For those who value precision and efficiency in their outdoor tasks, comprehending the intricate details of a chainsaw’s inner workings is essential. Knowing how each element interacts can lead to better maintenance and enhanced performance.

In this section, we will explore the various components that make up these powerful tools. A clear visual representation of these parts can significantly aid in troubleshooting and repairs, ensuring your equipment runs smoothly and effectively.

By delving into the specifics, you will gain insight into how each section contributes to the overall functionality. Whether you are a professional or a weekend warrior, understanding these aspects will ultimately improve your experience and prolong the life of your equipment.

Understanding Stihl MS311 Components

Grasping the intricacies of the various elements that make up a specific cutting tool is essential for optimal performance and maintenance. Each component plays a crucial role in ensuring the device operates efficiently, contributing to both longevity and effectiveness in usage.

Key Elements and Their Functions

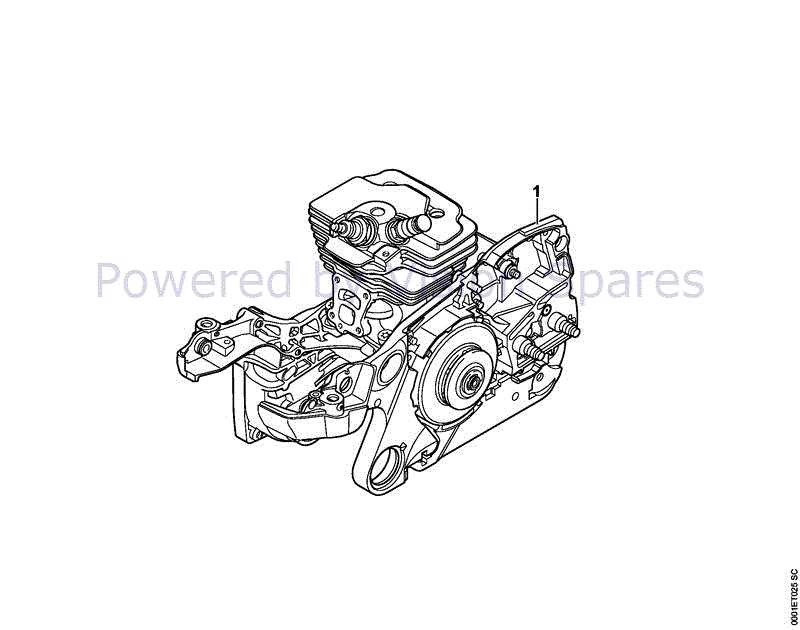

The engine serves as the powerhouse, converting fuel into mechanical energy. The chain assembly is vital for cutting, while the bar supports and guides the chain. Understanding these parts helps users troubleshoot issues and carry out necessary repairs.

Maintenance and Care

Regular inspection and servicing of these components can prevent malfunctions. Replacing worn-out elements ensures that the machine remains in top condition, providing the ultimate performance for various tasks.

Overview of MS311 Parts

This section provides a comprehensive look at the components that contribute to the functionality and performance of the machine. Understanding each element is essential for effective maintenance and optimal operation.

- Engine: The core component responsible for power generation.

- Bar: A crucial part that guides the cutting chain.

- Chain: Designed for efficient cutting and durability.

- Handle: Ensures comfort and control during use.

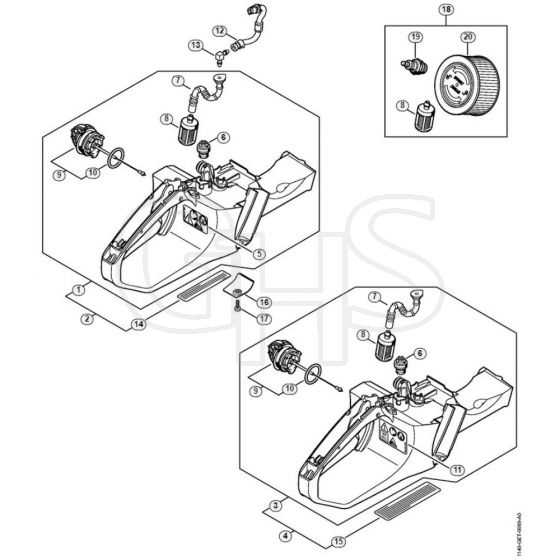

- Fuel System: Supplies the necessary energy for operation.

Each element plays a significant role in the overall efficiency of the equipment. Familiarity with these components allows users to delve deeper into maintenance and repair practices, enhancing the longevity of the tool.

Common Issues with Stihl Chainsaws

Chainsaws, like any mechanical tool, can experience a range of problems that affect their performance and reliability. Understanding these common issues can help users maintain their equipment effectively and prolong its lifespan.

Fuel and Starting Problems

One prevalent issue is related to fuel quality and starting difficulties. Using old or contaminated fuel can lead to poor engine performance, making it hard to start or keep running. Regularly checking and replacing the fuel can mitigate these problems.

Chain and Bar Wear

Another common concern is the wear and tear on the chain and guide bar. Dull chains can cause inefficient cutting and increase the risk of kickback. Regular sharpening and maintenance are essential to ensure optimal functionality and safety during use.

How to Read Parts Diagrams

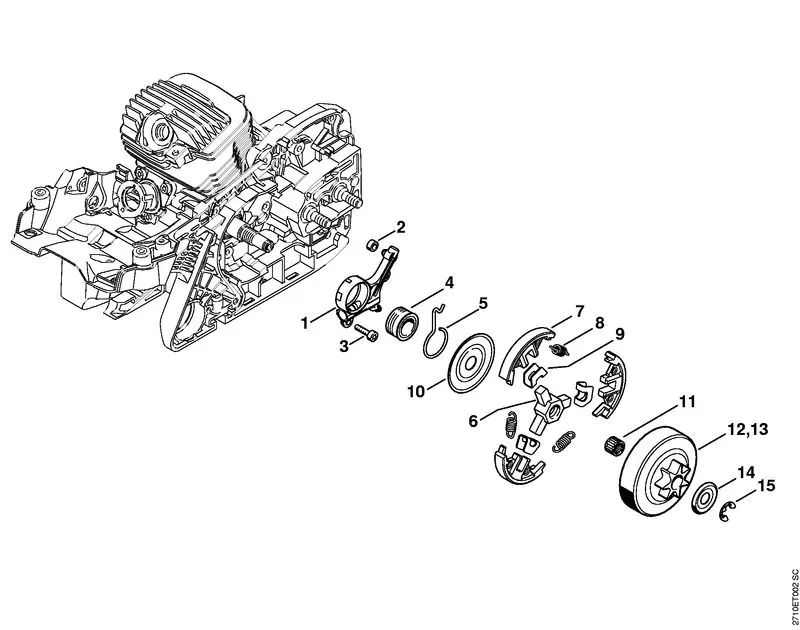

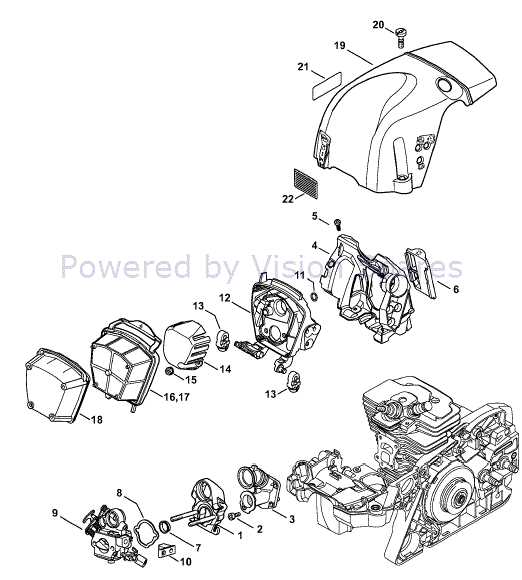

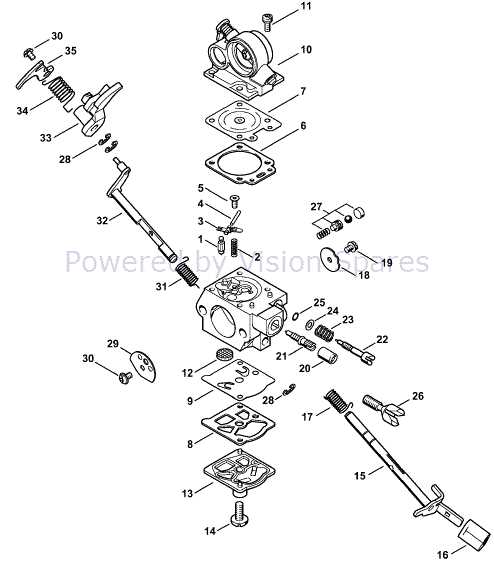

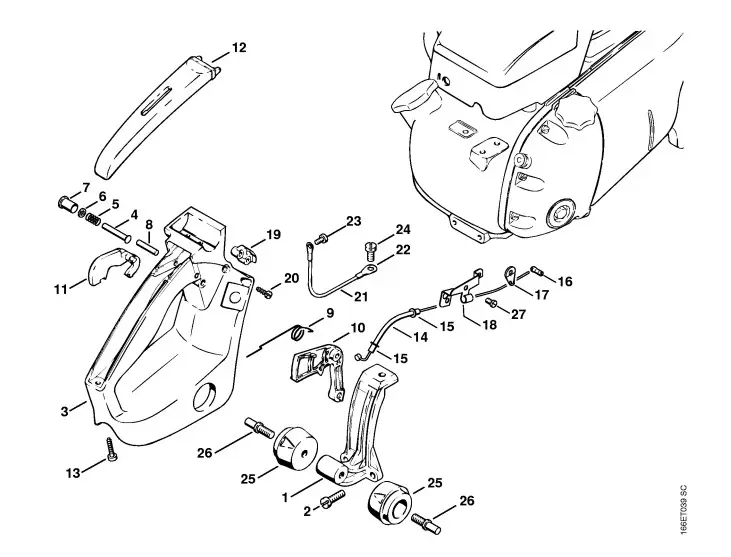

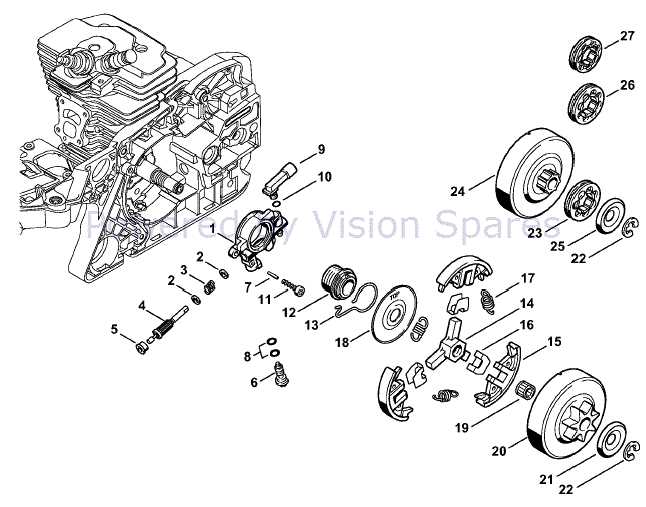

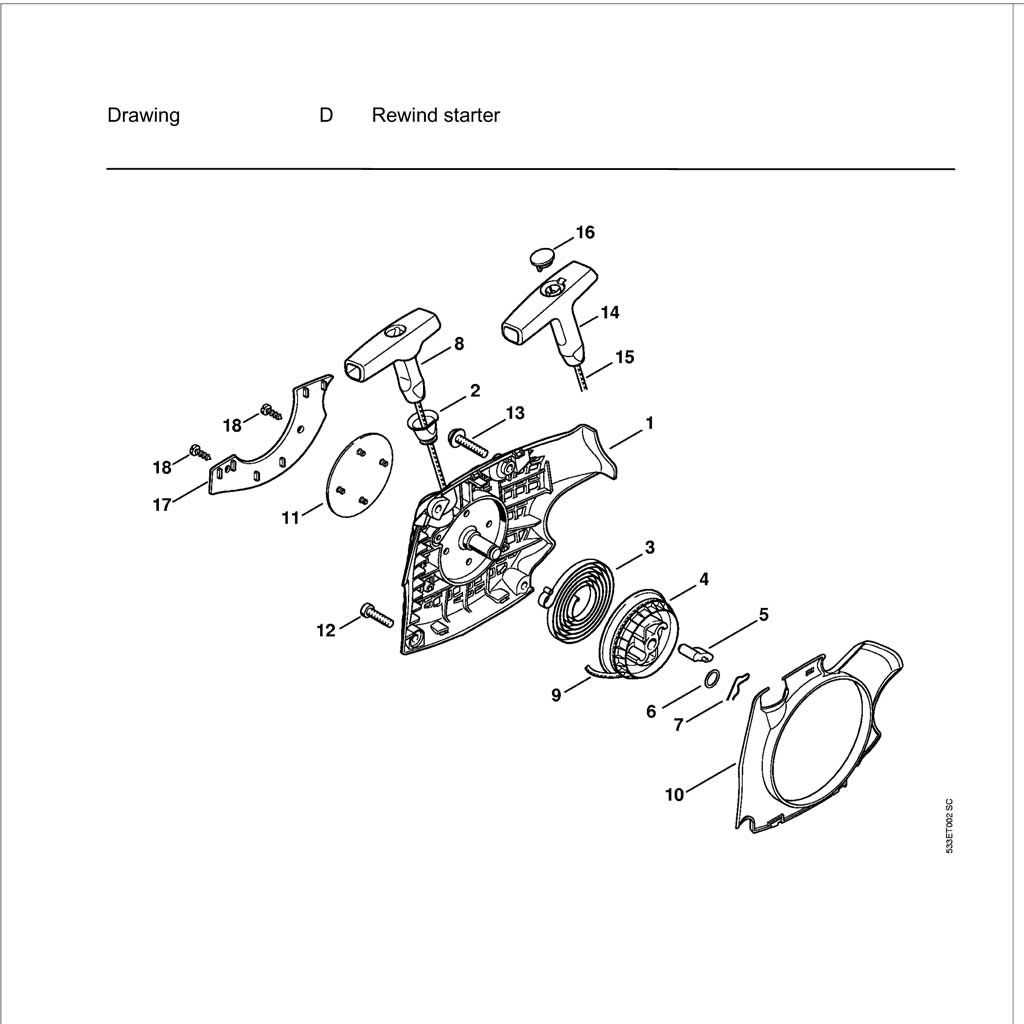

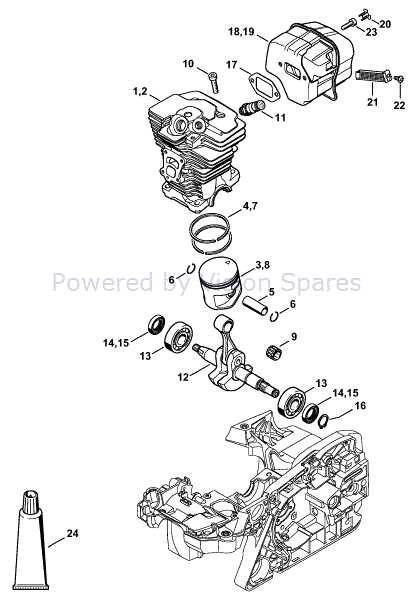

Understanding technical illustrations is essential for effective maintenance and repair of machinery. These visual guides provide a detailed overview of components and their arrangement, making it easier to identify what you need. By familiarizing yourself with the key elements of these representations, you can streamline your repair processes and ensure proper assembly.

Begin with the legend: Most illustrations include a legend that explains the symbols and notations used. This section is crucial, as it helps you decode what each part represents, preventing confusion during the identification process.

Pay attention to numbering: Each component is often assigned a unique number or code. By referencing this numbering, you can quickly locate the corresponding part in a catalog or when ordering replacements. This can save time and avoid mistakes in the selection process.

Observe the layout: The arrangement of items in the illustration usually mirrors how they fit together in the actual machine. By analyzing the spatial relationships, you can gain insights into assembly order and potential points of difficulty, which is vital for troubleshooting.

Identify common components: Some parts are frequently used across different models. Recognizing these can enhance your understanding of similar machines, allowing for easier repairs and maintenance in the future. Familiarity with these common elements can also help you in sourcing alternatives.

Practice regularly: The more you engage with these visual tools, the more adept you’ll become at interpreting them. Regular practice can significantly improve your efficiency and confidence when working on equipment.

Key Features of MS311 Model

This model stands out in the market for its exceptional performance and reliability, making it a preferred choice among professionals and enthusiasts alike. Its robust design ensures durability, allowing users to tackle various tasks with ease and confidence.

Powerful Engine: Equipped with a high-performance engine, this tool delivers impressive power and torque, enabling efficient cutting and trimming. The engine’s design enhances fuel efficiency, allowing for longer operational times without frequent refueling.

Lightweight Construction: The ergonomic build of this device contributes to its portability, making it easy to handle for extended periods. The balance between weight and power ensures that users can maneuver the tool effortlessly, reducing fatigue during prolonged use.

Advanced Safety Features: This model incorporates several safety mechanisms designed to protect the user. Features such as an automatic chain brake and anti-vibration technology contribute to a safer working environment, minimizing the risk of accidents and enhancing comfort.

Ease of Maintenance: The design allows for straightforward maintenance, making it simple for users to keep the tool in optimal condition. Quick-access components enable efficient servicing, ensuring that the equipment remains reliable over time.

Versatile Applications: Suitable for a wide range of tasks, this model excels in both professional and residential settings. Whether cutting firewood or performing landscape maintenance, its versatility makes it an invaluable tool for various projects.

Replacement Parts for MS311

When maintaining your equipment, knowing the components that can be replaced is essential for optimal performance. Identifying the correct substitutes ensures longevity and efficiency, allowing you to tackle tasks with confidence.

| Component | Description | Importance |

|---|---|---|

| Chain | The cutting element that slices through wood. | Critical for effective cutting performance. |

| Sprocket | Engages with the chain for movement. | Vital for smooth operation and reduced wear. |

| Filter | Cleans the air entering the engine. | Ensures optimal engine performance and longevity. |

| Bar | The metal arm that supports the chain. | Essential for stability and precision during use. |

Identifying MS311 Component Numbers

Understanding the unique identifiers for various components is essential for effective maintenance and repair. These identifiers allow users to locate the correct pieces needed for replacement or enhancement, ensuring optimal performance and longevity of the equipment. A clear grasp of these numbers facilitates easy reference during service or when ordering new components.

Importance of Component Identification

Accurate identification plays a crucial role in avoiding mismatches and ensuring compatibility. Knowing the specific numbers enables users to efficiently source replacements, thus minimizing downtime and enhancing productivity. This knowledge is particularly vital for professionals who rely on their tools for consistent work.

Where to Find Component Numbers

Component numbers can typically be located on the parts themselves or in the technical documentation provided with the equipment. Users are encouraged to consult the user manual or manufacturer’s resources for comprehensive information on where to find these identifiers. This practice not only aids in immediate needs but also serves as a valuable reference for future repairs.

Maintenance Tips for Chainsaw Longevity

Proper care and upkeep are essential for ensuring that your cutting tool remains efficient and reliable over time. Regular maintenance not only enhances performance but also extends the life of your equipment. Below are some practical tips to keep your chainsaw in optimal condition.

- Regular Cleaning: After each use, clean the exterior and the air filter to prevent dust and debris buildup. This helps in maintaining airflow and reduces the risk of overheating.

- Chain Maintenance: Regularly check the tension and sharpness of the cutting chain. A dull chain requires more effort and can cause excessive wear on the motor.

- Oil the Chain: Always use high-quality bar and chain oil. Proper lubrication minimizes friction and prolongs the life of both the chain and the bar.

- Inspect Components: Routinely inspect vital parts, such as the spark plug and fuel filter. Replace them as needed to ensure efficient operation.

- Store Properly: When not in use, store your tool in a cool, dry place. Consider hanging it or placing it on a shelf to avoid accidental damage.

Implementing these maintenance practices will not only enhance the performance of your equipment but also save you money on repairs and replacements in the long run.

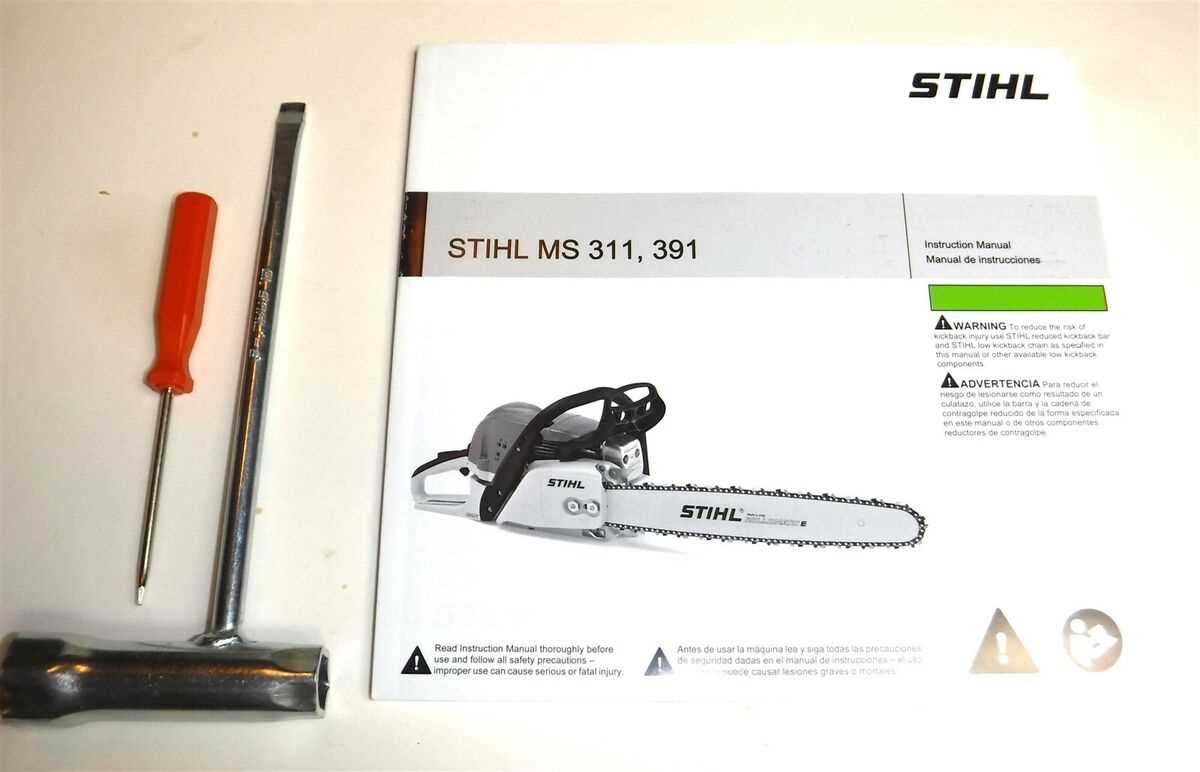

Tools Needed for MS311 Repairs

Repairing outdoor power equipment requires a specific set of instruments to ensure efficiency and accuracy. Proper tools not only facilitate the repair process but also enhance safety, enabling users to handle components effectively. Whether you are performing routine maintenance or addressing more significant issues, having the right equipment is essential for achieving optimal performance.

Essential Instruments

To begin, a quality set of wrenches and screwdrivers is crucial for loosening and tightening various fasteners. Additionally, a socket set can provide the versatility needed for different sizes of bolts. Torque wrenches are also recommended to ensure that components are secured to manufacturer specifications, preventing damage during operation.

Safety Gear

In addition to standard tools, safety equipment cannot be overlooked. Protective eyewear, gloves, and hearing protection should always be worn to minimize risk while working. Moreover, having a sturdy workbench and good lighting will further enhance the repair environment, ensuring that tasks are completed efficiently and safely.

Where to Buy MS311 Parts

When it comes to sourcing components for your outdoor power equipment, there are several avenues to explore. Whether you need replacements for maintenance or repairs, finding reliable suppliers is essential for ensuring optimal performance.

Authorized dealers are often the best choice for high-quality items, as they guarantee authenticity and compatibility. Additionally, many local hardware stores may carry essential supplies that meet your needs.

Online platforms offer a vast selection, allowing you to compare prices and read customer reviews. Websites specializing in equipment components can be particularly useful for hard-to-find items.

Consider checking auction sites and classified ads for second-hand options, which can be both cost-effective and sustainable. Finally, engaging with community forums can lead to recommendations for trusted sources.

Importance of Genuine Stihl Parts

Using authentic components in your equipment is crucial for maintaining optimal performance and longevity. High-quality parts ensure that your tools function effectively and safely, minimizing the risk of malfunctions or accidents. Investing in genuine replacements not only enhances the reliability of your machine but also protects your investment over time.

Benefits of Authentic Components

- Enhanced Performance: Genuine components are designed specifically for your equipment, providing better compatibility and efficiency.

- Increased Durability: Original parts are manufactured to meet strict quality standards, ensuring they withstand wear and tear.

- Safety Assurance: Authentic components are tested for safety, reducing the risk of accidents or injuries during operation.

- Warranty Protection: Using genuine parts typically keeps your warranty intact, protecting you from unexpected repair costs.

Risks of Using Imitation Parts

- Compromised Performance: Imitation parts may not fit correctly, leading to decreased efficiency and performance.

- Increased Maintenance Costs: Lower-quality components can lead to frequent breakdowns and the need for more repairs.

- Safety Hazards: Non-authentic parts can fail unexpectedly, posing risks to both the operator and the equipment.

- Loss of Warranty: Many manufacturers void warranties if non-genuine parts are used, leaving you vulnerable to additional expenses.

Step-by-Step Repair Guide

This guide provides a systematic approach to troubleshooting and fixing common issues with outdoor power tools. By following each step carefully, you can ensure that your equipment operates efficiently and safely, extending its lifespan and enhancing performance.

Begin by gathering the necessary tools and materials. A clean workspace is essential for effective repairs. Ensure you have screwdrivers, wrenches, and any replacement components readily available. Having everything organized will streamline the process and prevent unnecessary delays.

Next, consult the manufacturer’s manual for specifications and instructions relevant to your model. Understanding the design and function of various parts will enable you to identify problems more easily. Pay attention to diagrams that illustrate component placement and connections.

Once familiarized with the equipment, conduct a visual inspection. Look for any signs of wear, damage, or loose connections. This step can reveal obvious issues that require immediate attention, such as frayed wires or cracked housings.

After identifying potential problems, proceed to disassemble the tool carefully. Document each step, noting where screws and components belong. This will aid in reassembly and help prevent loss of parts. Keep small items in labeled containers to avoid confusion.

Address any issues found during disassembly. Replace worn or damaged parts, ensuring they match the specifications of your tool. If certain components are not functioning properly, cleaning them may also resolve performance problems.

Once repairs are completed, reassemble the equipment in the reverse order of disassembly. Double-check that all screws and connections are secure. Proper reassembly is crucial for the safe operation of the tool.

Finally, conduct a thorough test run after reassembly. Monitor the tool for any unusual sounds or behaviors. If it operates smoothly, you have successfully completed the repair. Regular maintenance will help prevent future issues and ensure optimal functionality.

Upgrading Your MS311 Performance

Enhancing the efficiency and functionality of your equipment can lead to significant improvements in performance and user experience. By focusing on specific components and modifications, you can optimize the machine’s capabilities, making it more powerful and reliable for various tasks.

One effective way to boost performance is by investing in high-quality air filters. These components can improve airflow, ensuring that the engine operates smoothly and efficiently. Regular maintenance and timely replacement of these filters will also prolong the lifespan of your machine.

Another crucial aspect is the ignition system. Upgrading to a more advanced spark plug can enhance combustion, leading to better fuel efficiency and increased power output. It’s essential to choose plugs that are compatible and specifically designed for your model to achieve the best results.

Furthermore, consider the benefits of using a premium grade of fuel. Higher octane ratings can contribute to smoother operation and improved performance, especially under heavy loads. Always consult the manufacturer’s recommendations to ensure you’re making the right choice for your machine.

Finally, don’t overlook the importance of regular maintenance. Routine checks on the chain, bar, and overall mechanical condition can prevent potential issues and ensure that your equipment runs at its best. Keeping everything in optimal shape will guarantee not only performance but also safety during operation.