The intricate workings of a powerful cutting tool are essential for efficiency and reliability in the field. To optimize performance and ensure longevity, it’s crucial to have a clear understanding of its various elements and how they interact. This section will delve into the layout of a renowned model, highlighting the significance of each component in the overall functionality.

When dealing with heavy-duty machinery, familiarity with individual sections can significantly enhance maintenance practices. Recognizing the roles played by different parts not only facilitates effective troubleshooting but also aids in the timely replacement of worn-out components. Such knowledge empowers users to keep their equipment in top shape, ensuring smooth operations during demanding tasks.

In this exploration, we will provide a detailed overview of the configuration and relationships among the key sections of the tool. By breaking down these components, users can better appreciate the engineering behind the machinery and its design, leading to informed decisions about care and enhancement of performance.

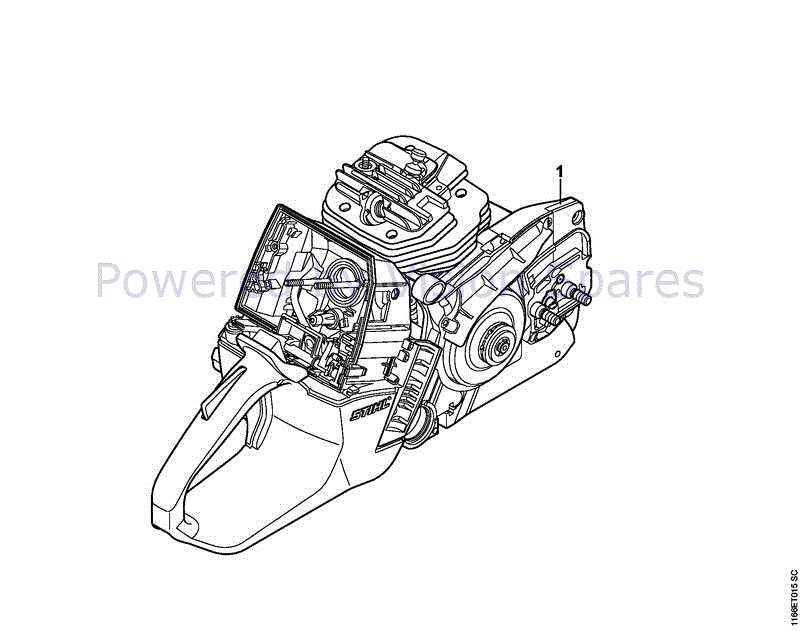

Understanding the Stihl MS661 Overview

This section provides an insight into a powerful and versatile tool designed for heavy-duty applications. Known for its reliability and efficiency, this machine is tailored for professionals and enthusiasts who demand high performance in challenging conditions. Its robust design ensures durability, making it suitable for various cutting tasks in forestry and landscaping.

Key Features

One of the standout characteristics of this equipment is its impressive engine capacity, which delivers exceptional cutting power. The ergonomic design enhances user comfort, reducing fatigue during prolonged use. Additionally, advanced technologies incorporated into its design promote fuel efficiency and reduce emissions, aligning with modern environmental standards.

Applications and Benefits

This tool excels in a wide range of applications, from felling large trees to trimming and pruning. Its versatility makes it an essential asset for professionals in the forestry industry and for those managing large properties. The combination of power, efficiency, and user-friendly features provides a significant advantage, allowing users to tackle demanding tasks with ease.

Key Components of the MS661 Chainsaw

This section explores the essential elements that contribute to the functionality and performance of a powerful cutting tool. Understanding these components can enhance user experience and maintenance practices, ensuring optimal operation.

| Component | Description |

|---|---|

| Engine | The heart of the machine, providing the necessary power for cutting tasks. |

| Guide Bar | Serves as the track for the chain, enabling precise cuts and maneuverability. |

| Chain | Features sharp teeth that cut through wood, playing a vital role in efficiency. |

| Air Filter | Prevents debris from entering the engine, maintaining optimal performance. |

| Fuel System | Delivers the right mix of fuel and oil to power the engine effectively. |

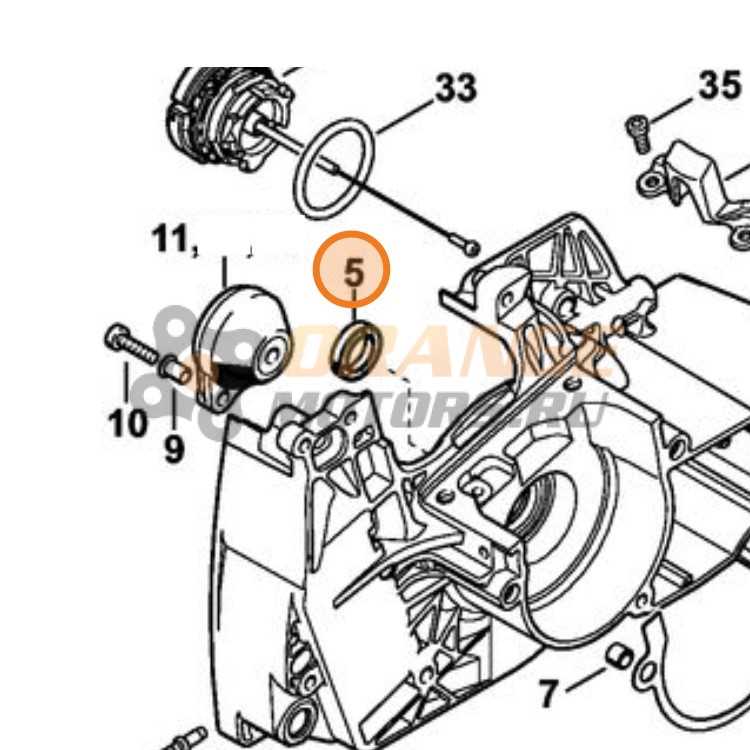

Importance of Parts Diagrams

Understanding the layout and components of machinery is essential for effective maintenance and repair. Visual representations of these elements not only simplify the identification process but also enhance overall efficiency when addressing issues or performing upgrades.

Enhanced Clarity

- Visual aids eliminate confusion regarding individual elements.

- Clear layouts allow for quick identification of required components.

Streamlined Repairs

- Facilitates accurate disassembly and reassembly.

- Reduces the risk of missing crucial parts during repairs.

- Enables users to delve into complex repairs with confidence.

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repair. These visuals provide a clear overview of the various elements involved, allowing users to identify and source individual pieces with ease.

Key Elements to Identify

- Labels: Pay attention to the identifiers next to each component, as they often correspond to specific parts numbers.

- Connections: Observe how elements are linked, as this can indicate assembly order and function.

- Views: Different perspectives (e.g., top, side) can offer a more comprehensive understanding of the layout.

Tips for Effective Usage

- Cross-reference the schematic with the user manual for clarity.

- Highlight or annotate parts of interest for easier navigation.

- Consult online resources or forums for additional insights from other users.

Common Repairs for MS661

Maintaining a high-performance power tool requires addressing frequent issues that may arise during operation. Understanding typical repairs can significantly enhance longevity and efficiency. This section highlights common problems and their solutions for optimal functionality.

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Fuel System Blockage | Difficulty starting, erratic idling | Clean or replace fuel filter; inspect fuel lines |

| Chain Tension Problems | Chain slipping, unusual noise | Adjust tension; check for wear and tear on the chain |

| Inefficient Air Filter | Reduced power, increased emissions | Clean or replace air filter; ensure proper sealing |

| Spark Plug Malfunction | Hard starting, poor performance | Inspect and replace spark plug; check ignition system |

| Oil Leakage | Visible oil on housing, loss of lubrication | Inspect gaskets and seals; replace as necessary |

Addressing these common issues promptly can ensure your tool remains reliable and performs at its best. Regular maintenance checks are essential to prevent larger complications down the line.

Finding Genuine Stihl Parts

When it comes to maintaining your equipment, ensuring that you use authentic components is crucial for optimal performance and longevity. These original items not only fit perfectly but also adhere to the manufacturer’s quality standards, ensuring safety and efficiency during operation.

Researching Authorized Dealers is the first step in your quest for genuine components. Many manufacturers provide lists of certified retailers where you can purchase these items with confidence.

Checking Serial Numbers can also help confirm authenticity. By comparing the serial numbers on your machine with those provided by the manufacturer, you can ensure that you’re investing in the right replacements.

Online Resources offer various platforms where users share their experiences and recommendations. Reading reviews and joining forums can provide insights into the best places to find reliable items.

Direct Manufacturer Purchases often guarantee that you receive authentic components. Many companies have online shops that allow you to buy directly, reducing the risk of counterfeit products.

Ultimately, taking the time to find genuine components can save you money and ensure your equipment runs smoothly for years to come.

Maintenance Tips for Longevity

Proper care and regular upkeep are essential to ensure the longevity of your equipment. By adopting a few key practices, you can enhance performance and extend the lifespan significantly. Routine checks and timely servicing can prevent minor issues from evolving into major repairs, saving both time and money.

Regular Cleaning

Consistent cleaning after use is crucial. Remove debris and residue from all components to prevent buildup, which can lead to overheating and mechanical failure. Pay special attention to air filters and cooling systems, ensuring they are free from blockages.

Lubrication and Inspection

Frequent lubrication of moving parts is vital for reducing friction and wear. Additionally, inspect all components regularly for signs of wear or damage. Early detection of issues can help in making necessary repairs before they escalate, ultimately maintaining optimal functionality.

Comparing MS661 with Other Models

This section explores the distinctions and similarities between a specific high-performance chainsaw and its counterparts in the market. By examining various features, users can determine which model best suits their needs.

- Power and Performance:

- Evaluate engine size and output.

- Consider cutting speed and efficiency.

- Weight and Balance:

- Compare overall weight for maneuverability.

- Assess weight distribution for comfort during use.

- Durability and Build Quality:

- Examine materials used in construction.

- Look into warranty options and service support.

- Ease of Use:

- Analyze starting mechanisms and controls.

- Review maintenance requirements and accessibility.

Ultimately, by delving into these aspects, users can make informed decisions tailored to their specific tasks and preferences.

Troubleshooting Common Issues

When operating high-performance equipment, encountering challenges is not uncommon. Identifying and resolving these issues promptly can enhance efficiency and prolong the lifespan of your tool. Below are some frequent problems users may face, along with practical solutions.

- Engine Won’t Start:

- Check fuel levels and ensure the mixture is correct.

- Inspect the spark plug for damage or wear.

- Ensure the air filter is clean and unobstructed.

- Loss of Power:

- Examine the fuel system for clogs or contamination.

- Inspect the ignition system for faulty components.

- Check for any blockages in the exhaust system.

- Excessive Vibration:

- Ensure all screws and bolts are tightly secured.

- Check for wear on the anti-vibration mounts.

- Inspect the cutting attachment for damage or imbalance.

- Overheating:

- Verify that the cooling fins are clean and free of debris.

- Check the fuel mixture to ensure it is not too lean.

- Inspect the exhaust for any restrictions that may impede airflow.

Addressing these common challenges requires attention to detail and a systematic approach. Regular maintenance can help prevent many of these issues from occurring in the first place.

Where to Buy Replacement Parts

Finding quality components for your outdoor power equipment is essential for maintaining optimal performance. Whether you’re dealing with a minor repair or a major overhaul, having access to reliable suppliers can make all the difference. This section will guide you through various avenues to obtain the necessary items for your machinery.

Authorized Dealers

One of the most trustworthy sources for acquiring replacements is through authorized dealers. These retailers offer genuine items, ensuring compatibility and reliability. Here are some benefits of purchasing from authorized vendors:

- Expert guidance on the right components.

- Warranty on items purchased.

- Access to special promotions or discounts.

Online Marketplaces

The internet provides a vast array of options for sourcing equipment essentials. Online platforms can offer competitive prices and a wide selection. Consider the following when shopping online:

- Check seller ratings and reviews for reliability.

- Verify return policies to ensure satisfaction.

- Compare prices across different websites for the best deal.

By exploring both local dealers and online options, you can secure the necessary components to keep your equipment running smoothly.