The efficiency and performance of a powerful engine rely heavily on its various components. This section will delve into the essential elements that make up a robust 20 horsepower engine, focusing on their functions and interconnections. A thorough understanding of these elements can greatly enhance maintenance and repair tasks, ensuring optimal operation.

Identifying each part is crucial for troubleshooting and replacement. By exploring the intricate relationships between the engine’s components, users can gain insights into potential issues and their resolutions. A well-maintained engine not only operates more efficiently but also extends its lifespan, ultimately providing better service and reliability.

Whether you are a seasoned technician or a novice, having access to a comprehensive overview of the engine’s elements is invaluable. Familiarizing yourself with these critical components will empower you to make informed decisions regarding upkeep and enhancements, leading to improved performance and satisfaction.

The 20 HP power unit is recognized for its reliability and efficiency in various applications. This section provides a comprehensive overview of its components and functionalities, aiming to enhance understanding and facilitate maintenance.

Key Features of the Engine

- Robust construction for durability

- Enhanced fuel efficiency

- Easy maintenance and servicing

- Versatile applications across different machinery

Common Applications

- Lawn mowers

- Garden tractors

- Generators

- Utility vehicles

Understanding the components of this engine type is crucial for proper upkeep and troubleshooting. By familiarizing oneself with the various elements, users can ensure optimal performance and longevity.

Key Features of 20 HP Intek Models

The 20 HP engine models offer a range of characteristics designed to enhance performance and efficiency. These features contribute to reliable operation across various applications, making them a popular choice among users seeking durability and power.

Performance and Power Delivery

- Consistent power output ideal for heavy-duty tasks

- Efficient fuel consumption for prolonged operation

- Robust torque for improved performance in challenging conditions

Durability and Maintenance

- Heavy-duty construction to withstand demanding environments

- Accessible components for easy maintenance and service

- Advanced cooling systems to prevent overheating

Common Applications for Intek Engines

Engines in the 20 horsepower range are widely utilized across various sectors due to their reliability and performance. These power units are designed to meet the demands of different applications, making them suitable for both residential and commercial use.

One of the primary areas where these engines excel is in outdoor power equipment. They are commonly found in lawn mowers, garden tractors, and snow blowers, providing sufficient power to handle demanding tasks efficiently. Additionally, these engines are often used in pressure washers, delivering the necessary force for effective cleaning.

| Application | Description |

|---|---|

| Lawn Equipment | Ideal for mowers and garden tractors, ensuring smooth cutting and maneuverability. |

| Pressure Washers | Offers high performance for thorough cleaning tasks in residential and commercial settings. |

| Snow Removal | Effective for snow blowers, helping to clear driveways and pathways during winter. |

| Generators | Used in portable generators, providing reliable power supply during outages. |

Understanding Engine Components and Functions

Engines consist of various essential elements that work together to create power and ensure optimal performance. Each component plays a vital role in the overall functionality, contributing to the efficient operation of the machinery. Grasping the purpose of these individual parts is crucial for maintaining and troubleshooting the engine.

The main components of an engine include:

- Crankshaft: Converts linear motion into rotational motion, driving the vehicle.

- Pistons: Move up and down within the cylinders, compressing fuel and air for combustion.

- Valves: Control the intake of air and fuel, as well as the exhaust of combustion gases.

- Cylinder: Houses the piston and is where combustion takes place.

- Camshaft: Operates the valves in synchronization with the pistons’ movement.

Understanding how these components interact enhances knowledge of engine operation. For example:

- The crankshaft rotates as the pistons move, generating power.

- Valves open and close at precise times to ensure optimal fuel-air mixture intake and exhaust gas expulsion.

- The camshaft timing is critical for maintaining engine efficiency and performance.

Familiarity with these essential components facilitates better care and management of the engine, ultimately leading to improved longevity and performance.

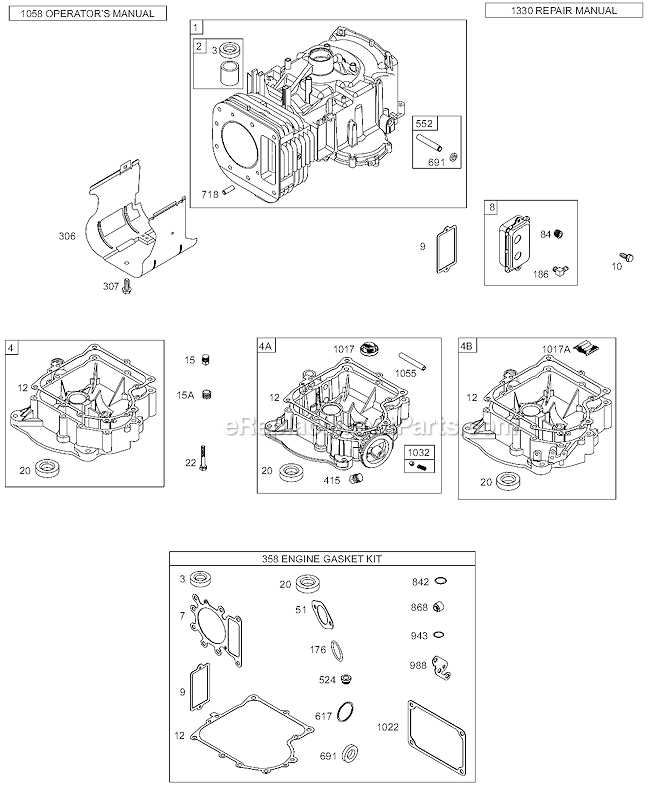

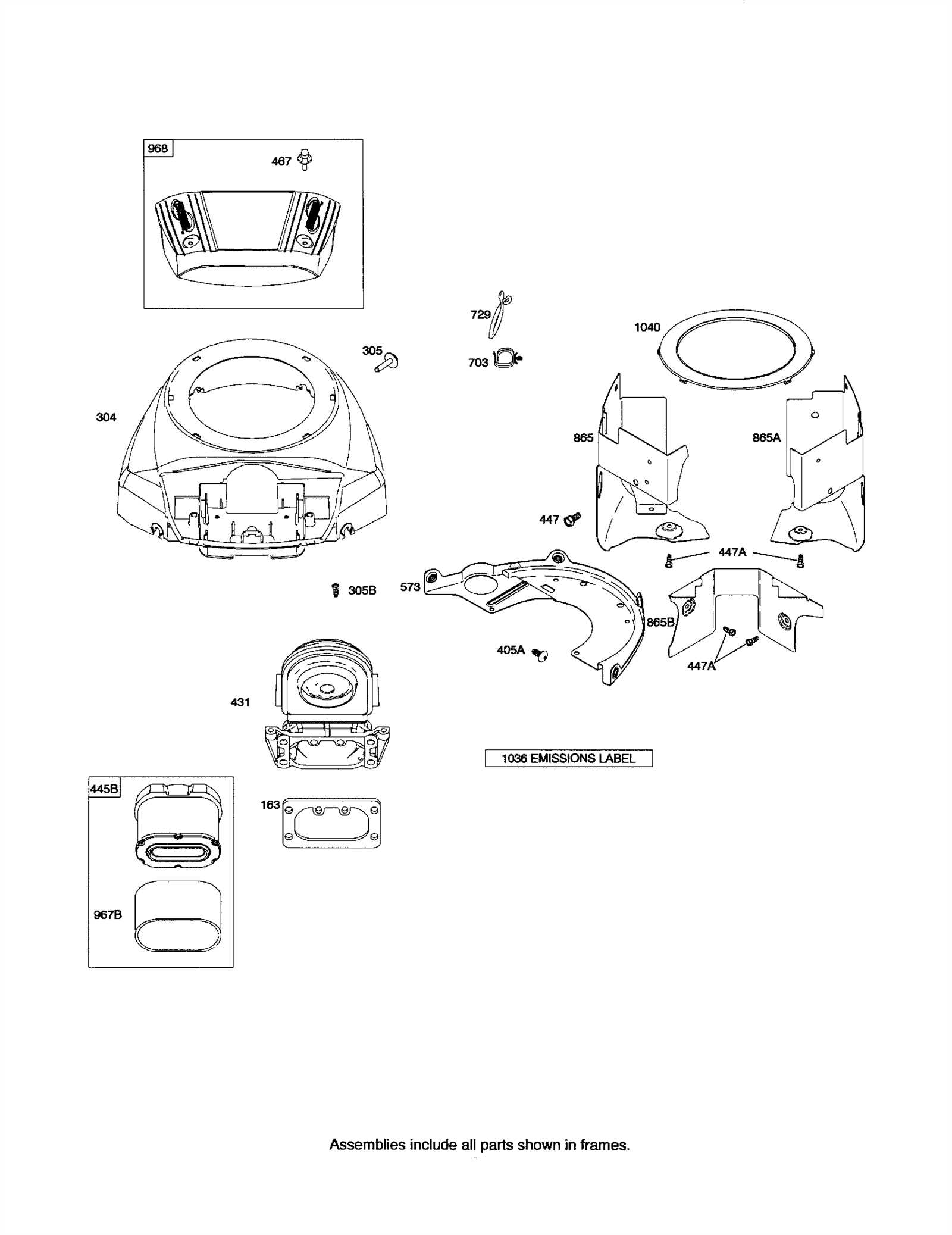

How to Read Parts Diagrams Effectively

Understanding technical illustrations is crucial for anyone involved in machinery maintenance or repair. These visual guides provide a clear representation of various components, helping users identify and locate specific elements. By mastering the art of interpreting these illustrations, individuals can streamline their repair processes and ensure accurate assembly or disassembly of equipment.

1. Familiarize Yourself with Symbols: Each illustration typically includes a set of symbols and notations that represent different components. Take the time to learn what each symbol signifies to avoid confusion during repairs.

2. Follow the Sequence: Often, illustrations are organized in a sequential manner, indicating the order in which parts should be assembled or disassembled. Pay attention to this flow to enhance your efficiency and prevent errors.

3. Use Reference Numbers: Most illustrations include reference numbers that correspond to a list of components. Cross-referencing these numbers can help you identify the correct items needed for your specific task.

4. Study the Layout: Examine the overall layout of the illustration. Understanding the spatial relationship between different components can provide insight into how they function together, aiding in troubleshooting and repairs.

5. Practice Makes Perfect: The more you work with technical illustrations, the more proficient you will become at interpreting them. Take the time to practice with different sets to build your confidence and skill.

Essential Maintenance Tips for Longevity

Proper upkeep is crucial for ensuring the durability and efficiency of any engine. By following some basic guidelines, you can extend the life of your equipment and enhance its performance. Regular attention to key components helps prevent unexpected breakdowns and maintains optimal functionality.

Regular Oil Changes: Routine oil changes are essential for keeping the engine running smoothly. Use high-quality oil and replace it according to the manufacturer’s recommendations. Clean oil reduces friction and prevents wear on internal parts.

Air Filter Maintenance: A clean air filter is vital for optimal air intake. Regularly inspect and replace the filter as needed. This simple task can significantly improve performance and fuel efficiency.

Check Spark Plug Condition: Inspecting and replacing spark plugs can lead to better ignition and smoother operation. Worn or dirty plugs can cause misfiring and decreased efficiency.

Inspect Fuel System: Ensure that the fuel system is free from contaminants. Regularly check for leaks and replace old fuel to maintain engine performance. Clean fuel lines and filters contribute to reliable operation.

Routine Cleaning: Keeping the exterior and components clean helps prevent debris buildup that can affect performance. Regularly wipe down surfaces and remove any grass, dirt, or dust accumulation.

By implementing these straightforward maintenance practices, you can enhance the longevity of your engine and ensure it operates at its best for years to come.

Identifying Replacement Parts and Accessories

When maintaining or repairing machinery, recognizing the appropriate components and accessories is crucial for optimal performance. Proper identification ensures that replacements fit correctly and function as intended, ultimately extending the lifespan of the equipment.

Several strategies can assist in the identification of essential components:

| Method | Description |

|---|---|

| Manual Reference | Consulting the manufacturer’s manual can provide valuable insights into specific components, including part numbers and compatibility. |

| Online Resources | Utilizing official websites and forums can yield diagrams and discussions that clarify which components are suitable for replacement. |

| Consulting Experts | Engaging with professionals or experienced individuals in the field can offer guidance on sourcing and identifying necessary components. |

By leveraging these methods, individuals can ensure they obtain the correct items, facilitating smoother repairs and maintenance tasks.

Common Issues and Troubleshooting Solutions

This section addresses frequent problems encountered with small engines and offers practical solutions to ensure smooth operation. Understanding these common issues can help users maintain performance and extend the lifespan of their equipment.

Frequent Problems

Users may experience a variety of issues that hinder engine efficiency. The following table summarizes these challenges along with potential causes:

| Issue | Possible Causes |

|---|---|

| Engine Won’t Start | Fuel blockage, dead battery, faulty ignition system |

| Overheating | Insufficient cooling, dirty air filter, low oil level |

| Uneven Power Output | Worn spark plugs, fuel quality issues, air intake problems |

Troubleshooting Steps

To resolve these issues, follow these steps:

- Check fuel levels and ensure the fuel line is clear.

- Inspect and replace spark plugs if necessary.

- Clean or replace air filters to enhance airflow.

- Monitor oil levels and change the oil as needed.

Tools Needed for Engine Repairs

Repairing an engine requires a specific set of instruments to ensure efficiency and effectiveness in the maintenance process. Having the right tools not only simplifies the task but also enhances the quality of repairs, making them more reliable and durable.

Essential Tools

- Socket Set

- Wrenches

- Screwdrivers

- Pliers

- Torque Wrench

- Oil Filter Wrench

Additional Accessories

- Work Gloves

- Safety Glasses

- Shop Manual

- Cleaning Supplies

- Magnetic Tray for Small Parts

Resources for Finding Original Parts

Locating genuine components for outdoor power equipment can be a challenging task. However, several resources can assist enthusiasts and professionals alike in identifying the correct items needed for their machines. Utilizing reliable sources is essential to ensure compatibility and quality.

Manufacturer Websites: Visiting the official website of the equipment’s manufacturer is often the best starting point. They typically offer a catalog of available components, complete with specifications and compatibility information.

Authorized Dealers: Seeking assistance from authorized dealers can provide access to original items. These dealers are knowledgeable about the specific equipment and can guide you in selecting the right components for repairs or upgrades.

Online Marketplaces: Several reputable online platforms specialize in equipment components. These websites often have user-friendly search functions that allow you to find specific items by entering model numbers or descriptions.

Community Forums: Engaging with online communities dedicated to outdoor equipment can be beneficial. Members often share valuable insights and resources, including where to find authentic components and personal experiences regarding their reliability.

Local Repair Shops: Local repair shops may have access to original components or be able to order them on your behalf. Establishing a relationship with a trusted technician can also lead to valuable advice on maintenance and part selection.

Safety Precautions During Maintenance

When performing maintenance on machinery, adhering to safety guidelines is crucial to prevent accidents and ensure effective operation. Proper precautions can minimize risks and enhance the longevity of equipment.

Here are essential safety measures to consider:

- Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and ear protection.

- Ensure the equipment is powered off and disconnected from any power source before beginning maintenance tasks.

- Keep the work area clean and free of clutter to avoid slips and falls.

- Use tools that are specifically designed for the task at hand, ensuring they are in good condition.

- Be aware of your surroundings and keep bystanders away from the maintenance area.

Following these guidelines not only protects the individual performing the maintenance but also contributes to the overall safety and efficiency of the machinery.

Expert Recommendations for Engine Performance

To achieve optimal performance in small engines, it’s essential to follow expert advice that enhances functionality and longevity. By adhering to best practices, users can ensure their machinery operates efficiently and reliably over time. Proper maintenance, timely upgrades, and careful monitoring are key components of successful engine management.

Regular Maintenance Checks

Performing routine inspections is crucial for identifying potential issues before they escalate. Check oil levels, replace filters, and inspect belts regularly to maintain peak operation. Keeping the engine clean from debris and ensuring air intake pathways are clear will also contribute to smoother functionality.

Quality Fuel and Lubricants

Using high-quality fuel and lubricants can significantly improve engine performance. Opt for fuels that are free from impurities, and select lubricants that meet the manufacturer’s specifications. This not only maximizes efficiency but also reduces wear and tear on internal components, promoting a longer lifespan for the engine.