When it comes to maintaining equipment, it’s essential to have a clear overview of how various mechanisms fit together. Having access to a detailed breakdown of individual elements ensures that you can keep everything running smoothly, whether you’re troubleshooting an issue or performing routine care.

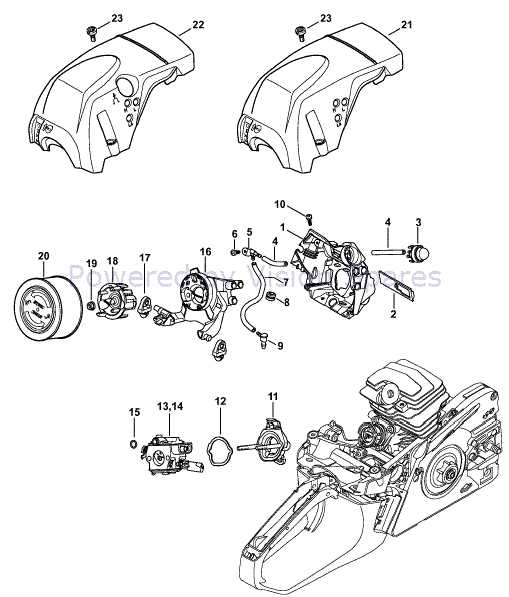

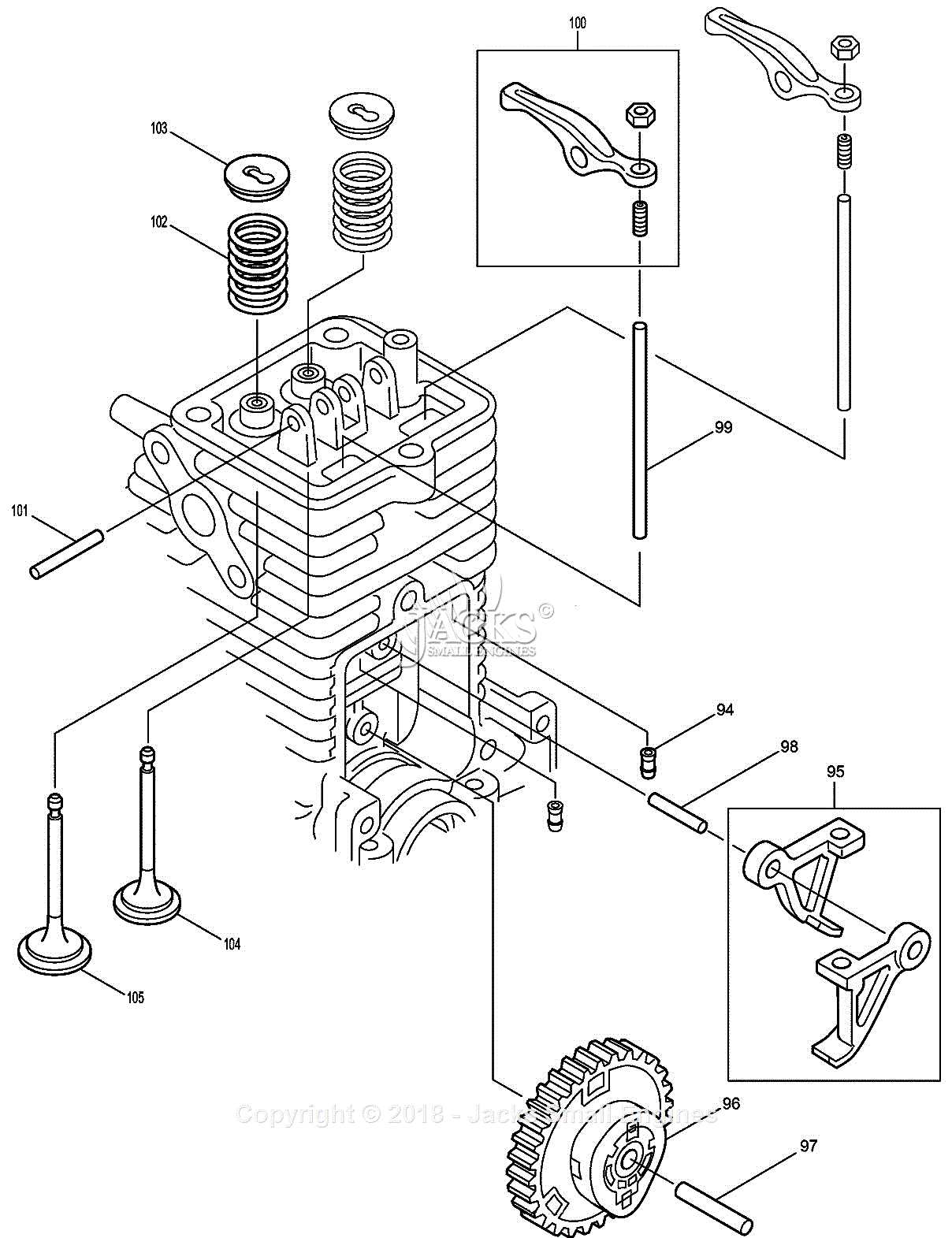

In this section, we explore the intricate arrangement of the main functional units. Each part plays a crucial role in the machine’s performance, and knowing how they interact with one another will help you make informed decisions during repairs or adjustments.

By gaining insight into how these pieces are organized, you’ll be better equipped to handle any necessary upkeep, ensuring efficiency and extending the overall lifespan of your tool.

Stihl MS251 Components Overview

This powerful tool is built from a combination of various key elements that work together to ensure optimal performance. Each part plays a crucial role in the overall functionality, contributing to both efficiency and durability. Understanding how these elements connect can provide insight into its reliability and maintenance.

| Component | Function | |||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Engine | The core driving force that powers the entire system, delivering the energy required for operation. | |||||||||||||||||||||||||||||||||||||||||||

| Bar and Chain | Designed for cutting through tough materials, these two parts work in unison to ensure smooth and effective cuts. | |||||||||||||||||||||||||||||||||||||||||||

| Component | Description | |||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Guide Bar | A flat, elongated metal piece that supports the movement of the chain during cutting operations. | |||||||||||||||||||||||||||||||||||||

| Chain Tensioner | Ensures the chain is kept at optimal tension to avoid slippage or malfunction during use. | |||||||||||||||||||||||||||||||||||||

| Sprocket | A small wheel with teeth, which drives the chain along

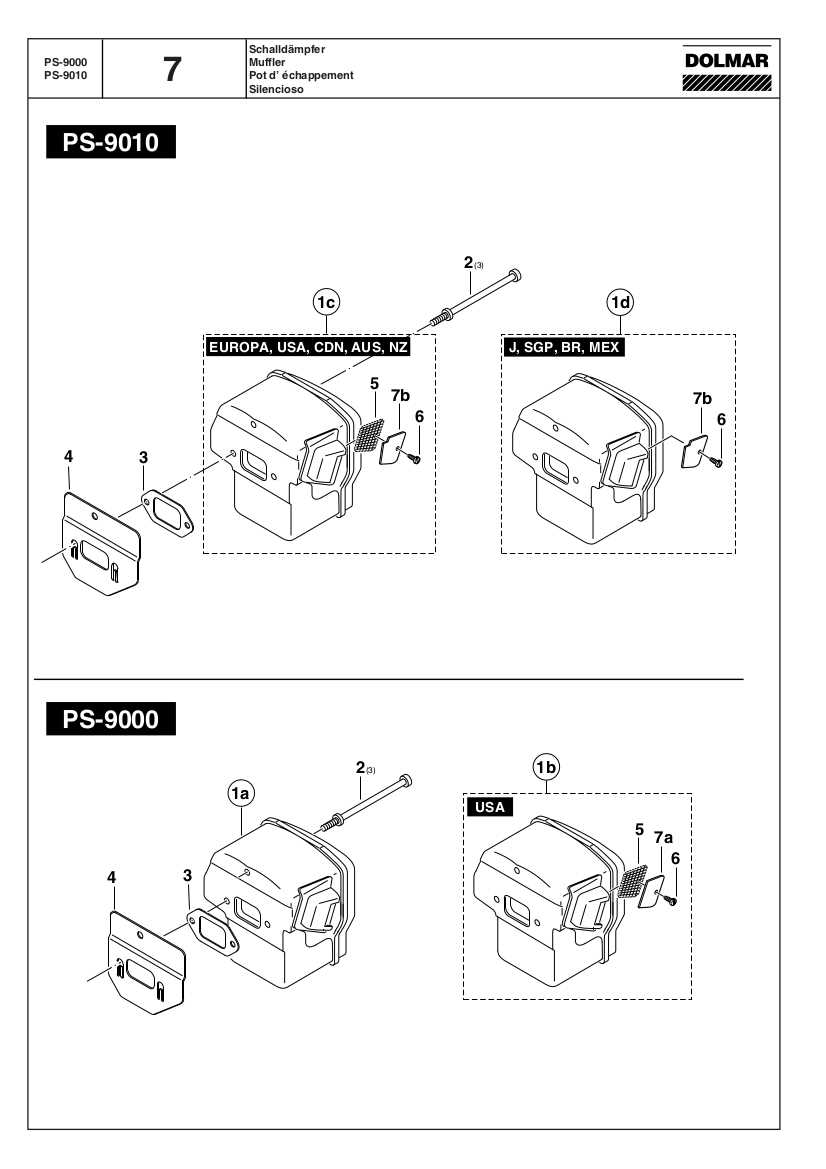

Fuel System Components and MaintenanceThe fuel system is essential for the proper functioning of a chainsaw, ensuring efficient fuel delivery to the engine. Proper upkeep of this system is crucial for optimal performance, preventing issues related to fuel flow and combustion. Regular inspection and cleaning of the components involved in fuel transfer can significantly extend the lifespan of your equipment. Key elements of the fuel system include the tank, lines, filter, and carburetor, each playing a vital role in ensuring that the engine receives the correct fuel mixture. Regular maintenance tasks, such as checking for leaks, replacing filters, and cleaning the carburetor, help maintain smooth operation and prevent malfunctions caused by dirt or blockages. Understanding how to properly maintain these components is fundamental to keeping the equipment running reliably. Routine care and timely replacements of worn parts are essential practices to ensure safety, performance, and longevity of the machinery. Guide to Ignition and Electrical Parts

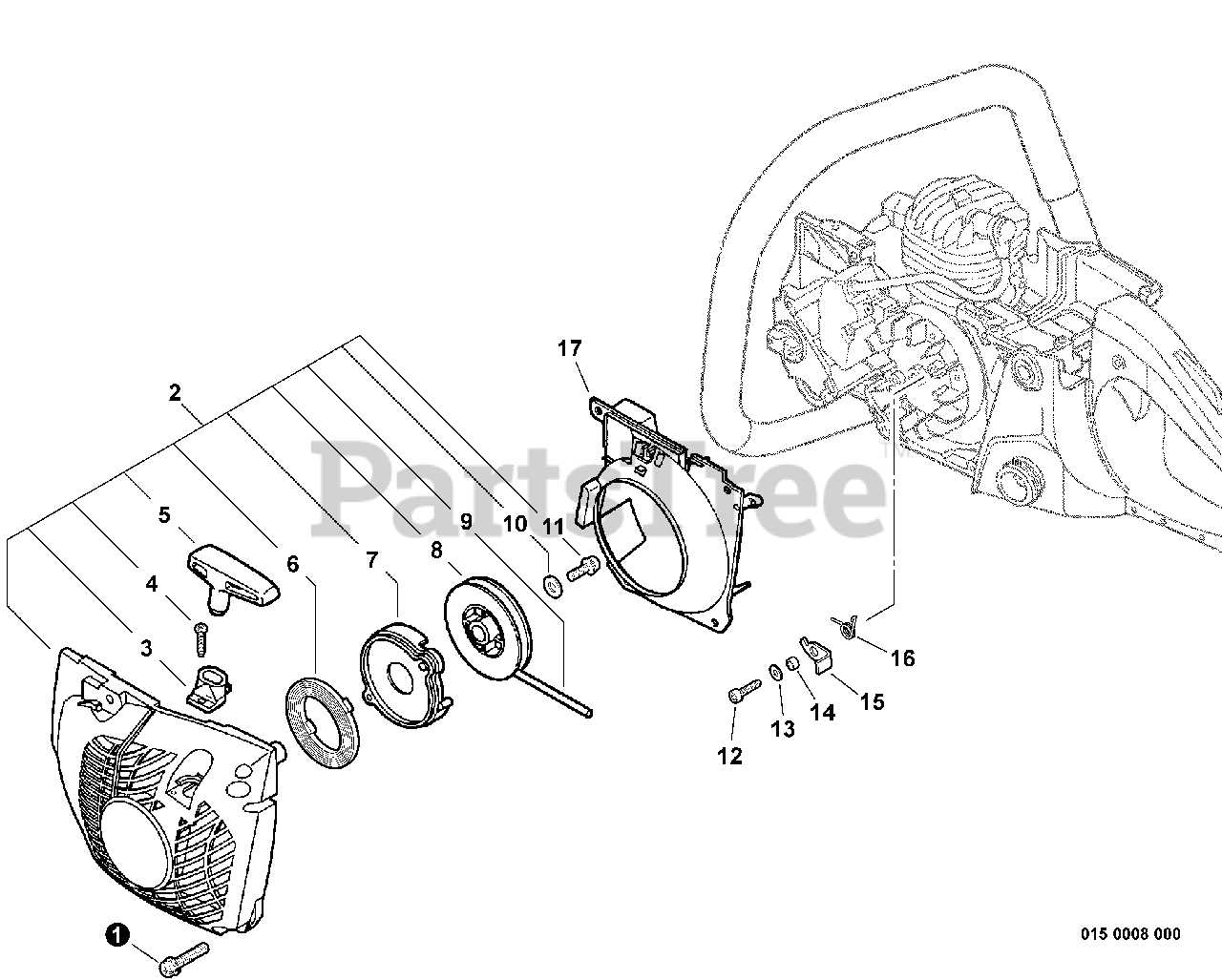

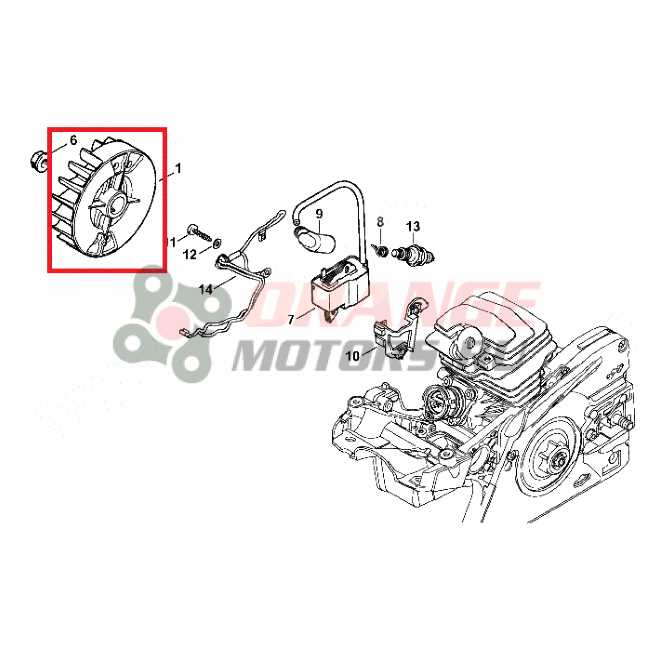

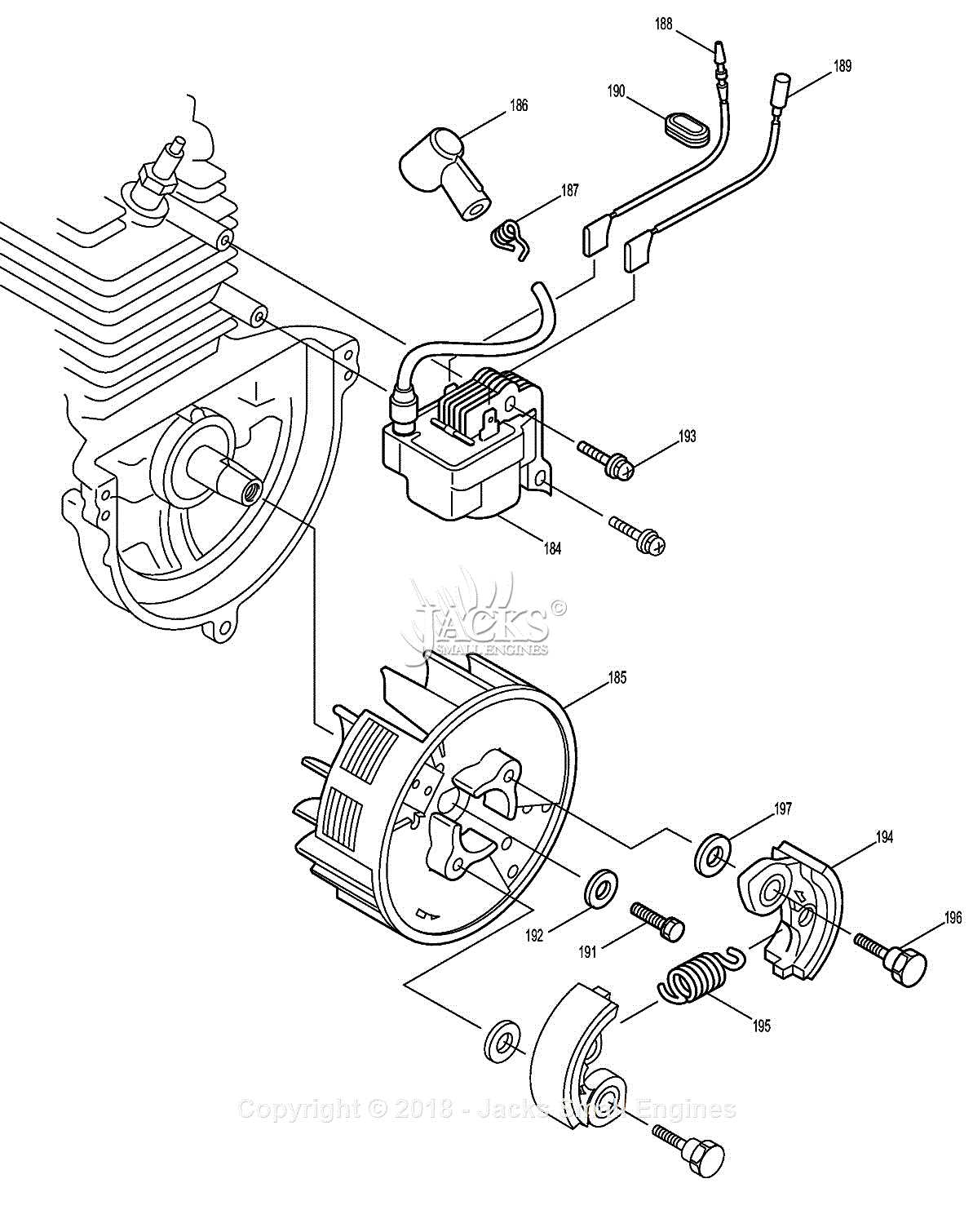

This section provides a comprehensive overview of the components responsible for ignition and electrical functionality in outdoor power tools. Understanding these elements is crucial for ensuring optimal performance and troubleshooting potential issues. From spark plugs to ignition coils, each component plays a vital role in the overall operation of the machinery. Key components in the ignition and electrical system include:

By familiarizing yourself with these essential components, you can enhance your understanding of the tool’s electrical systems, making it easier to perform maintenance and address any issues that may arise. Chain Tensioner Assembly ExplainedThe chain tensioning mechanism is a crucial component in ensuring optimal performance and safety of cutting equipment. This assembly is responsible for maintaining the proper tightness of the chain, preventing slippage and ensuring efficient cutting action. Understanding its components and functionality can help users maintain their equipment more effectively. Components of the Chain Tensioner

The tensioner assembly comprises several key parts that work together to adjust and maintain the chain’s tightness. Each component plays a vital role in the overall operation, ensuring smooth and efficient chain movement.

Importance of Proper Tensioning

Maintaining the correct tension in the chain is vital for safe and efficient operation. A chain that is too loose can slip, leading to inefficient cutting and potential damage to the equipment. Conversely, an overly tight chain can cause excessive wear on components and increase the risk of breakage. Regular checks and adjustments of the tensioner assembly are recommended to ensure optimal performance. Air Filter and Carburetor InteractionThe relationship between the air intake system and the fuel delivery mechanism is crucial for optimal engine performance. A clean and efficient air filter plays a vital role in maintaining the proper air-fuel mixture, ensuring that the engine operates smoothly and efficiently. As air enters the engine, it first passes through the air filter, which traps dirt and debris. This process is essential to prevent contaminants from entering the combustion chamber, where they could cause damage or inefficient burning. When the air filter becomes clogged, it restricts airflow, leading to an inadequate supply of air to the carburetor. The carburetor’s primary function is to mix fuel with air in the correct proportions. A well-functioning carburetor relies on a steady and sufficient flow of air to create the desired mixture. If the air filter is obstructed, the carburetor may struggle to maintain the ideal air-fuel ratio, resulting in poor engine performance, increased emissions, and potential damage over time. Regular maintenance of the air filter is therefore essential for the longevity and efficiency of the engine. Replacing or cleaning the filter at appropriate intervals ensures that the carburetor receives a consistent airflow, allowing for optimal fuel mixing and overall engine health. Common Wear Parts and Replacements

Every tool experiences wear and tear over time, particularly when used frequently in demanding conditions. Understanding which components are susceptible to degradation is essential for maintaining optimal performance. Regular inspection and timely replacement of these elements can significantly extend the lifespan of your equipment. Several components are known for their tendency to wear out. These include items that come into direct contact with materials or are subjected to friction and stress. Recognizing the signs of wear will help in planning maintenance and ensuring efficiency during operations.

By focusing on these common wear items and adhering to the suggested maintenance schedules, users can ensure their tools remain efficient and effective, minimizing unexpected failures during operation. Oil Pump and Lubrication SystemThe efficient functioning of a power tool heavily relies on its oil delivery mechanism. This system ensures that critical components receive the necessary lubrication to operate smoothly, reducing friction and wear. Proper maintenance of the lubrication setup is essential for the longevity and performance of the equipment. Components of the Lubrication System

Functionality of the Oil PumpThe oil pump operates by creating pressure that pushes the lubricant through the system. It is crucial for the pump to maintain consistent pressure to ensure adequate oil distribution. If the pump fails, it can lead to insufficient lubrication, causing severe damage to engine components. Regular inspection and maintenance of the lubrication system are vital for optimal performance. Replacing worn-out components and ensuring proper oil levels can significantly enhance the reliability and lifespan of the equipment. Best Practices for Chainsaw Part CareMaintaining the various components of a cutting tool is crucial for optimal performance and longevity. Regular attention to each element not only ensures safe operation but also enhances the efficiency of the equipment. Following a few simple practices can greatly extend the life of your tool and improve its functionality. Regular Cleaning and Inspection

Keeping the tool clean is essential for preventing dirt and debris from affecting performance. Here are some recommended practices:

Lubrication and StorageProper lubrication and storage play a vital role in maintaining functionality. Consider these tips:

|