Maintaining your outdoor machinery is essential for optimal performance and longevity. A thorough grasp of its various components not only enhances functionality but also aids in troubleshooting potential issues. When you delve into the assembly of your device, clarity on each element can lead to more effective maintenance practices.

In this section, we aim to provide a comprehensive overview of the internal structure and mechanisms involved. By breaking down the individual elements, users can gain insight into how they work together seamlessly. This understanding is the ultimate key to ensuring your equipment remains in top-notch condition.

Whether you’re a novice or an experienced user, familiarizing yourself with these components will empower you to make informed decisions about repairs and upgrades. A well-informed operator is better equipped to enhance the performance and lifespan of their machinery.

Understanding the Stihl RE 128 Plus

This section delves into the essential aspects of a high-performance cleaning device designed for both residential and commercial use. Recognized for its efficiency and versatility, this equipment stands out in its category, making it an ideal choice for various cleaning tasks.

Key Features

Among the notable characteristics of this model are its powerful motor, user-friendly controls, and a compact design that enhances maneuverability. The effective water pressure combined with adjustable settings allows users to tackle a wide range of surfaces and dirt types effortlessly.

Maintenance and Care

Regular upkeep is crucial for optimal performance. Key maintenance tasks include checking fluid levels, cleaning filters, and inspecting hoses for wear. Proper care not only extends the lifespan of the machine but also ensures consistent efficiency during operation.

| Feature | Description |

|---|---|

| Motor Power | Provides reliable performance for various cleaning applications. |

| Weight | Lightweight design for ease of transport and use. |

| Adjustable Pressure | Allows customization for different cleaning needs. |

| Durability | Constructed with high-quality materials for longevity. |

Key Features of the RE 128 Plus

This model stands out due to its exceptional design and functionality, tailored for efficiency and ease of use. Its advanced features ensure that users can achieve optimal performance while handling various tasks around their property.

Powerful Motor: Equipped with a robust engine, this unit delivers consistent power, making it suitable for both light and heavy-duty cleaning tasks.

Compact Design: The streamlined shape allows for easy maneuverability in tight spaces, enhancing the user experience when tackling challenging areas.

Adjustable Pressure Settings: Users can customize the water pressure to match the requirements of different surfaces, ensuring effective cleaning without damage.

Durable Construction: Built with high-quality materials, this machine is designed to withstand regular use, ensuring longevity and reliability over time.

Easy Maintenance: The thoughtful design simplifies upkeep, allowing for quick access to essential components, making it user-friendly for everyone.

Eco-Friendly Operation: Its efficient water usage not only conserves resources but also minimizes environmental impact, aligning with modern sustainability goals.

Importance of Maintenance for Longevity

Regular upkeep is essential for ensuring the extended life of any equipment. Consistent care not only enhances performance but also prevents unexpected failures and costly repairs. By implementing a routine maintenance schedule, users can significantly improve the reliability and efficiency of their machinery.

Benefits of Routine Care

- Increased efficiency in operation

- Reduced likelihood of breakdowns

- Improved safety during use

- Extended lifespan of components

Key Maintenance Practices

- Regular cleaning to remove dirt and debris

- Frequent inspection of key components for wear and tear

- Lubrication of moving parts to prevent friction

- Replacement of worn-out elements as needed

By prioritizing these practices, users can ensure that their tools remain in peak condition, ultimately leading to better performance and longer service life.

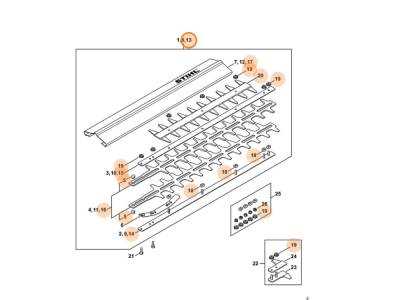

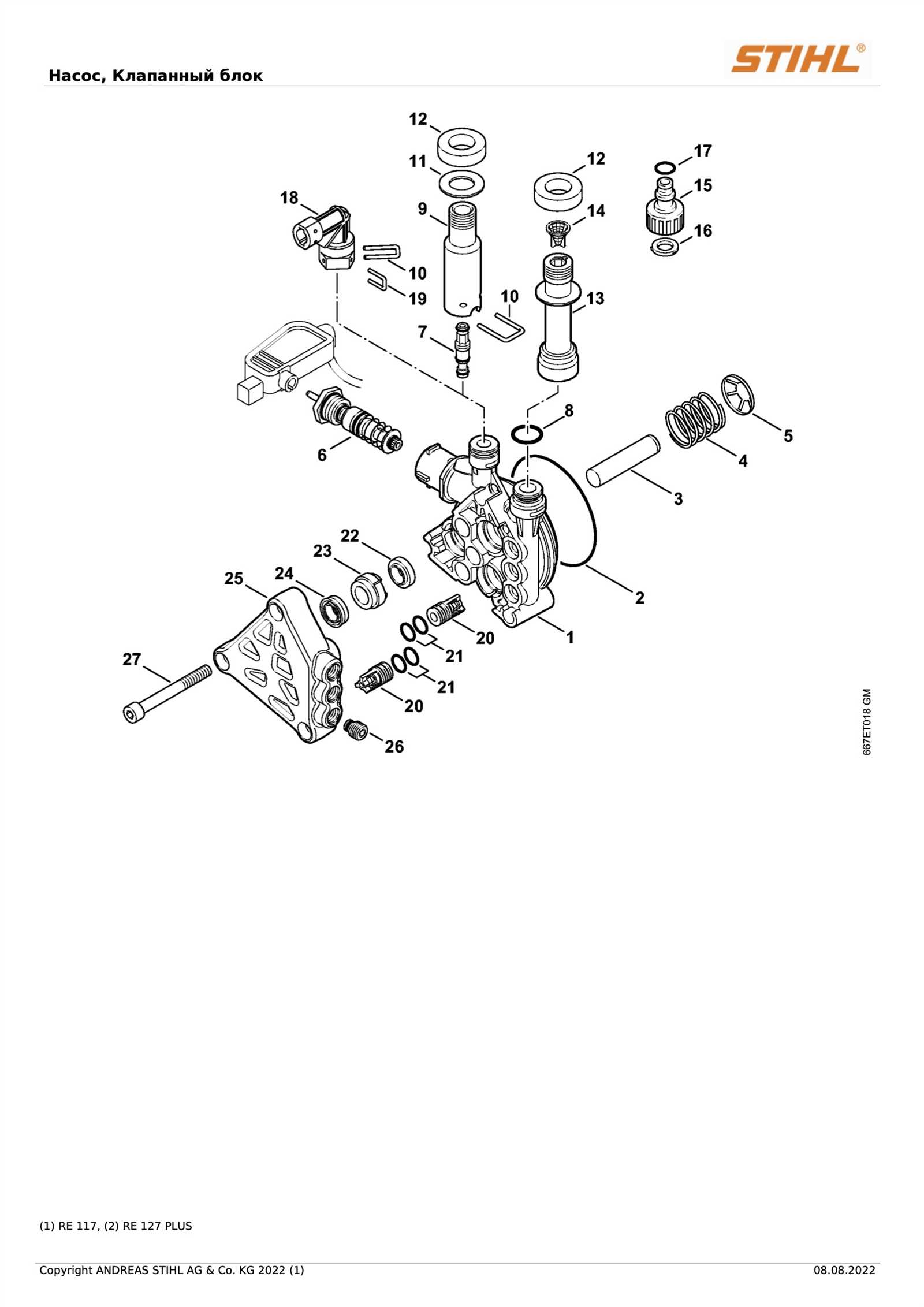

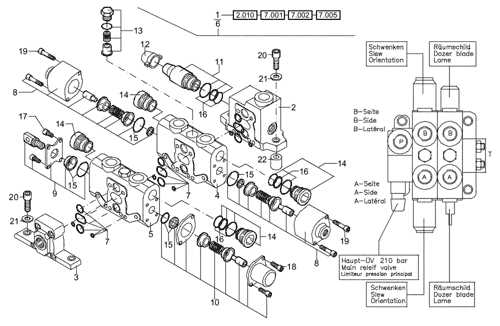

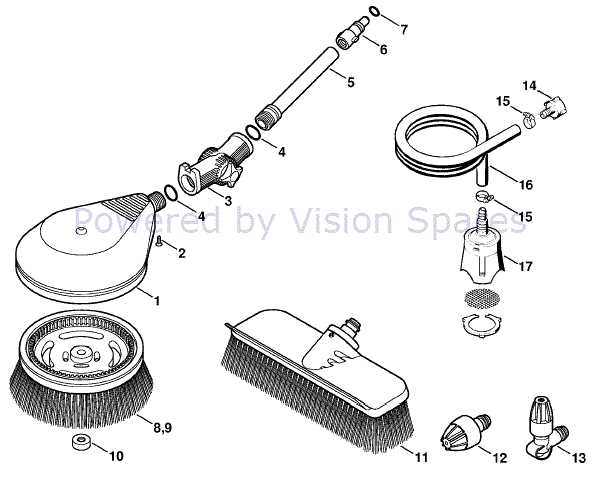

How to Read the Parts Diagram

Understanding the visual representation of components can greatly enhance your ability to maintain and repair your equipment. These illustrations serve as a roadmap, guiding you through the various elements and their relationships.

First, identify the sections that are categorized, as they often group similar components together. Each item typically has a unique identifier, which you can use to find specific pieces when ordering replacements.

Next, pay attention to the annotations or notes that accompany the illustration. They provide crucial information regarding assembly, compatibility, and special tools needed for installation.

Finally, familiarize yourself with any legends or keys that explain symbols and colors. This knowledge will ultimately aid you in navigating the visual guide with confidence and efficiency.

Common Issues and Troubleshooting Tips

When operating outdoor power equipment, users may encounter various challenges that can hinder performance and efficiency. Understanding these common problems and knowing how to resolve them can greatly enhance the experience and extend the lifespan of the machinery.

1. Equipment Won’t Start: One of the most frequent issues is the inability to start the machine. This could be due to several factors, including a drained battery, clogged fuel lines, or a faulty ignition system. Ensure that the battery is charged and check the fuel quality; old or contaminated fuel can cause starting problems.

2. Uneven Pressure Output: If the pressure output is inconsistent, it may indicate a blockage in the nozzle or a worn-out pump. Regularly inspect and clean the nozzle, and replace any damaged components as needed to restore optimal performance.

3. Overheating: Machines can overheat if they are operated for extended periods without breaks. Ensure that the cooling vents are not blocked and allow the equipment to cool down as necessary. Regular maintenance, including checking for dirt buildup, can help prevent this issue.

4. Leaking Fluids: Leaks can occur from various seals and connections. Inspect the machine for any signs of fluid leakage and replace worn or damaged seals promptly to avoid further complications.

5. Unusual Noises: Strange sounds during operation often signal underlying issues. Listen for grinding, rattling, or hissing noises, which may indicate loose parts or mechanical failure. Conduct a thorough inspection and tighten or replace components as needed.

By being aware of these common issues and implementing the suggested troubleshooting tips, users can maintain their equipment more effectively, ensuring reliable performance and longevity.

Essential Replacement Parts for Efficiency

Maintaining optimal performance in your equipment relies on the timely replacement of key components. Ensuring these elements are in top condition not only enhances functionality but also extends the lifespan of your tools. Here, we explore crucial elements that contribute to seamless operation and efficiency.

Key Components for Optimal Functionality

- Filters: Clean air and water filters prevent contamination and support engine performance.

- Seals: Effective seals minimize leaks and maintain pressure, ensuring reliable operation.

- Hoses: Quality hoses withstand wear and tear, reducing the risk of breaks that can hinder performance.

- Blades: Sharp, durable blades improve cutting efficiency and reduce strain on the engine.

Maintenance Tips for Longevity

- Regularly inspect components for signs of wear or damage.

- Replace filters and seals according to the manufacturer’s guidelines.

- Keep blades sharpened and well-maintained to ensure optimal cutting performance.

- Store equipment in a dry place to prevent deterioration of hoses and other materials.

By focusing on these essential elements, you can ensure that your equipment remains efficient and reliable for all your needs.

Where to Buy Stihl Parts Online

Finding high-quality components for outdoor power equipment can greatly enhance performance and longevity. Numerous online retailers specialize in these essential supplies, providing a wide selection that caters to various needs. By exploring different options, users can discover competitive pricing and convenience in purchasing.

Trusted Retailers

Reputable e-commerce platforms offer a vast inventory, ensuring that users have access to authentic components. Websites such as Amazon and eBay often feature user reviews, which can aid in selecting reliable items. Additionally, many manufacturers provide their own online stores, simplifying the search for specific requirements.

Specialty Stores and Forums

For those seeking expert advice, specialized websites and online communities can be invaluable. Forums dedicated to outdoor tools often have sections for buying and selling equipment, where users can find recommendations for trusted sellers. These platforms foster connections with fellow enthusiasts, enhancing the buying experience.

Comparison with Other Stihl Models

This section explores the distinctions and similarities between various models from the renowned manufacturer, emphasizing performance and design features. Understanding these nuances can guide users in selecting the most suitable equipment for their needs.

Performance Metrics: While some units are designed for heavy-duty tasks, others prioritize lightweight maneuverability. The analyzed model strikes a balance, making it ideal for moderate use.

Design Features: Ergonomics and user-friendliness vary across models. The focus on comfort and ease of use in this particular model enhances overall efficiency, similar to higher-end counterparts.

Conclusion: By delving into these comparisons, users can appreciate how each model meets different demands, leading to informed decisions that align with their specific requirements.

DIY Repairs: A Step-by-Step Guide

Embarking on home repairs can be both fulfilling and cost-effective. Understanding the components of your equipment and knowing how to address common issues empowers you to tackle repairs with confidence. This guide provides a structured approach to assist you in diagnosing problems and performing maintenance efficiently.

Assessing the Situation

Before diving into repairs, it’s crucial to identify the specific issue. Begin by observing the equipment for any signs of malfunction. Take note of unusual sounds, leaks, or performance drops. Gathering this information will help you pinpoint the necessary steps for resolution.

Gathering Tools and Materials

Once you’ve diagnosed the problem, gather the required tools and replacement items. Here’s a quick reference table to assist you:

| Tool/Material | Purpose |

|---|---|

| Screwdriver Set | For removing and tightening screws |

| Wrench | For loosening and tightening nuts and bolts |

| Replacement Parts | To swap out damaged or worn components |

| Cleaning Supplies | To maintain and clean parts during repair |

With the right tools and a clear understanding of the issue, you can confidently proceed with the repair process, ensuring your equipment runs smoothly for years to come.

Safety Precautions When Using Equipment

Ensuring safety while operating machinery is crucial to prevent accidents and injuries. By adhering to basic guidelines, users can create a secure environment and enhance overall efficiency.

General Guidelines

- Always wear appropriate personal protective equipment (PPE).

- Read the manufacturer’s manual thoroughly before use.

- Inspect the equipment for any damages or malfunctions before starting.

Operating Procedures

- Keep bystanders at a safe distance.

- Use equipment only for its intended purpose.

- Maintain a clear work area to avoid tripping hazards.

Maximizing Performance with Proper Use

To achieve optimal efficiency and longevity from your equipment, understanding and implementing best practices is crucial. Proper handling not only enhances functionality but also ensures safety during operation. By focusing on maintenance and usage guidelines, you can significantly boost the overall performance of your machinery.

Regular Maintenance: Keeping your tools in top condition involves routine inspections and timely servicing. Check for any wear and tear, ensuring that all components are functioning as intended. Lubrication of moving parts and replacing worn elements can prevent larger issues down the line.

Correct Operation Techniques: Familiarizing yourself with the correct operational techniques is vital. Always follow manufacturer recommendations regarding usage settings and limits. Using the right technique not only improves efficiency but also reduces the risk of accidents or equipment damage.

Environment Considerations: The surrounding environment plays a significant role in performance. Ensure you operate in optimal conditions, avoiding extreme temperatures or dampness that may hinder functionality. Adapt your approach based on the working environment to maximize efficiency.

By incorporating these practices, you will not only enhance the performance of your tools but also extend their lifespan, making your investment worthwhile.