When working with outdoor equipment designed for multiple tasks, it’s important to have a clear view of how its internal elements function. A well-organized layout of the individual mechanisms ensures smooth operation and easier maintenance. This section offers an in-depth look into the various elements that contribute to the efficiency of this versatile machine.

Whether you’re performing routine maintenance or need to replace certain mechanisms, having a clear overview of how everything fits together is essential. Each component plays a crucial role in delivering the performance users rely on, and understanding their arrangement can greatly extend the lifespan of the tool.

In this guide, we will explore the different mechanisms that keep the device running efficiently, focusing on their functions, placement

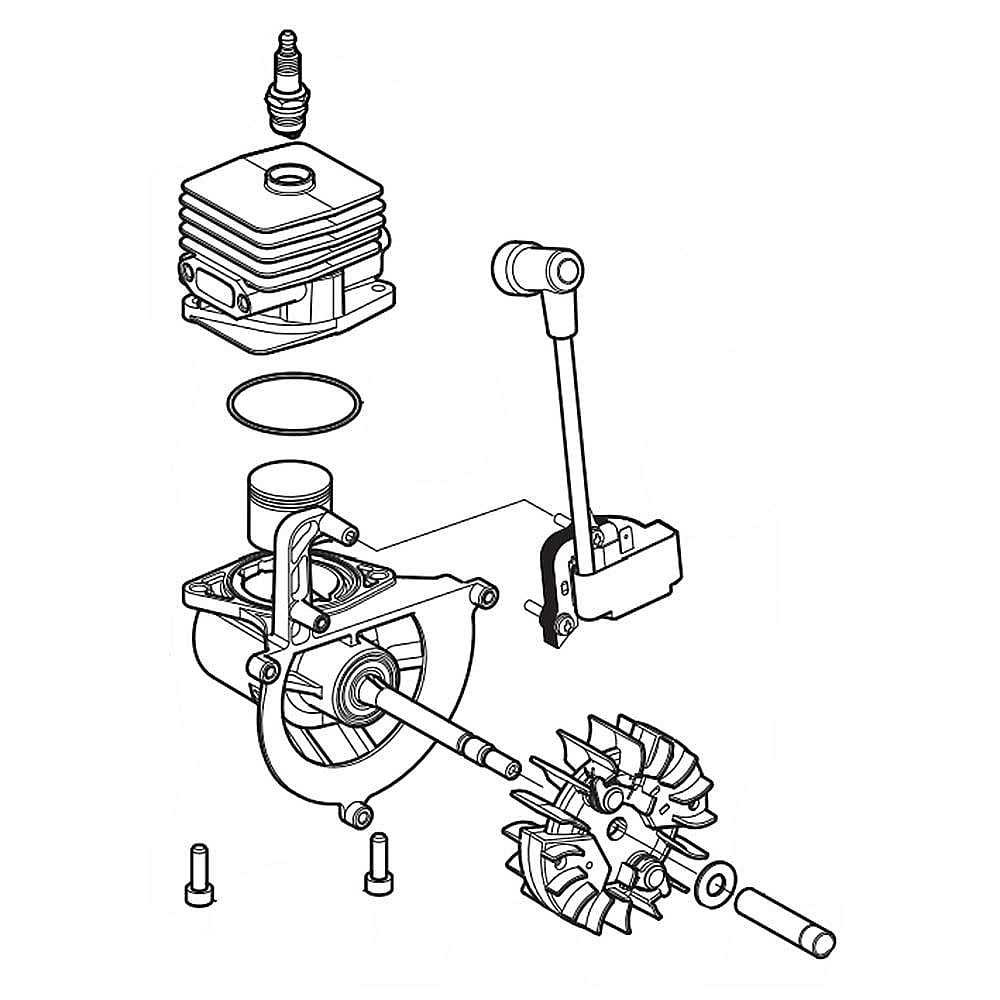

Overview of Stihl MM55C Components

This section offers a detailed exploration of the various mechanical and structural elements that contribute to the functionality of the device. Understanding these key elements is essential for ensuring optimal performance and longevity.

Core Mechanisms

- Engine: Powers the machine, enabling efficient soil preparation and other tasks.

- Transmission: Transfers power from the engine to the rotating tools for effective operation.

- Air Filtration System: Protects internal components by preventing debris and dust from entering the engine.

Additional Features

- Handlebar Assembly: Offers control and maneuverability during use.

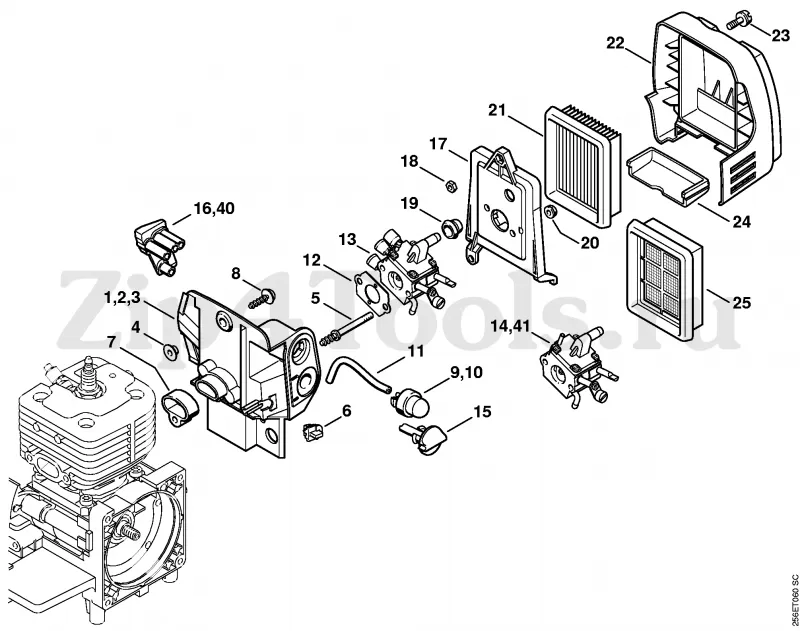

- Exploring the Engine Assembly

The engine assembly is a critical component that drives the overall functionality of the machine. Understanding its structure helps in maintaining optimal performance and ensuring that each element works harmoniously. This section will break down the key elements that make up this essential part of the machine.

Main Engine Block

The central engine block houses vital mechanical elements that generate power. It’s crafted to withstand high temperatures and pressures, ensuring durability and efficiency. Proper care and regular checks of this component can prolong the life of the entire system.

Supporting

Details of the Transmission Mechanism

The transmission mechanism plays a vital role in converting and delivering power from the engine to various components, ensuring efficient operation. By channeling energy through a complex set of gears and shafts, the system allows for smooth and controlled performance in diverse conditions.

Below is a breakdown of key components involved in the transmission mechanism:

Component Function Drive Shaft Transfers rotational force from the engine to the gearbox. Gearbox Regulates speed and torque by shifting gears. Air Filter Maintenance for Longevity

Proper care of the air filter is essential for ensuring the engine operates smoothly and efficiently over time. A well-maintained filter prevents debris from entering the engine, enhancing both performance and durability. Regular attention to this component can significantly extend the lifespan of your equipment.

Steps to Clean the Air Filter

- Remove the cover protecting the air intake system.

- Carefully take out the filter without allowing any dirt to fall into the engine.

- Inspect the filter for visible damage or excessive dirt buildup.

- If washable, clean the filter with mild soap and water, ensuring it dries completely before reinstalling.

- For non-washable filters,

Fuel System Parts Breakdown

The fuel system is essential for ensuring efficient engine operation, delivering the necessary mixture of air and fuel to maintain performance. Understanding the components involved can help with regular upkeep and troubleshooting, leading to better longevity and reliability of the equipment.

Below is an outline of the primary elements within the fuel system:

- Fuel Tank: Stores the fuel required for the engine to operate and is connected to various lines and filters to ensure a clean supply.

- Fuel Lines: Flexible tubes that transport the fuel from the tank to the carburetor, ensuring a consistent fl

Understanding the Throttle Control System

The throttle control system plays a crucial role in the performance and efficiency of small engine machinery. This system allows the operator to regulate the engine’s power output by adjusting the air-fuel mixture, ultimately influencing speed and functionality. A well-functioning throttle control ensures optimal operation, enhancing the user experience and prolonging the equipment’s lifespan.

Components of the Throttle Control System

Key elements of the throttle control system include the throttle lever, cable, and butterfly valve. The throttle lever, typically located on the handle, enables the user to manipulate the throttle position with ease. The connecting cable transmits the lever’s movements to the butterfly valve, which controls the airflow into the engine. This interaction is vital for maintaining the desired speed and performance.

Troubleshooting Common Issues

Common issues with the throttle control system may involve stiffness or unresponsiveness of the throttle lever. Regular maintenance, such as lubricating the cable and inspecting the components for wear, can help mitigate these problems. Ensuring that the throttle system functions smoothly is essential for achieving optimal performance from the machinery.

Ignition System Key Parts

The ignition system is a critical component in ensuring the efficient operation of a small engine. Its primary role is to generate a spark that ignites the fuel-air mixture, allowing the engine to start and run smoothly. Understanding the essential components of this system is vital for proper maintenance and troubleshooting.

- Ignition Coil: This device transforms low voltage into high voltage, creating the spark needed to ignite the fuel.

- Spark Plug: A key element that receives the high-voltage spark from the ignition coil, causing combustion within the engine cylinder.

- Flywheel Magnet: This component contains magnets that generate a magnetic field, triggering the ignition coil when the engine turns.

- Contact Points: These electrical contacts open and close to regulate the flow of electricity in the ignition system, impacting the timing of the spark.

- Wiring Harness: A series of wires connecting various ignition components, ensuring proper electrical flow throughout the system.

Each part plays a crucial role in the ignition process, and any malfunction can lead to starting issues or decreased engine performance. Regular inspections and replacements of worn components are essential to maintain optimal functionality.

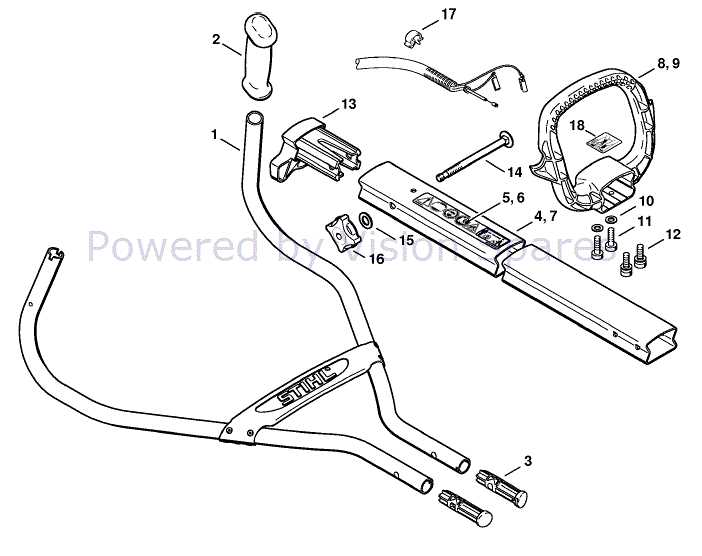

Handle and Grip Design Features

The design of handles and grips plays a crucial role in the overall functionality and user experience of outdoor equipment. Ergonomically shaped grips ensure comfortable handling, allowing users to maintain control during operation. The selection of materials and textures significantly affects grip stability and user fatigue, making it essential to focus on these aspects when evaluating various models.

Key elements that influence the efficiency of handle and grip designs include:

Feature Description Ergonomic Shape Curved contours that fit the hand’s natural grip for reduced strain. Material Composition Use of high-quality, durable materials to enhance grip and comfort. Textured Surfaces Non-slip textures provide a secure hold even in wet conditions. Adjustable Features Customizable grips to accommodate various hand sizes and preferences. Overall, the thoughtful integration of these design elements leads to improved performance and a more enjoyable user experience during prolonged use.

Examining the Blade and Cutting Attachments

Understanding the various components of cutting tools is essential for maintaining their efficiency and performance. This section delves into the different types of blades and attachments available for enhancing the functionality of these devices. By recognizing the characteristics of each type, users can select the most suitable options for their specific tasks.

Types of Cutting Blades

- Metal Blades: Ideal for tougher materials, these blades provide durability and strength.

- Plastic Blades: Lightweight and flexible, they are best suited for softer vegetation.

- Composite Blades: Combining features of both metal and plastic, these offer versatility for various applications.

Attachment Options

- Brush Cutter Attachments: Perfect for tackling dense brush and small trees.

- Trimmer Heads: Designed for precision trimming along edges and around obstacles.

- Edging Attachments: Useful for creating clean lines along sidewalks and driveways.

Choosing the right blade and attachment not only improves cutting efficiency but also prolongs the lifespan of the equipment. Regular inspection and maintenance of these components ensure optimal performance and safety during use.

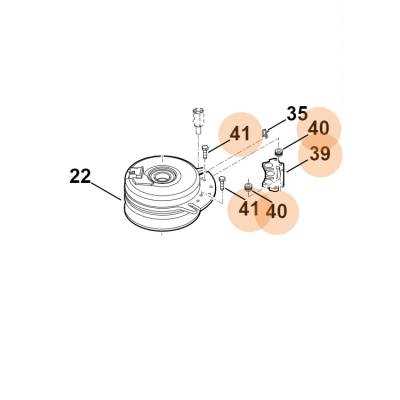

Clutch Mechanism Overview

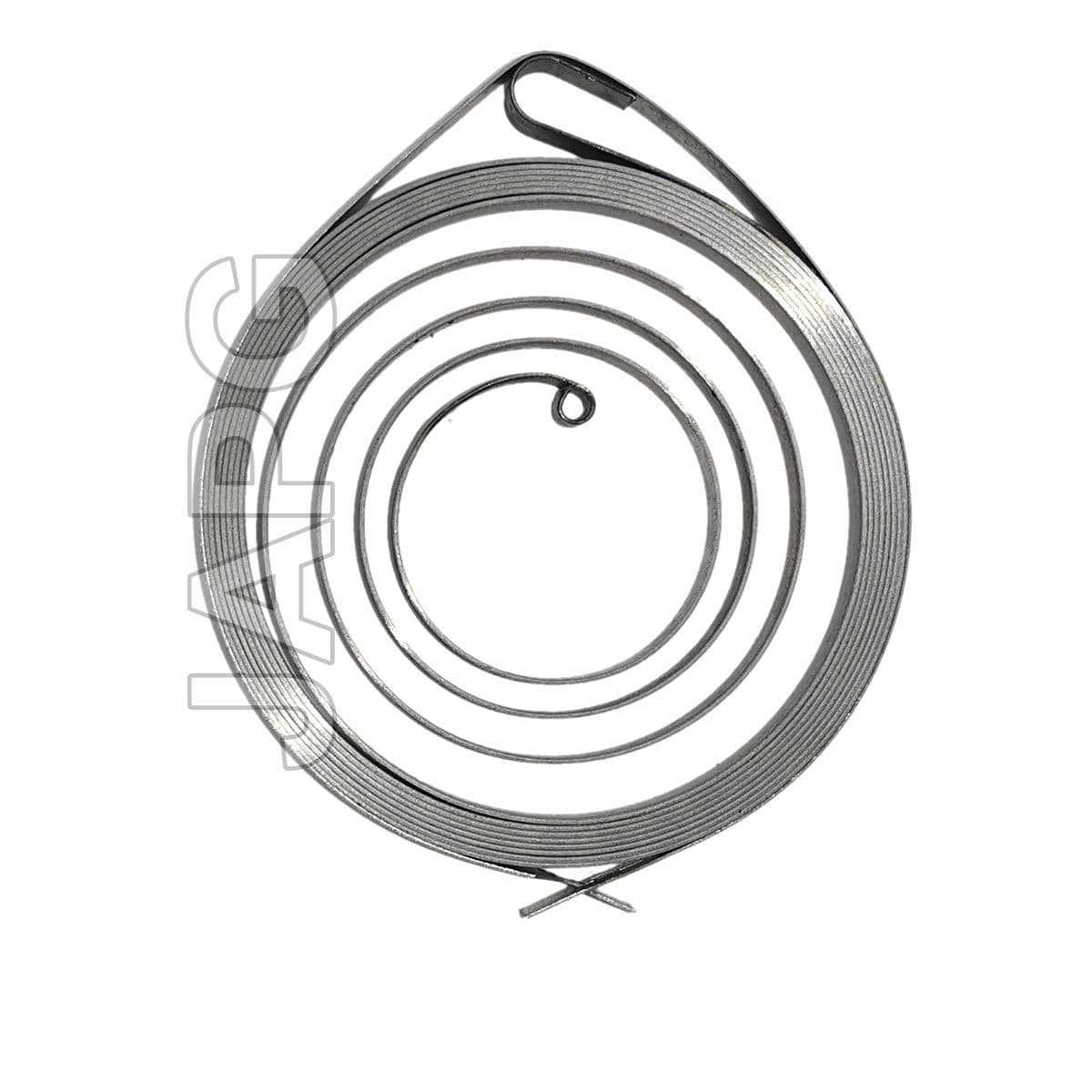

The clutch system plays a vital role in the operation of various outdoor equipment, facilitating the engagement and disengagement of power transmission. This mechanism allows for smooth transitions between idle and active states, ensuring optimal performance during use. Understanding its components and functionality is essential for maintenance and troubleshooting.

Components of the Clutch System

The clutch assembly comprises several key elements, including the clutch drum, friction plates, and springs. Each part contributes to the overall efficiency and effectiveness of the mechanism. The clutch drum serves as the housing for the friction plates, while the friction plates are responsible for creating the necessary grip when engaged. Springs assist in returning the system to its original position when disengaged, allowing for a responsive operation.

Functionality and Maintenance

Proper functionality of the clutch mechanism is crucial for ensuring smooth operation of the equipment. Regular maintenance, such as inspecting and replacing worn components, can enhance performance and prolong the lifespan of the system. Understanding how the mechanism works and recognizing signs of wear can aid in timely interventions, thus maintaining efficiency during operation.

Protective Guards and Safety Features

Ensuring user safety is paramount when operating any machinery. Various protective elements and safety mechanisms are designed to minimize the risk of accidents and injuries. These components work together to create a secure working environment, allowing users to focus on their tasks without unnecessary concerns.

One of the primary safety features includes guards that shield moving parts, preventing accidental contact during operation. These barriers are strategically placed to cover sharp edges and rotating elements, thus reducing the chance of injury. Additionally, many devices incorporate emergency shut-off switches that immediately halt operation when activated, offering a quick response in critical situations.

Moreover, ergonomic designs enhance user control, making it easier to handle the equipment safely. Features such as anti-vibration systems further contribute to comfort, allowing for prolonged use without fatigue. Regular inspection and maintenance of these safety features are essential to ensure their effectiveness, promoting a safer experience for all operators.

Frame and Structural Support Components

The framework and structural support elements of a gardening tool play a crucial role in its overall functionality and durability. These components are designed to provide stability and strength, ensuring that the equipment can withstand various tasks in diverse environments. Understanding the arrangement and materials used in these parts is essential for effective maintenance and repair.

Key components of the framework include:

Component Description Main Frame The primary structure that supports the entire assembly and provides rigidity. Support Brackets Elements that reinforce connections between different parts, enhancing stability. Mounting Plates Flat surfaces that secure attachments and components to the main body. Cross Members Bars that connect the frame at various points, distributing stress and enhancing support.