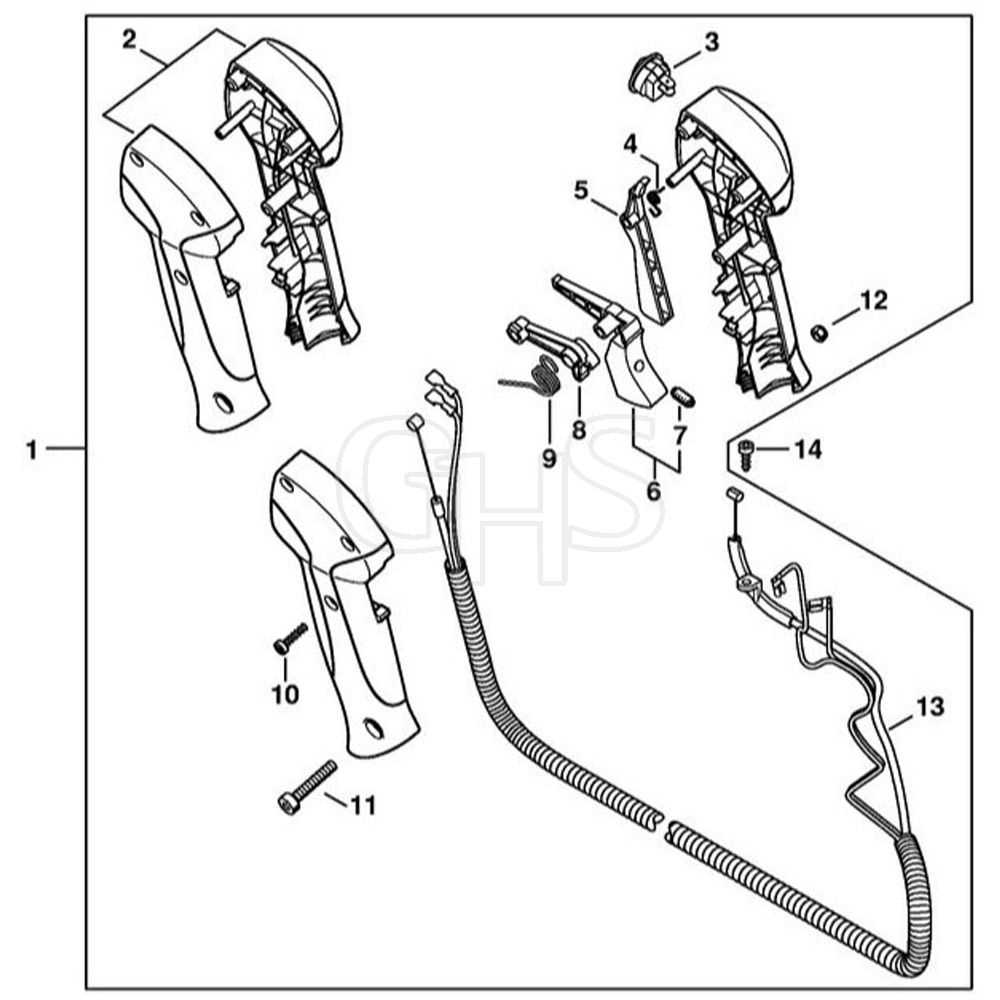

Handle and Control Layout

The arrangement of the handle and controls plays a crucial role in ensuring ease of use and operator comfort. A well-thought-out design allows for smooth handling, making the operation more efficient and intuitive. Each element is positioned to provide quick access, promoting both safety and control during use.

Main Grip

The primary grip is ergonomically shaped to reduce strain on the user. Its location enables a firm grasp, allowing for steady maneuvering. This section is crafted to fit naturally in hand, ensuring secure handling even during extended periods of operation.

Control Interface

The control interface is strategically placed near the main grip for effortless access. Essential functions are grouped together to minimize hand movement, ensuring the operator can make quick adjustments without losing focus on the task. The design prioritizes both accessibility and responsiveness.

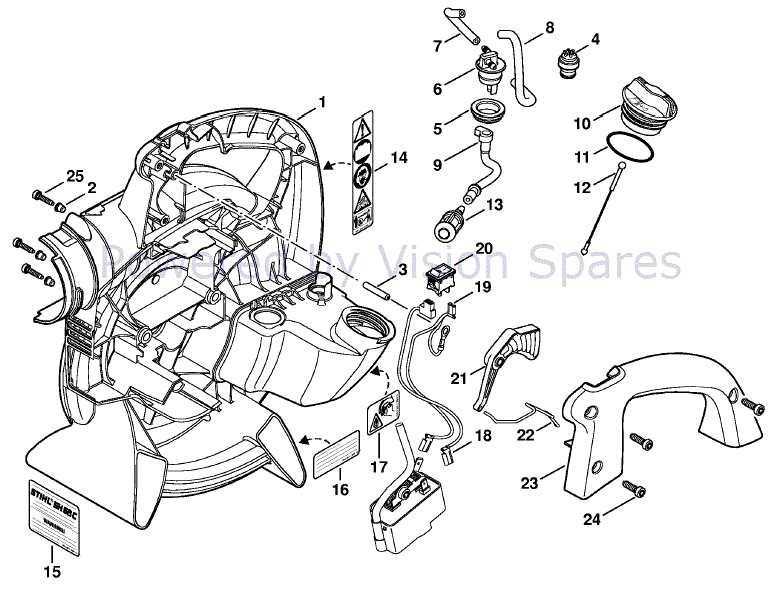

Air Filter System Configuration

The air filtration setup plays a crucial role in maintaining optimal performance for outdoor equipment. This system ensures that the engine receives clean air, which is essential for efficient combustion and overall functionality. Proper configuration of the air intake components can significantly enhance the longevity and reliability of the machinery.

Components of the Filtration System

The configuration typically includes various elements such as the air filter, intake manifold, and housing. The air filter is designed to trap dirt, debris, and other particles, preventing them from entering the engine. It is essential to choose a filter that meets the specific requirements of the equipment for effective operation.

Maintenance Practices

Regular maintenance of the filtration system is vital for ensuring its efficiency. Cleaning or replacing the air filter according to the manufacturer’s guidelines helps maintain airflow and performance. Neglecting this aspect can lead to reduced power output and increased wear on engine components, ultimately affecting the machine’s operational lifespan.

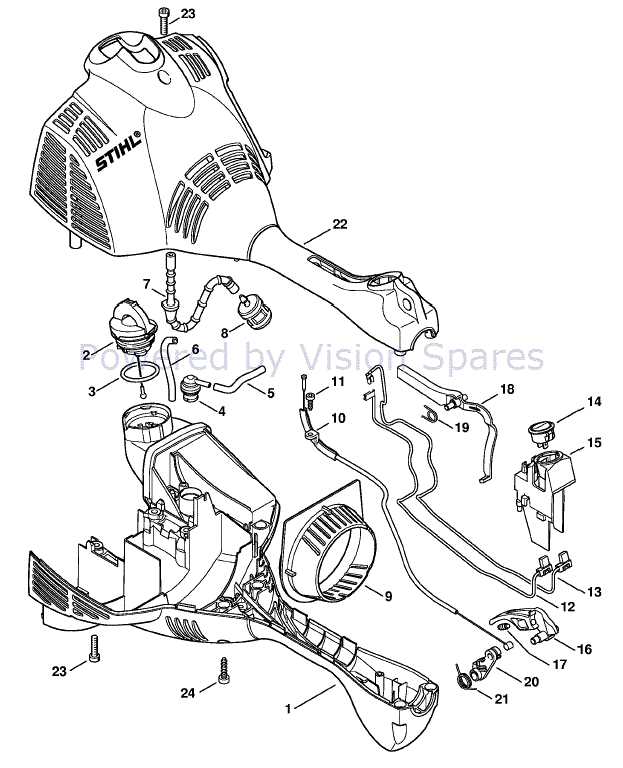

Fuel Tank and Line Connections

The connections between the fuel reservoir and the delivery lines play a crucial role in ensuring the efficient operation of the equipment. Properly designed and maintained connections facilitate the smooth flow of fuel, preventing leaks and ensuring reliable performance during use.

In this section, we will explore the essential components involved in these connections, including the tank itself, hoses, and fittings. Each element must be compatible and securely attached to guarantee optimal fuel delivery to the engine.

Fuel Reservoir: The fuel container is designed to hold the required amount of liquid while maintaining structural integrity under various operating conditions. It is important to check for any signs of wear or damage that could lead to leaks.

Hoses and Lines: Flexible tubing connects the tank to the engine, allowing fuel to flow seamlessly. These lines must be inspected regularly for cracks or blockages that could hinder fuel flow.

Connections and Fittings: Secure fittings are essential for preventing fuel leakage. They should be tightened to the manufacturer’s specifications, ensuring that they can withstand pressure and vibrations during operation.

Regular maintenance of these components will not only enhance the performance of the machine but also extend its lifespan. Ensuring that the fuel tank and associated lines are in optimal condition is vital for safe and efficient operation.

Examining the Exhaust System

The exhaust system plays a crucial role in the efficient operation of outdoor power equipment. It is designed to direct exhaust gases away from the engine while minimizing emissions and noise. Understanding its components and functionality is essential for proper maintenance and performance enhancement.

Key Components

- Exhaust Pipe: This component channels exhaust gases from the engine to the outside atmosphere.

- Muffler: Designed to reduce noise produced by the engine, the muffler helps in quiet operation while ensuring efficient gas flow.

- Gaskets: These seal joints between components, preventing leaks that could affect performance.

- Heat Shield: Protects surrounding parts from heat generated by the exhaust, ensuring safe operation.

Maintenance Tips

- Regularly inspect the exhaust system for signs of wear or damage.

- Clean the muffler and exhaust pipe to prevent blockages and maintain optimal airflow.

- Replace gaskets if any leaks are detected, ensuring a proper seal.

- Check for loose connections and tighten as necessary to avoid exhaust leaks.

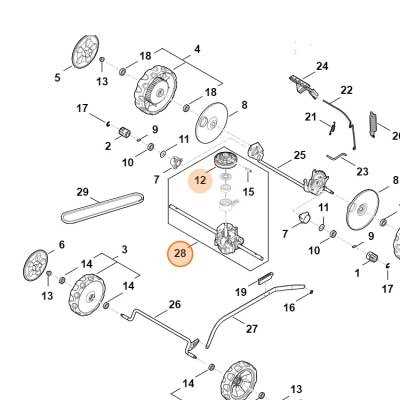

Clutch and Drive Belt Layout

The arrangement of the engagement mechanism and transmission belt is crucial for ensuring optimal performance in any machinery. Understanding the configuration of these components allows for better maintenance and troubleshooting. This section focuses on the design and function of the engagement assembly and belt system, which work together to transmit power efficiently.

Engagement Mechanism Overview

The engagement mechanism serves as the link between the engine and the operational components. It is designed to engage and disengage the power transfer, ensuring that the machine operates smoothly. The clutch typically comprises various elements, including springs and pads, which work in unison to maintain the desired tension and connection during operation.

Belt System Functionality

The drive belt plays a vital role in transferring motion from the engine to the working parts of the device. Its layout is engineered to optimize power delivery and reduce slippage, allowing for efficient operation. Regular inspection and proper alignment of the belt are essential for maintaining functionality and preventing premature wear.

Starter Assembly Details

The starter mechanism plays a vital role in initiating the operation of outdoor power equipment. Understanding the components and their functions within this assembly is essential for effective maintenance and troubleshooting. This section outlines the key elements involved in the starter system and their respective roles.

Main Components

- Starter Rope: A durable cord used to manually engage the engine.

- Recoil Starter: A mechanism that allows the rope to retract after pulling.

- Pulley: Helps to guide the starter rope and provides a smooth engagement with the engine.

- Spring: Responsible for the recoil action, ensuring the rope returns to its original position.

- Mounting Plate: Secures the assembly to the main body of the equipment.

Assembly Process

- Begin by positioning the mounting plate onto the equipment’s housing.

- Attach the recoil starter to the mounting plate, ensuring proper alignment.

- Secure the pulley onto the recoil starter, confirming it rotates freely.

- Thread the starter rope through the pulley and attach it to the handle.

- Finally, install the spring to enable the recoil function of the starter mechanism.

Regular inspection and maintenance of these components can prevent operational issues and extend the lifespan of the equipment. Familiarity with the assembly details aids in ensuring efficient functionality.

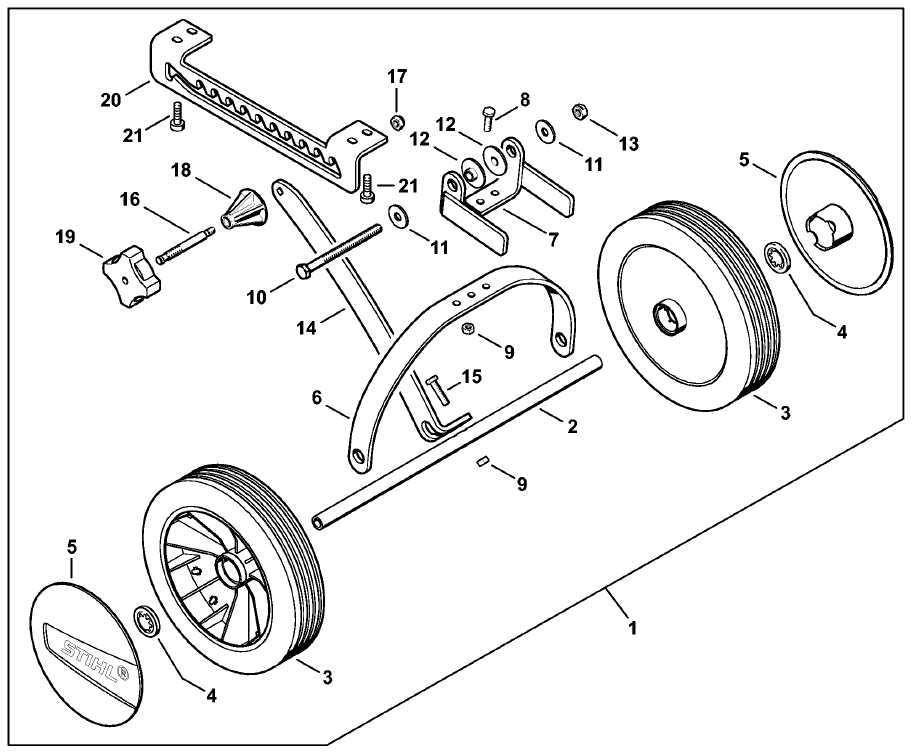

Wheel and Axle Arrangement

The configuration of wheels and axles plays a crucial role in the overall functionality and maneuverability of the equipment. This assembly is designed to ensure smooth movement and stability, allowing for efficient operation across various terrains. Understanding the components involved in this arrangement is essential for maintenance and optimal performance.

Components of the Arrangement

- Wheels: These circular elements facilitate movement and provide traction. They are typically designed to withstand different types of surfaces.

- Axles: Axles serve as the central shafts that connect the wheels, enabling them to rotate together. Their strength is vital for supporting the weight of the equipment.

- Bearings: Bearings reduce friction between moving parts, allowing for smoother wheel rotation and enhancing the lifespan of the assembly.

Maintenance Tips

- Regularly inspect the wheels for wear and damage to ensure safety and efficiency.

- Check axle alignment to prevent uneven wear and improve handling.

- Lubricate bearings to minimize friction and prolong the life of the wheel and axle system.

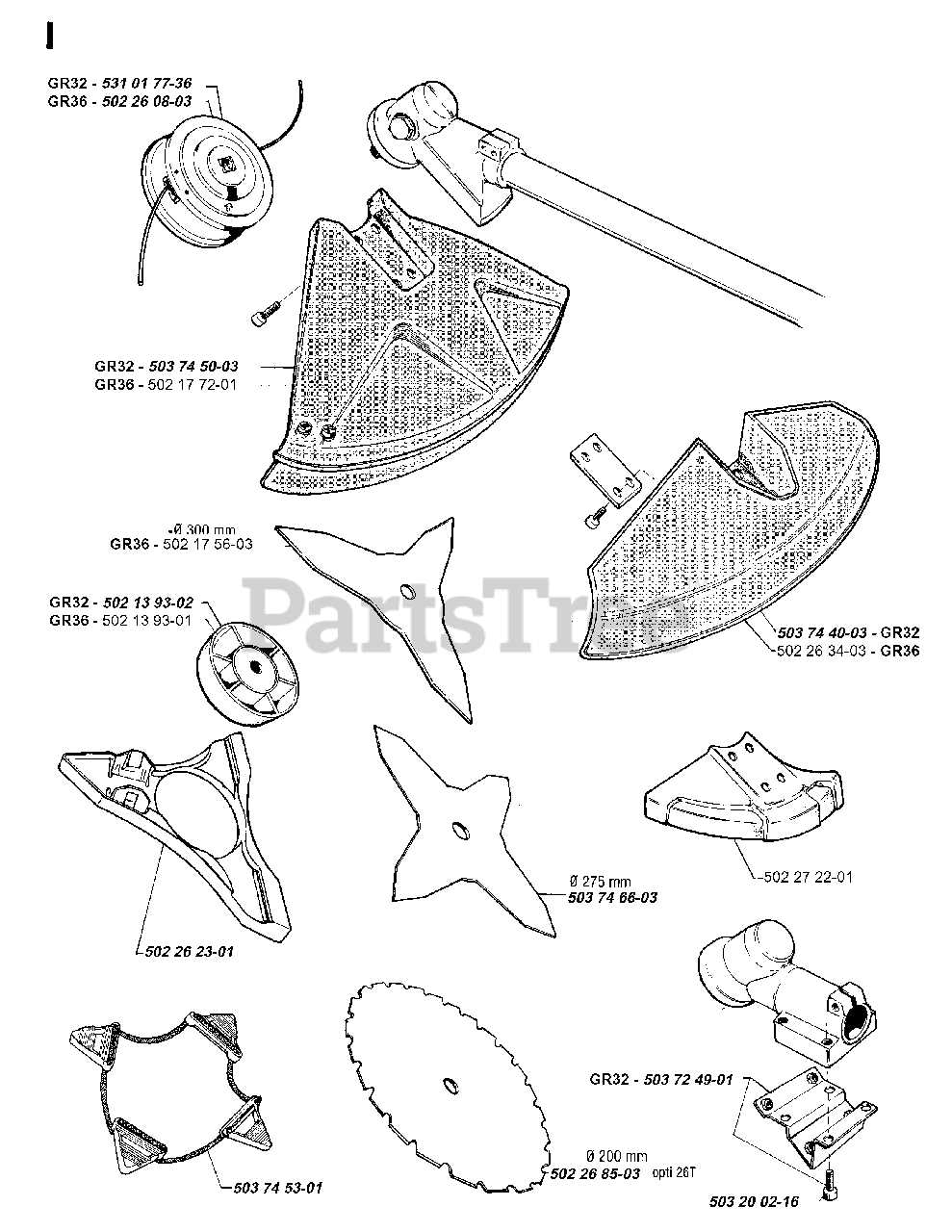

Guide to Replacement Parts

Maintaining the functionality of your equipment is essential for optimal performance. Knowing how to identify and source the necessary components can enhance its longevity and efficiency. This section provides an overview of various elements you may need to consider when looking to replace specific components, ensuring your equipment continues to operate smoothly.

| Component | Description | Typical Signs of Wear |

|---|---|---|

| Engine Filter | Prevents dirt and debris from entering the engine. | Reduced power, unusual noises. |

| Blade Assembly | The cutting mechanism that handles various tasks. | Worn edges, ineffective cutting. |

| Fuel Line | Transfers fuel from the tank to the engine. | Leaking fuel, cracks, or discoloration. |

| Starter Rope | Used to initiate the engine’s operation. | Difficult to pull, frayed or broken rope. |

| Drive Belt | Transfers power from the engine to the cutting tools. | Squealing noises, slippage during operation. |

By understanding these essential components and their roles, you can make informed decisions about replacements. Regular checks and timely updates to your equipment not only improve its performance but also save you from potential issues in the long run.