Tips for Identifying Chainsaw Parts Accurately

Understanding the various components of a chainsaw can be challenging, especially for those who are unfamiliar with mechanical equipment. Proper identification is crucial for maintenance and repair, helping ensure that the correct replacements are found and applied effectively. Below are several practical techniques that will assist in recognizing key elements of your chainsaw with precision.

Familiarize Yourself with the Key Components

It’s essential to have a basic understanding of the primary elements of your chainsaw. Begin by looking at the engine, bar, and cutting chain. These are the most frequently encountered components and knowing their relative locations and functions will simplify identification. Referencing the user manual can also be beneficial for understanding the general layout of these mechanisms.

Use a Clear Visual Reference

A visual guide can be an invaluable tool when it comes to identify

Maintenance Insights for Stihl MS290 Owners

Proper upkeep of your chainsaw is essential to ensure its longevity and reliable performance. Regular attention to the equipment’s core components, coupled with timely checks, can prevent unexpected issues and extend the life of the tool. Understanding how to maintain your device efficiently helps you avoid costly repairs and downtime.

Start by focusing on routine cleaning, including clearing any debris that may accumulate during use. Ensure that all moving parts are well-lubricated to reduce wear and tear. Inspecting the chain and adjusting its tension as needed will promote optimal cutting performance, while sharpening it periodically ensures efficient operation.

Additionally, keeping the air filter clean and replacing it when necessary is crucial for smooth engine operation. Checking fuel and oil levels, as well as ensuring proper mixture ratios, plays a vital role in preventing damage to internal components. By dedicating time to regular maintenance, you can expect consistent, high-quality performance from your tool over the long term.

Where to Find Reliable Replacement Parts

When it comes to maintaining or repairing equipment, having access to trustworthy and durable components is crucial. Selecting the right supplier can ensure longevity and optimal performance for your machinery. The availability of authentic replacements plays a key role in keeping your device running smoothly over time.

Online Retailers

Many reputable websites offer high-quality components. These platforms often provide detailed product descriptions and customer reviews, allowing you to make informed decisions. Look for verified sellers and check for authenticity guarantees before purchasing.

Authorized Dealers

Another reliable source for obtaining components is through authorized dealers. These shops typically stock genuine items and provide support in case you need advice or assistance during the purchasing process. It’s also worth considering certified repair

Best Practices for Ordering Stihl Parts Online

When sourcing replacement components through digital platforms, it’s essential to follow several strategies to ensure a smooth and efficient process. By doing a little research and paying attention to key details, you can avoid common pitfalls and get the exact items needed quickly and reliably.

Verify Compatibility: Ensure that the parts you are considering match the specifications of your equipment. Always check model numbers and descriptions carefully to avoid receiving incompatible products.

Use Trusted Retailers: Prioritize shopping from well-known and authorized vendors. This helps guarantee that the components you purchase are genuine and of high quality, preventing issues with durability or functionality.

Read Reviews and Ratings: Before finalizing a purchase, review customer feedback. This can provide valuable insight into the reliability of the seller and the quality of the parts offered, helping you make an informed decision.

Keep Track of Serial Numbers: When looking for specific items, make note of your equipment’s serial numbers. This can be essential when verifying the compatibility and ensuring you order the right component for your machine.

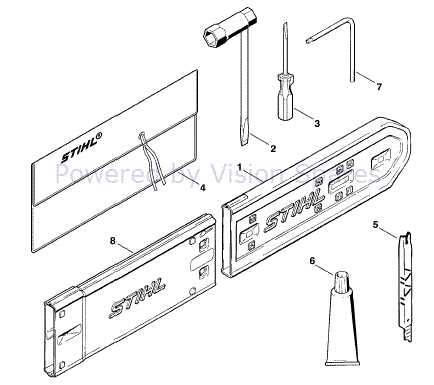

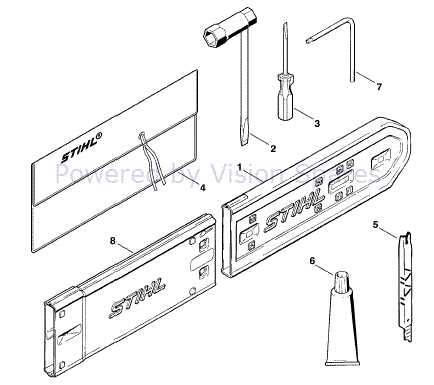

Essential Tools for Chainsaw Part Replacement

Proper maintenance and timely replacement of components in your chainsaw are crucial to ensure optimal performance and longevity. To complete these tasks efficiently and safely, having the right set of tools is essential. These instruments help you carry out the work with precision, making the replacement process easier and reducing the risk of damage.

- Screwdrivers: A variety of screwdrivers are necessary to handle different types of screws found in various chainsaw models.

- Wrenches: Several sizes of wrenches are useful for loosening and tightening bolts during disassembly and reassembly.

- Torque Wrench: Ensures that fasteners are tightened to the correct specifications, preventing under or over-tightening.

- Pliers: These are handy for gripping, twisting, or cutting wires and cables that may need adjustment or replacement.

- File and Sharpening Kit: Maintaining the cutting edges sharp is vital for the chainsaw’s effective functioning, and these tools help in that process.

Why You Should Use OEM Parts

When maintaining or repairing your equipment, selecting the right components is essential for ensuring optimal performance and longevity. Original equipment manufacturer (OEM) components are specifically designed for your machine, guaranteeing compatibility and reliability that aftermarket alternatives may not provide. Using these factory-made replacements can reduce the risk of breakdowns and help maintain the warranty.

Long-Term Reliability

OEM components are created with precision, making them more durable and reliable than non-genuine options. This can prevent frequent repairs and prolong the lifespan of your equipment, allowing it to operate at its best over time. By using the original parts, you’re ensuring that your machine will perform as intended without unexpected interruptions.

Better Fit and Performance

One of the main reasons to choose OEM is the perfect fit they offer. These components are manufactured to meet the exact specifications of your equipment, ensuring proper installation and seamless operation. This level of precision helps preserve the efficiency and overall functionality of your machine, which can be compromised by ill-fitting, generic parts.

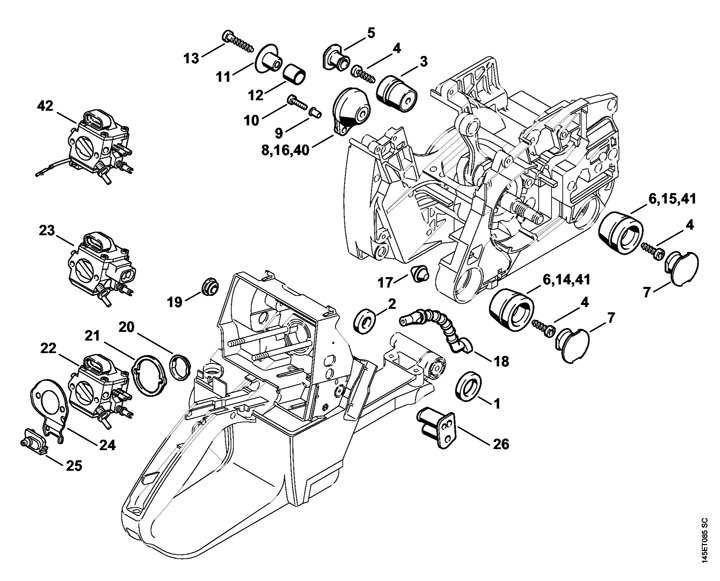

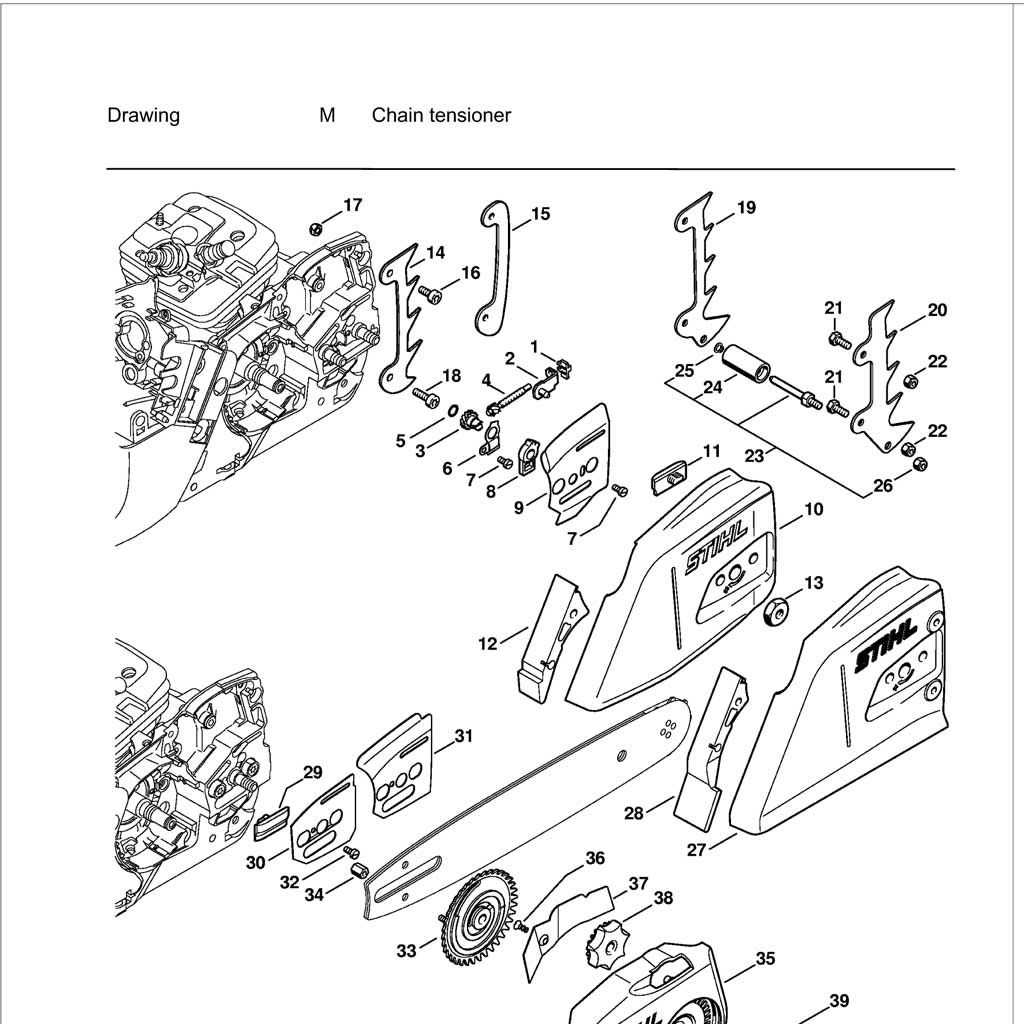

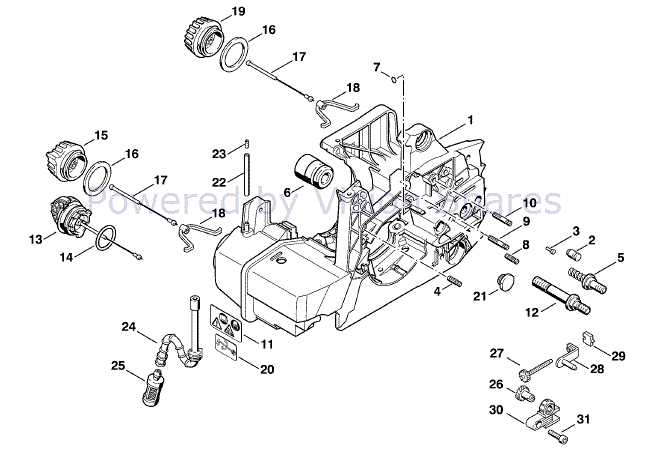

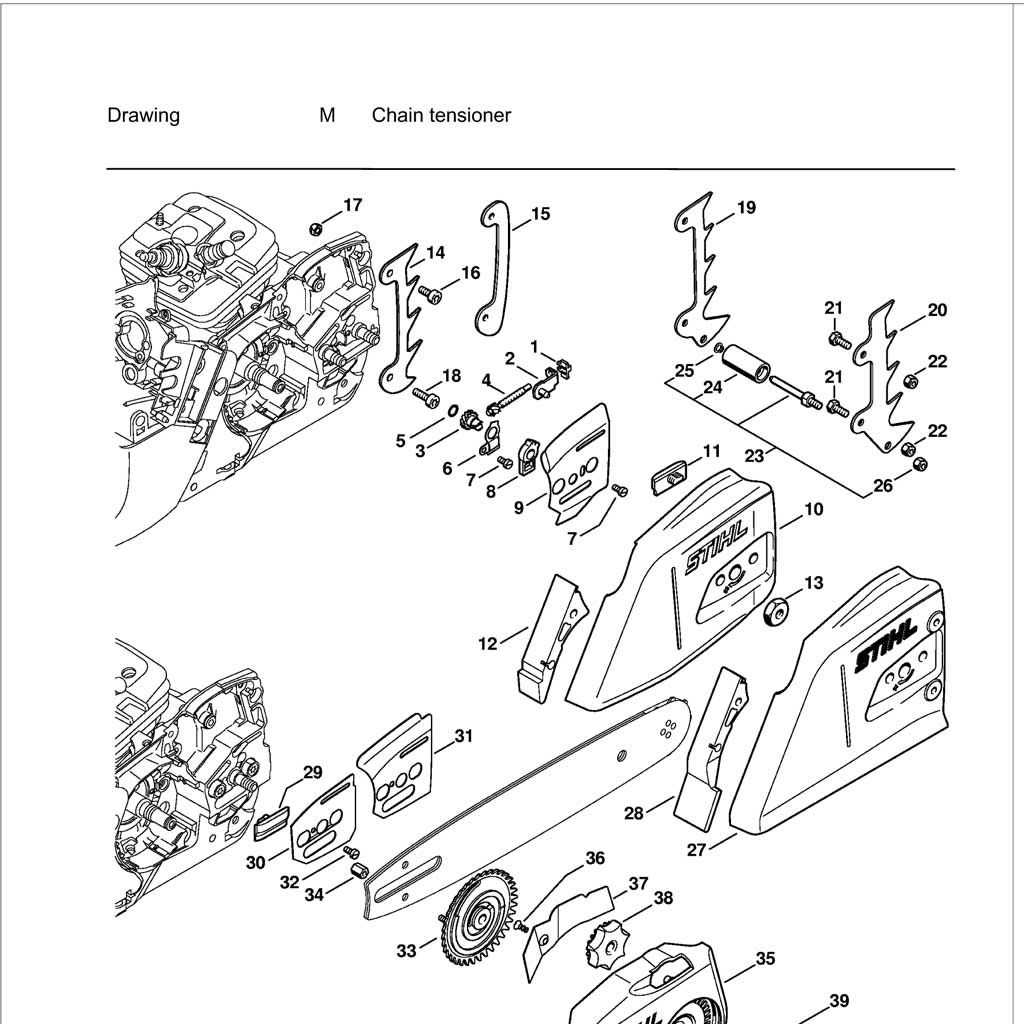

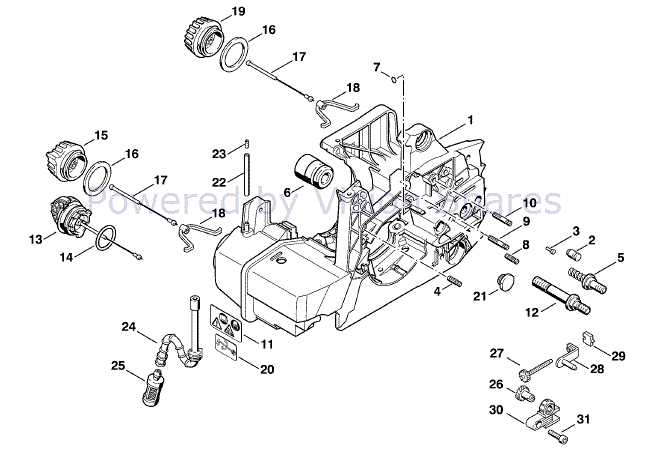

Decoding the Stihl MS290 Parts Diagram

Understanding the structure of a chainsaw can be a daunting task, especially when trying to pinpoint how different components interact. This guide simplifies the process by breaking down the essential elements and offering insights into the machine’s internal layout.

Key Components Overview

The internal mechanics rely on a series of crucial sections working together to ensure smooth operation. Familiarizing yourself with these areas can help during maintenance or repairs.

- Engine block – the heart of the machine, driving its functionality

- Cutting system – responsible for the saw’s sharp and efficient performance

- Fuel system – crucial for providing the necessary energy

- Exhaust mechanism – controls the release of gases

Understanding the Connection Between Parts

Every element in the system is interconnected, contributing to overall performance. Identifying these relationships helps to understand the machine’s efficiency and allows for proper troubleshooting.

- Power transfer from the

Common Chainsaw Parts and Their Functions

A chainsaw is a complex tool made up of several key components, each playing a vital role in its overall operation. Understanding the individual elements and how they contribute to the machine’s function can help with both maintenance and efficient use. Below, we explore the main sections of the chainsaw, offering insights into their purpose and importance.

The engine serves as the powerhouse, driving the chain around the guide bar. Without it, the saw wouldn’t have the force required to cut through wood. Another critical piece is the guide bar, which directs the chain and allows for smooth cutting action. The chain itself is composed of sharp teeth, each responsible for cutting through various materials.

The throttle control is an essential feature, allowing the operator to manage the speed of the chain. Paired with the throttle lock, it ensures safety by preventing accidental operation. Additionally, the chain brake is

How to Prolong the Life of Your Chainsaw

Maintaining the longevity of your cutting tool requires consistent care and attention. By adopting best practices, you can ensure that your device operates efficiently and remains in optimal condition for years to come. Below are some essential tips to help you enhance the lifespan of your chainsaw.

Regular Maintenance

- Clean After Use: Remove debris and sap from the saw after each use to prevent buildup.

- Check the Chain Tension: Proper tension is crucial. Regularly inspect and adjust as needed.

- Sharpen the Chain: A sharp chain cuts more efficiently and reduces strain on the engine.

- Inspect the Bar: Regularly check the guide bar for wear and replace if necessary.

Proper Usage Techniques

- Avoid Overworking: Do not force the tool through thick materials; allow it to cut at its own pace.

- Use Correct Fuel: Always use the recommended fuel mixture to avoid engine damage.

- Store Properly: Keep the chainsaw in a dry place, protected from extreme temperatures and moisture.

By following these guidelines, you can significantly extend the operational life of your cutting tool, ensuring it remains a reliable partner for your outdoor tasks.

|