The functionality of handheld devices designed for liquid application relies on a precise combination of internal mechanisms. These devices are widely used across various industries to evenly distribute fluids over large areas. To ensure optimal performance, each component plays a vital role in maintaining efficiency and reliability.

By examining the structure and connections within such equipment, users can better comprehend how the different elements contribute to the overall process. This knowledge is essential for those who wish to perform maintenance or troubleshoot potential issues.

Detailed insights into the inner workings of these tools can provide significant benefits, ensuring proper care and enhancing longevity. Understanding each element’s function will allow users to make informed decisions when addressing mechanical problems or replacing specific elements.

Overview of the Stihl SG20 Sprayer

The device is designed to efficiently handle the application of liquid solutions across various surfaces. Its functionality allows for the precise distribution of substances, making it an essential tool for both large-scale and small-scale tasks.

Equipped with a robust mechanism, the tool ensures consistent performance and reliability during prolonged use. Its ergonomic design provides comfort during operation, minimizing strain and allowing for extended periods of use without fatigue.

Additionally, the system includes a set of easily accessible components that contribute to its overall durability. The device’s structure supports easy maintenance and cleaning, ensuring long-term functionality and reducing downtime.

Key Components of the SG20 Model

The manual liquid dispersal device is comprised of several essential elements that ensure its proper operation. These components work in harmony to deliver a consistent and controlled flow, making the device efficient for a variety of applications. Understanding the core features of the equipment can help in maintaining its longevity and functionality.

Pump Mechanism: The heart of the device, responsible for creating the necessary pressure to distribute liquids. A properly functioning pump is critical for effective operation, ensuring a smooth and consistent output.

Reservoir: This large container holds the liquid, allowing for extended use without frequent refilling. Its durable material ensures that it can withstand various conditions while keeping the contents secure.

Pressure Regulator: A vital part that helps control the flow and prevents over-pressurization. Adjusting this feature allows users to customize the pressure according to their specific needs, enhancing versatility.

Delivery Hose: The conduit

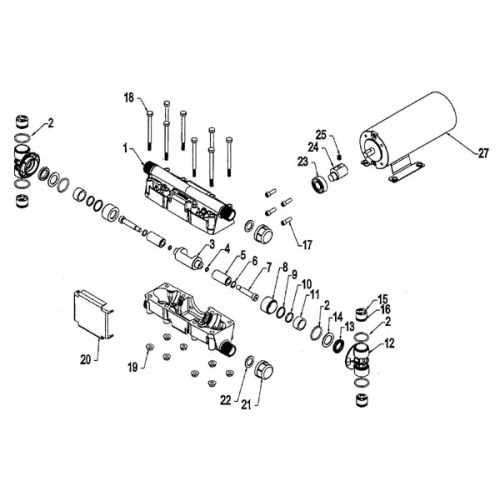

Pump Mechanism and Functionality

The pump mechanism is essential for creating the pressure needed to distribute liquid effectively. By converting manual energy into fluid movement, it ensures consistent output through the nozzle. The internal components work together to generate force, enabling smooth and controlled application.

Pressure generation is achieved through a system of valves and seals, which regulate the flow and maintain stability. This process prevents leaks and ensures efficient performance even under prolonged use.

Proper maintenance of the pump mechanism guarantees longevity and reliability, ensuring that each component continues to operate at peak efficiency.

Sprayer Nozzle Types and Uses

The variety of nozzle designs plays a crucial role in determining the effectiveness of liquid distribution. Each type serves specific purposes, offering different spray patterns, droplet sizes, and flow rates. These features affect the precision, coverage, and efficiency of applications, making it important to select the right nozzle for the task at hand.

Fan-shaped Nozzles are widely known for their ability to provide even distribution across a surface. They are ideal for tasks requiring uniform coverage, such as applying liquid to broad areas.

Cone-shaped Nozzles offer a more concentrated spray, either in a hollow or full pattern, and are often used when precision in targeting specific spots is necessary. These nozzles are especially effective in environments with dense or hard-to-reach areas.

Adjustable Nozzles provide flexibility, allowing the

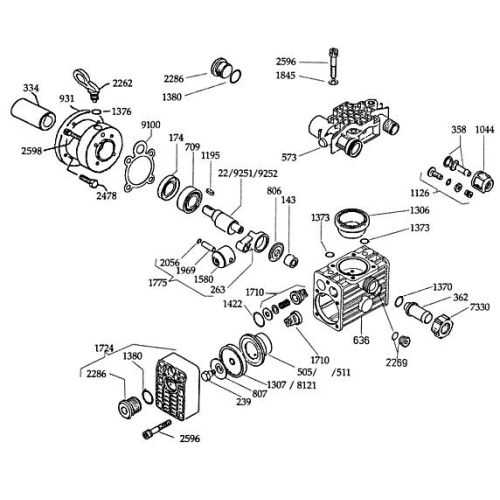

Understanding the Pressure Regulator

The pressure regulator plays a crucial role in ensuring consistent fluid flow and maintaining desired pressure levels during operation. By controlling the force with which liquid is dispensed, it allows the user to adjust settings according to the task at hand. A well-functioning regulator prevents over-pressurization and ensures that the system operates smoothly and efficiently.

How the Regulator Works

At its core, the regulator is designed to manage the flow by reducing the incoming pressure to a more controlled level. This adjustment is done through internal mechanisms that balance the pressure difference between the input and output. Accurate pressure control leads to optimal performance and reduced wear on the system.

Benefits of Proper Pressure Regulation

Maintaining the correct pressure not only improves performance but also extends the longevity of the components. With proper regulation, the risk of leaks, malfunctions,

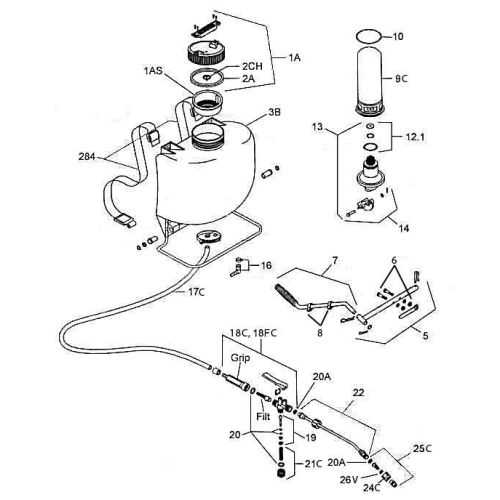

Hose and Trigger Assembly Guide

This section provides a comprehensive overview of the components involved in the hose and trigger assembly of a liquid application device. Understanding these elements is crucial for effective operation and maintenance, ensuring optimal performance and longevity.

Components Overview

- Hose: The flexible conduit that transports the liquid from the reservoir to the nozzle.

- Trigger Mechanism: The device that allows the user to control the flow of liquid by opening and closing the outlet.

- Connectors: Fittings that secure the hose to the trigger assembly and the main unit.

- Nozzle: The end piece that directs the liquid, which can vary in shape and size depending on the application.

Assembly Steps

- Begin by ensuring all components are clean and free from debris.

- Attach the hose to the trigger mechanism using the designated connectors, ensuring a tight fit.

- Secure the nozzle to the end of the hose, checking for compatibility with the existing setup.

- Perform a test by activating the trigger to ensure proper flow and functionality.

Regular inspection and maintenance of the hose and trigger assembly will enhance the efficiency of your liquid application device and prevent potential malfunctions.

Tank Design and Capacity Overview

The construction and volume of a liquid storage unit play a crucial role in its overall functionality and efficiency. A well-designed reservoir ensures optimal distribution of the fluid while accommodating various application needs. Understanding the structural elements and capacity considerations is essential for effective use and maintenance.

Structural Features

Contemporary liquid containers often incorporate advanced materials that enhance durability and resistance to environmental factors. These features contribute to the longevity of the unit, preventing leaks and ensuring safe operation. Additionally, ergonomic designs facilitate easier handling and transportation, making them user-friendly.

Capacity Considerations

Capacity is a fundamental aspect that determines the unit’s suitability for different tasks. Variations in size allow users to select the most appropriate option based on specific requirements, ranging from small-scale operations to larger, more demanding applications. Understanding the implications of capacity aids in optimizing performance and efficiency.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires consistent care and attention. By following a few essential practices, you can significantly extend the lifespan and performance of your machine.

Here are some key maintenance tips to keep your device in top shape:

- Regular Cleaning: After each use, thoroughly clean the exterior to remove dirt and debris. This helps prevent corrosion and damage to components.

- Routine Inspections: Frequently check for any signs of wear or damage. Early detection of issues can prevent costly repairs and downtime.

- Proper Storage: Store the equipment in a cool, dry place to protect it from moisture and extreme temperatures. Covering it can also shield it from dust.

- Lubrication: Regularly lubricate moving parts to ensure smooth operation. This reduces friction and helps to avoid premature wear.

- Fluid Checks: Monitor fluid levels, including oil and fuel. Ensure they are at the recommended levels to maintain optimal performance.

By implementing these practices, you can ensure that your equipment remains reliable and functional for many years to come.

Replacing the Pump Seal Parts

Maintaining the integrity of the fluid delivery system is essential for optimal performance. One crucial component that often requires attention is the sealing mechanism, which ensures that leaks are minimized and the equipment operates efficiently. Regular inspection and timely replacement of these seals can prevent more extensive damage and enhance the lifespan of the equipment.

To begin the replacement process, gather the necessary tools, including a wrench set, pliers, and a suitable replacement seal. Start by disconnecting the power source and draining any remaining liquid from the system to avoid spills. Carefully remove the existing seals, noting their arrangement for accurate reinstallation. Clean the sealing surfaces thoroughly to remove any debris or residue.

Once prepared, position the new seal in its designated location. Ensure that it fits snugly and is aligned properly to avoid future leaks. Reassemble the components, tightening them to the manufacturer’s specifications. Finally, restore the fluid to the system and test for leaks to confirm that the new seal is functioning as intended. This maintenance step is vital for ensuring the reliability of the equipment during operation.

Troubleshooting Common SG20 Issues

When operating a garden application device, various problems may arise that can hinder its performance. Understanding these issues is essential for maintaining optimal functionality and ensuring efficient use. This section addresses frequent complications and provides guidance on identifying and resolving them effectively.

Inconsistent Output: One of the primary concerns users face is irregular fluid distribution. This can result from a clogged nozzle or improper pressure settings. To rectify this, inspect the nozzle for any obstructions and ensure that the pressure is set according to the manufacturer’s specifications.

Difficulty Starting: If the equipment fails to start, check the fuel supply and battery condition. Ensure that there is an adequate amount of fuel and that the battery is fully charged. Additionally, verify that all switches are in the correct positions for operation.

Excessive Leaking: Leaks can occur due to worn seals or loose connections. Inspect the hoses and joints for any signs of wear or damage. Replacing any faulty components will help restore proper function and prevent further leakage.

Unusual Noises: If the machine produces abnormal sounds during operation, it may indicate a mechanical issue. Check for loose parts and ensure that all components are securely attached. If the problem persists, consult a professional technician for a thorough inspection.

Cleaning and Storing the Sprayer

Proper maintenance of your application device is essential to ensure its longevity and optimal performance. Regular cleaning and correct storage can prevent damage and ensure that it functions effectively for years to come.

Cleaning Procedures

After each use, it is crucial to thoroughly cleanse the equipment to remove any residual substances. Start by rinsing the tank and all components with clean water. Pay special attention to the nozzles and filters, as they can easily become clogged. If needed, use a gentle brush to scrub away any buildup. Following this, flush the entire system with a solution specifically designed for cleaning, ensuring that all internal parts are treated.

Storage Tips

Once the equipment is clean, it is important to store it correctly. Keep it in a dry, cool place to avoid exposure to extreme temperatures and humidity, which can degrade materials. For added protection, consider covering the device with a breathable tarp or cloth. Regularly inspecting the equipment during storage will help identify any potential issues before the next use.