When it comes to maintaining your machinery, having a clear understanding of its various elements is crucial. This section aims to provide a comprehensive overview of the essential components that contribute to the efficient functioning of your device. Familiarity with these elements can enhance your ability to troubleshoot and perform necessary repairs effectively.

In this guide, you will find detailed information about the individual components, their functions, and how they interconnect within the system. By exploring this information, you can gain valuable insights into the assembly and operational efficiency of your equipment. Whether you are a seasoned technician or a novice user, understanding these components will empower you to take better care of your machinery.

Recognizing components in machinery can be a straightforward process when equipped with the right tools and knowledge. Understanding the various elements of your equipment not only aids in maintenance but also enhances overall efficiency. This guide will provide you with useful strategies to effectively identify the necessary components.

Utilizing Reference Guides

Reference materials are invaluable when it comes to identifying specific components. These resources often include illustrations or lists that clarify the appearance and function of each part. By consulting these guides, users can quickly determine the required elements for repairs or replacements.

Visual Inspection Techniques

A careful visual inspection can yield significant insights into the components of your equipment. Observing color, shape, and size can help distinguish between different elements. It is beneficial to have a basic understanding of how each piece interacts within the machine.

| Characteristic | Observation Tips |

|---|---|

| Color | Note the specific hues to match parts accurately. |

| Shape | Compare with diagrams for proper identification. |

| Size | Measure dimensions to ensure compatibility. |

| Condition | Assess wear and tear to determine replacement needs. |

Maintenance Tips for TS420 Users

Proper upkeep is essential for ensuring the longevity and optimal performance of your equipment. Regular maintenance helps prevent unexpected issues and keeps your machine running smoothly. Here are some effective strategies to enhance the reliability and efficiency of your tool.

Regular Inspection

Conduct frequent checks of your equipment to identify any signs of wear or damage. Pay special attention to critical components that can affect functionality.

| Component | Inspection Frequency | Notes |

|---|---|---|

| Filters | Every Use | Clean or replace as necessary to ensure optimal airflow. |

| Blades | Weekly | Check for sharpness and any signs of chipping. |

| Fuel System | Monthly | Inspect for leaks and ensure fuel quality is maintained. |

Cleaning Procedures

Keeping your equipment clean is crucial for preventing debris build-up, which can impair performance. After each use, wipe down the surfaces and remove any dirt or residue.

Where to Find Replacement Parts

When it comes to maintaining your equipment, locating suitable components is crucial for ensuring optimal performance and longevity. Various sources are available for acquiring the necessary items, whether you are making repairs or performing routine maintenance.

Online Retailers

The internet offers a vast selection of suppliers, allowing you to browse and compare options from the comfort of your home. Here are some reliable online sources:

- Dedicated tool and equipment websites

- General e-commerce platforms

- Manufacturer’s official site

- Specialty retailers focused on outdoor equipment

Local Stores

If you prefer to see the items in person, consider visiting physical shops. These places often carry a range of components and can provide expert advice. Look for:

- Hardware stores

- Home improvement centers

- Local dealers that specialize in equipment

- Repair shops that offer replacement items

By exploring these options, you can find the right components to keep your machinery running smoothly.

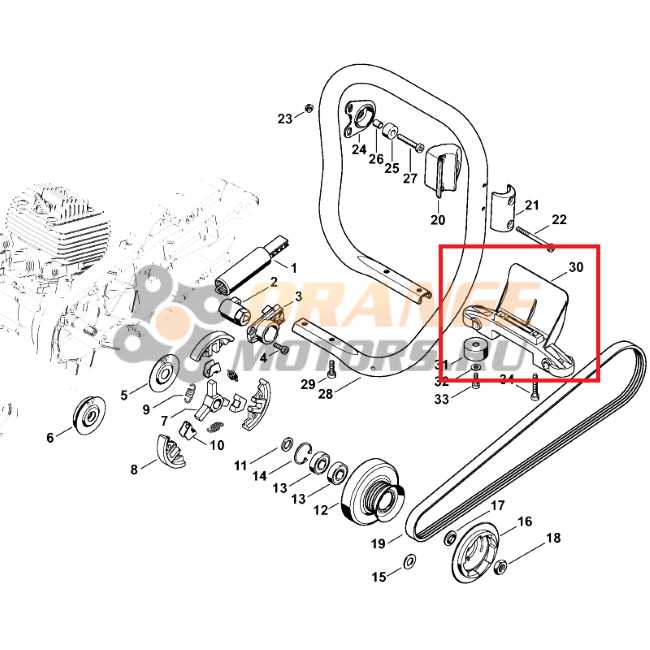

Understanding the TS420 Engine Layout

The arrangement of components within a power tool engine is crucial for its performance and efficiency. A well-structured layout not only enhances functionality but also simplifies maintenance and repairs. This section delves into the key features of a specific engine design, focusing on how its elements work together to provide optimal power and reliability.

Key Components of the Engine

Each part of the engine plays a vital role in its operation. Understanding the significance of these components helps users appreciate the engineering behind effective machinery. Below is a table summarizing the essential elements and their functions:

| Component | Function |

|---|---|

| Cylinder | Houses the piston and facilitates combustion. |

| Piston | Converts fuel energy into mechanical power. |

| Crankshaft | Transfers motion from the piston to the output. |

| Carburetor | Mixes air and fuel for combustion. |

| Ignition System | Initiates the combustion process. |

Benefits of a Well-Designed Layout

A thoughtful arrangement of engine parts leads to improved efficiency and reduced wear over time. By ensuring that components are positioned for optimal airflow and ease of access, manufacturers enhance the tool’s longevity and user experience. Understanding these principles is essential for both operators and technicians when servicing or operating the equipment.

Benefits of Using Original Parts

Utilizing authentic components in your machinery offers numerous advantages that enhance performance and longevity. These original items are specifically designed to meet the exact specifications of the equipment, ensuring optimal functionality and reliability.

One significant benefit is the assurance of quality. Genuine components undergo rigorous testing and adhere to strict manufacturing standards, which reduces the risk of malfunctions and costly repairs. Additionally, using original parts can improve safety, as they are crafted to fit seamlessly within the system, minimizing the chances of operational failures.

Moreover, selecting authentic items often results in better efficiency. They work harmoniously with other machine elements, leading to smoother operations and increased productivity. This compatibility can also prolong the life of your equipment, as original parts are built to endure the demands of heavy use.

| Advantages | Description |

|---|---|

| Quality Assurance | Manufactured to high standards, ensuring reliability. |

| Safety | Designed for proper fit, reducing the risk of failures. |

| Enhanced Efficiency | Improves overall performance and productivity. |

| Longevity | Contributes to the extended life of the machinery. |

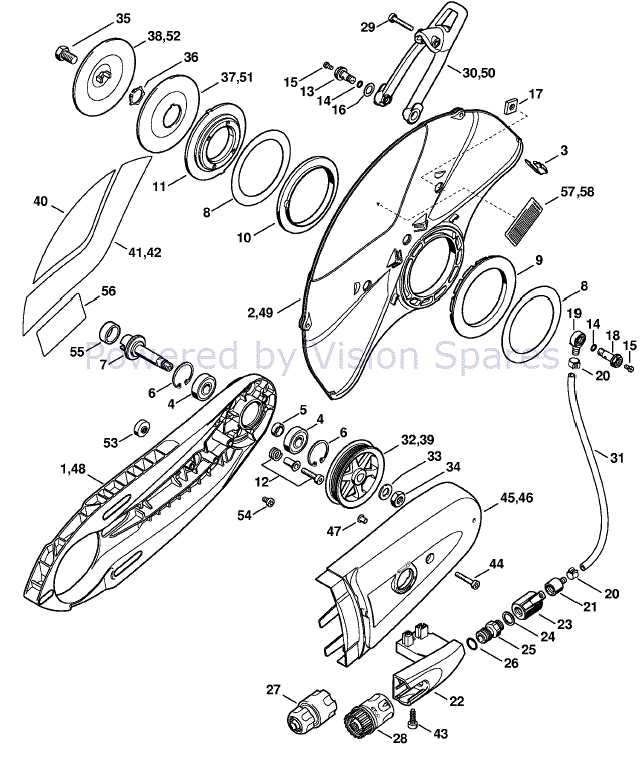

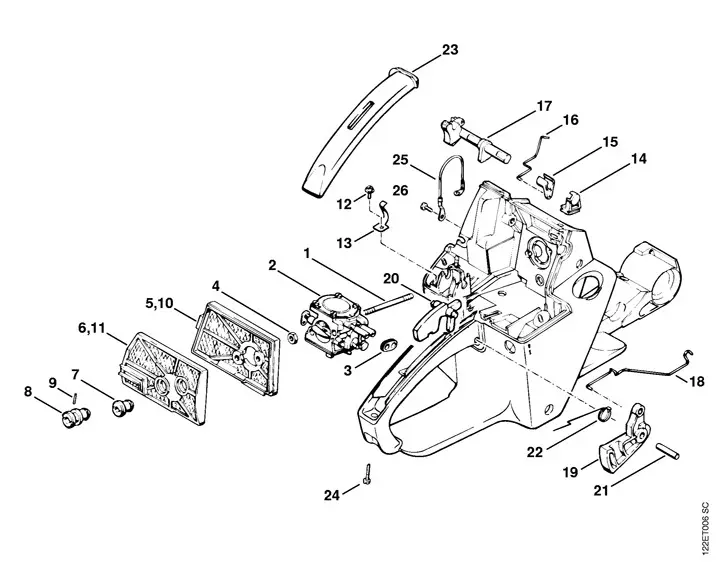

Detailed Parts Breakdown for TS420

This section provides a comprehensive overview of the various components that make up the machine, offering insights into their functions and interconnections. Understanding these elements is crucial for maintenance and troubleshooting, ensuring optimal performance during use.

Each segment of the equipment is meticulously crafted to fulfill specific roles, contributing to the overall efficiency and effectiveness. Key elements include the cutting mechanism, which plays a vital role in its operation, and the engine assembly, which powers the entire system.

Key Components:

- Cutting Blade: Essential for achieving precise cuts, designed to withstand high levels of wear.

- Drive Shaft: Transmits power from the engine to the cutting tool, ensuring smooth operation.

- Fuel System: Manages the delivery of fuel to the engine, crucial for optimal performance.

- Cooling System: Prevents overheating, maintaining the equipment’s longevity and reliability.

By familiarizing oneself with these individual elements, operators can ensure better upkeep and address any potential issues that may arise during operation. This understanding fosters a proactive approach to maintenance, ultimately enhancing the user’s experience.

Safety Precautions When Repairing

When undertaking any maintenance or repair tasks on machinery, prioritizing safety is essential. Proper precautions help to prevent accidents and ensure a smooth working process. Understanding the risks involved and preparing adequately can make a significant difference in the overall safety of the operation.

Essential Safety Gear

- Protective Eyewear: Always wear safety goggles to shield your eyes from flying debris.

- Gloves: Use sturdy gloves to protect your hands from sharp edges and chemical exposure.

- Hearing Protection: If working with loud equipment, earplugs or earmuffs can help prevent hearing damage.

- Non-Slip Footwear: Wear appropriate shoes to maintain traction and prevent slips in potentially hazardous areas.

Work Environment Safety

- Clean Workspace: Ensure that the area is free from clutter and obstacles that could pose tripping hazards.

- Proper Lighting: Adequate lighting is crucial to see clearly and avoid accidents.

- Ventilation: Work in a well-ventilated space to minimize exposure to fumes and harmful substances.

- Emergency Equipment: Keep a first aid kit and fire extinguisher nearby, readily accessible in case of emergencies.