Trigger

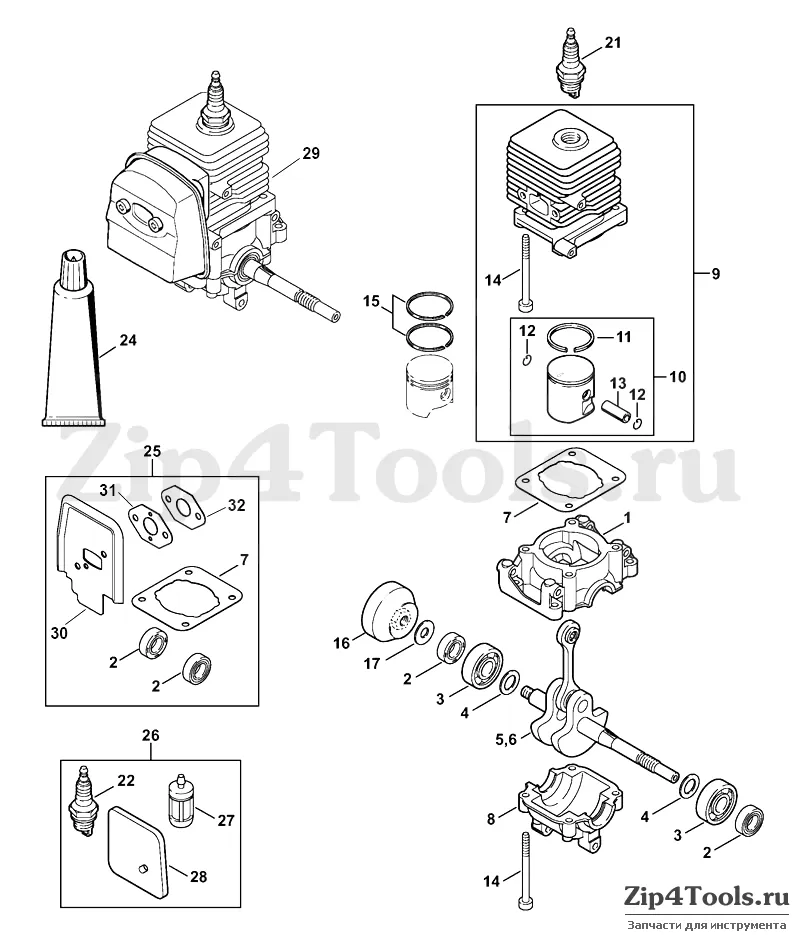

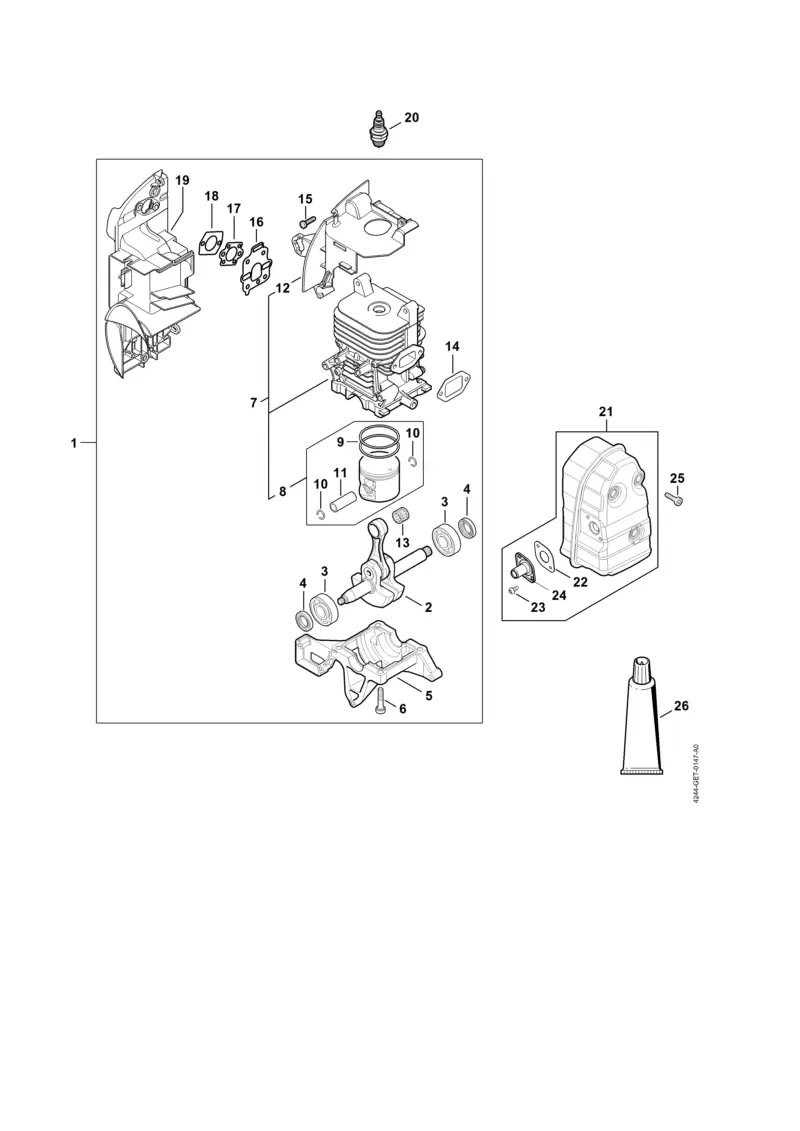

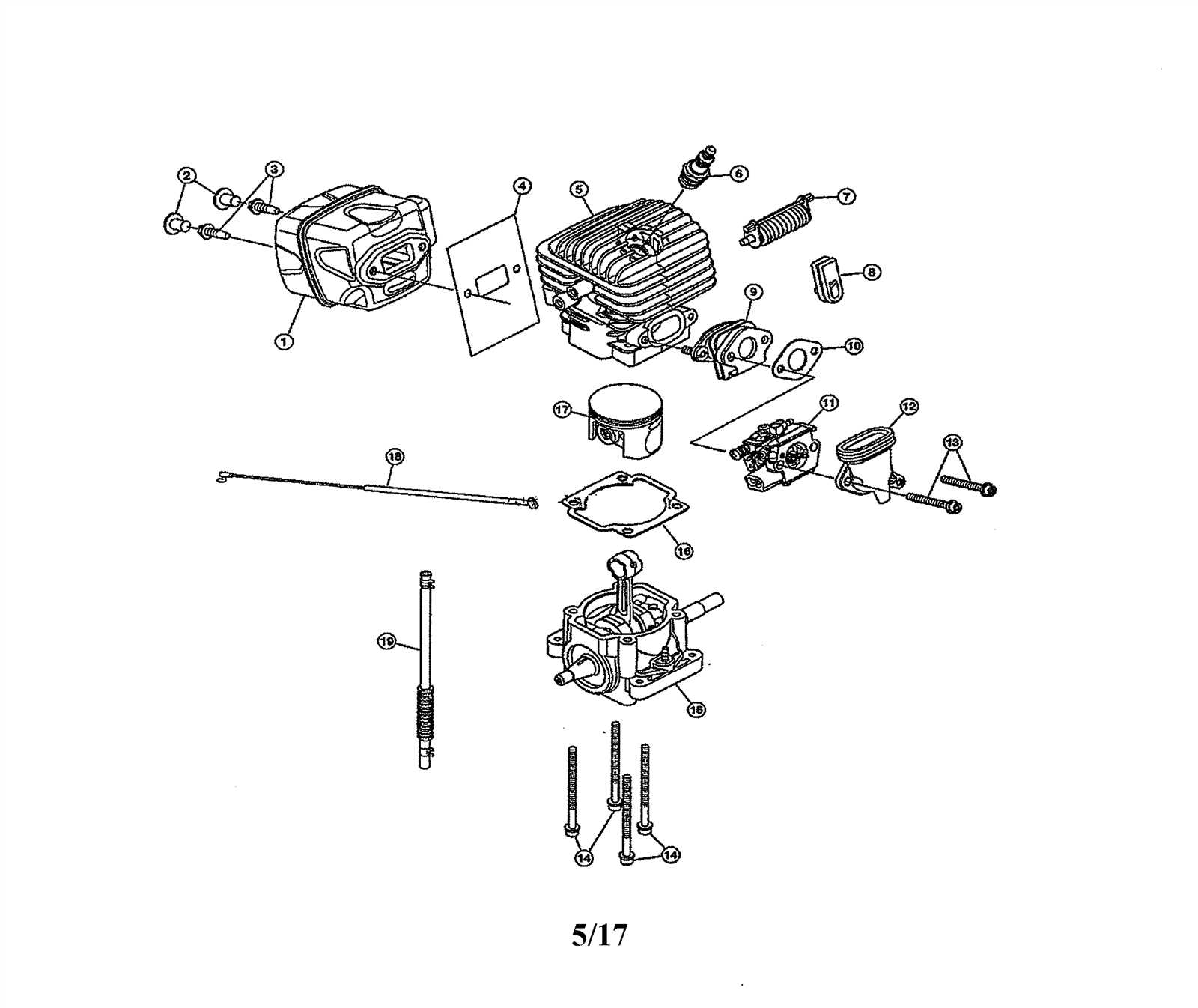

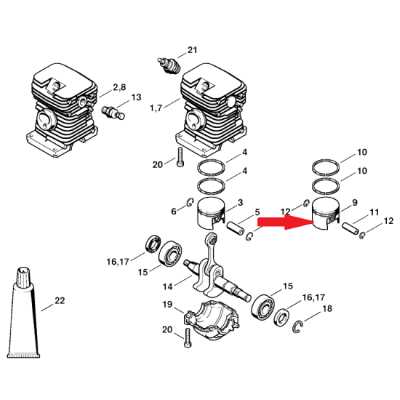

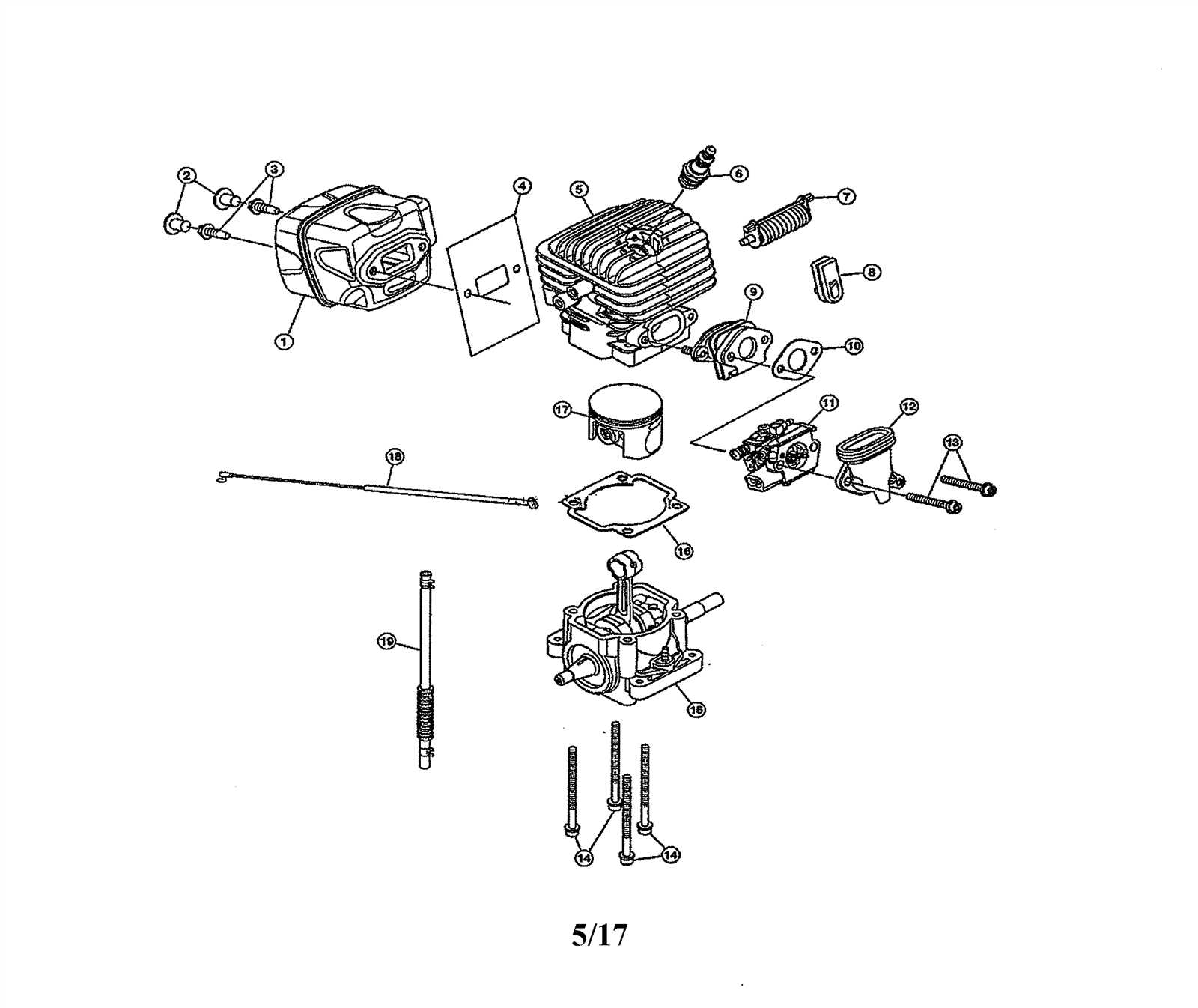

Understanding Engine Mechanics

Engine mechanics revolve around the intricate interaction of multiple components, each playing a crucial role in generating power. To comprehend how these systems work together, it is essential to explore the key elements involved in the process.

- The combustion chamber initiates energy production through fuel ignition.

- Pistons convert energy from combustion into mechanical force.

- The crankshaft transforms this mechanical force into rotational movement.

- Valves control the intake and exhaust of gases within the engine.

By breaking down these functions, we gain insights into the principles of engine operation, which are essential for maintaining optimal performance.

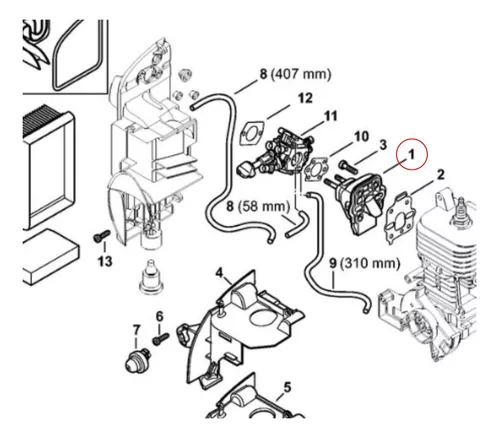

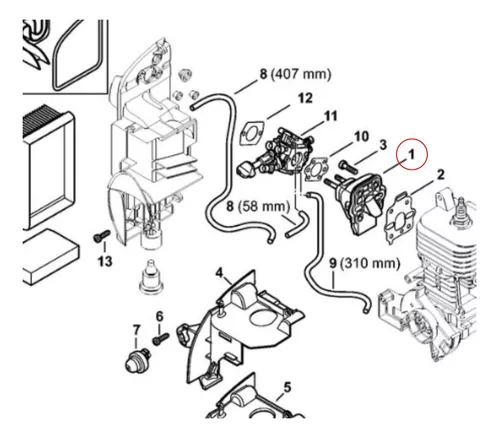

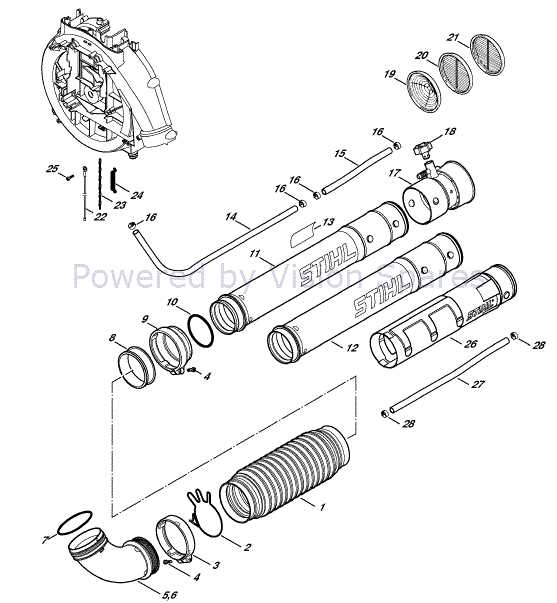

Fuel System Breakdown

The fuel system plays a crucial role in ensuring the efficient operation of any outdoor equipment. It is responsible for delivering the right amount of fuel to the engine, enabling smooth performance during various tasks. Understanding the different elements that compose the fuel system can help identify potential issues and ensure the longevity of the machine.

Key components include the fuel tank, which stores the necessary liquid, and the lines that transport it towards the engine. Additionally, filters are in place to prevent any impurities from reaching sensitive parts, maintaining optimal function. Regular maintenance and inspection of these components are essential for consistent performance.

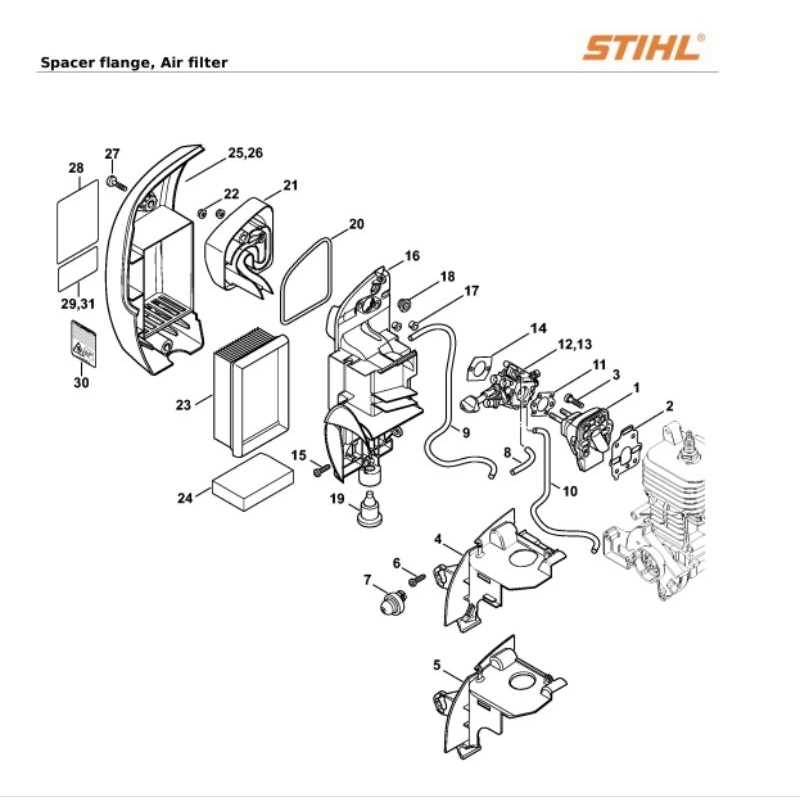

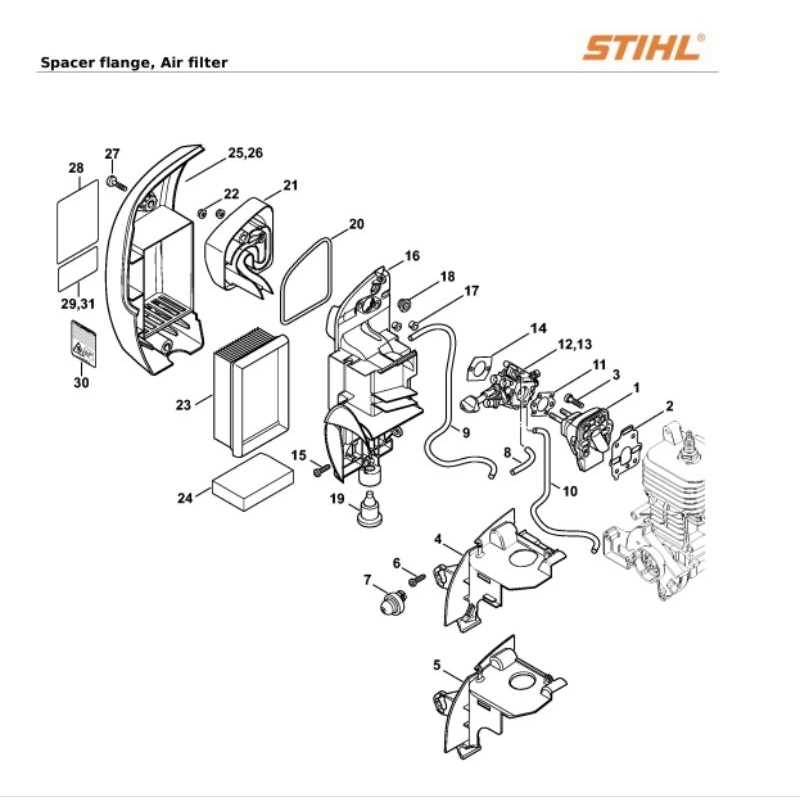

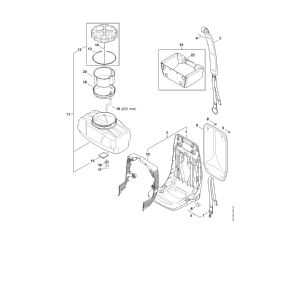

Air Filtration and Cleaning

Proper air filtration is crucial for ensuring the longevity and efficient operation of any outdoor equipment. By maintaining clean airflow, you reduce the risk of engine wear and improve overall performance. Regular cleaning of the air filter and related components is essential to keep the machine running smoothly in various environments.

Importance of Regular Maintenance

Ensuring the air filtration system is well-maintained helps prevent debris and dust from entering the engine. Neglecting this system can lead to clogging, reduced power output, and even permanent damage over time. A clean filter allows the engine to breathe freely, maintaining consistent performance.

- Check the air filter regularly for buildup or blockages.

- Replace the filter as needed, depending on usage frequency and environment.

- Ensure all components are properly sealed to prevent unfiltered air from entering.

Steps for Proper Cleaning

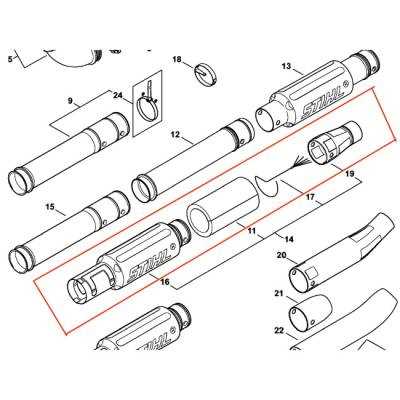

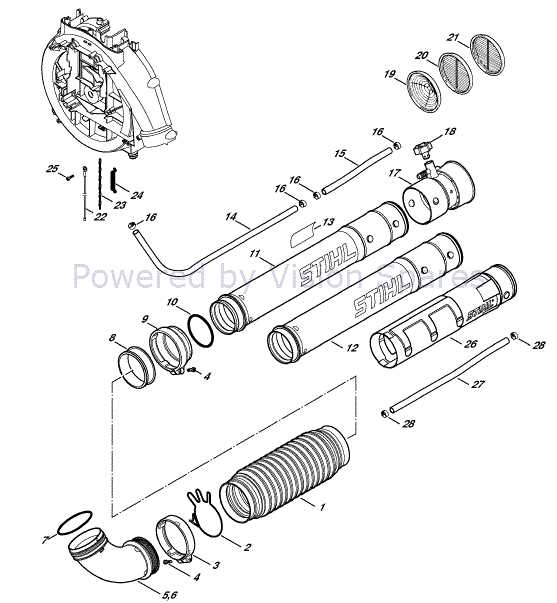

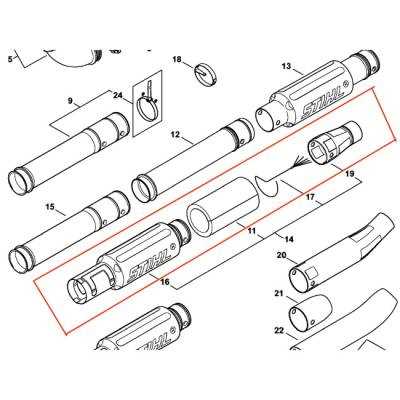

Nozzle Options and Configurations

When it comes to optimizing performance in various applications, selecting the right nozzle is crucial. Different configurations can significantly impact the efficiency and effectiveness of operations. Understanding the available choices allows users to tailor their equipment to specific tasks, enhancing productivity.

Types of Nozzles

There are several types of nozzles available, each designed for particular uses. The choice depends on factors such as spray pattern, flow rate, and the intended application. Below is a table highlighting common nozzle types and their characteristics:

| Nozzle Type |

Application |

Flow Rate |

Spray Pattern |

| Standard Nozzle |

General use |

Variable |

Fan |

| Adjustable Nozzle |

Versatile tasks |

Variable |

Adjustable |

| Flat Fan Nozzle |

Targeted spraying |

Consistent |

Flat fan |

| Conical Nozzle |

Wide coverage |

Higher flow |

Conical |

Choosing the Right Nozzle

Selecting the appropriate nozzle depends on the specific needs of the task at hand. Considerations such as the type of material being applied, the required coverage area, and environmental factors should guide the decision-making process. By carefully evaluating these aspects, users can ensure optimal performance and achieve desired results.

Proper Maintenance for Longevity

Ensuring the durability and efficient operation of your equipment requires regular upkeep and attention. Implementing a systematic maintenance routine can prevent potential issues and extend the life of your device.

Key maintenance practices include:

- Regular Cleaning: Remove debris and residue from all components to avoid buildup that can hinder performance.

- Routine Inspections: Check for signs of wear or damage in essential parts, addressing any concerns promptly.

- Proper Lubrication: Ensure moving parts are adequately lubricated to minimize friction and reduce wear.

- Filter Replacement: Change air and fuel filters as needed to maintain optimal airflow and fuel efficiency.

- Fuel Management: Use high-quality fuel and store it properly to prevent degradation.

By following these guidelines, you can enhance the reliability of your equipment and ensure it performs at its best for years to come.

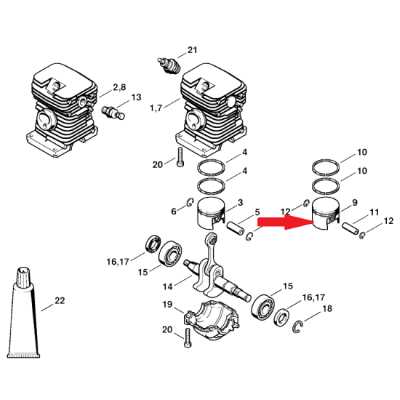

Common Replacement Parts Guide

In any mechanical device, understanding the essential components that may require replacement is crucial for optimal functionality. This guide highlights frequently needed elements that ensure your equipment operates smoothly, extending its lifespan and enhancing performance.

Key Components to Monitor

Regular maintenance often reveals the necessity for specific items to be swapped out due to wear or damage. Familiarizing yourself with these components can help prevent unexpected breakdowns.

| Component |

Function |

Signs of Wear |

| Air Filter |

Filters air entering the engine for combustion. |

Reduced power, excessive smoke. |

| Fuel Filter |

Removes impurities from the fuel before reaching the engine. |

Engine stalling, poor acceleration. |

| Spark Plug |

Ignites the air-fuel mixture within the engine cylinder. |

Hard starting, misfiring. |

| Starter Rope |

Engages the engine to start the device. |

Rope fraying, difficulty starting. |

Tips for Replacement

When replacing components, always refer to your device’s manual for specifications and guidelines. Using genuine parts ensures compatibility and performance, leading to better results in the long run.

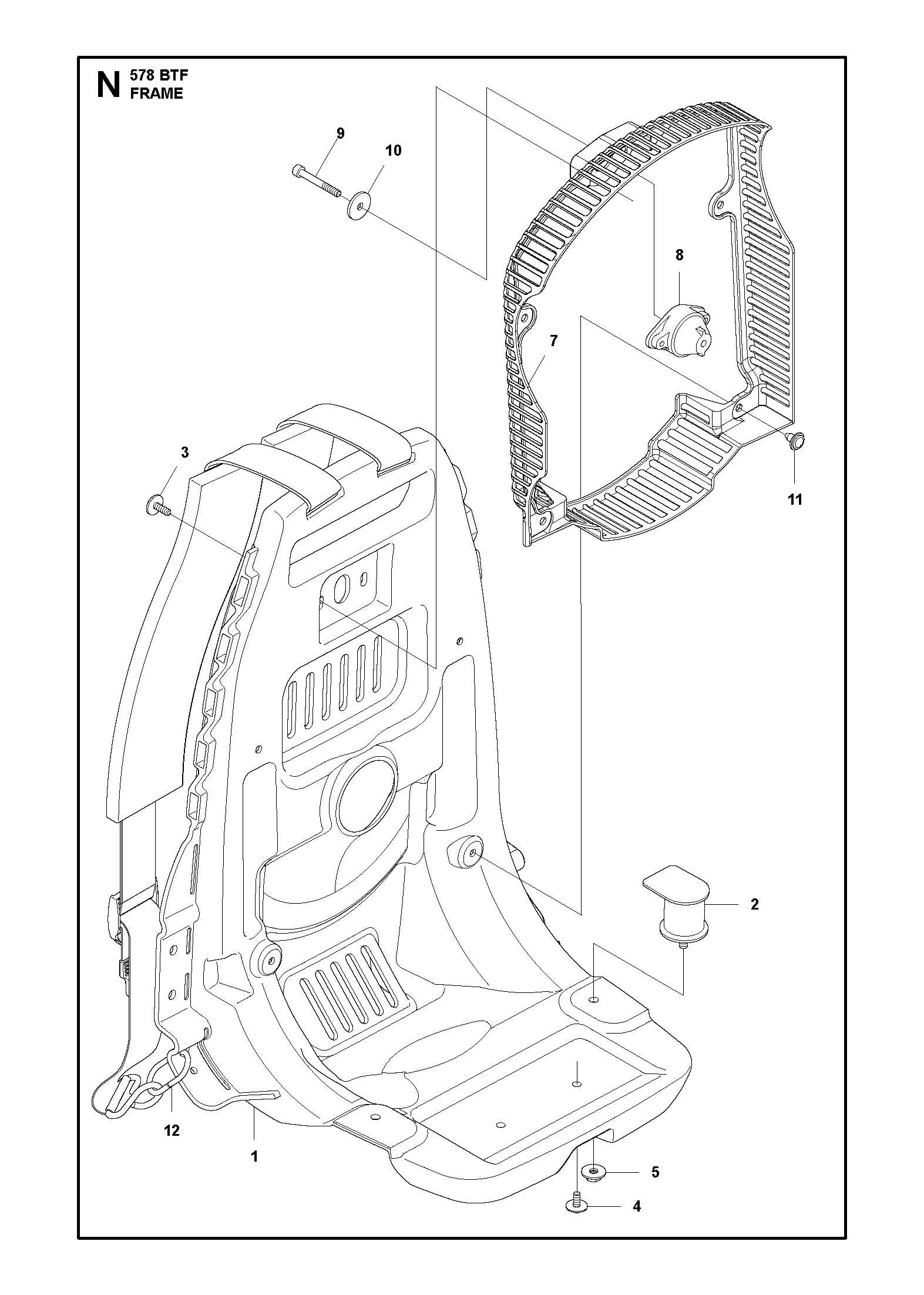

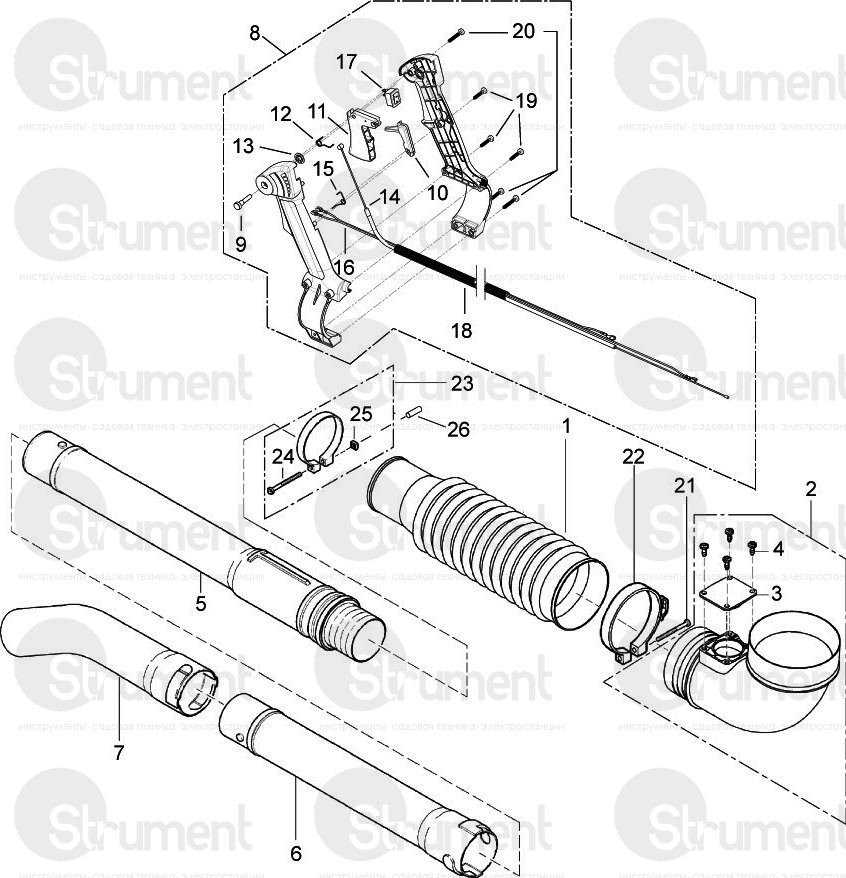

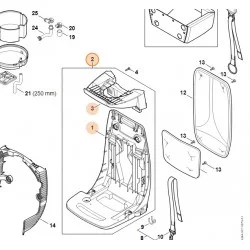

Assembly and Disassembly Tips

Proper techniques for assembling and disassembling machinery are crucial for maintenance and longevity. Understanding the order of operations and the necessary tools can significantly enhance efficiency and prevent damage to components. Below are some helpful suggestions to streamline these processes.

| Step |

Description |

| 1 |

Before starting, ensure all necessary tools are at hand to avoid interruptions during the process. |

| 2 |

Consult the user manual for specific instructions and recommended practices to ensure accuracy. |

| 3 |

Label and organize all components as you disassemble to make reassembly straightforward. |

| 4 |

Work in a clean, well-lit environment to minimize the risk of losing small parts and to promote safety. |

| 5 |

Use the appropriate torque settings when reassembling to avoid over-tightening, which can lead to damage. |

Troubleshooting Common Issues

Maintaining optimal performance in outdoor power equipment often requires addressing frequent problems that may arise during operation. Understanding these common challenges can aid users in diagnosing issues swiftly, ensuring reliable functionality.

One prevalent difficulty is the engine starting issue. If the machinery fails to start, it could be due to a depleted fuel supply or a clogged air filter. Regular checks on these components can prevent operational interruptions.

Another common concern is overheating, which may result from insufficient airflow or a malfunctioning cooling system. Ensuring that vents are clear and that the cooling mechanisms are functioning properly is essential for maintaining safe temperatures during use.

Additionally, users may encounter reduced power output, often linked to worn spark plugs or dirty fuel lines. Replacing these elements promptly can restore the equipment’s efficiency and enhance overall performance.

By systematically addressing these typical issues, users can extend the life of their outdoor equipment and ensure that it operates at peak efficiency.

Upgrades and Compatibility

This section delves into enhancements and the adaptability of components within specific equipment. Understanding the relationship between various parts is essential for optimizing performance and ensuring longevity. When considering upgrades, it’s crucial to assess compatibility with existing features to achieve the desired outcomes.

Enhancing Performance

Implementing advanced features can significantly boost efficiency and functionality. Whether it’s upgrading the engine, improving fuel systems, or integrating cutting-edge technology, these modifications often lead to superior operational capabilities. It’s advisable to consult with experts to identify the most beneficial enhancements tailored to individual needs.

Compatibility Considerations

Before proceeding with any modifications, verifying the compatibility of new components is vital. Using parts designed for a specific model ensures seamless integration and prevents potential issues. Always refer to manufacturer guidelines and recommendations to guarantee that upgrades align with the existing setup.

Using the Correct Tools for Repairs

Ensuring that you have the right tools for maintenance tasks is crucial for achieving optimal results. Using appropriate equipment not only facilitates efficient work but also prevents damage to the device. When engaging in repairs, being well-equipped can make a significant difference in both the process and the outcome.

Essential Tools for Maintenance

To effectively perform repairs, consider investing in a quality set of tools tailored to your needs. Commonly required items include screwdrivers, wrenches, and pliers. Each tool serves a specific purpose, enhancing precision and effectiveness during the repair process. Additionally, utilizing protective gear ensures safety while handling various components.

Organizing Your Workspace

Creating a well-organized workspace is essential for any repair project. Having your tools sorted and easily accessible can save time and reduce frustration. Consider using a toolbox or a designated area to keep everything in order. A clutter-free environment allows for better focus and minimizes the risk of losing important items during repairs.

Safety Features and Guidelines

Ensuring safety during operation is paramount when using any power equipment. Various built-in mechanisms and user protocols are designed to protect the operator and those nearby. Understanding these features is essential for maximizing safety and preventing accidents.

One crucial aspect is the presence of emergency shut-off systems that allow users to quickly halt operations in case of an emergency. Additionally, protective guards are often installed to minimize the risk of injury from moving parts. Operators should also be familiar with the appropriate personal protective equipment (PPE), such as goggles and gloves, to enhance safety during use.

Moreover, proper training and adherence to guidelines are vital for safe operation. Regular maintenance checks should be performed to ensure that safety features are functioning correctly. By following established safety protocols and utilizing available features, users can significantly reduce the likelihood of accidents and injuries.

|