Understanding the internal structure of small engines is crucial for effective maintenance and repairs. This section offers a detailed exploration of the key elements that drive performance and durability in mechanical systems. By familiarizing yourself with the individual components, you can ensure that the engine runs efficiently and reliably.

We’ll dive into the critical assemblies that form the foundation of these engines, providing clear insights into how each element interacts with the others. Proper knowledge of these systems will empower users to troubleshoot and service their machines with confidence.

Accurate knowledge of how mechanical elements fit together is essential for anyone looking to maintain longevity and optimal functionality. This guide will serve as a reference for understanding the relationships between various engine sections.

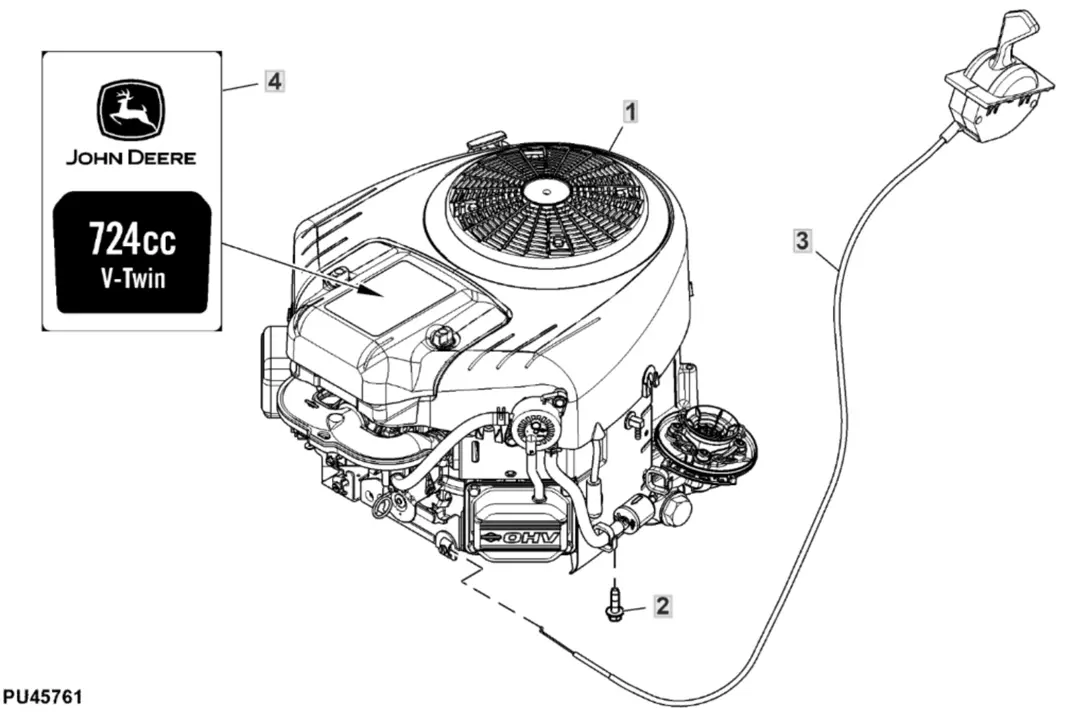

Overview of the Briggs and Stratton Engine

The engine in question is a robust and reliable power source, often used in various machinery. Designed for efficiency, it features a powerful mechanism capable of delivering substantial energy output for demanding tasks. This motor excels in providing smooth operation, making it a popular choice for those seeking long-lasting performance and durability.

With a focus on maximizing fuel efficiency and minimizing emissions, this engine integrates advanced technologies that ensure consistent power delivery. Its construction promotes easy maintenance, ensuring that essential components are accessible for regular servicing, which extends the overall lifespan of the machine.

Notable features of this model include a well-balanced design that reduces vibrations, contributing to quieter operation and enhanced user comfort. It also includes several safety enhancements, ensuring reliable use in various conditions, from light-duty tasks to more intense applications.

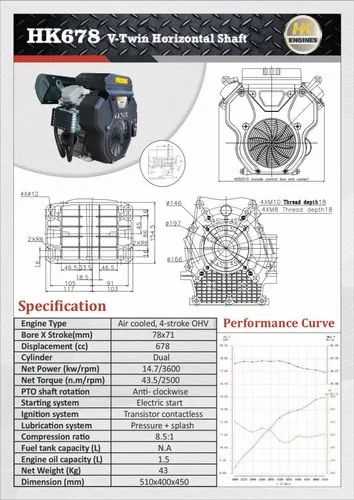

Main Components of the V-Twin Engine

The V-shaped motor design consists of several key elements that work together to ensure optimal performance and power generation. Each part plays a crucial role in the combustion process, enabling the motor to operate efficiently and with stability. Understanding these core elements helps in the maintenance and repair of the engine, ensuring its longevity and reliability.

One of the central elements is the crankshaft, which converts the reciprocating motion of the pistons into rotational force. Alongside it, the pistons move within the cylinders, compressing fuel and air to create the necessary energy. Valves regulate the intake and exhaust of gases, while the camshaft coordinates their timing. Additional components, such as the ignition system and cooling mechanisms, support smooth operation and prevent overheating.

Understanding the 22HP Engine Power Output

The power output of this specific engine type is crucial for delivering efficient performance in various machines. It is designed to handle significant workloads, making it suitable for heavy-duty tasks. The engine’s strength allows it to manage multiple systems within the equipment, ensuring smooth operation even under pressure. Understanding how the energy is distributed across the machine helps in maximizing its potential and ensuring longevity.

Power Distribution and Efficiency

This engine is built to balance power distribution across all working components. By optimizing energy flow, it helps achieve consistent performance. The design minimizes energy waste, improving fuel efficiency and reducing operational costs.

Ensuring Optimal Performance

Regular maintenance and proper tuning are key to maintaining the engine’s high performance. Checking critical elements like fuel intake, exhaust systems, and airflow can significantly extend the lifespan of the engine while maintaining strong output. Keeping these aspects in check ensures the engine operates at its full capacity.

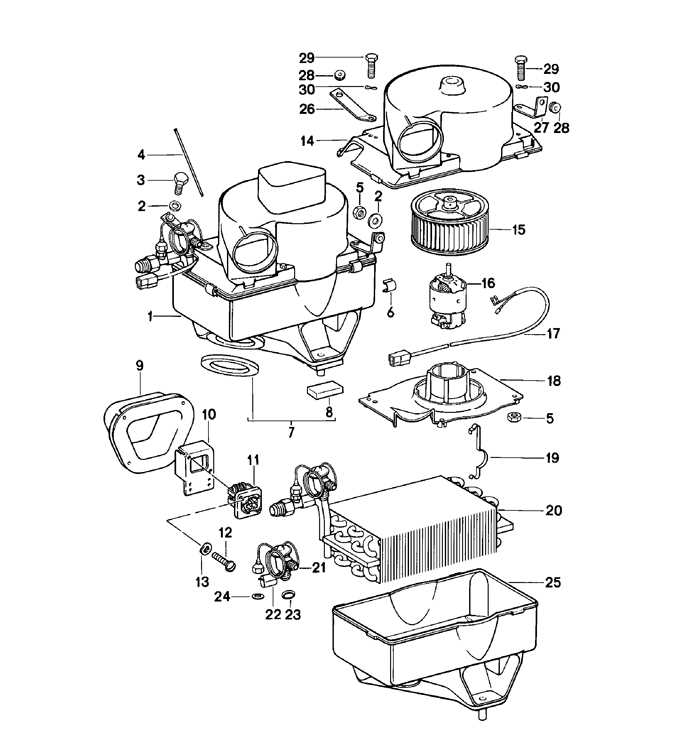

Fuel System Parts Breakdown

The fuel system consists of several key components that work together to ensure the engine operates smoothly and efficiently. Each element is essential for delivering the correct mixture of fuel and air to the combustion chamber, maintaining optimal performance.

At the heart of the system is the carburetor, which regulates the blend of air and fuel. The fuel is transported through lines and filters, ensuring it remains clean and free of contaminants before reaching the engine. Additionally, fuel pumps are responsible for moving the liquid from the tank to the carburetor, while the fuel injectors play a critical role in precise delivery into the engine.

Other significant components include the fuel tank, which stores the liquid, and the fuel

Exhaust System and Its Functionality

The exhaust system plays a crucial role in managing the outflow of gases generated during engine combustion. It ensures the efficient removal of emissions, allowing the engine to maintain optimal performance while reducing harmful byproducts. Proper ventilation through this system enhances the overall functioning of the machine, ensuring a smooth and clean operation.

In addition to guiding exhaust gases safely out of the engine, this system minimizes noise, aiding in quieter operations. Furthermore, by reducing backpressure, it contributes to better fuel efficiency and overall engine longevity. Regular maintenance of this component ensures both environmental compliance and the prolonged life of the motor.

Ignition System Components and Diagram

The ignition system is a crucial aspect of small engines, responsible for initiating the combustion process. Understanding its components is essential for effective maintenance and troubleshooting. This section outlines the key elements involved in the ignition mechanism, illustrating their functions and interconnections.

Key Components of the Ignition System

- Ignition Coil: Generates the high voltage needed to create a spark at the spark plug.

- Spark Plug: Ignites the air-fuel mixture by producing a spark, enabling combustion.

- Magneto: Provides electrical power for the ignition system, often integrated into the engine.

- Kill Switch: Allows for quick engine shutdown by interrupting the ignition circuit.

- Wiring Harness: Connects all electrical components, ensuring proper communication between them.

Understanding the System Layout

The layout of the ignition system illustrates the arrangement of its components. Each part plays a vital role in ensuring the engine operates efficiently. The ignition coil and magneto work together to generate and deliver the electrical charge necessary for ignition, while the spark plug creates the spark that initiates combustion.

Cooling System Overview and Maintenance

The cooling mechanism plays a crucial role in ensuring optimal performance and longevity of the engine. This system prevents overheating by dissipating excess heat generated during operation. Understanding its components and maintenance needs is essential for effective management.

Key Components

- Radiator: Responsible for transferring heat away from the engine.

- Cooling Fan: Enhances airflow through the radiator to improve cooling efficiency.

- Hoses: Transport coolant between the engine and the radiator.

- Water Pump: Circulates coolant throughout the system.

Maintenance Tips

- Regularly check coolant levels to ensure proper operation.

- Inspect hoses for signs of wear, leaks, or damage.

- Clean the radiator and fan to prevent dust buildup.

- Replace coolant according to the manufacturer’s recommendations to maintain effectiveness.

Lubrication Components and Their Functions

Effective lubrication is crucial for the optimal functioning of an engine. The various elements involved in this process play significant roles in ensuring that all moving parts operate smoothly, reducing friction and wear. Understanding these components helps maintain the longevity and performance of the engine.

Key Lubrication Elements

- Oil Pump: This component circulates lubricating fluid throughout the engine, ensuring that every part receives adequate protection against wear.

- Oil Filter: It removes impurities and contaminants from the lubricant, helping to maintain clean and effective lubrication.

- Oil Reservoir: This holds the lubricating fluid until it is needed, ensuring a consistent supply to the engine components.

Importance of Lubrication

Proper lubrication not only enhances engine efficiency but also extends its operational life. Regular maintenance and timely replacement of lubrication components are essential to prevent overheating and other potential issues.

Carburetor System and Its Parts

The carburetor is a crucial component of an internal combustion engine, playing a vital role in mixing air and fuel to create a combustible mixture. This system ensures optimal performance and efficiency by regulating the ratio of air to fuel, which directly affects engine power and emissions.

Within this assembly, several key components work together to achieve the desired mixture. The float chamber maintains a consistent fuel level, while the needle valve controls fuel flow. The venture, a narrowing section, accelerates the airflow, creating a vacuum that draws fuel into the airstream. Additionally, the throttle valve regulates airflow into the engine, enabling the operator to control speed and power output effectively.

Regular maintenance of the carburetor system is essential for reliable engine operation. Cleanliness and proper adjustments ensure that each part functions harmoniously, preventing issues such as poor performance or starting difficulties. Understanding the individual elements of this system can significantly enhance troubleshooting and repair efforts.

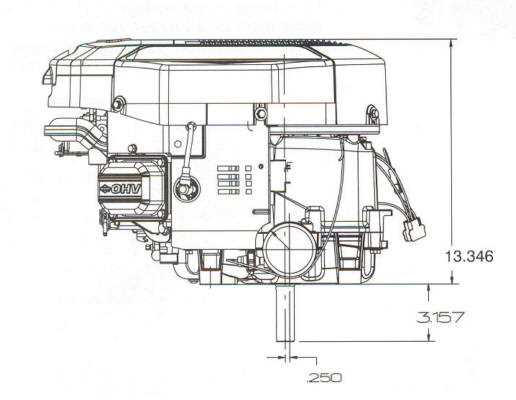

Engine Block Design and Structure

The design and construction of an engine block play a crucial role in the overall performance and durability of an internal combustion engine. This fundamental component serves as the foundation for various engine elements, providing essential support and alignment. Its structure must balance strength and weight, ensuring optimal operation under various conditions while minimizing unnecessary mass.

Material Selection

Choosing the right materials for the engine block is vital for achieving desired performance characteristics. Typically, cast iron and aluminum alloys are favored due to their strength-to-weight ratios and heat dissipation properties. The selected material directly influences the engine’s efficiency, longevity, and capacity to withstand thermal and mechanical stresses.

Cooling System Integration

An effective cooling system is integral to maintaining the engine’s operational temperature. The engine block design incorporates passages for coolant flow, which helps regulate heat buildup during combustion. This integration is essential for preventing overheating and ensuring consistent performance, especially during extended use.

Maintenance Tips for Longevity

Regular upkeep is essential for enhancing the lifespan of your equipment. By following a few simple strategies, you can ensure optimal performance and reduce the risk of unexpected failures.

Routine Checks

- Inspect the oil levels frequently and change it as needed.

- Check air filters regularly for dirt and debris, replacing them when necessary.

- Examine the spark plugs for wear and replace them to maintain ignition efficiency.

Seasonal Care

- Before the onset of winter, prepare the machine by draining any fuel to prevent degradation.

- Clean the exterior thoroughly to remove any grime or buildup that can cause corrosion.

- Store in a dry, sheltered location to protect against environmental damage.

By implementing these practices, you can significantly extend the operational life of your equipment and ensure it remains in top working condition.