When it comes to ensuring the optimal performance of your outdoor equipment, understanding how its components function together is essential. The layout of various mechanical elements plays a crucial role in maintaining smooth operation. A detailed breakdown can significantly simplify the process of upkeep and repairs, allowing users to quickly identify and address any issues that arise over time.

In this guide, we delve into the specifics of a popular tool used for landscaping tasks. By examining the setup of key elements, you’ll be equipped with the knowledge needed to handle repairs and routine care with greater efficiency. Whether you’re looking to replace a single element or conduct more extensive maintenance, having a clear layout ensures a hassle-free experience.

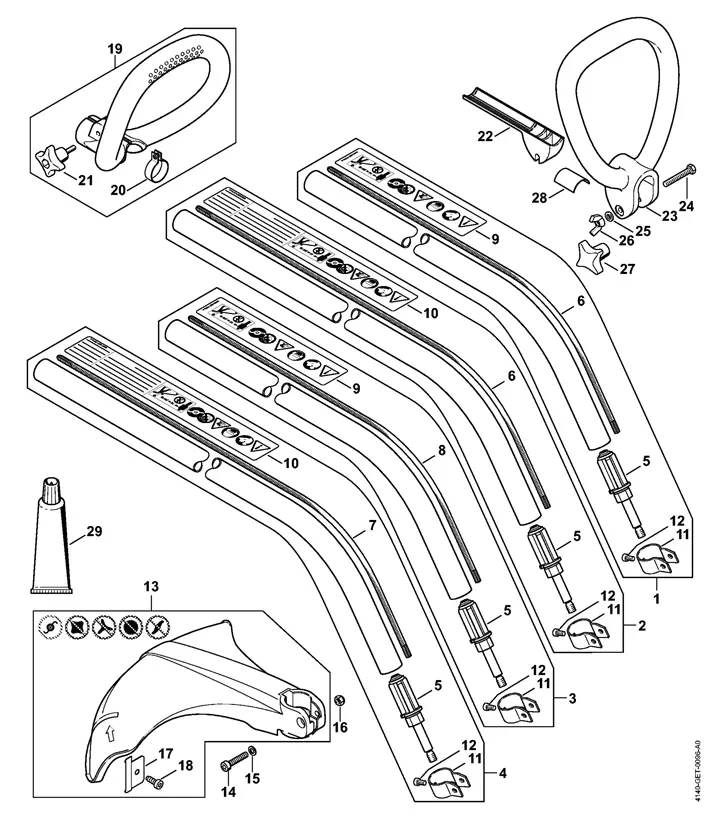

Understanding the Components of Stihl FS 56 RC

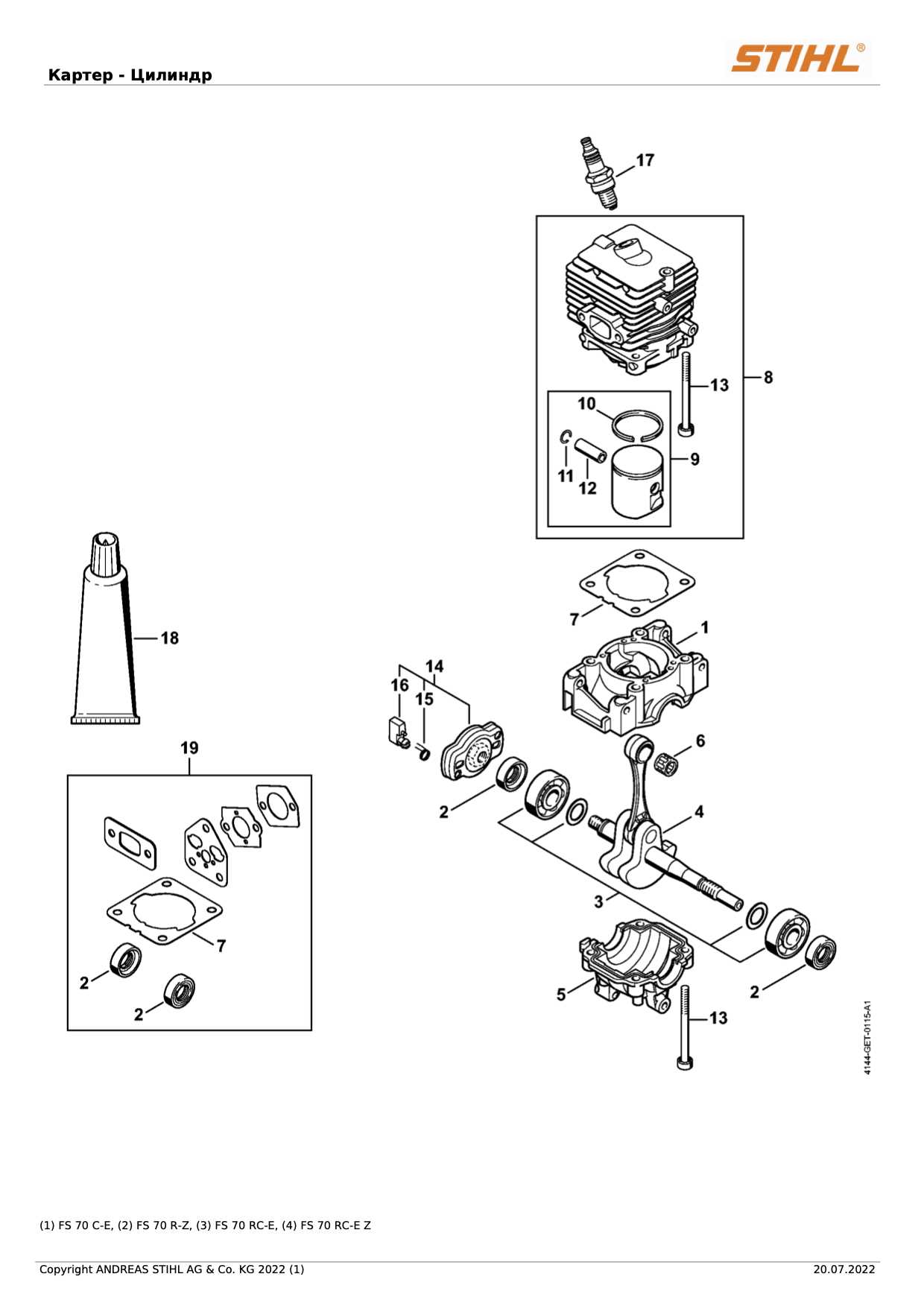

When exploring the mechanical structure of this model, it is essential to familiarize oneself with the different parts that make the equipment function smoothly. Each element, from the engine to the cutting mechanism, plays a vital role in ensuring efficiency and long-lasting performance. Proper understanding of these elements allows for better maintenance and handling, ultimately prolonging the lifespan of the equipment.

Engine and Power System

The heart of the device lies in its power source. The engine provides the necessary force to drive the cutting unit, with fuel combustion and air regulation working together for optimal performance. Key components like the fuel tank

How to Access a Parts Diagram

When it comes to repairing or maintaining equipment, one of the most important resources is having a clear visual reference to locate components. A detailed illustration of the mechanical layout can be crucial for identifying elements and ensuring proper replacement.

Where to Find the Right Visual Resources

To locate the appropriate schematics, you can explore a few different approaches. Many manufacturers offer downloadable guides or instructional materials directly on their websites. These typically include step-by-step breakdowns of the internal configuration, making it easier to understand how each component fits into the system.

- Visit the manufacturer’s official website and search for your model.

Key Maintenance Tips for Your Trimmer

Proper care and regular upkeep are essential for ensuring the longevity and performance of your outdoor tool. Consistent attention to its various components will not only keep it operating smoothly but also prevent common issues that arise from neglect or misuse.

Clean the air filter regularly: A blocked air filter can reduce efficiency and put strain on the engine. It’s important to inspect and clean it frequently, especially after extended use, to avoid dirt buildup.

Check the fuel system: Make sure to monitor the fuel level and quality, replacing any old or contaminated fuel. Stale gasoline can affect the motor’s function and lead to starting difficulties.

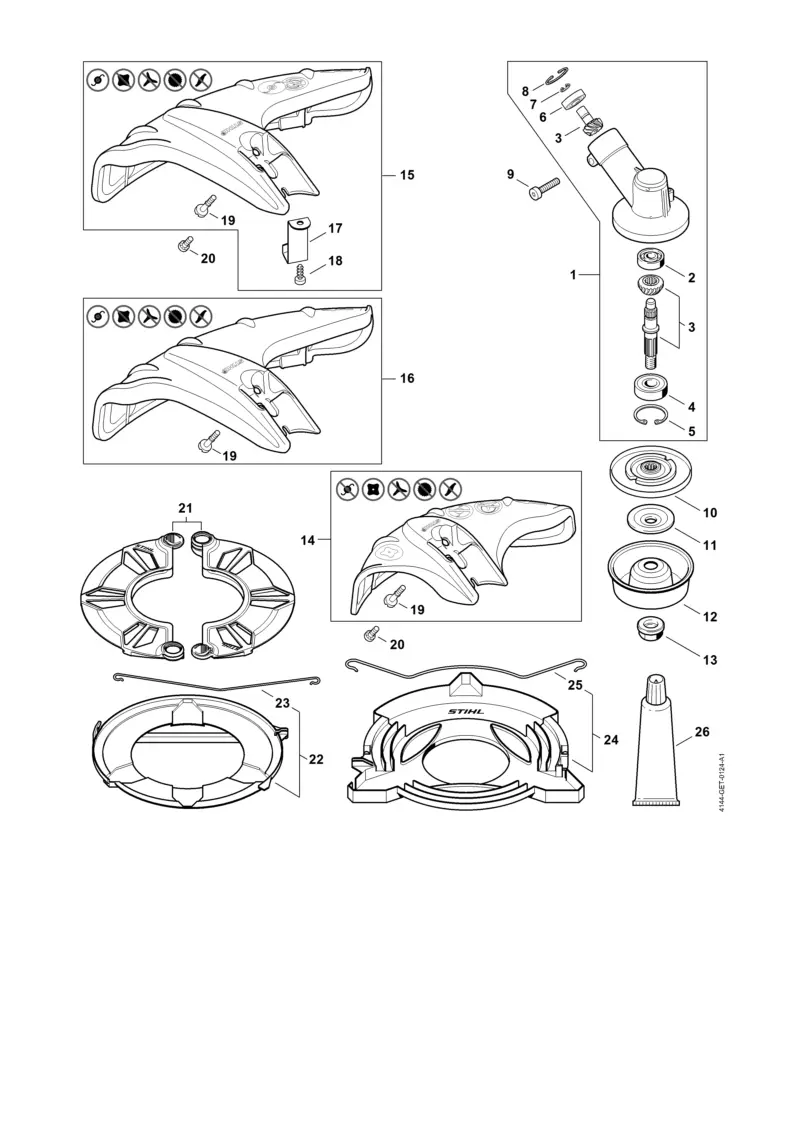

Replacing the Cutting Head Assembly

Over time, the cutting tool at the bottom of the machine may wear out or become damaged, requiring a replacement to maintain optimal performance. Replacing this component is a relatively simple process that can be done with basic tools. Below is a step-by-step guide to ensure a smooth replacement.

- Turn off the engine: Before starting, make sure the machine is fully powered off and cool to prevent any accidents.

- Remove the old assembly: Locate the fastener securing the current tool. Use a wrench or screwdriver to loosen it, and carefully remove the damaged component.

- Best Practices for Fuel System Care

Proper maintenance of the equipment’s fuel system is essential to ensure its longevity and optimal performance. Regular care can prevent issues related to engine efficiency, fuel consumption, and long-term wear. A well-maintained system helps avoid breakdowns and costly repairs by ensuring smooth operation under various conditions.

One key aspect of care is to always use the recommended type and quality of fuel. Poor-quality fuel can lead to clogs and inefficiencies, affecting the equipment’s overall functionality. It’s also important to mix the fuel with the right additives to keep the system clean and reduce the buildup of harmful deposits.

Periodic inspection of the fuel filter is another crucial step. A dirty or clogged filter can restrict the

Identifying Wear on the Drive Shaft

Regular maintenance of the mechanical system is essential for ensuring optimal performance and longevity. One crucial component that requires attention is the drive shaft, as it plays a vital role in transferring power. Over time, this component can experience wear, leading to decreased efficiency and potential failure. Understanding how to identify signs of wear can help users address issues before they escalate.

Common Signs of Wear

- Visual Inspection: Look for cracks, bends, or any unusual deformation.

- Increased Vibration: Noticeable vibrations during operation may indicate imbalance or wear.

- Noise: Unusual sounds, such as grinding or rattling, can signal problems within the system.

Assessment Techniques

- Check for Play: Gently move the shaft to detect any excessive movement that shouldn’t be present.

- Lubrication Inspection: Ensure that the shaft is adequately lubricated; lack of lubrication can accelerate wear.

- Professional Evaluation: If unsure, consult a technician to perform a detailed inspection.

Guide to Air Filter Replacement

Maintaining optimal performance of your outdoor equipment is crucial for its longevity and efficiency. One key aspect of this upkeep involves regularly changing the air filtration component, which prevents debris and dirt from entering the engine. A clean filter ensures proper airflow, enhances fuel efficiency, and ultimately prolongs the life of your machine.

Step 1: Begin by gathering the necessary tools, which typically include a screwdriver and a clean, dry cloth. Make sure your equipment is powered off and cool to touch to avoid any accidents.

Step 2: Locate the air filtration system. This is usually housed near the engine and may require the removal of a cover. Carefully unscrew or unclip the cover to expose the filter.

Step 3: Remove the old filtration element by gently pulling it out. Inspect it for any signs of damage or excessive dirt. If it appears worn, replacing it is essential.

Step 4: Before installing a new filter, clean the housing with a dry cloth to remove any residual dust or debris. Ensure that the new component fits snugly in its designated space.

Step 5: Reattach the cover securely to prevent any contaminants from entering the system. Make sure all screws or clips are fastened properly.

Following these steps will help maintain the efficiency of your equipment, ensuring it operates smoothly and effectively for years to come. Regular inspections and replacements of the air filtration system are recommended to keep your machinery in top condition.

Optimal Use of the Throttle System

The efficient operation of a motorized tool greatly depends on the effective utilization of its acceleration control mechanism. Understanding how to properly engage this system enhances both performance and fuel efficiency, allowing users to achieve their tasks with greater ease and effectiveness. Mastery of this feature is essential for maintaining the longevity of the equipment while also ensuring safety during operation.

To maximize performance, it is crucial to recognize the relationship between throttle engagement and power output. Users should aim for a smooth transition when activating the control, as abrupt movements can lead to unnecessary strain on the engine and may affect cutting performance.

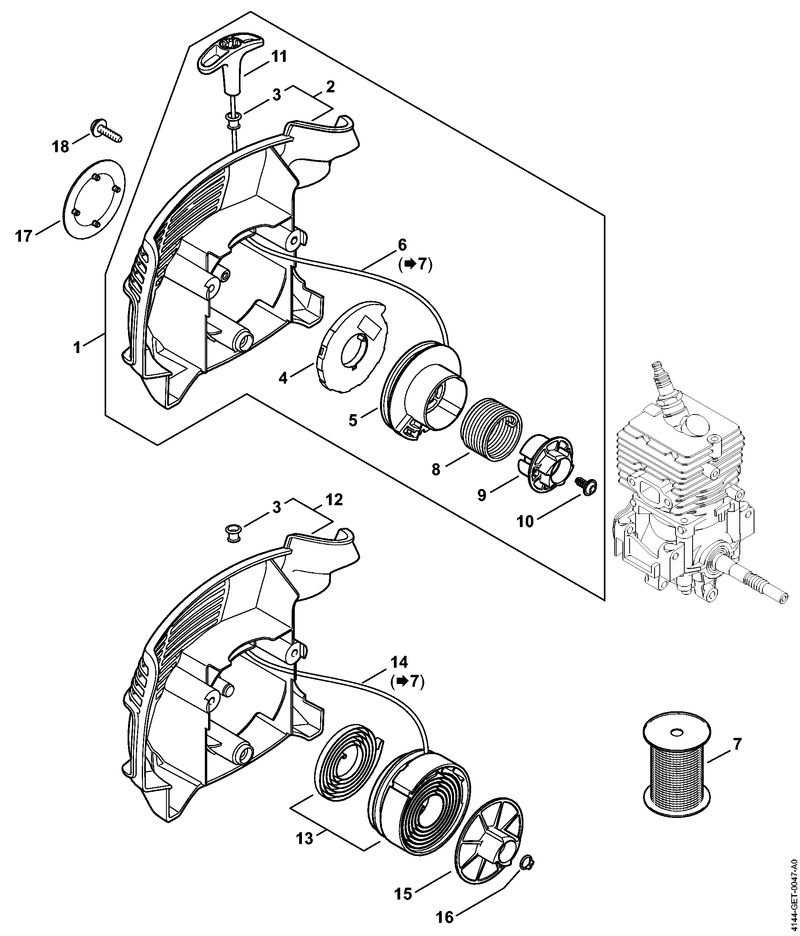

Tip Description Gradual Acceleration Slowly increase throttle to reach optimal power without sudden jumps that can disrupt tool operation. Consistent Pressure Maintain a steady hand on the control for even cutting, preventing uneven wear on the blade. Throttle Release Release the control gradually when finishing, allowing the engine to idle smoothly and reducing wear. Regular Maintenance Check the throttle system regularly to ensure it operates smoothly, avoiding any hindrances during use. Troubleshooting Common Starter Issues

Starting difficulties can often be a frustrating experience when attempting to operate your equipment. Identifying and resolving these problems is essential for maintaining optimal performance. In this section, we will explore the common challenges that users may encounter with the ignition system and provide helpful solutions to get your device running smoothly again.

1. Insufficient Fuel Supply

One of the primary reasons for starting issues is a lack of fuel reaching the engine. Ensure that the fuel tank is adequately filled with the appropriate mixture. If necessary, inspect the fuel lines for any blockages or leaks that may prevent proper flow.

2. Clogged Air Filter

An obstructed air filter can restrict airflow, making it difficult for the engine to draw in the necessary air for combustion. Regularly check and clean or replace the air filter to maintain efficient operation.

3. Spark Plug Problems

The spark plug plays a crucial role in igniting the fuel-air mixture. If it is dirty, worn, or improperly gapped, it may not create a sufficient spark. Remove the spark plug for inspection and replace it if necessary, ensuring proper installation for reliable ignition.

4. Faulty Starter Mechanism

If the starter mechanism is malfunctioning, it may not engage correctly when you attempt to start the machine. Check for any visible damage or wear, and ensure all components are functioning properly. Lubrication may also help in restoring smooth operation.

5. Battery Issues

If your equipment utilizes a battery, ensure it is charged and in good condition. A weak or dead battery will prevent the starter from functioning. Regular maintenance of the battery terminals can also prevent connection issues.

By systematically addressing these common issues, you can enhance the reliability of your device and enjoy a seamless experience in your outdoor tasks.

Choosing the Right Replacement Parts

When maintaining outdoor equipment, selecting the appropriate components is crucial for optimal performance and longevity. Understanding how to identify quality alternatives can significantly impact the efficiency of your device. Making informed decisions will not only enhance functionality but also ensure safety during operation.

Quality Matters: Always prioritize high-grade materials over cheaper options. Reliable components tend to perform better and last longer, reducing the need for frequent replacements.

Compatibility: Verify that the new components are designed to work seamlessly with your specific model. Using incompatible alternatives can lead to malfunctions and costly damage.

Manufacturer Recommendations: Consulting the manufacturer’s guidelines can provide valuable insights. They often specify the most effective replacements and their expected lifespan, helping you make a well-informed choice.

Cost-Effectiveness: While it may be tempting to opt for lower-priced alternatives, consider the overall value. Investing in quality replacements can save money in the long run by reducing the frequency of purchases and improving efficiency.

By focusing on these key factors, you can confidently select suitable components that will keep your equipment running smoothly for years to come.

Safety Precautions for Trimmer Operation

Ensuring safety during operation is crucial to prevent accidents and injuries. Proper precautions and awareness can significantly reduce risks associated with using this type of equipment. Following essential guidelines will help maintain a safe working environment and promote effective use.

Before commencing any work, it’s vital to inspect the equipment for any damage or wear. Ensure that all components are secure and functioning correctly. Protective gear should always be worn, including gloves, eye protection, and appropriate footwear to shield against debris.

Precaution Description Read the Manual Familiarize yourself with the manufacturer’s instructions to understand operational limits and safety features. Clear the Area Remove any obstacles or hazards in the working vicinity to prevent accidents during operation. Avoid Distractions Stay focused while operating the equipment and avoid multitasking or engaging in conversations that may divert your attention. Work in Daylight Whenever possible, perform tasks during daylight hours for better visibility and awareness of surroundings. Keep Others at a Distance Ensure that bystanders, especially children and pets, are at a safe distance while working. By adhering to these safety measures, operators can effectively minimize risks and enhance their overall experience while using the equipment. Remember that safety is a continuous practice that requires vigilance and responsibility.

How to Download PDF Diagrams Easily

Accessing visual guides and instructional materials can significantly enhance your understanding of equipment and tools. These resources often provide clear illustrations, making it simpler to identify components and comprehend their functionalities. Here are some effective methods to obtain such documents swiftly.

Utilizing Manufacturer Websites

Many manufacturers offer downloadable resources directly on their official sites. These are often the most reliable and up-to-date sources. Follow these steps to navigate:

Step Description 1 Visit the manufacturer’s website. 2 Search for the model or type of equipment. 3 Look for a section dedicated to resources or support. 4 Select the appropriate link to download the desired material. Exploring Online Forums and Communities

Online platforms dedicated to enthusiasts and professionals often share valuable documents. Engaging with these communities can lead to discovering various resources shared by other users. To effectively find what you need:

Step Description 1 Join forums related to your equipment or industry. 2 Use the search function to look for shared documents. 3 Post requests if you cannot find the specific resource.