In the realm of outdoor machinery, familiarity with the various elements that comprise your tool is essential for maintenance and optimal performance. A comprehensive overview of these components can greatly enhance your ability to troubleshoot and repair effectively.

Visual representations serve as invaluable resources, allowing users to quickly identify each section of their device. By exploring these illustrations, you can delve into the ultimate configuration of your machine and ensure every part functions seamlessly.

Whether you’re a seasoned professional or an enthusiastic hobbyist, grasping the intricacies of your equipment will empower you to undertake repairs with confidence. This understanding not only facilitates better upkeep but also extends the lifespan of your tools.

Stihl MS 192 TC Chainsaw Overview

This section provides a comprehensive look at a popular model designed for precise cutting tasks, emphasizing its performance and features that cater to both professionals and enthusiasts.

- Engine Power: Equipped with a robust motor for efficient cutting.

- Weight: Lightweight design allows for extended use without fatigue.

- Ease of Use: User-friendly controls for seamless operation.

- Durability: Built with high-quality materials to withstand rigorous tasks.

- Maintenance: Simplified upkeep process to ensure longevity.

Whether for trimming, felling, or firewood preparation, this model delivers reliable performance in various conditions.

Key Components of the Stihl MS 192 TC

This section explores the essential elements that contribute to the functionality and efficiency of this cutting tool. Understanding these components can enhance maintenance and improve performance.

Major Elements

- Engine: The heart of the machine, providing necessary power.

- Guide Bar: A crucial part that supports the cutting chain.

- Chain: The component responsible for cutting through materials.

- Air Filter: Ensures clean air intake for optimal engine performance.

- Fuel Tank: Stores the mixture needed for operation.

Additional Features

- Chain Brake: Enhances safety by stopping the chain instantly.

- Starter System: Facilitates easy ignition of the engine.

- Vibration Dampening: Reduces operator fatigue during prolonged use.

- Clutch: Engages and disengages the chain as needed.

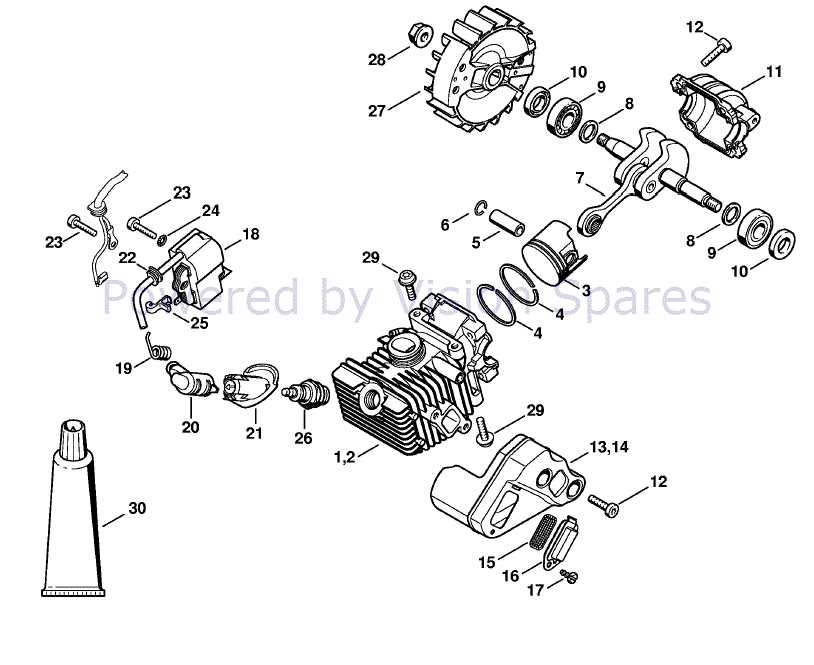

Understanding the Stihl MS 192 TC Engine

The power unit of this model is designed to deliver reliable performance for various tasks, from trimming to felling. Its robust construction ensures durability, while its engineering focuses on efficiency and ease of use. Knowing the key components and their functions is essential for optimal operation and maintenance.

This engine features a two-stroke design, providing a balance between power output and weight. The combination of fuel and air is ignited in the combustion chamber, resulting in the power needed to drive the cutting tools effectively. Regular maintenance and understanding of the internal parts contribute to the longevity and performance of the machine.

| Component | Function |

|---|---|

| Piston | Compresses the fuel-air mixture for ignition. |

| Cylinder | Houses the piston and contains the combustion process. |

| Crankshaft | Translates the linear motion of the piston into rotational motion. |

| Ignition System | Initiates combustion by creating a spark. |

| Carburetor | Mixes air with fuel for the optimal combustion ratio. |

| Exhaust System | Directs waste gases away from the engine. |

Understanding these components allows users to perform routine checks and maintenance tasks, ensuring the engine operates smoothly. Regular inspections can prevent costly repairs and extend the lifespan of the equipment.

Fuel System Parts of the Stihl MS 192 TC

The fuel system is essential for the efficient operation of any outdoor power equipment. It ensures that the engine receives the correct mixture of fuel and air for optimal performance. Understanding the components involved can help in maintaining and troubleshooting issues that may arise.

Key Components

- Fuel Tank: Stores the fuel for the engine.

- Fuel Filter: Cleans the fuel before it reaches the engine.

- Fuel Lines: Transport fuel from the tank to the engine.

- Carburetor: Mixes air and fuel for combustion.

Maintenance Tips

- Regularly inspect fuel lines for leaks or wear.

- Replace the fuel filter as recommended to ensure clean fuel flow.

- Check the carburetor for blockages and adjust as necessary.

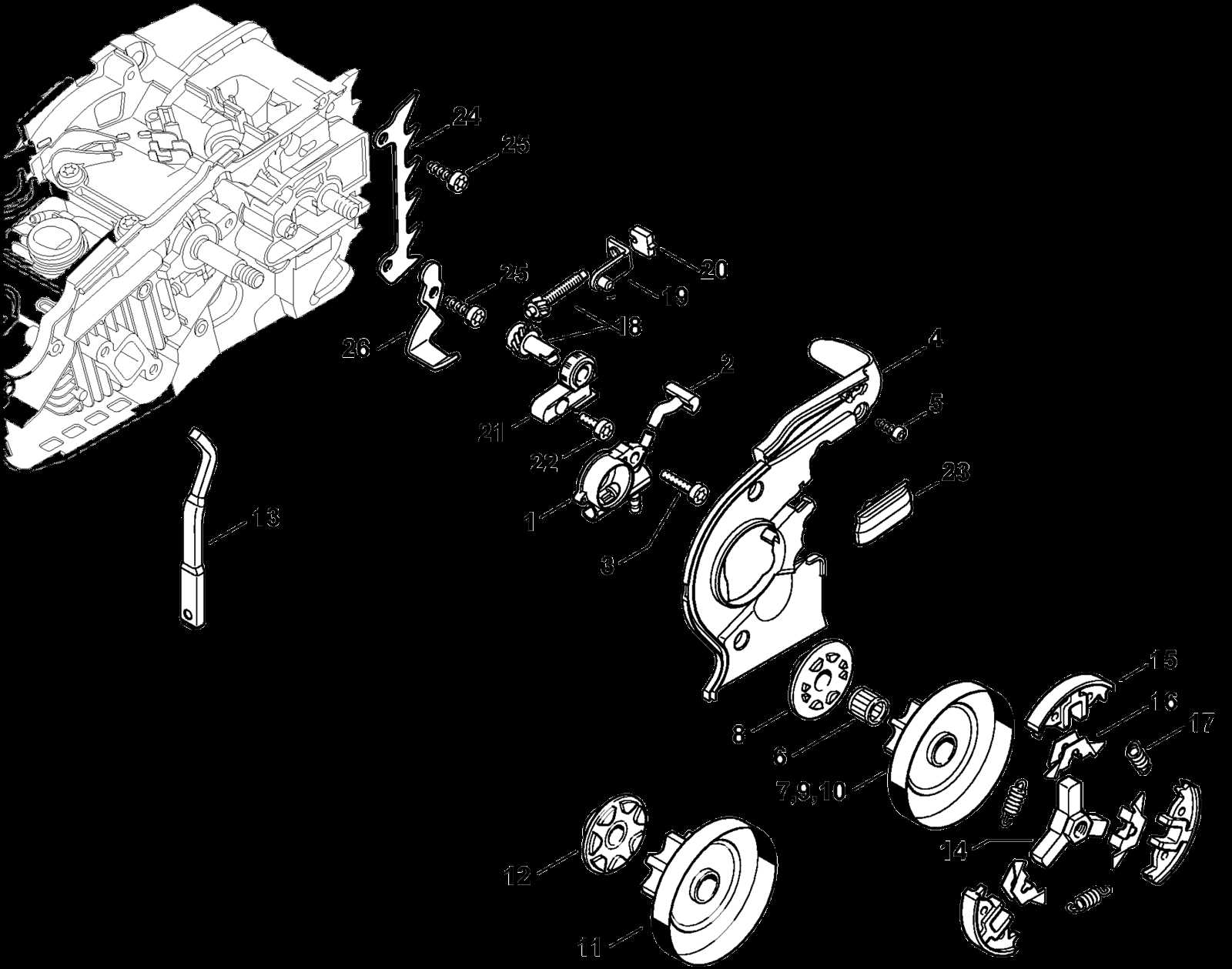

Ignition System Breakdown for Stihl MS 192 TC

The ignition mechanism is a crucial component that ensures the efficient operation of any power tool. Understanding its structure and functionality can greatly enhance maintenance and troubleshooting processes. This section delves into the essential elements that make up the ignition assembly, outlining their roles and interconnections.

Key Components of the Ignition Mechanism

- Coil: Generates the high voltage required to ignite the fuel-air mixture.

- Spark Plug: Creates a spark that ignites the mixture, initiating combustion.

- Flywheel: Contains magnets that work with the coil to produce electrical energy.

- Ignition Module: Controls timing and intensity of the spark produced.

Functionality Overview

The ignition system operates through a series of precise actions. When the engine is cranked, the flywheel spins, generating a magnetic field that induces voltage in the coil. This voltage travels to the ignition module, which regulates the spark timing. Finally, the current reaches the spark plug, igniting the fuel and enabling the engine to run smoothly.

Regular inspection and timely replacement of these components can prevent operational failures and extend the lifespan of the equipment.

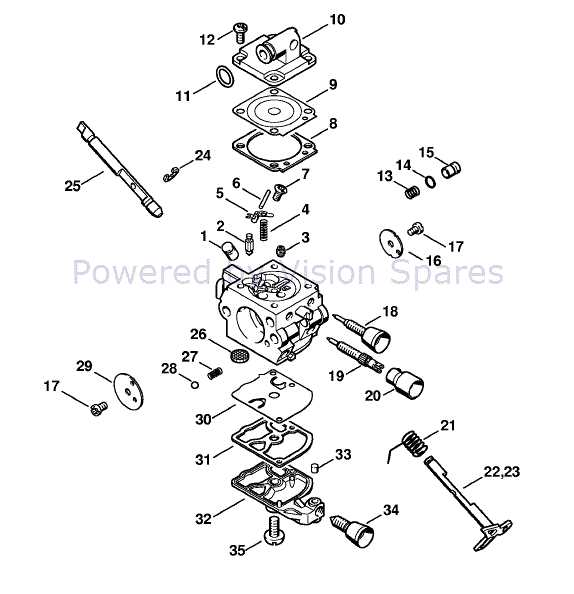

Carburetor Parts in the Stihl MS 192 TC

The carburetor is a vital component that ensures the optimal mixture of air and fuel, which is essential for efficient engine performance. Understanding its various elements can enhance maintenance and troubleshooting efforts.

Float Chamber: This section regulates the fuel level, allowing for a steady supply to the combustion process.

Needle Valve: This element controls the flow of fuel into the float chamber, ensuring the right balance for combustion.

Throttle Plate: Responsible for controlling airflow, this component plays a crucial role in regulating engine speed and power output.

Mixture Screw: This adjustment allows for fine-tuning the fuel-air ratio, optimizing engine performance for different conditions.

By familiarizing yourself with these key components, you can delve deeper into the functionality and maintenance of the carburetor, ultimately enhancing the efficiency of your machine.

Chain and Bar Assembly for Stihl MS 192 TC

The chain and bar assembly is a crucial component of any cutting tool, enabling efficient and effective operation. Understanding its elements and maintenance is vital for optimal performance.

This assembly consists of several key parts:

- Guide bar

- Cutting chain

- Chain tensioner

- Chain drive links

- Bar nuts

Each of these components plays an ultimate role in the functionality of the tool:

- Guide Bar: Supports the chain during cutting.

- Cutting Chain: Engages with the wood, making the cuts.

- Chain Tensioner: Ensures proper tension for safe operation.

- Drive Links: Connect the chain to the power unit.

- Bar Nuts: Secure the guide bar in place.

Regular inspection and maintenance of this assembly will prolong the life of the tool and enhance cutting efficiency.

Exhaust System Overview for Stihl MS 192 TC

The exhaust system plays a critical role in the performance and efficiency of any combustion engine, serving to direct gases away from the engine and reduce emissions. Understanding its components can enhance maintenance and optimize operation.

Key Components

The main elements include the muffler, which minimizes noise and channels exhaust gases, and the exhaust pipe that connects the engine to the muffler. These parts work together to ensure proper airflow and maintain engine temperature.

Maintenance Tips

Regular inspection of the exhaust system is essential. Look for any signs of damage or blockage, which can hinder performance. Keeping connections tight and clean can ultimately improve efficiency and extend the life of the engine.

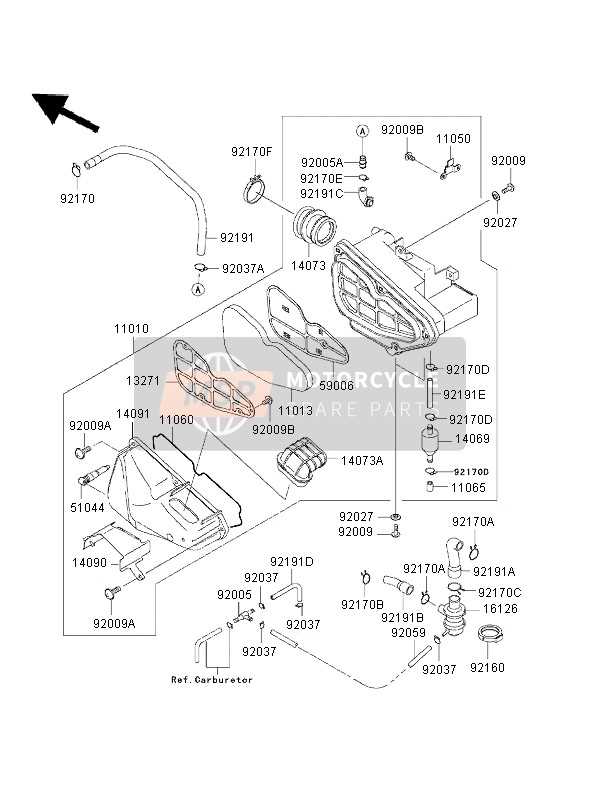

Air Filter and Intake Components of Stihl MS 192 TC

Effective air filtration is crucial for optimal engine performance and longevity. Properly functioning intake elements ensure that the power tool operates efficiently by maintaining the right air-to-fuel ratio, ultimately enhancing its performance.

Key Elements of the Air Filtration System

- Filter element: Traps dust and debris.

- Cover: Protects the filter from external contaminants.

- Intake manifold: Directs airflow to the engine.

- Sealing gaskets: Ensure a tight fit to prevent leaks.

Maintenance Tips

- Regularly check and clean the filter to prevent clogging.

- Inspect the intake components for damage or wear.

- Replace the filter according to the manufacturer’s recommendations.

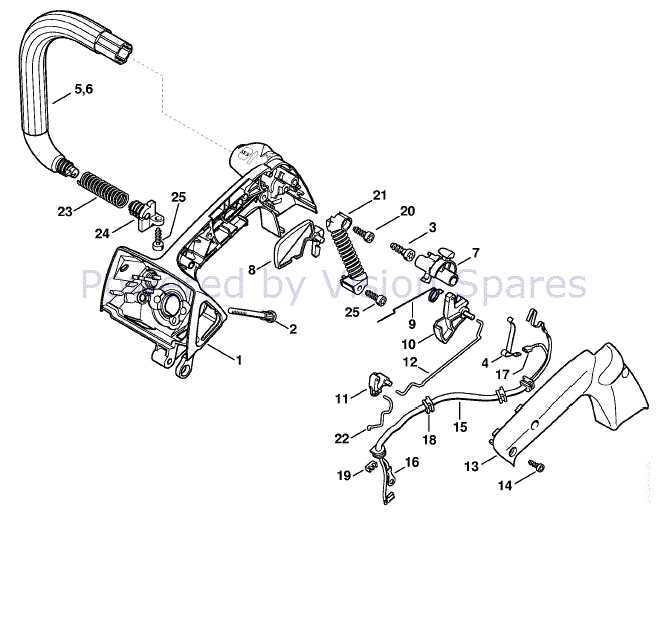

Handle and Control Elements of Stihl MS 192 TC

The design of handheld power equipment incorporates various components that enhance user experience and functionality. Understanding the arrangement and purpose of these elements is essential for optimal operation and safety.

The handle serves as the primary interface between the user and the machine, allowing for comfortable grip and control. Ergonomically designed, it reduces fatigue during extended use and ensures that the operator can maintain a steady and secure hold.

Control levers are strategically placed to allow for easy access and manipulation. These controls enable the user to adjust power settings, engage or disengage functions, and manage the equipment’s operation with precision. Each lever is typically color-coded or shaped distinctly to prevent confusion during use.

The throttle trigger is a crucial element, providing the ability to regulate engine speed with just a finger’s movement. This feature allows for fine control over the tool’s performance, especially during intricate tasks or when working in varying conditions.

Safety mechanisms are integrated into the handle and control system to minimize risks during operation. Features such as a lockout switch prevent accidental engagement, ensuring that the equipment remains inactive when not in use.

Overall, the handle and control components are vital to achieving efficiency and safety, making the equipment user-friendly while delivering powerful performance.

Oil Pump and Lubrication System for Stihl MS 192 TC

The efficiency of any cutting tool relies heavily on its lubrication system, which plays a crucial role in ensuring smooth operation and longevity. A well-designed oil pump facilitates the optimal delivery of lubricant, minimizing friction and wear on vital components. This section will explore the features and functions of the lubrication system in detail.

Functionality of the Oil Pump

The oil pump is responsible for circulating lubricant throughout the engine, ensuring that all moving parts receive adequate protection. This system is engineered to maintain consistent pressure, allowing for effective oil flow even under varying operational conditions. The precision of the pump contributes significantly to the overall performance and durability of the tool.

Maintenance and Troubleshooting

Regular maintenance is essential to keep the lubrication system functioning effectively. Users should periodically check the oil level and inspect for any signs of leaks or blockages. In case of diminished performance, troubleshooting steps should include examining the oil pump for wear and ensuring that the oil is free of contaminants. A well-maintained system leads to optimal performance and extends the lifespan of the equipment.

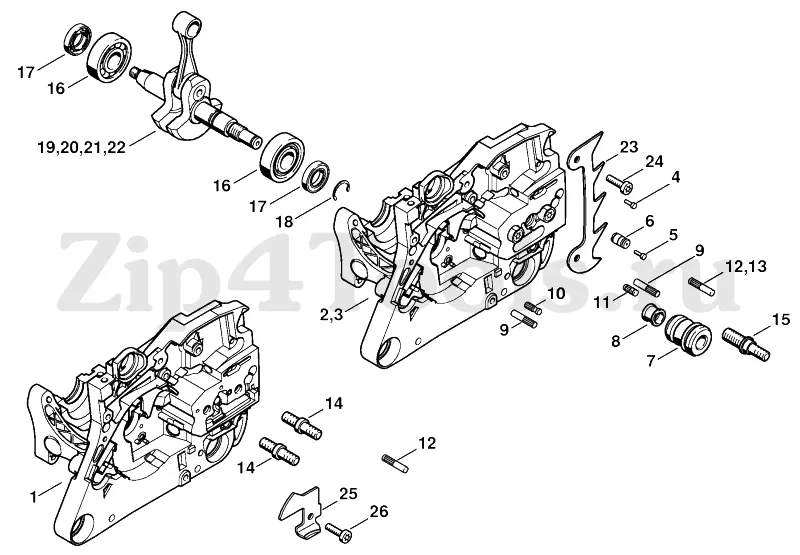

Clutch and Drive Mechanism in Stihl MS 192 TC

The clutch and drive mechanism is a critical component in chainsaw design, responsible for transferring power from the engine to the cutting chain. This system ensures that the chain operates efficiently while allowing the user to maintain control during operation. A well-functioning clutch allows for smooth engagement and disengagement, enabling the user to start the saw safely without the chain moving unnecessarily.

Functionality of the Clutch System

The clutch operates through centrifugal force, engaging the drive when the engine reaches a certain speed. This mechanism is designed to provide optimal performance, minimizing wear on the chain and ensuring it only spins when necessary. The materials used in the clutch components are crucial for durability and performance, as they must withstand significant friction and heat during operation.

Drive Mechanism Characteristics

The drive mechanism consists of a series of gears and sprockets that convert rotational energy into the linear movement of the chain. The design of these components is essential for maintaining proper tension and alignment, which directly impacts cutting efficiency. Regular maintenance and timely replacement of worn-out parts within this system are vital for sustaining the overall performance of the tool.