This section aims to provide a comprehensive guide to the essential elements of a 20 hp engine, focusing on its structure and functionality. Understanding these components is crucial for effective maintenance and troubleshooting, enabling users to maximize performance and longevity.

In this overview, we will delve into the various components that contribute to the engine’s operation. Each element plays a vital role, from the ignition system to the fuel delivery mechanisms. Gaining insight into these critical aspects will enhance your ability to perform repairs and modifications efficiently.

Whether you are a seasoned technician or a novice enthusiast, familiarizing yourself with the engine’s assembly will empower you to make informed decisions regarding its upkeep. This knowledge can significantly reduce downtime and improve overall efficiency in various applications.

This section aims to provide insights into a specific category of small power sources commonly used in various machinery. These engines are known for their durability, efficiency, and wide applications, making them a popular choice among users seeking reliable performance. Understanding the fundamental components that comprise these engines can enhance maintenance practices and prolong their operational lifespan.

Key Features of These Power Sources

- Robust design that withstands harsh conditions

- High power-to-weight ratio for enhanced maneuverability

- Versatile applications across multiple types of equipment

Common Components to Recognize

- Cylinder head

- Piston assembly

- Crankshaft

- Fuel system

- Ignition components

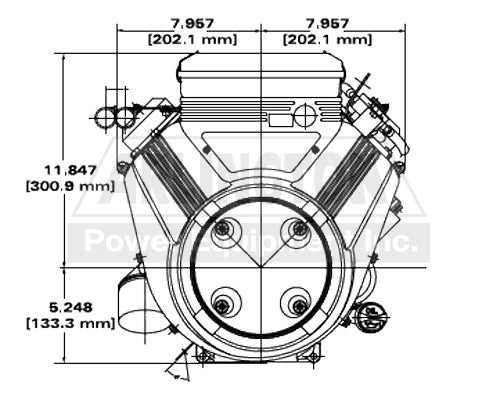

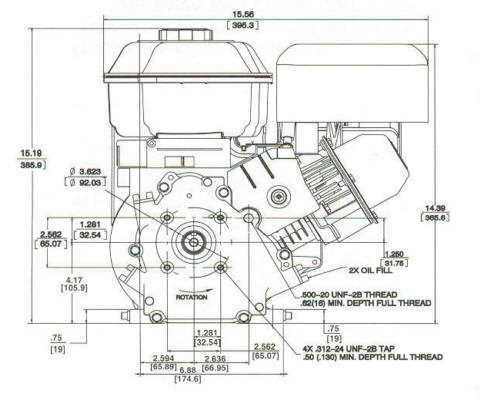

Key Components of 20 HP Models

The functionality and efficiency of 20 horsepower engines depend on several crucial elements that work together seamlessly. Understanding these vital components is essential for effective maintenance and optimal performance, ensuring that the engine operates at its best under various conditions.

Essential Elements

Among the main components, one can find the fuel delivery system, ignition assembly, and cooling mechanisms. Each of these parts plays a significant role in ensuring that the engine runs smoothly and reliably. Proper knowledge of their functions aids in troubleshooting and repair efforts, making it easier to address any issues that may arise.

Component Overview

| Component | Function |

|---|---|

| Fuel Pump | Delivers fuel to the combustion chamber. |

| Ignition Coil | Generates electrical spark for ignition. |

| Cylinder Head | Houses the valves and combustion chamber. |

| Crankshaft | Converts linear motion into rotational energy. |

| Air Filter | Prevents debris from entering the engine. |

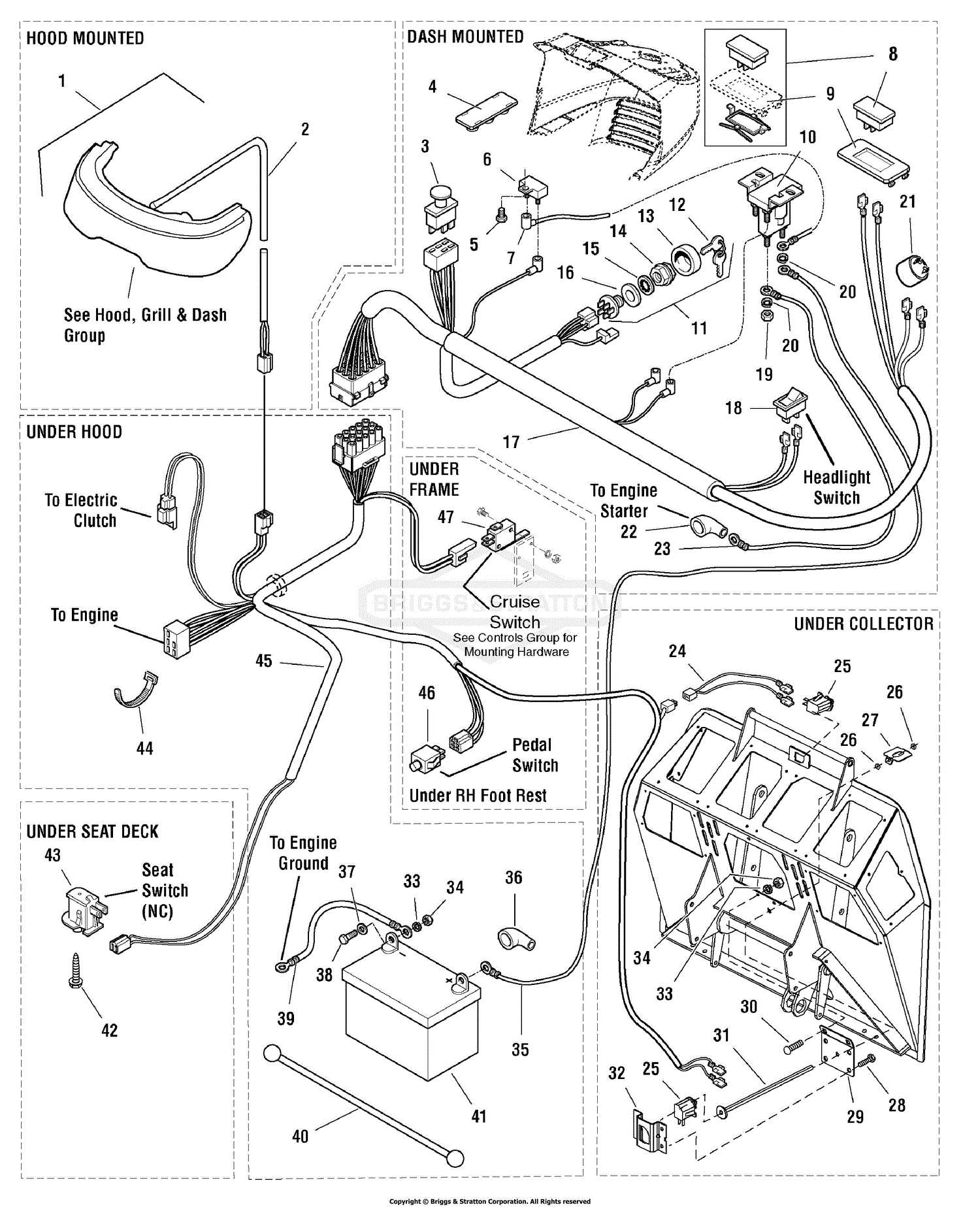

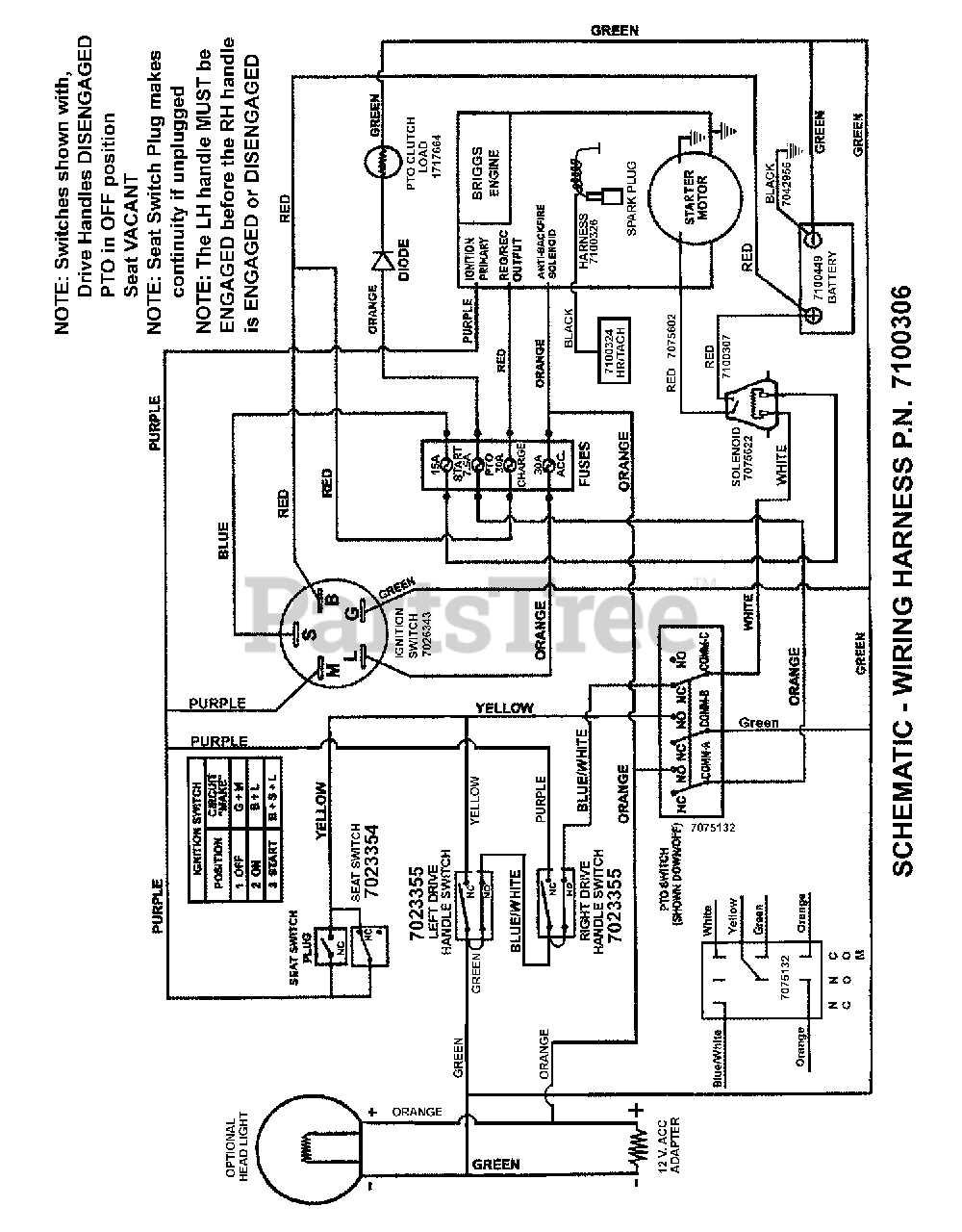

Understanding Engine Diagrams

Engine schematics serve as valuable tools for visualizing the complex interconnections and functions within a motor. These illustrations provide insight into various components, their placements, and how they work together to ensure optimal performance.

By examining these representations, users can gain a clearer understanding of the following:

- Component identification: Recognizing each element and its specific role within the system.

- Assembly process: Grasping how different pieces fit together and their order of installation.

- Troubleshooting: Identifying potential issues by visualizing the relationships between parts.

- Maintenance: Knowing where to focus efforts for upkeep and repair.

Familiarity with these schematics enhances both user experience and mechanical knowledge, allowing for more informed decisions during repair or assembly tasks.

Importance of Accurate Part Identification

Identifying components accurately is crucial for ensuring optimal performance and longevity of machinery. A precise understanding of each element’s role and specifications allows for better maintenance and repair practices, ultimately saving time and resources.

Benefits of Accurate Component Identification

- Enhanced Performance: Knowing the correct specifications leads to improved functionality.

- Reduced Downtime: Quick and accurate identification minimizes the time spent on repairs.

- Cost-Effective Repairs: Proper identification helps in sourcing the right replacements, avoiding unnecessary expenses.

Consequences of Misidentification

- Incorrect replacements can lead to operational failures.

- Potential damage to other components may occur due to incompatible parts.

- Increased repair costs result from repeated attempts to fix issues caused by misidentified elements.

Common Maintenance Practices for Longevity

Regular upkeep is essential for ensuring the extended lifespan of any engine. By adhering to simple maintenance routines, users can prevent common issues, enhance performance, and ensure reliable operation over time. Proper attention to maintenance can significantly reduce the risk of costly repairs, ultimately preserving the integrity of the machinery.

Routine Oil Changes

Changing the oil at regular intervals is crucial for optimal functioning. Fresh oil lubricates internal components effectively, reducing friction and preventing wear. It is advisable to follow the manufacturer’s guidelines regarding the type and frequency of oil changes to maintain peak performance.

Air Filter Inspection

Maintaining a clean air filter is vital for optimal airflow and engine efficiency. A clogged filter can restrict air intake, leading to performance issues and increased fuel consumption. Regularly inspecting and replacing the air filter, when necessary, will promote better combustion and prolong the life of the engine.

In summary, consistent maintenance practices are the key to ensuring durability and efficient operation. By investing time in simple tasks like oil changes and air filter checks, users can significantly enhance the longevity of their equipment.

Identifying Wear and Tear Signs

Recognizing signs of deterioration is crucial for maintaining optimal performance and prolonging the lifespan of your engine. Regular inspections can help identify issues before they escalate into major problems, ensuring that your equipment operates efficiently.

Common indicators of wear include unusual noises, vibrations, and leaks. Pay attention to any changes in sound, as they may signal internal damage or component failure. Additionally, check for excess movement or shaking, which can indicate that parts are worn or misaligned. Fluid leaks can also suggest that seals or gaskets are compromised and may require replacement.

Another sign to monitor is decreased performance. If you notice a drop in power or efficiency, it may be time to investigate further. Regular maintenance and timely identification of these signs will contribute to the longevity and reliability of your engine.

Replacement Parts: Where to Find Them

When maintaining small engines, sourcing the right components is crucial for optimal performance. Whether you’re looking for specific items or general replacements, various options are available to help you keep your machinery running smoothly.

One of the most reliable sources for these components is authorized dealers, who can provide genuine replacements tailored to your engine’s model. Additionally, local hardware stores often stock essential supplies, making it convenient to find what you need.

Online retailers have become increasingly popular, offering a vast selection of components with the added benefit of home delivery. Websites specializing in engine parts often provide detailed descriptions, ensuring you select the correct items for your repair needs.

Another option includes salvage yards, where you might discover used components at a fraction of the original cost. These venues can be particularly beneficial for those looking for hard-to-find items, though it’s essential to verify the condition before purchase.

Lastly, forums and community groups dedicated to engine maintenance can be valuable resources. Engaging with fellow enthusiasts can lead to recommendations for trustworthy suppliers and insights on where to locate specific components.

Step-by-Step Assembly Instructions

This section provides a detailed guide for assembling the engine components efficiently. By following these sequential steps, you can ensure a smooth assembly process, which contributes to the overall performance and longevity of the machinery.

Preparation Before Assembly

Before starting the assembly, gather all necessary tools and components. Ensure that you have a clean workspace to avoid losing any small parts. Reviewing the components involved will help familiarize you with each item’s function, which is essential for effective assembly.

Assembly Steps

Begin by securing the base component to ensure stability. Next, carefully position the engine block, aligning it with the pre-drilled holes. Utilize screws or bolts to fasten each component securely, checking for proper alignment as you proceed. Pay attention to any specific torque specifications to avoid damage. After attaching all major components, conduct a thorough inspection to confirm that everything is correctly assembled and secure.

Once assembly is complete, perform a brief test to verify functionality. This final step is crucial for identifying any issues before the machinery is put to use. Regular maintenance checks post-assembly will further enhance operational efficiency.

Troubleshooting Engine Performance Issues

Addressing performance challenges in small engines is essential for maintaining efficiency and reliability. By identifying the underlying causes of issues, users can implement effective solutions to restore optimal operation. This section outlines common problems and their remedies, helping to enhance engine functionality.

Common Symptoms and Their Causes

Engines may exhibit various symptoms when performance declines. Understanding these signs is crucial for effective troubleshooting. Below is a table summarizing typical issues and possible explanations:

| Symptom | Possible Cause |

|---|---|

| Hard to start | Weak battery, clogged fuel line, or faulty ignition |

| Stalling during operation | Dirty air filter, low fuel levels, or overheating |

| Poor acceleration | Worn spark plug, fuel contamination, or incorrect throttle settings |

| Excessive smoke | Oil leaks, incorrect fuel mixture, or worn piston rings |

Recommended Solutions

Once the symptoms and potential causes have been identified, taking the following steps can help resolve performance issues:

- Inspect and replace filters regularly to ensure proper airflow and fuel delivery.

- Check electrical connections and battery condition to maintain reliable starting.

- Examine spark plugs for wear and replace if necessary to ensure efficient combustion.

- Monitor engine temperature and ensure cooling components are functioning correctly.

Popular Accessories for Enhanced Functionality

When it comes to optimizing performance and extending the capabilities of small engines, a range of accessories can significantly improve their utility. These enhancements can cater to various tasks, making equipment more versatile and efficient in operation.

One noteworthy accessory is the performance air filter, designed to boost airflow and enhance engine efficiency. This upgrade can lead to improved throttle response and overall power. Additionally, considering a high-capacity fuel tank can ensure longer operational periods, reducing the frequency of refueling during extensive use.

Another valuable addition is a specialized muffler that minimizes noise without sacrificing performance. This feature is particularly beneficial in residential areas where sound levels must be kept in check. For those who frequently work in diverse terrains, durable wheel attachments can provide better traction and stability, enhancing maneuverability.

Lastly, integrating a maintenance kit with essential tools and components will ensure your engine remains in peak condition, extending its lifespan and reliability. These accessories not only improve functionality but also contribute to a more enjoyable and productive experience.

Safety Tips for Engine Repairs

When undertaking maintenance or repairs on small engines, it is crucial to prioritize safety. Proper precautions can prevent accidents and ensure a smooth repair process. Following guidelines will help you work efficiently while minimizing risks associated with mechanical tasks.

Preparation and Personal Protective Equipment

Before starting any repair work, gather the necessary tools and materials. Ensure that you wear appropriate personal protective equipment (PPE), such as gloves, goggles, and sturdy footwear. This equipment helps safeguard against potential hazards like sharp components or flying debris.

Working Environment

Create a clean and organized workspace to avoid accidents. Ensure good lighting and ventilation, and keep flammable materials away from your working area. Regularly inspect tools for wear or damage, and replace any faulty equipment to maintain a safe working environment.

Comparing Different Briggs and Stratton Models

This section aims to explore various engine types, highlighting their unique features and applications. By examining the specifications and performance characteristics, users can better understand which model suits their needs, whether for lawn care, construction, or other outdoor tasks.

Engine Power and Size: Different models offer a range of power outputs, allowing users to select engines based on the demands of their tasks. Smaller units are ideal for light-duty applications, while larger options provide the necessary power for more intensive use.

Durability and Maintenance: The construction quality varies across models, impacting their longevity and the frequency of maintenance required. Users should consider the materials used and the ease of accessing components for servicing.

Fuel Efficiency: Fuel consumption is another critical factor to assess when comparing engines. More efficient models can save users money over time, especially with regular usage.

Technology Features: Some engines incorporate advanced technologies that enhance performance, reduce emissions, or improve starting efficiency. Evaluating these innovations can help users make informed decisions about which engine best aligns with their values and requirements.

Frequently Asked Questions about Engine Parts

This section addresses common inquiries regarding components found within small engines. Understanding these elements can significantly aid in maintenance and troubleshooting.

What should I do if my engine won’t start?

If the engine fails to start, first check the fuel level and ensure that the fuel is fresh. Inspect the ignition system and battery for any issues. If problems persist, examining the air intake and exhaust pathways may help identify blockages.

How can I tell if a component needs replacement?

Signs of wear, such as unusual noises, leaks, or decreased performance, often indicate that a component may require replacement. Regular inspections and maintenance can help identify these issues early.

Are there universal components I can use?

While some components are universal, many are specifically designed for certain engine models. Always consult the manufacturer’s specifications to ensure compatibility.

How often should I perform maintenance?

Regular maintenance is essential for optimal performance. It’s generally recommended to check oil levels, air filters, and spark plugs every 25 to 50 hours of operation, or at least once a season.

Where can I find replacement components?

Replacement components can be sourced from authorized dealers, online retailers, or local hardware stores. It’s important to ensure that the components meet the required specifications for your engine.