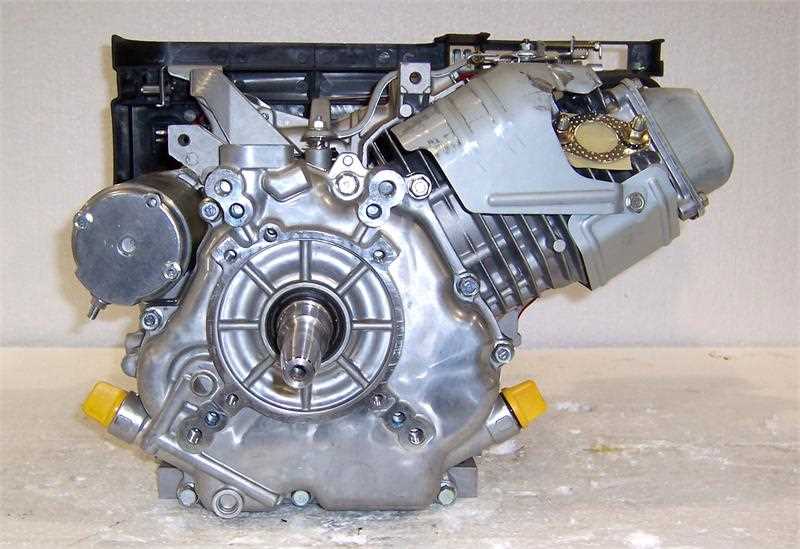

Understanding the intricate structure of high-performance motors is crucial for maintaining their longevity and efficiency. This section provides a detailed examination of the various elements that come together to create a reliable and powerful engine. Each piece plays a pivotal role in ensuring smooth operation and optimal output, offering insight into how these machines deliver consistent performance.

Efficient engine maintenance depends on familiarizing yourself with the internal layout of the machinery. By knowing where each element is positioned and how it contributes to the overall functionality, you can better address any issues that may arise. From fuel systems to the cooling mechanism, every part has a specific task that enhances the engine’s capability.

For those looking to optimize their motor’s functionality, having a clear understanding of the mechanical layout is essential. With the correct approach, you can ensure seamless operations and extend the machine’s lifespan. This guide offers an insightful look into the various sections, enabling you to navigate the complexities of motor maintenance with ease.

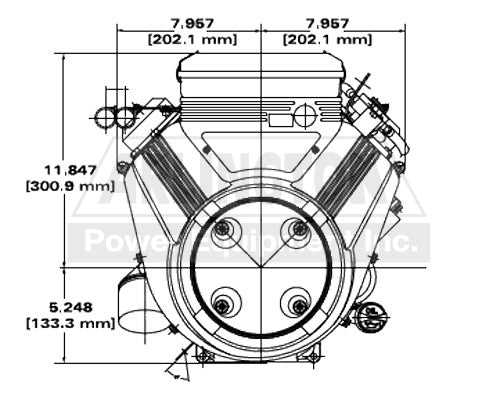

Briggs and Stratton Vanguard Overview

The power units known for their durability and efficiency are often chosen for a wide range of demanding applications. These machines are designed to provide consistent performance, making them a preferred option in various industries. With a reputation for handling tough environments, these engines are built to last and deliver reliable operation.

Key Features

One of the notable aspects of these engines is their ability to maintain power under heavy loads. This capability is supported by advanced technology that ensures smoother operation and reduces wear over time. Fuel efficiency and low maintenance requirements are additional advantages that make these power units a popular choice among professionals.

Applications

These engines are versatile and used in several sectors, from construction equipment to agricultural machinery. Their robust design allows them to function optimally in various environments, providing a dependable source of energy for multiple applications.

Common Applications of 23 HP Engine

The 23 HP engine is widely utilized in a variety of machines across different industries due to its powerful performance and reliability. Its versatility makes it suitable for both professional and recreational uses, where consistent power is essential. Many machines that require a robust and efficient engine for heavy-duty tasks often incorporate this type of motor.

Lawn Care Equipment

This engine is frequently found in commercial lawn mowers, allowing for efficient and quick maintenance of large areas. Its strong performance ensures smooth operation even on uneven terrain, making it a popular choice for landscapers.

Construction and Industrial Equipment

The engine is also commonly used in industrial settings, powering machines such as generators, pressure washers, and small construction vehicles. Its durability and ability to handle demanding tasks make it indispensable in these fields.

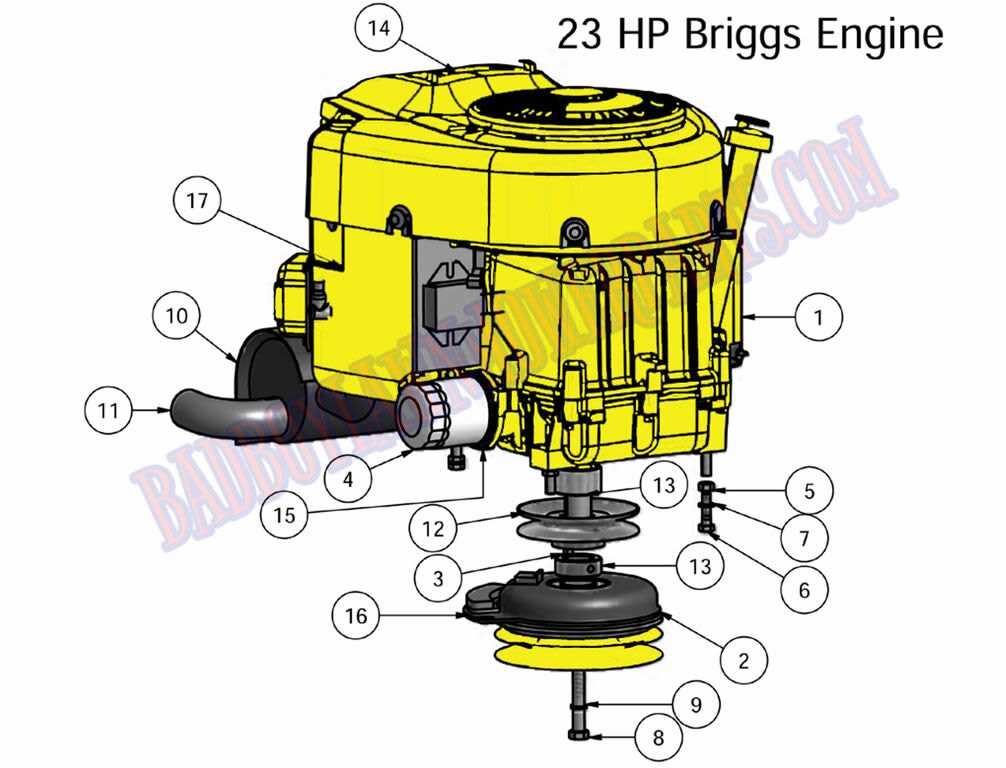

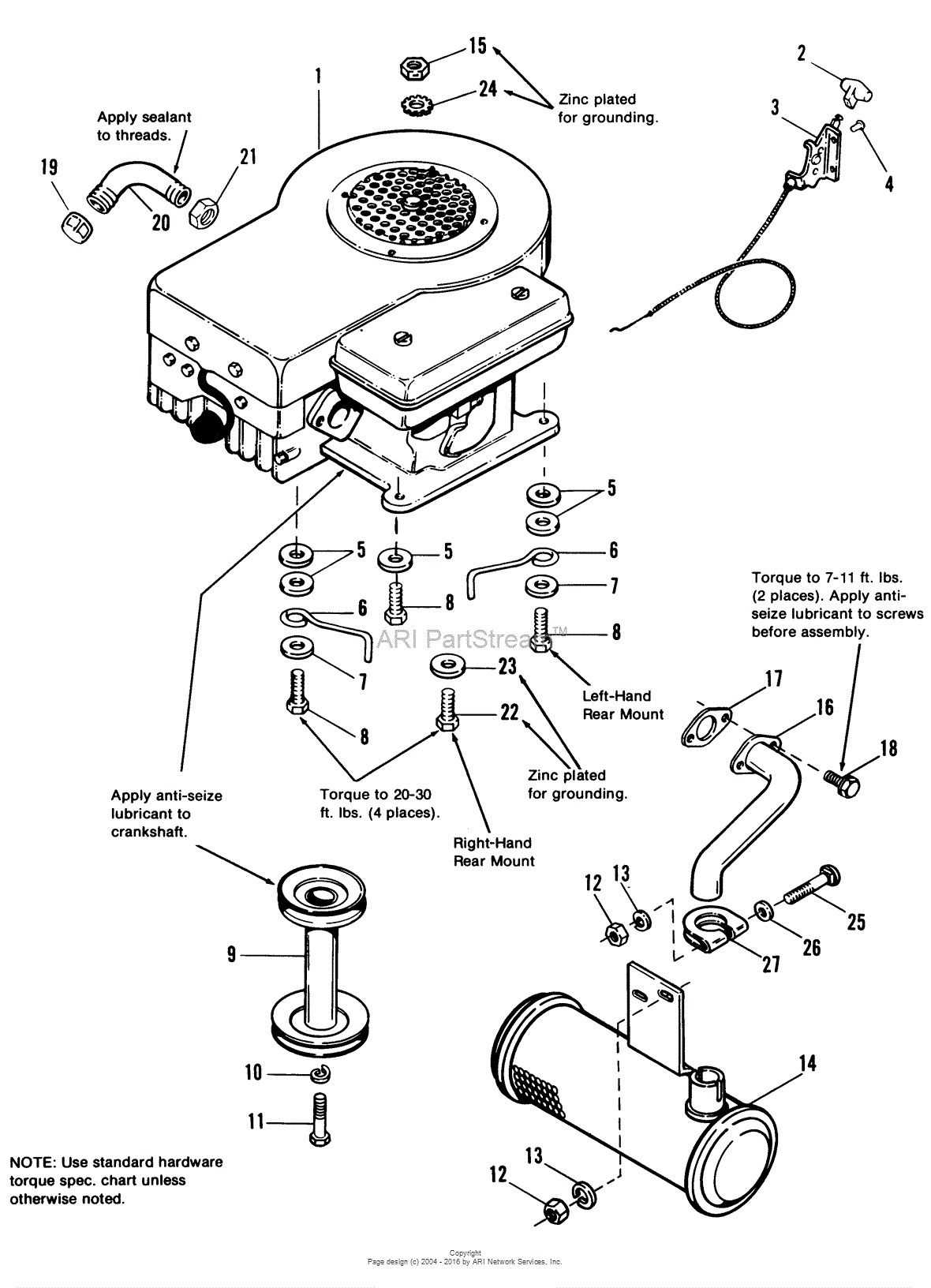

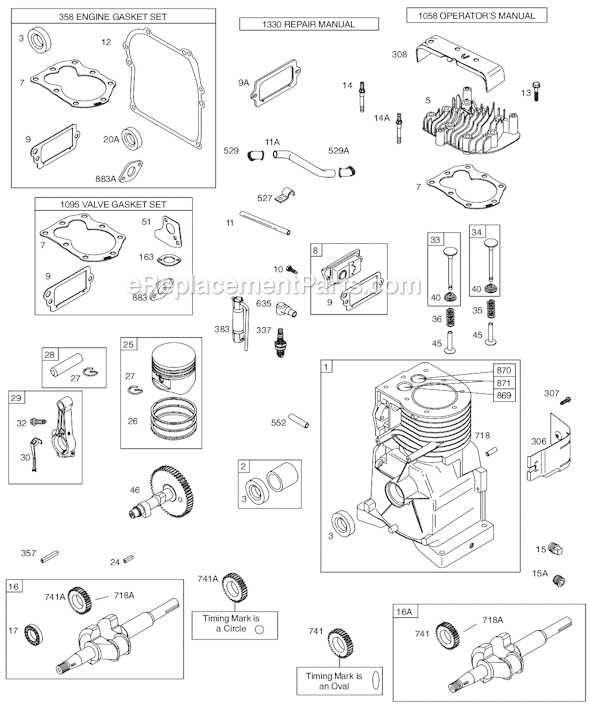

Key Components in the 23 HP Vanguard

The engine in question operates with various essential elements that contribute to its efficient performance. These elements ensure the unit functions reliably under diverse conditions, supporting its overall durability and power output. Understanding the core elements can help maintain optimal performance and assist in any necessary repairs or adjustments.

Core Elements and Their Functions

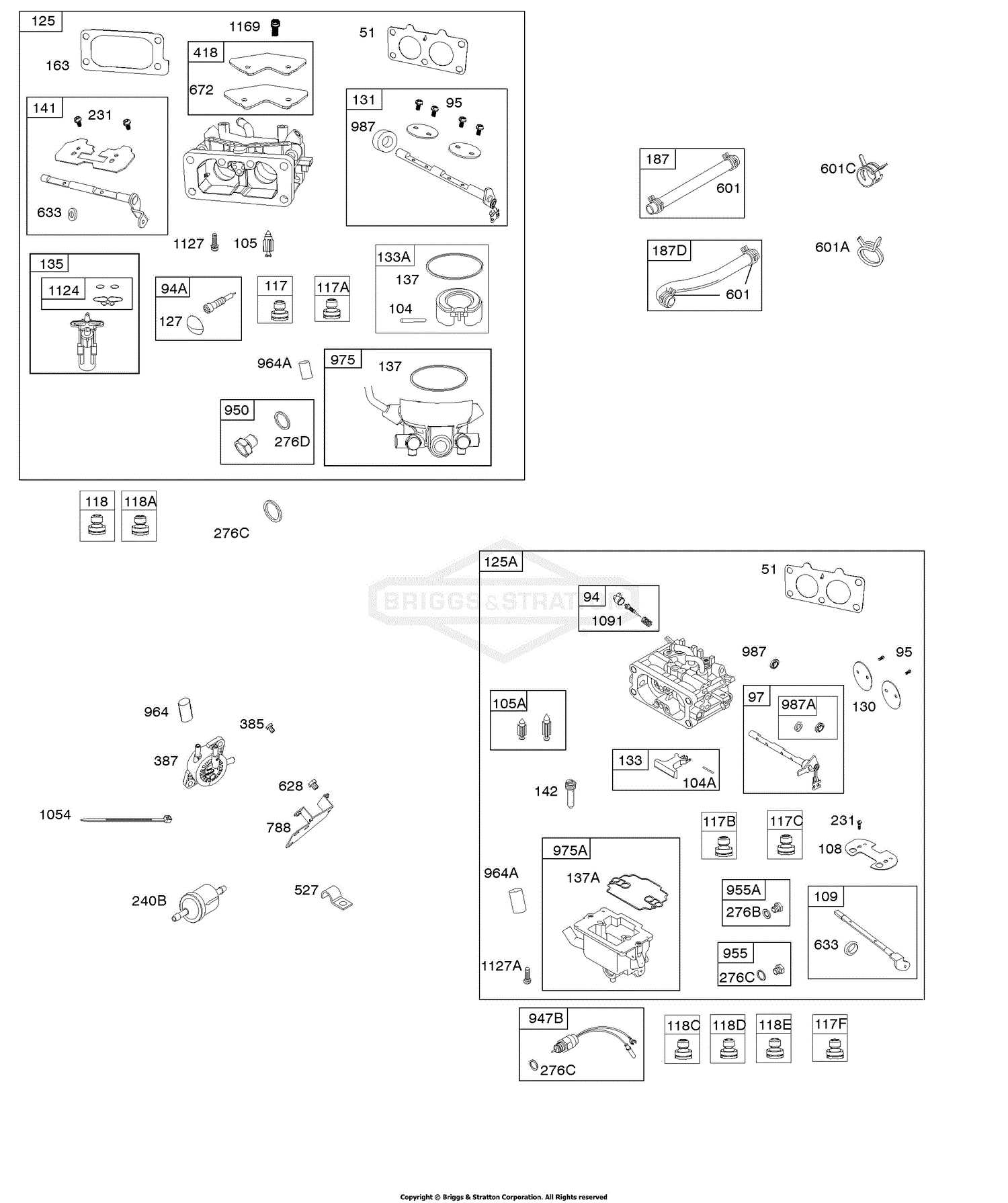

The main elements of this engine system include components responsible for air intake, fuel delivery, combustion, and exhaust management. Each plays a vital role in ensuring smooth operation and maintaining consistent power. Properly maintained, these parts work together to reduce wear and prolong the life of the system.

| Component | Function | |||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Air Filter | Ensures clean air reaches the combustion chamber. | |||||||||||||||||||||||||||||||||||||

| Carburetor | Regulates the mixture of fuel and air for

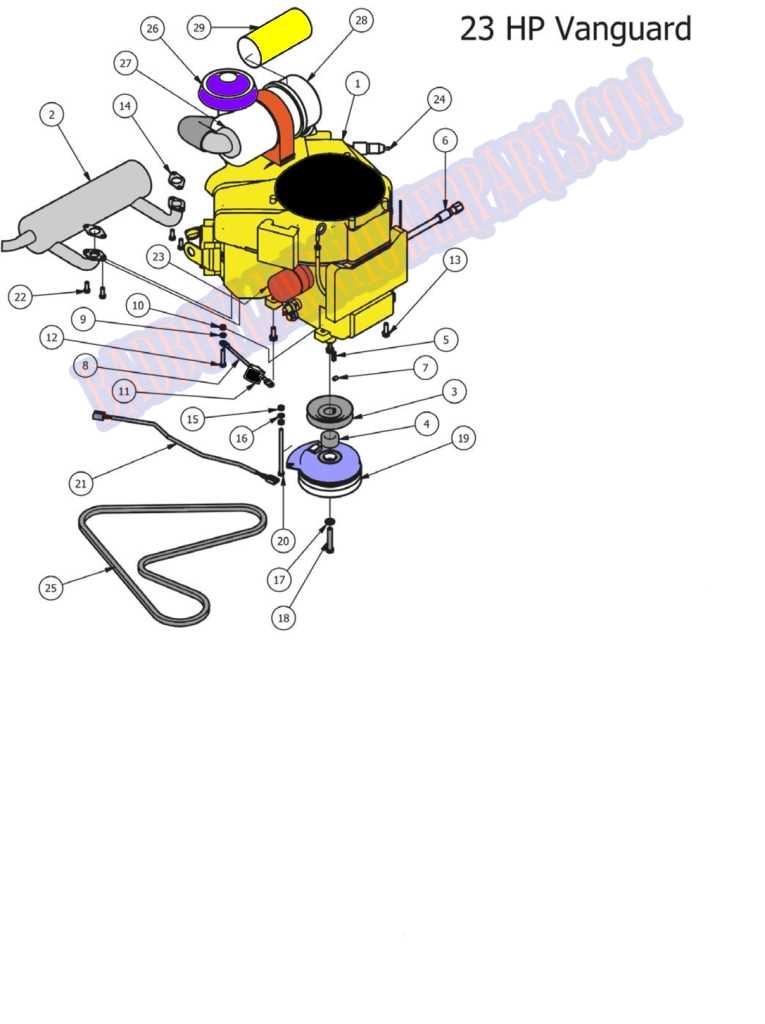

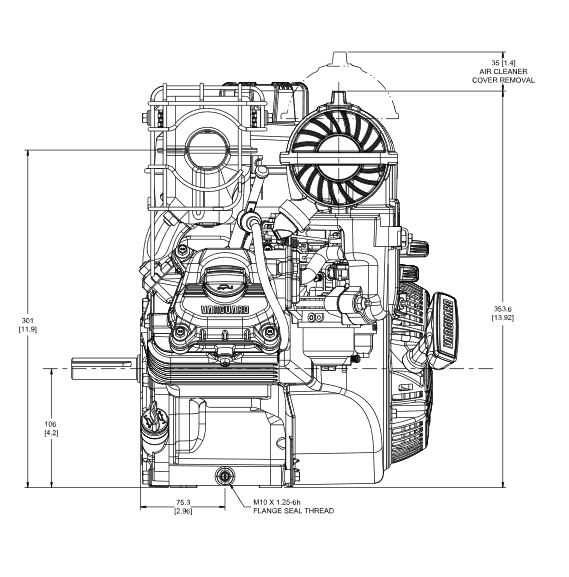

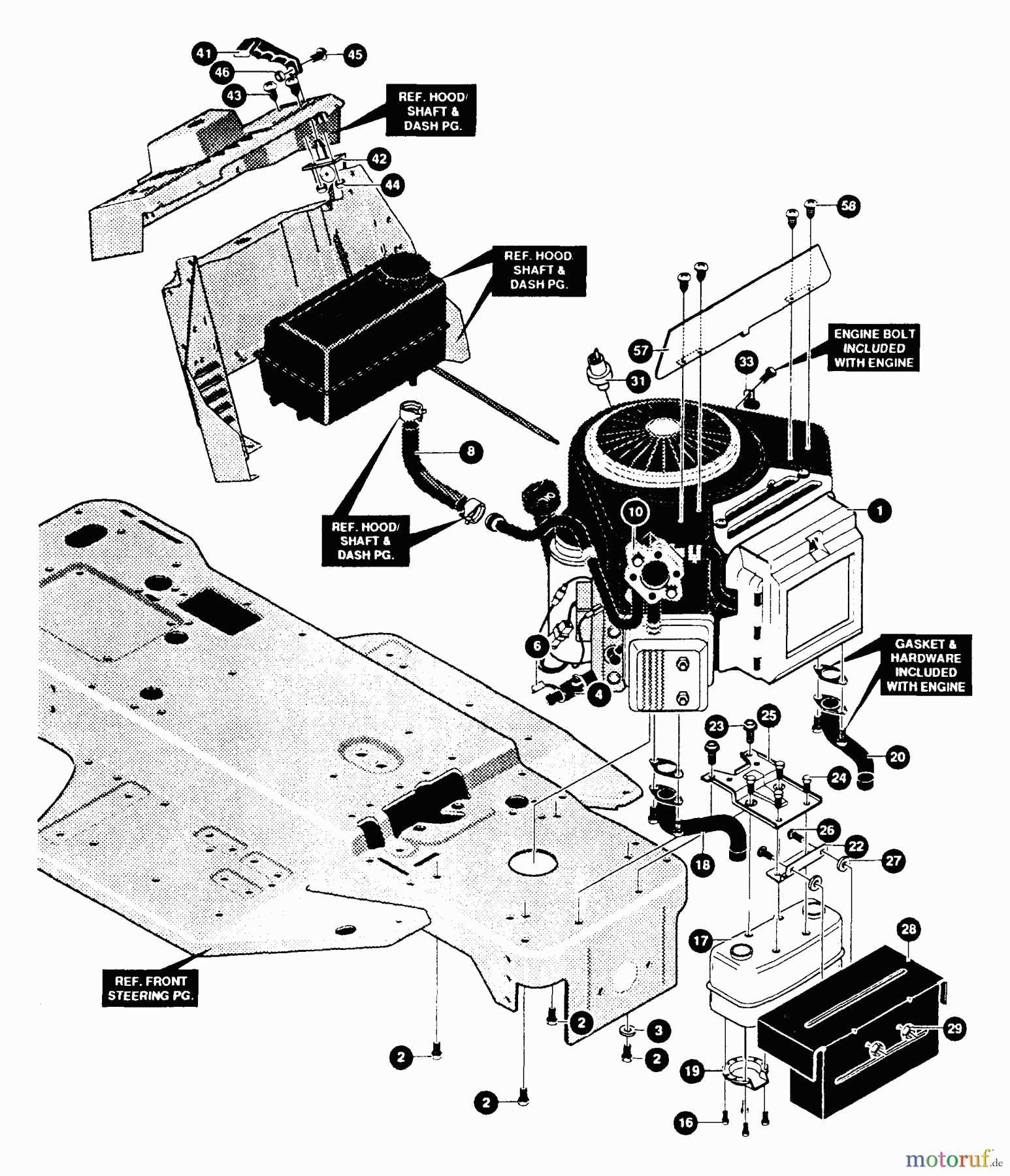

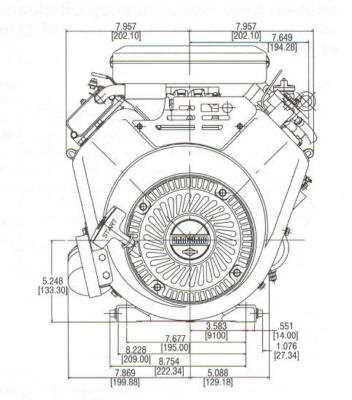

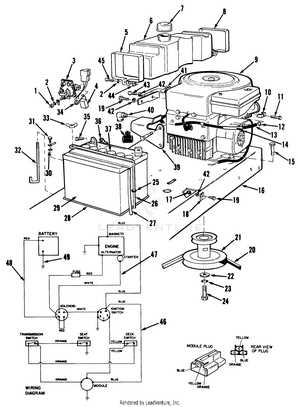

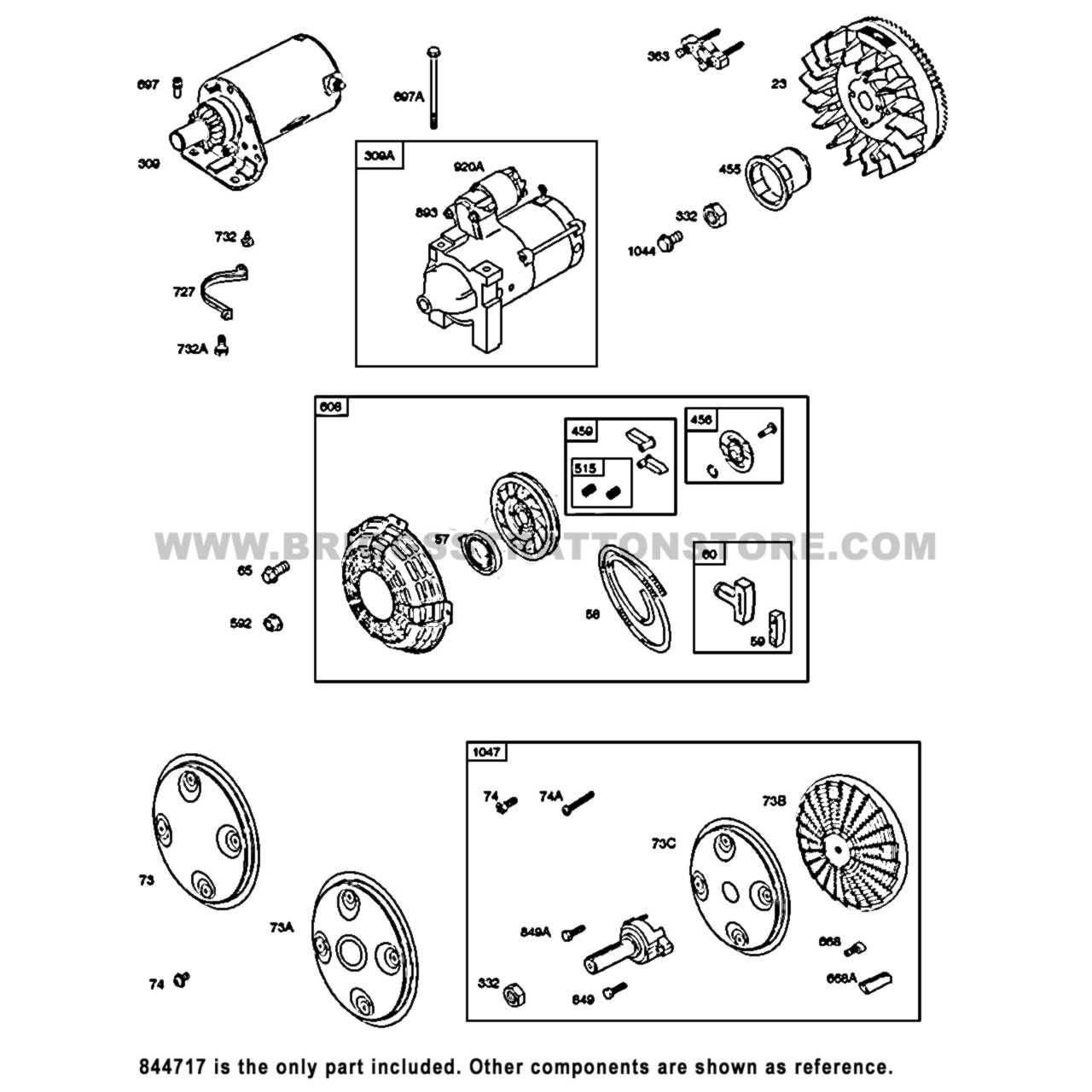

Understanding the Parts Diagram LayoutThe layout of a mechanical illustration provides a comprehensive view of various components and their relationship to one another. This visual guide is designed to help users identify individual elements and understand how they fit together within a larger system. By examining the arrangement carefully, one can pinpoint connections and understand the flow of assembly. A key aspect of this type of layout is its clarity, which enables easy identification of different sections. Each element is typically numbered or labeled, allowing users to cross-reference with a list for proper identification.

Accurate identification not only ensures efficient repairs but also prolongs the lifespan of the motor by allowing precise maintenance. Consistently practicing these steps will enhance your ability to recognize engine components with confidence. Maintenance Tips for Briggs Vanguard EnginesProper upkeep is essential for ensuring the longevity and optimal performance of high-powered engines. Regular attention to maintenance not only enhances efficiency but also minimizes the risk of unexpected failures. By following specific guidelines, users can keep their engines running smoothly and effectively. 1. Regular Oil Changes: Maintaining clean oil is crucial for engine health. It is recommended to change the oil every 50 hours of operation or at least once a season. This practice prevents dirt and debris from accumulating, which can cause wear and tear on internal components. 2. Air Filter Inspection: A clean air filter ensures that the engine receives an adequate amount of air for combustion. Inspect the filter regularly and replace it as needed, especially in dusty environments. This simple step can significantly improve engine performance. 3. Spark Plug Replacement: Spark plugs play a vital role in engine ignition. Regularly check and replace worn or damaged spark plugs to ensure efficient starting and smooth operation. This can also help improve fuel efficiency. 4. Fuel System Care: Using fresh fuel is essential for optimal performance. Old or contaminated fuel can lead to starting issues and decreased efficiency. It’s advisable to empty the fuel tank if the engine will not be used for an extended period, and to use a fuel stabilizer to maintain fuel quality. 5. Cooling System Maintenance: Keeping the cooling system clean is vital for preventing overheating. Regularly check coolant levels and inspect hoses for any signs of wear. Cleaning debris from the cooling fins can also enhance airflow and cooling efficiency. 6. Belt and Cable Checks: Inspect belts and cables for signs of wear or damage. Replace frayed or cracked belts immediately to avoid potential breakdowns. Properly adjusted cables ensure that all controls function smoothly and reliably. By adhering to these maintenance tips, users can significantly enhance the reliability and performance of their engines. Regular maintenance not only prolongs the lifespan of the equipment but also ensures safe and efficient operation. Signs of Wear in Engine Components

Understanding the signs of deterioration in engine elements is crucial for maintaining optimal performance and longevity. As machinery ages, various components may exhibit signs of wear that can affect overall efficiency. Recognizing these indicators early can prevent more severe damage and costly repairs. Common Indicators of DeteriorationSeveral symptoms can suggest that engine components are beginning to wear down. Unusual noises, such as knocking or grinding, often point to mechanical issues. Additionally, a decrease in power output or increased fuel consumption can indicate inefficiencies caused by worn parts. Visual Signs of Damage

Physical inspection can reveal a lot about the condition of engine elements. Look for cracks, discoloration, or excessive buildup of debris. Cracks may indicate structural failure, while discoloration can be a sign of overheating or chemical degradation. Regular maintenance and thorough inspections can help identify these issues before they escalate. Replacing Critical Parts for Longevity

Ensuring the durability and optimal performance of machinery relies heavily on the timely replacement of essential components. Over time, various elements within the system can experience wear and tear, potentially leading to decreased efficiency or even operational failures. By proactively addressing these issues, operators can maintain smooth functionality and prolong the lifespan of their equipment. Identifying Key Components

Recognizing which elements require regular inspection and replacement is crucial for effective maintenance. Some critical components may include filters, seals, and belts, which play vital roles in the overall operation. Regular checks can prevent unexpected breakdowns and enhance reliability. Replacement ScheduleEstablishing a systematic replacement schedule is beneficial for maintaining the integrity of the machinery. Following manufacturer recommendations and considering operational hours can guide decisions on when to replace key components. Regular maintenance checks can help identify parts that may need immediate attention.

Importance of Using Genuine Replacement PartsUtilizing authentic components for maintenance and repair is crucial for the longevity and efficiency of machinery. Quality parts ensure that the equipment operates as intended, minimizing the risk of failures and enhancing overall performance. Benefits of Authentic Components

Consequences of Using Imitation Parts

Troubleshooting Common Issues with Diagrams

When dealing with mechanical equipment, understanding the various components and their functions is essential for effective problem-solving. This section aims to provide insights into identifying and rectifying typical malfunctions that may arise, using illustrative representations to enhance comprehension. One of the most frequent concerns is the engine not starting. This issue may stem from inadequate fuel flow or electrical failures. Consulting the schematic can assist in pinpointing the fuel line or ignition system components that may require attention. Another common problem is the equipment overheating. Overheating can be attributed to insufficient cooling or blockage in airflow. By examining the layout, one can locate the cooling fins and air intakes, ensuring they are clear and functioning correctly. Furthermore, a lack of power output can signify problems with the engine’s internal mechanisms. By analyzing the diagrams, users can track down potential issues such as faulty valves or air filters that could hinder performance. In conclusion, leveraging visual aids can significantly streamline the troubleshooting process. By familiarizing oneself with the equipment’s structure, operators can swiftly identify and resolve common issues, enhancing overall efficiency. Where to Find Parts and Diagrams OnlineWhen it comes to maintaining and repairing machinery, locating the necessary components and schematics is essential. The internet offers a plethora of resources that cater to enthusiasts and professionals alike. These resources not only provide valuable information but also help streamline the process of sourcing the required items for efficient repairs. Online Retailers and Marketplaces

Many online retailers specialize in equipment components, offering an extensive selection of items. Marketplaces such as eBay or Amazon allow users to search for specific components by entering relevant keywords. These platforms often include customer reviews and ratings, which can aid in making informed purchasing decisions. Manufacturer Websites

Visiting the official websites of manufacturers is another reliable approach. These sites frequently feature comprehensive catalogs, including detailed images and descriptions. Additionally, users may find user manuals and other documentation that can guide them in identifying the correct components needed for their machinery. In summary, leveraging online resources can significantly enhance the search for components and schematics. Utilizing online retailers, marketplaces, and official manufacturer websites ensures access to a wide array of options, facilitating efficient maintenance and repairs. |