In the realm of small machinery, the intricate design of various engine components plays a crucial role in their functionality and maintenance. A clear representation of these elements aids users in identifying and sourcing necessary replacements or upgrades. This section will explore the arrangement and relationships among engine parts, ensuring a comprehensive understanding for both novice and experienced users.

Visual aids serve as invaluable tools for simplifying the complexities involved in engine maintenance. By illustrating the configuration of components, users can better appreciate the mechanical relationships and functions of each part. This knowledge not only enhances repair efficiency but also extends the lifespan of the machinery through informed care.

Whether you are troubleshooting issues or performing routine maintenance, having access to a well-structured visual representation empowers you to take proactive measures. Grasping the layout of engine elements fosters confidence and competence, allowing for more effective management of your equipment.

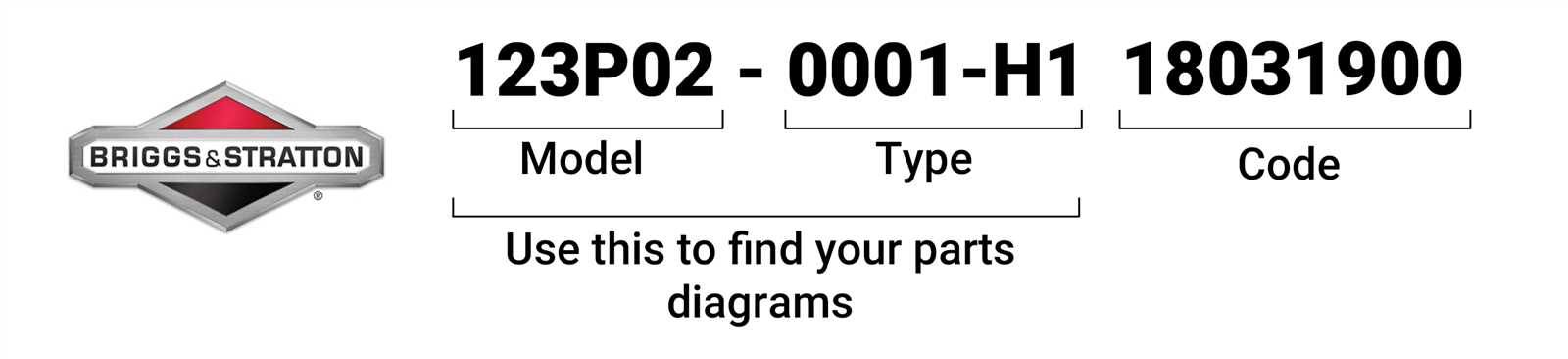

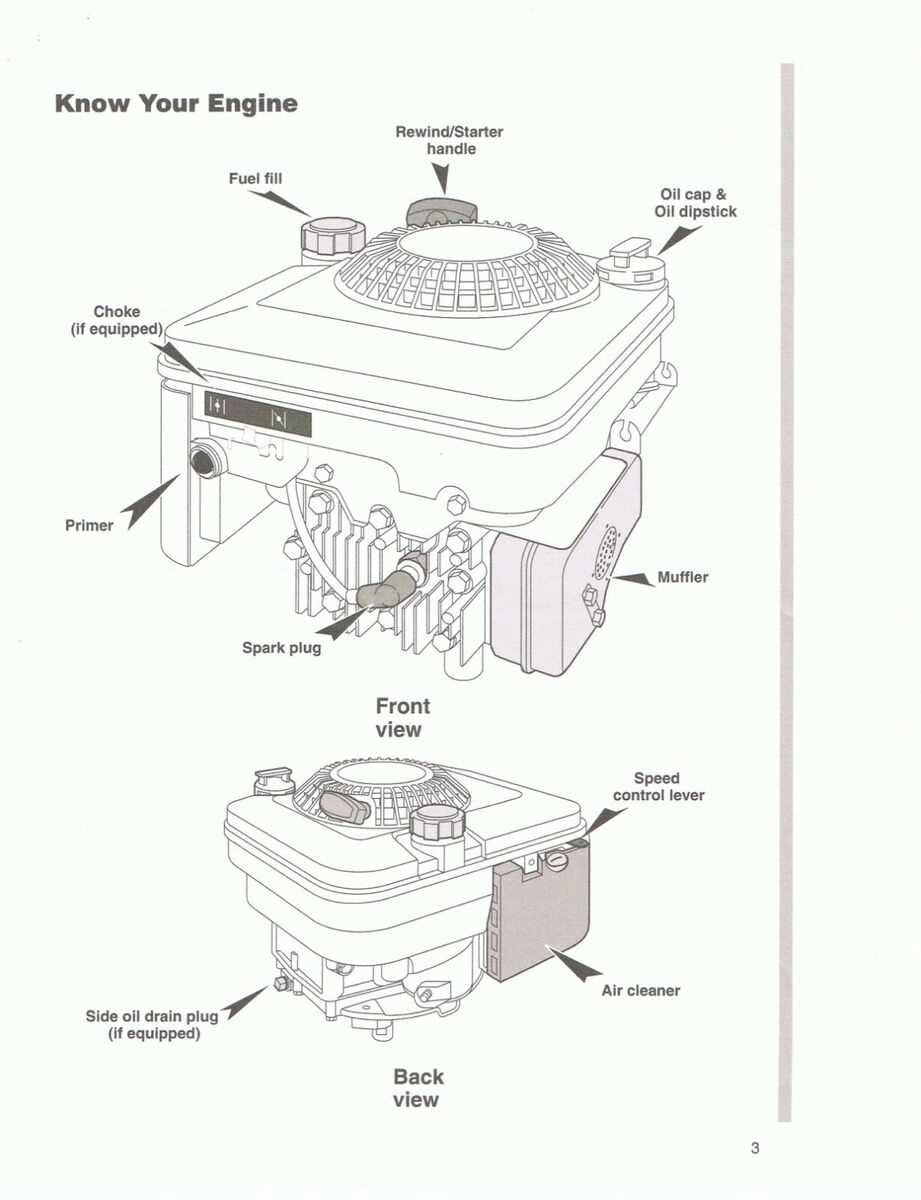

This section provides a comprehensive insight into a specific engine model known for its reliability and efficiency. Understanding its components is essential for maintenance, repair, and optimal performance.

Key Features of the Engine

- Compact design suitable for various applications.

- Durable materials ensuring longevity.

- Efficient fuel consumption enhancing performance.

Importance of Understanding Components

- Facilitates easy identification of parts during servicing.

- Helps in troubleshooting issues effectively.

- Promotes proper maintenance practices for longevity.

Understanding Engine Components

Engines are intricate machines that consist of various elements, each playing a crucial role in the overall functionality. Gaining knowledge about these components is essential for effective maintenance and troubleshooting. This section will delve into the key elements that make up an engine, emphasizing their importance and interrelationships.

Key Engine Elements

- Fuel System: Responsible for delivering the necessary fuel to the combustion chamber.

- Ignition System: Initiates the combustion process through a spark, ensuring efficient energy conversion.

- Cooling System: Maintains optimal operating temperatures to prevent overheating.

- Exhaust System: Channels away harmful gases produced during combustion.

- Crankshaft: Converts the linear motion of the pistons into rotational motion, driving the engine.

Importance of Understanding

Familiarity with these components enhances the ability to identify potential issues and implement timely solutions. Regular inspection and maintenance of each element not only prolongs the engine’s lifespan but also optimizes its performance, ensuring reliability and efficiency.

Common Issues and Solutions

When operating outdoor equipment, users may encounter a variety of challenges that can affect performance. Understanding these frequent problems and their corresponding remedies is essential for maintaining functionality and efficiency. Here, we explore some typical issues and provide effective solutions to help users troubleshoot and resolve them quickly.

Engine Start Problems

One of the most common difficulties faced by operators is the failure of the engine to start. This issue can arise from several factors, including fuel starvation, stale gasoline, or a faulty ignition system. To address this, ensure that the fuel is fresh and clean, check the fuel lines for blockages, and inspect the spark plug for wear or damage. Replacing the spark plug or cleaning it can often restore starting capability.

Overheating Concerns

Another significant issue is overheating, which can lead to severe engine damage if not managed promptly. This can result from insufficient lubrication, debris clogging the cooling fins, or prolonged operation under heavy loads. Regularly checking the oil level and changing it as necessary can prevent overheating. Additionally, keeping the cooling system clear of dirt and grass clippings is crucial for maintaining optimal temperature control.

Maintenance Tips for Longevity

Proper upkeep of your small engine equipment is essential for ensuring its durability and optimal performance. By following a few simple maintenance practices, you can extend the life of your machinery and keep it running smoothly for years to come.

Regular Inspections

Conducting routine checks on various components can help identify wear and tear before it leads to major issues. Inspect the fuel system, air filter, and spark plug periodically to ensure they are in good condition. Clean or replace parts as necessary to maintain efficiency.

Scheduled Oil Changes

Changing the oil at regular intervals is crucial for engine health. Fresh oil reduces friction and helps in cooling the engine. Be sure to use the recommended oil type and follow the manufacturer’s guidelines for change intervals to maximize performance.

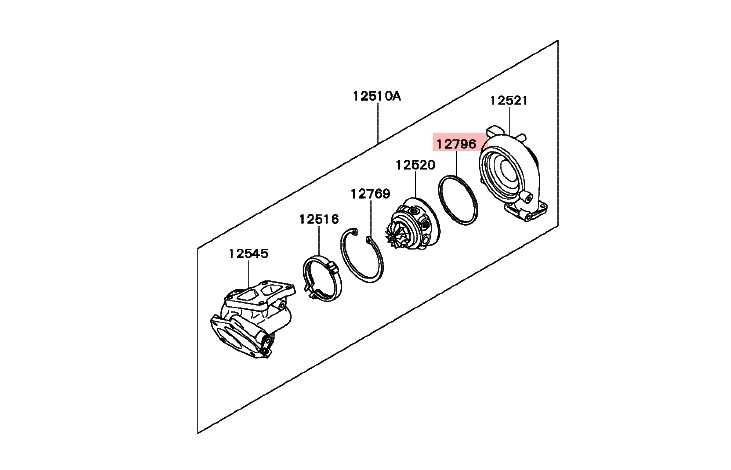

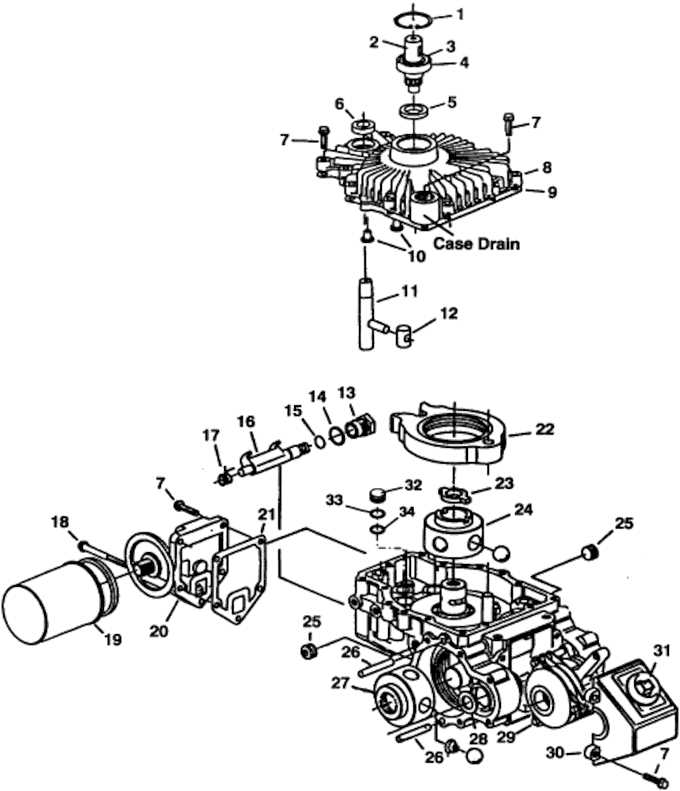

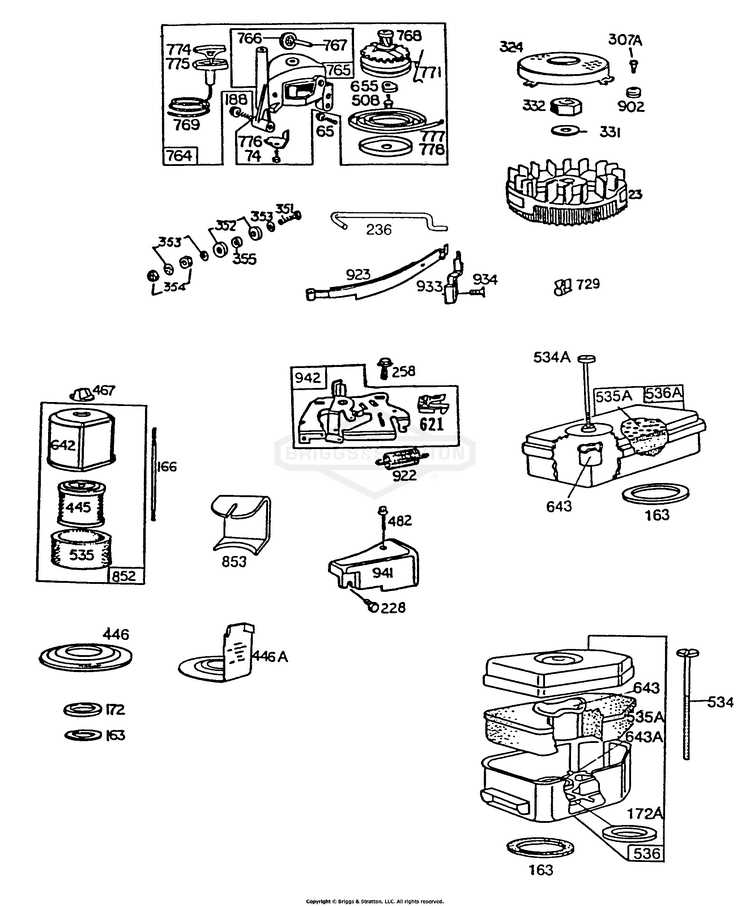

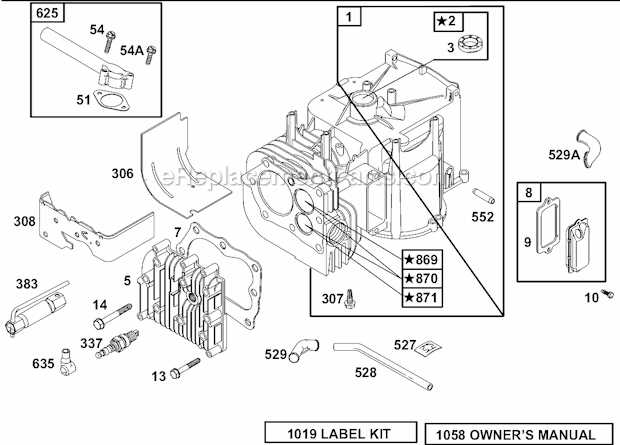

Identifying Replacement Parts

Recognizing the necessary components for machinery maintenance is crucial for ensuring optimal performance and longevity. Understanding how to identify the specific elements required for replacement can significantly enhance the efficiency of repairs and upkeep.

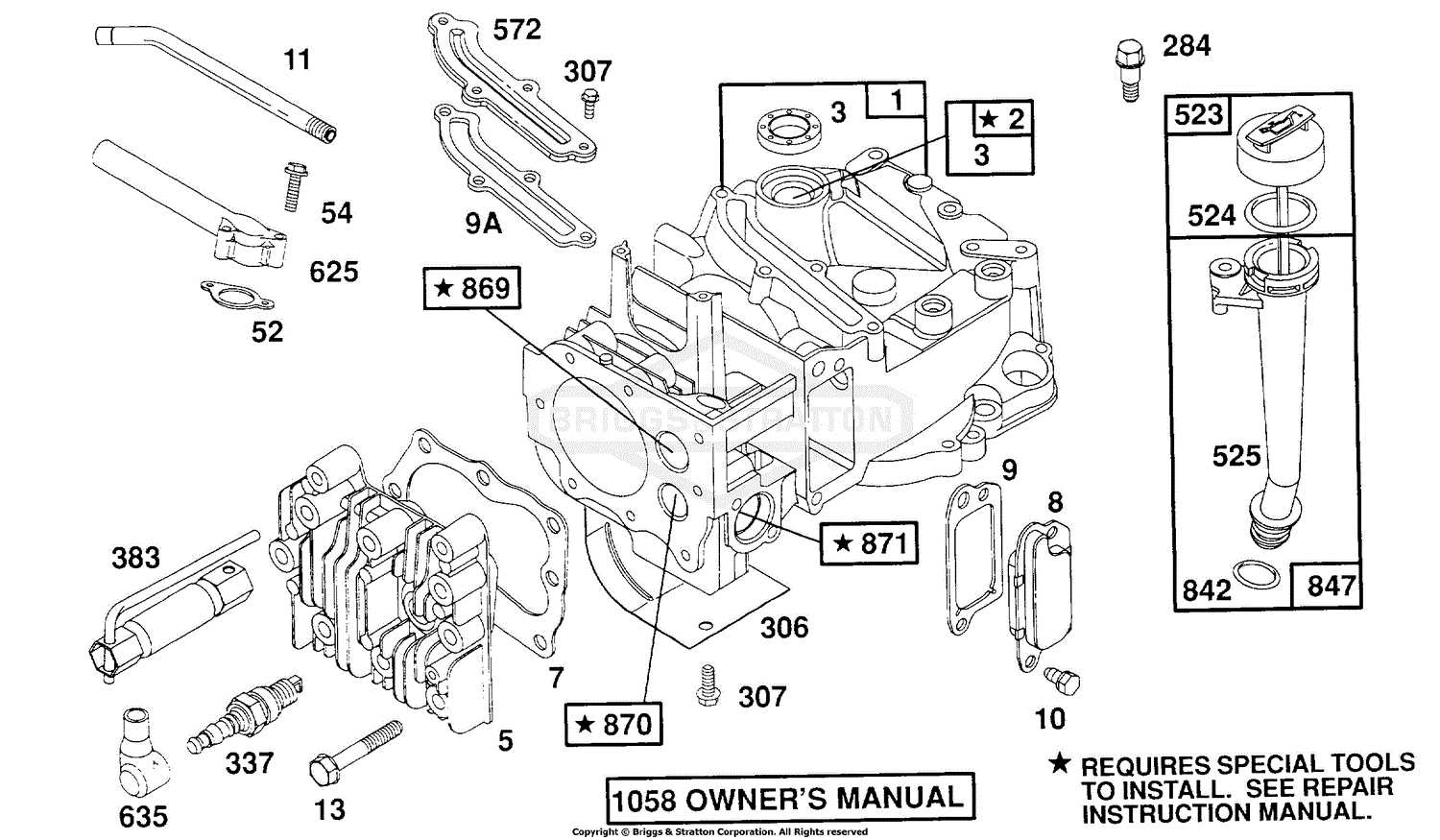

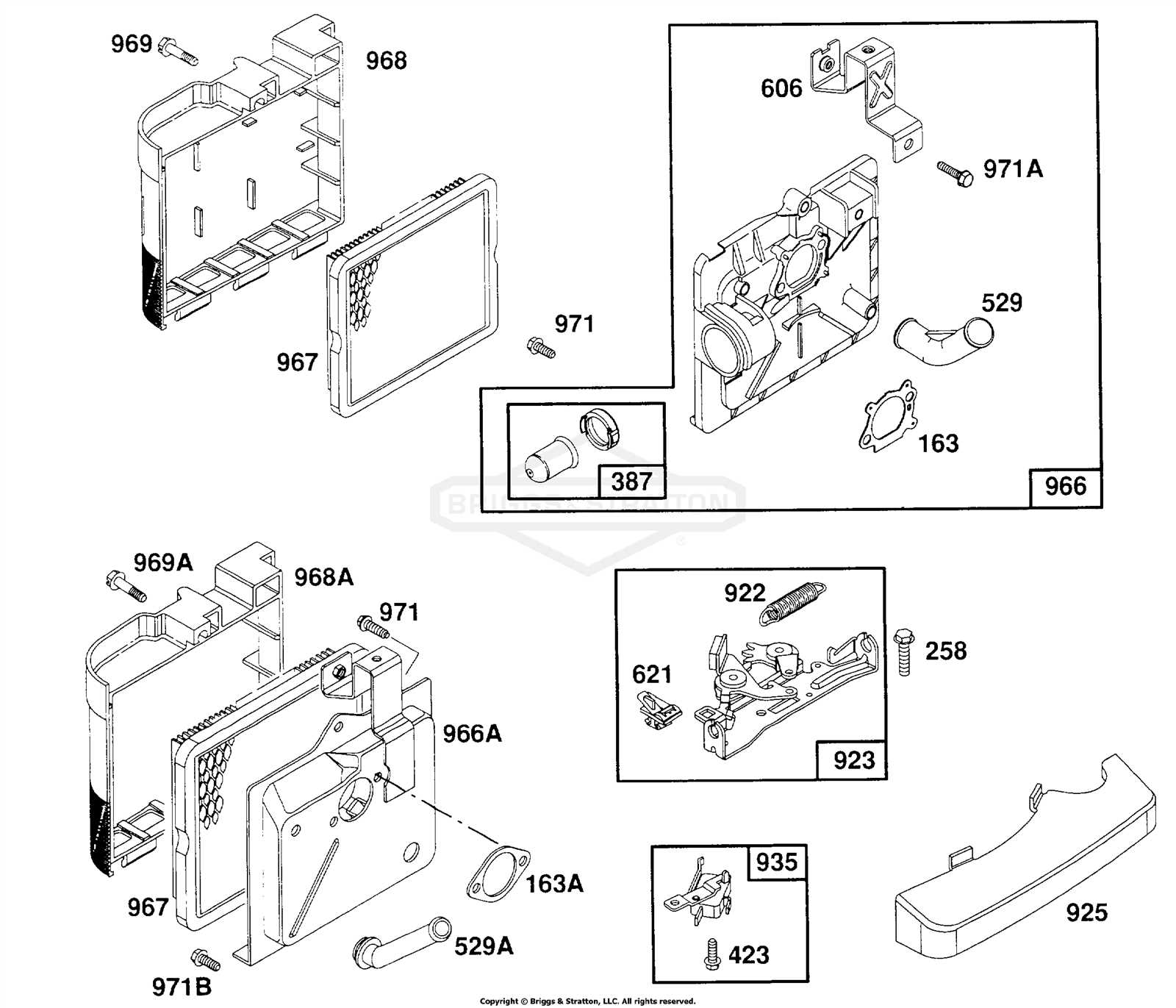

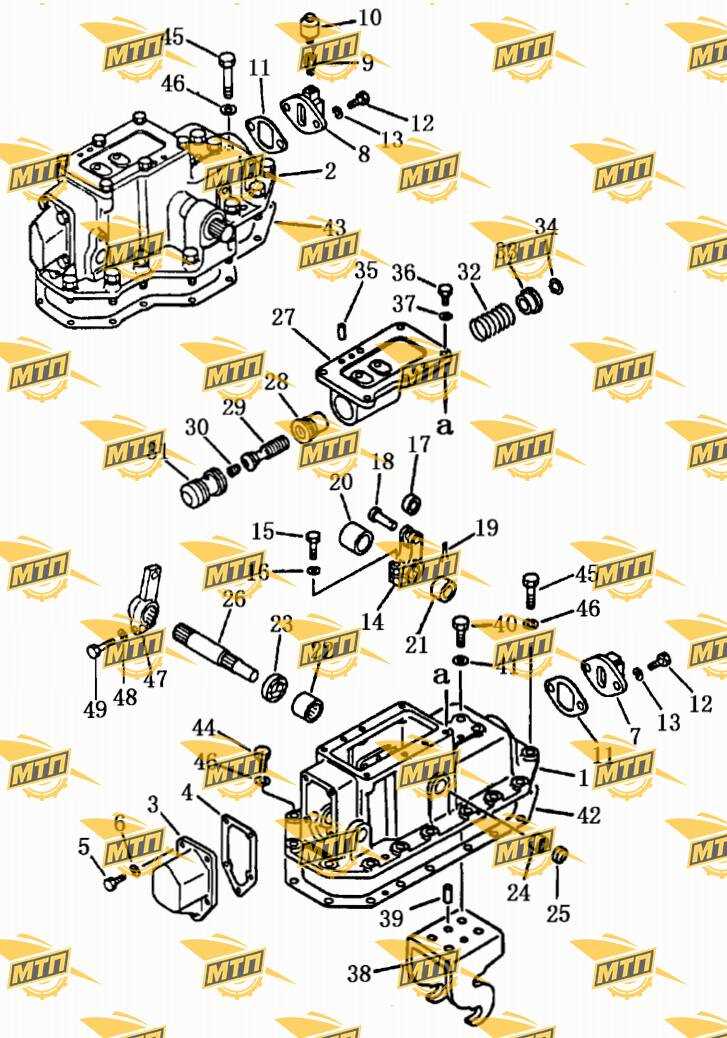

To assist in locating the correct components, refer to a detailed schematic that outlines the various sections of the device. This can provide valuable insights into the configuration and compatibility of each element.

| Component | Description | Common Issues |

|---|---|---|

| Fuel System | Includes the fuel tank and carburetor. | Leaks, poor fuel flow. |

| Ignition | Consists of the spark plug and ignition coil. | Difficulty starting, misfiring. |

| Air Filter | Filters debris from incoming air. | Clogging, reduced airflow. |

| Exhaust | Includes the muffler and exhaust pipe. | Excess noise, emissions issues. |

Utilizing the information from these schematics can streamline the process of finding the appropriate replacements, thus promoting a more effective maintenance routine.

Importance of Genuine Parts

Utilizing authentic components is crucial for maintaining the efficiency and longevity of outdoor equipment. These original pieces are designed to fit perfectly, ensuring optimal performance and safety.

Here are several reasons why choosing genuine components is essential:

- Quality Assurance: Original items are manufactured to stringent standards, providing reliability and durability.

- Performance Optimization: Authentic components are engineered specifically for your equipment, enhancing overall functionality.

- Warranty Protection: Using genuine replacements often preserves warranty coverage, protecting your investment.

- Compatibility: Original components ensure seamless integration, reducing the risk of malfunction or damage.

- Resale Value: Equipment maintained with authentic parts generally retains higher resale value compared to those using inferior alternatives.

In conclusion, opting for original replacements not only safeguards your machinery but also guarantees peak performance and reliability over time.

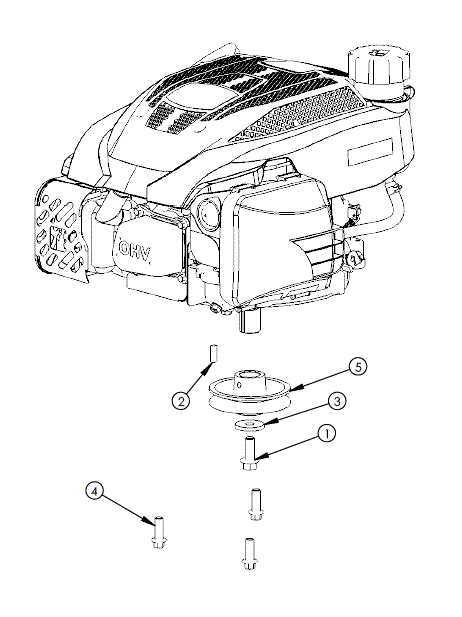

Step-by-Step Assembly Instructions

This section provides a comprehensive guide for correctly putting together the components of a small engine model. By following these detailed steps, users will ensure that each element fits together seamlessly, enhancing the overall functionality and performance of the equipment.

Preparing the Components

Before starting the assembly process, gather all necessary components and tools. Ensure that each piece is clean and free from any debris that could interfere with the assembly. Having a clear workspace will facilitate a smoother process and minimize the risk of losing any parts.

Assembly Procedure

Begin by connecting the base to the power unit, making sure to align the mounting points accurately. Once secured, attach the intake and exhaust components according to the provided specifications. Verify that all fasteners are tightened adequately to prevent any future operational issues.

Tools Required for Repairs

To successfully execute maintenance tasks on small engine equipment, a variety of tools is essential. Having the right instruments on hand can significantly streamline the repair process and ensure efficiency.

Here are the essential tools you should consider:

- Wrenches: Various sizes, both standard and metric, are crucial for loosening and tightening bolts.

- Screwdrivers: A set of flathead and Phillips screwdrivers will help in securing or removing screws.

- Pliers: Needle-nose and standard pliers are useful for gripping and manipulating small components.

- Socket Set: A complete socket set allows for easier access to nuts in confined spaces.

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications, preventing damage.

- Oil Filter Wrench: Helpful for changing oil filters during maintenance.

Having these tools readily available will facilitate effective repairs and maintenance, contributing to the longevity of the equipment.

Diagram Analysis for Clarity

Understanding the layout of mechanical components is crucial for effective maintenance and repair. A detailed illustration can significantly enhance one’s ability to identify each element and comprehend their interrelations within a complex system.

This section aims to explore the various aspects of the schematic representation, focusing on its role in facilitating troubleshooting and part replacement. By dissecting the visual aid, users can gain valuable insights into the functionality and positioning of each component.

Moreover, such analysis empowers individuals to recognize potential issues before they escalate, ensuring smoother operation and prolonging the lifespan of the equipment. A thorough examination of the layout not only aids in immediate repairs but also fosters a deeper understanding of the machine’s overall mechanics.

FAQs About Parts and Maintenance

This section addresses common inquiries regarding components and upkeep of outdoor equipment. Understanding these aspects can enhance the longevity and performance of your machinery.

What should I do if a component breaks?

If a piece of equipment fails, it is essential to identify the specific issue. Consult your user manual for troubleshooting tips or consider seeking assistance from a qualified technician for repairs.

How often should I perform maintenance?

Regular maintenance is crucial for optimal performance. It is advisable to follow the manufacturer’s recommendations, which typically suggest inspections and servicing at least once per season.

Where can I find replacement components?

Replacement items are available through authorized dealers or online retailers specializing in outdoor machinery. Ensure that the replacements match the specifications of your equipment for compatibility.

Is it necessary to use original components?

While aftermarket alternatives may be more affordable, using original components is recommended for reliability and performance. Authentic parts are designed specifically for your equipment, ensuring proper functionality.

Can I perform maintenance myself?

Many maintenance tasks, such as oil changes and air filter replacements, can be completed by the owner. However, more complex repairs should be left to professionals to avoid further issues.

Where to Purchase Parts

Finding the right components for your small engine can be a straightforward process if you know where to look. Several options are available to help you obtain the necessary items for maintenance and repairs, ensuring your equipment runs smoothly.

Here are some reliable sources to consider:

- Authorized Dealers: Visit local dealers who specialize in outdoor power equipment. They often carry a range of items and can assist you in locating specific components.

- Online Retailers: Numerous e-commerce platforms offer a vast selection of items. Look for websites that specialize in engine supplies, where you can search for your specific needs.

- Aftermarket Suppliers: Explore companies that provide alternative solutions. They often offer similar items at competitive prices.

- Local Repair Shops: Consider reaching out to nearby repair facilities. They may stock essential items or be able to order them for you.

- Manufacturer’s Website: Check the official website for the manufacturer, which may have a dedicated section for replacements and accessories.

By exploring these options, you can ensure that you find the right items to keep your equipment in top shape.