The efficient operation of a cutting machine relies heavily on its intricate assembly of elements. Each component plays a vital role in ensuring the device performs optimally. By gaining insights into the arrangement and functionality of these parts, users can enhance their knowledge and troubleshooting skills, leading to improved maintenance and performance.

Recognizing the layout of the various components can aid in identifying potential issues and facilitating repairs. Whether you are a seasoned technician or a newcomer to machinery, familiarizing yourself with the assembly will empower you to handle your equipment more effectively. Detailed visual representations can serve as invaluable tools in this learning process, providing clarity and guidance.

Ultimately, understanding the configuration of your machine’s elements not only promotes longevity but also enhances overall efficiency. With the right knowledge, users can ensure their equipment remains in peak condition, ready to tackle any task with confidence.

This section provides a comprehensive overview of a specific cutting tool known for its robust design and efficient performance. It highlights the essential features that make this equipment a popular choice among professionals in various fields, including construction and landscaping. Understanding the fundamental aspects of this model helps users appreciate its capabilities and applications in real-world scenarios.

| Feature | Description |

|---|---|

| Engine Type | High-performance two-stroke engine for maximum power output. |

| Weight | Lightweight construction for easy handling and transportation. |

| Blade Size | Compatible with various blade sizes for diverse cutting tasks. |

| Fuel Efficiency | Designed to optimize fuel consumption while delivering superior performance. |

| Durability | Built with high-quality materials to withstand demanding working conditions. |

Essential Components of the Tool

Understanding the critical elements of this cutting device is vital for effective operation and maintenance. Each component plays a significant role in ensuring optimal performance, reliability, and safety. Below is a breakdown of the essential parts that make up this powerful equipment.

- Engine: The heart of the tool, responsible for powering the entire unit.

- Blade: A crucial part for cutting through various materials with precision.

- Fuel Tank: Holds the necessary fuel for operation, affecting performance and runtime.

- Air Filter: Keeps dirt and debris from entering the engine, ensuring longevity and efficiency.

- Starter Mechanism: Facilitates easy ignition, allowing for quick startup and shutdown.

- Handle: Provides user control and comfort during operation, critical for safety.

- Guard: Protects the user from debris and enhances safety while using the tool.

- Throttle Trigger: Allows for precise control over engine speed and cutting power.

Each of these elements is integral to the overall functionality of the equipment. Regular inspection and maintenance of these components can greatly extend the tool’s lifespan and ensure safe usage.

Common Issues with TS400 Parts

When dealing with machinery, users often encounter a range of challenges that can affect performance and efficiency. Understanding these issues is essential for maintaining optimal functionality and ensuring longevity. This section explores frequent problems related to components, highlighting potential causes and solutions.

Wear and Tear

Wear and tear is a prevalent issue affecting various elements. Over time, constant use leads to degradation, resulting in decreased efficiency. Regular inspections can help identify signs of fatigue, allowing for timely replacements and maintaining overall performance.

Improper Installation

Another common concern is improper installation, which can lead to malfunctions and safety hazards. Components must be fitted correctly to ensure seamless operation. It is crucial to follow manufacturer guidelines during assembly and consult professionals if uncertainties arise.

Maintenance Tips for Longevity

To ensure the extended life of your equipment, regular upkeep is essential. Proper maintenance not only enhances performance but also reduces the risk of unexpected failures. By adopting a few simple practices, you can significantly prolong the lifespan of your tools.

Regular Cleaning: Keeping your machinery clean is crucial. After each use, remove dust, debris, and any residue. This prevents wear and tear on components and helps maintain optimal functionality.

Lubrication: Frequent lubrication of moving parts is vital for smooth operation. Use the recommended lubricants to minimize friction and protect against corrosion. Always check for any signs of wear before applying lubricant.

Inspections: Conduct routine inspections to identify potential issues before they escalate. Look for cracks, loose screws, or any abnormalities that might indicate a problem. Early detection can save time and costly repairs.

Follow Manufacturer Guidelines: Adhere to the maintenance schedule provided by the manufacturer. Regular servicing, as specified, ensures your equipment operates efficiently and safely. This includes replacing worn parts and performing necessary adjustments.

By implementing these maintenance tips, you can enjoy reliable performance and longevity from your tools, ensuring they remain effective for years to come.

Identifying Replacement Parts

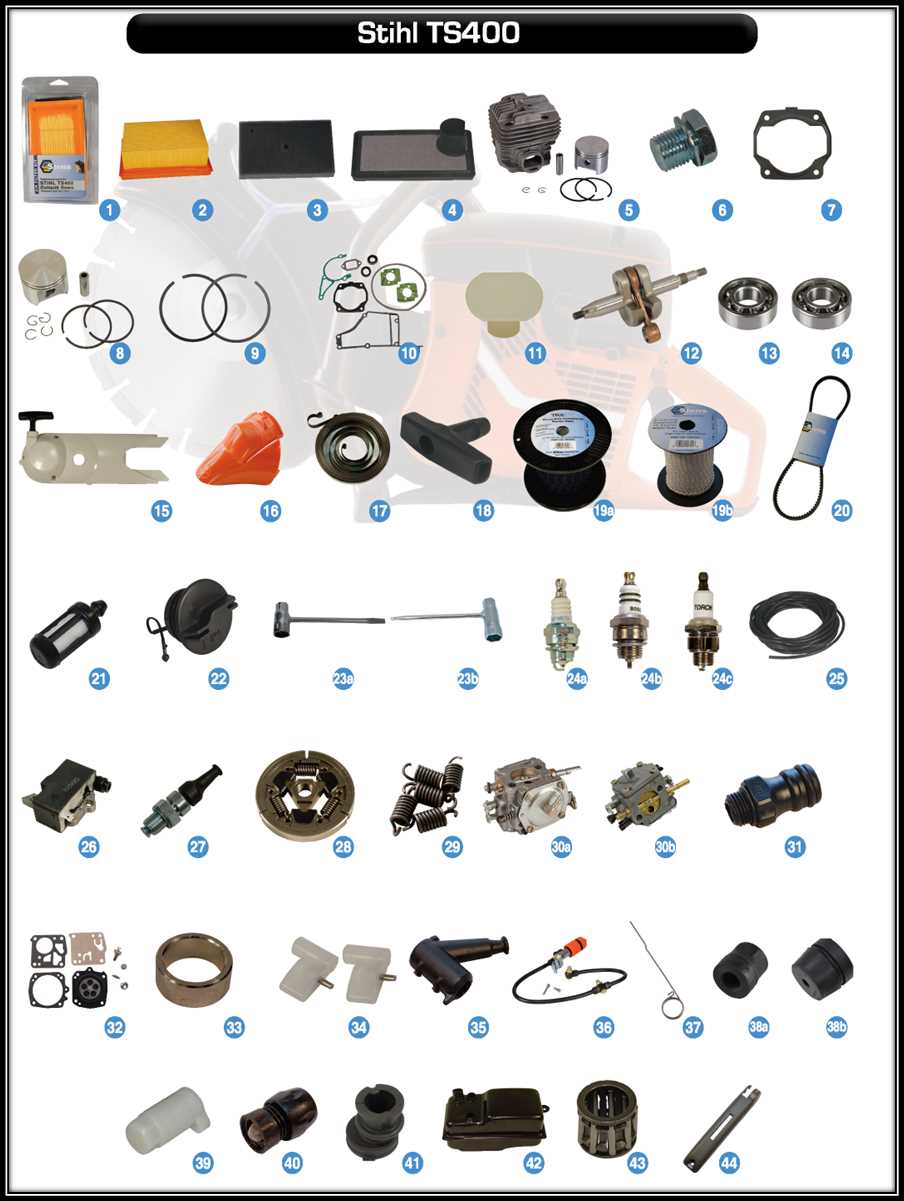

Understanding the components of your equipment is crucial for effective maintenance and repair. Knowing how to recognize and locate the various elements will help you ensure optimal performance and longevity. This section will guide you through the process of identifying necessary replacements, focusing on key features and functions.

Common Components to Recognize

When seeking substitutes, it is important to familiarize yourself with the common components that may require replacement. Recognizing these essential parts will assist you in selecting the appropriate items for your equipment.

| Component | Description | Function |

|---|---|---|

| Blade | Cutting tool used for various tasks | Facilitates effective cutting of materials |

| Handle | Gripping section for user control | Ensures stability and comfort during operation |

| Engine | Power source for the tool | Generates the necessary power for operation |

Steps for Identifying Components

To accurately identify components needing replacement, follow these steps:

- Inspect the equipment for wear or damage.

- Refer to the user manual for a list of components.

- Compare the existing components with available replacements.

- Consult with a professional if uncertain about compatibility.

Where to Purchase TS400 Parts

When seeking components for your cutting tool, it is essential to identify reliable sources that offer quality replacements. Various options exist, from authorized retailers to online platforms, ensuring you find the necessary items efficiently.

Authorized Dealers

Visiting authorized distributors is one of the best ways to ensure you acquire genuine components. These establishments typically have a comprehensive inventory and knowledgeable staff who can assist with any queries.

Online Retailers

Numerous e-commerce websites specialize in outdoor equipment and accessories. These platforms often provide a wider selection and competitive pricing, allowing you to compare options conveniently.

| Source Type | Advantages | Considerations |

|---|---|---|

| Authorized Dealers | Genuine products, expert advice | Potentially higher prices |

| Online Retailers | Wider selection, competitive pricing | Shipping times, varying quality |

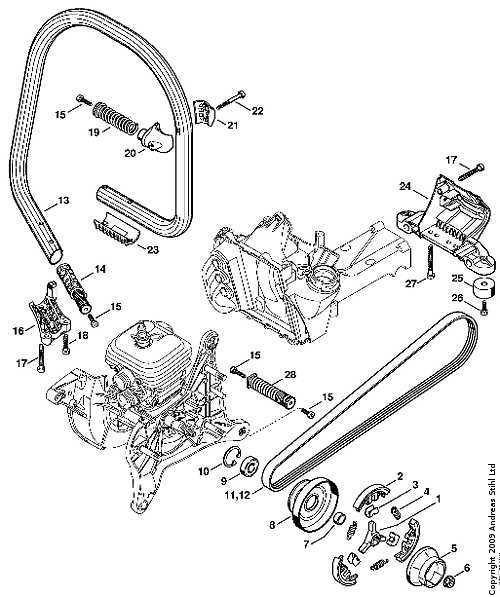

Understanding the Parts Diagram

Comprehending the illustration of components is essential for effective maintenance and repair of equipment. This visual representation serves as a guide, showcasing each individual piece and its relation to others within the system. By familiarizing oneself with this schematic, users can identify necessary replacements and understand the assembly process better.

Importance of Familiarity

Being acquainted with the visual guide enhances troubleshooting skills and enables quicker diagnosis of issues. Recognizing the specific role of each component aids in efficient repairs, minimizing downtime and improving overall functionality.

Utilizing the Visual Reference

When referring to the schematic, it is beneficial to approach it systematically. Start by identifying the main sections, then progressively focus on smaller elements. This methodical analysis fosters a deeper understanding of the machinery’s inner workings and simplifies the repair process.

Safety Precautions While Repairing

Ensuring safety during maintenance work is crucial to prevent accidents and injuries. Whether you are replacing components or conducting routine inspections, following proper safety measures protects both the individual and the equipment. This section outlines essential precautions to take when engaging in repair tasks.

Wear Appropriate Protective Gear

Before starting any repair work, make sure to wear the necessary protective equipment. This includes safety goggles to shield your eyes from debris, gloves to protect your hands from sharp edges, and sturdy footwear to provide support and minimize the risk of slips. Additionally, consider using hearing protection if the equipment generates loud noises during operation.

Work in a Well-Ventilated Area

Perform repairs in a space that offers good ventilation. Proper airflow helps dissipate fumes and dust that may be released during maintenance tasks. If working indoors, ensure windows are open or use exhaust fans to promote circulation. Avoiding enclosed spaces can significantly reduce health risks associated with inhalation of harmful substances.

Always disconnect power sources before beginning any work to avoid accidental activation. By taking these safety measures, you can ensure a more secure and efficient repair process.

Upgrading Parts for Better Performance

Enhancing the functionality of your machinery can lead to significant improvements in efficiency and durability. By selecting high-quality components, you can ensure smoother operation and increased output. Upgrades not only boost performance but also prolong the lifespan of the equipment, making it a worthwhile investment for any user.

Choosing Quality Components

When considering enhancements, it’s crucial to select top-grade materials that meet or exceed manufacturer specifications. Quality components can greatly influence the overall effectiveness of your equipment. Investing in durable parts leads to reduced maintenance and fewer breakdowns, ultimately saving time and resources.

Installation and Maintenance Tips

Proper installation is key to maximizing the benefits of any upgrade. Ensure that all new components are fitted correctly and securely. Regular maintenance is equally important; routinely check for wear and tear to maintain optimal performance. This proactive approach will help you avoid costly repairs and keep your machinery running smoothly.

DIY Repair vs. Professional Service

When it comes to fixing equipment, individuals often face the choice between tackling the task themselves or seeking assistance from a skilled technician. Both options present unique advantages and challenges, influencing the decision based on various factors such as expertise, time, and cost.

Advantages of DIY Repair

One of the main benefits of handling repairs independently is the potential for significant cost savings. By avoiding labor fees, enthusiasts can allocate their budget towards quality components or tools. Additionally, engaging in self-repair can enhance one’s technical skills and foster a sense of accomplishment. For those with experience, tackling straightforward issues can be both rewarding and efficient.

Benefits of Professional Service

Conversely, employing the services of a professional ensures that repairs are executed with expertise and precision. Technicians possess specialized knowledge and experience that can lead to quicker resolutions, particularly for complex issues. This option also eliminates the risk of accidental damage that might arise from inexperience. Ultimately, for individuals with limited time or those uncertain about their repair capabilities, seeking professional help can provide peace of mind.