Exploring the intricacies of small motor mechanisms unveils a wealth of information crucial for maintenance and repair. Having a comprehensive overview of individual elements is essential for both enthusiasts and professionals alike. Knowledge of how each part interacts enhances efficiency and ensures longevity of the equipment.

Identifying the components within these engines allows for more informed decisions regarding replacements and upgrades. Whether troubleshooting performance issues or performing routine check-ups, familiarity with each piece contributes significantly to successful outcomes.

Moreover, a visual representation of these elements serves as an invaluable tool. It aids in understanding the layout and function of each segment, simplifying the process of assembly or disassembly. By grasping this foundational knowledge, users can achieve optimal performance from their machinery.

Understanding Briggs and Stratton Engines

This section explores the intricacies of small engines, focusing on their design, functionality, and applications. These power sources are widely utilized in various outdoor equipment, providing reliable performance for both residential and commercial tasks.

Key Components

- Engine Block: The core structure housing the internal mechanisms.

- Piston: Converts fuel combustion into mechanical energy.

- Cylinder: Contains the piston and facilitates combustion.

- Crankshaft: Transforms linear motion from the piston into rotational motion.

- Carburetor: Mixtures air and fuel for optimal combustion.

Maintenance Tips

- Regularly change the oil to ensure smooth operation.

- Inspect and clean the air filter to prevent debris buildup.

- Check spark plugs for wear and replace as needed.

- Examine fuel lines for leaks and deterioration.

- Keep the engine clean to promote cooling and efficiency.

Overview of the 550EX Series

The 550EX Series represents a remarkable line of small engines designed for efficiency and reliability in outdoor equipment. Engineered for various applications, these power units excel in providing optimal performance while maintaining user-friendly features. Their robust design and innovative technology ensure a smooth operation, making them suitable for both casual users and professionals alike.

Key Features

This series is equipped with several noteworthy characteristics, such as enhanced fuel efficiency, easy starting mechanisms, and low maintenance requirements. The incorporation of advanced materials contributes to longevity and durability, allowing for extensive use without compromising performance. These attributes make the 550EX Series a preferred choice among enthusiasts.

Applications

Versatility defines the 550EX Series, as these engines are commonly utilized in lawn mowers, pressure washers, and various outdoor machinery. Their adaptability allows users to tackle a wide range of tasks efficiently, making them an ultimate solution for different gardening and landscaping needs.

Key Specifications of the 140cc Model

This section highlights the essential features and technical aspects of a specific engine model, focusing on its performance, design, and efficiency. Understanding these specifications can aid in maintenance and optimal use.

Engine Performance

- Power Output: 5.5 horsepower

- Fuel Type: Gasoline

- Displacement: 140cc

Design Features

- Weight: Approximately 30 lbs

- Dimensions: Compact for easy handling

- Cooling System: Air-cooled for efficient operation

These specifications serve as a guide for users to better understand the capabilities and functionalities of the engine, enhancing their overall experience.

Common Applications for 550EX Engines

These small yet powerful engines are widely utilized across various outdoor equipment, enhancing performance and reliability. Their versatility makes them suitable for numerous tasks, catering to both residential and commercial needs.

Lawn Mowers: One of the most prevalent uses is in lawn maintenance. Their efficient operation allows for effective grass cutting, ensuring a well-kept lawn.

Pressure Washers: These engines provide the necessary power for high-pressure cleaning applications, making them ideal for residential cleaning tasks.

Generators: In the realm of power generation, they serve as reliable sources for backup electricity, especially during outages.

String Trimmers: Their lightweight design complements string trimmers, facilitating easy handling and maneuverability while tackling overgrown vegetation.

Snow Blowers: In colder climates, these engines are crucial for snow removal equipment, helping to clear driveways and sidewalks efficiently.

Ultimately, the adaptability of these engines makes them a favored choice among manufacturers and users alike, driving various machinery with consistent performance.

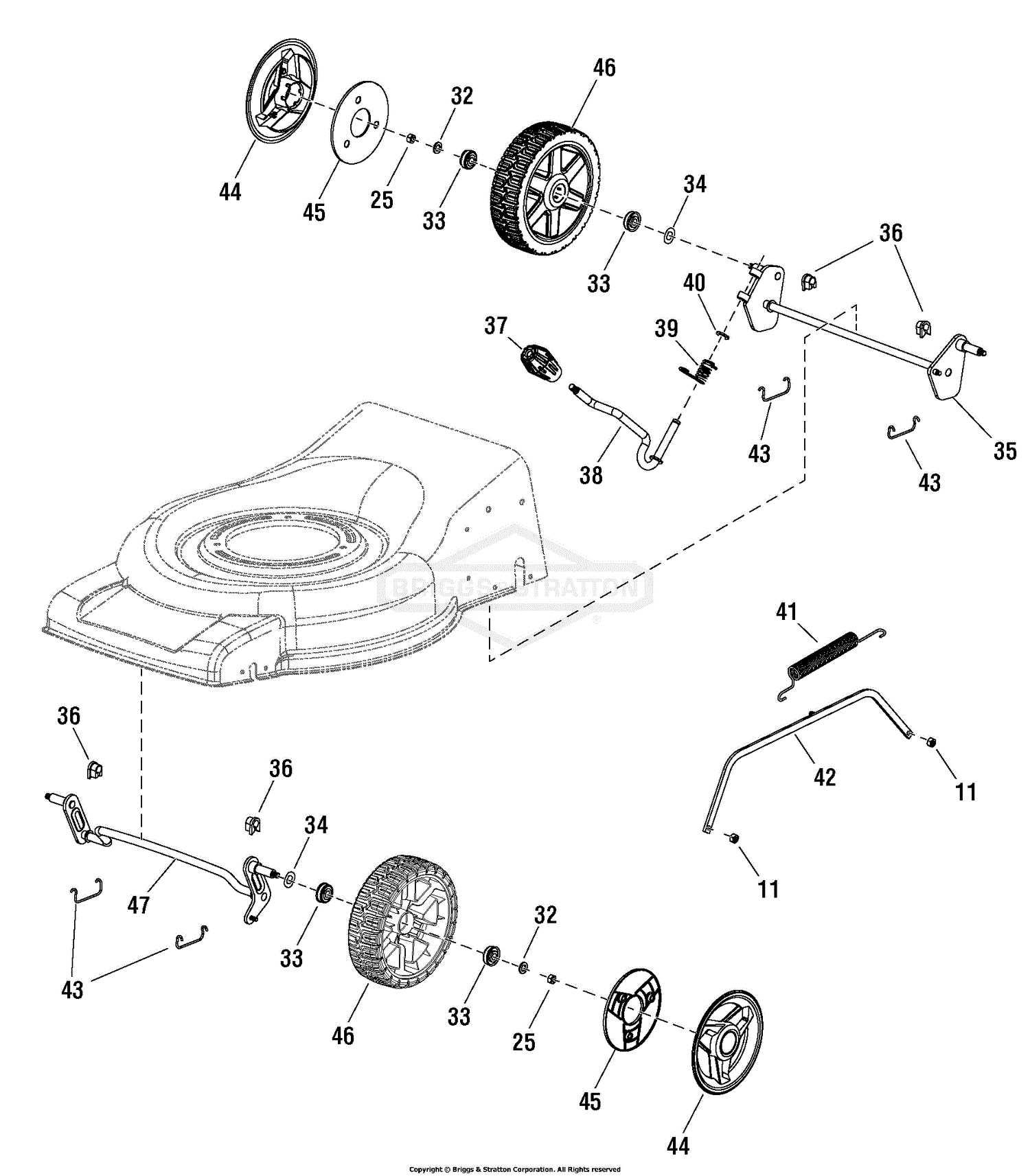

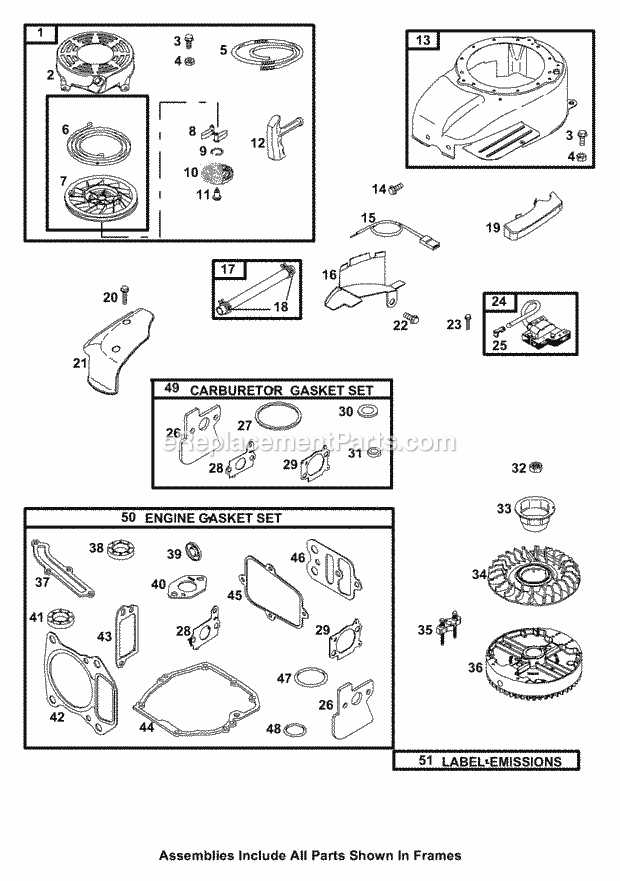

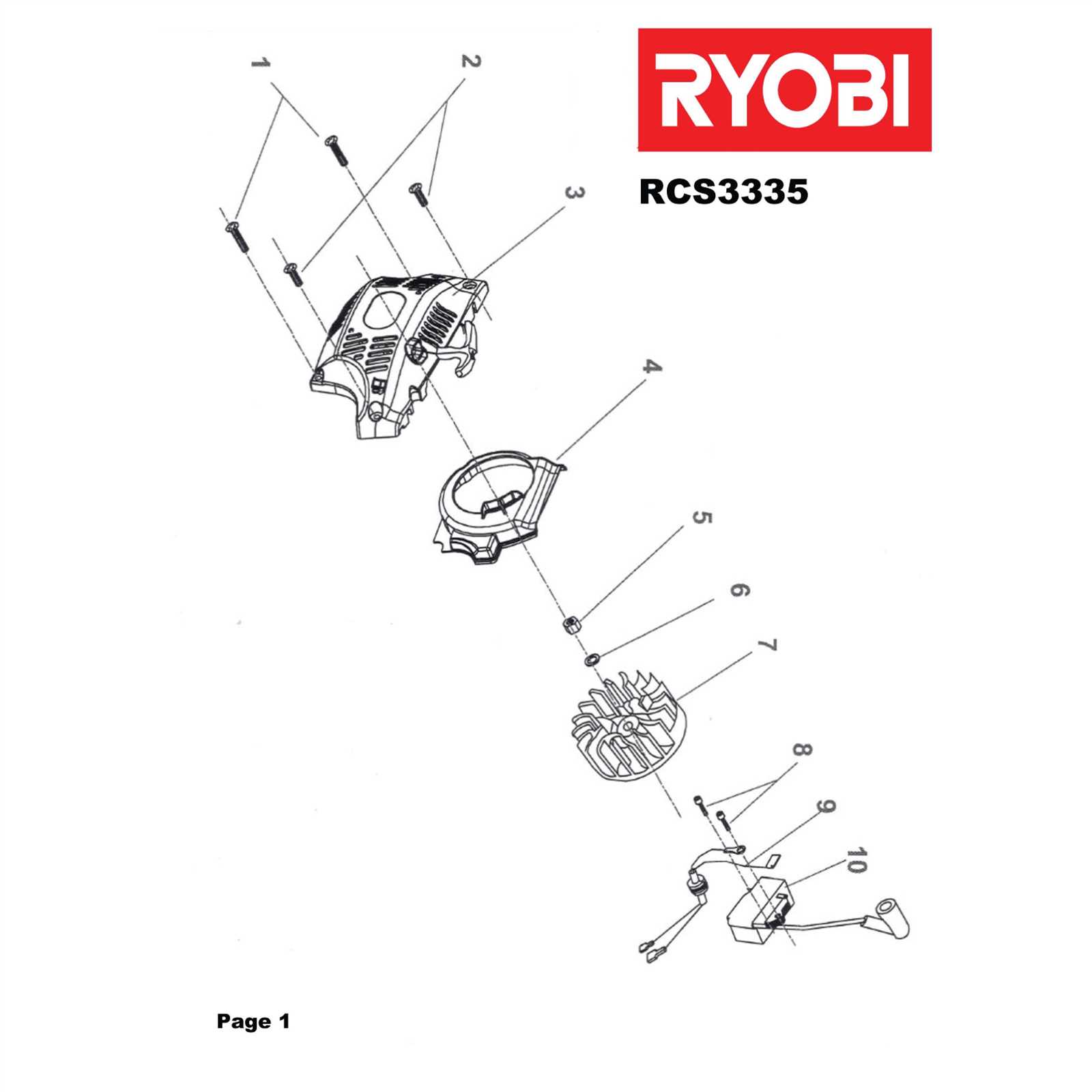

Importance of Parts Diagrams

Understanding the layout and components of a machine is crucial for effective maintenance and repair. Visual representations serve as essential tools for both novice and experienced technicians, simplifying the process of identifying parts and their functions.

Benefits of Visual Guides

- Enhanced Clarity: Illustrations provide a clear view of how each component fits together, reducing confusion during assembly or disassembly.

- Streamlined Repairs: Having a reference can expedite troubleshooting, allowing users to quickly pinpoint issues and solutions.

- Improved Learning: Visual aids help in grasping the operational mechanisms, facilitating better understanding for those unfamiliar with the machinery.

Effective Maintenance Practices

- Regularly consult visual guides during routine checks to ensure all components are functioning optimally.

- Use the illustrations to create a checklist for replacing worn-out elements, ensuring that no part is overlooked.

- Refer to the visuals when modifying or upgrading equipment, aiding in the selection of compatible replacements.

Identifying Essential Components

Understanding the key elements of a small engine is crucial for effective maintenance and repair. Each component plays a vital role in the overall functionality, ensuring optimal performance and longevity. By familiarizing yourself with these critical parts, you can enhance your troubleshooting skills and make informed decisions during servicing.

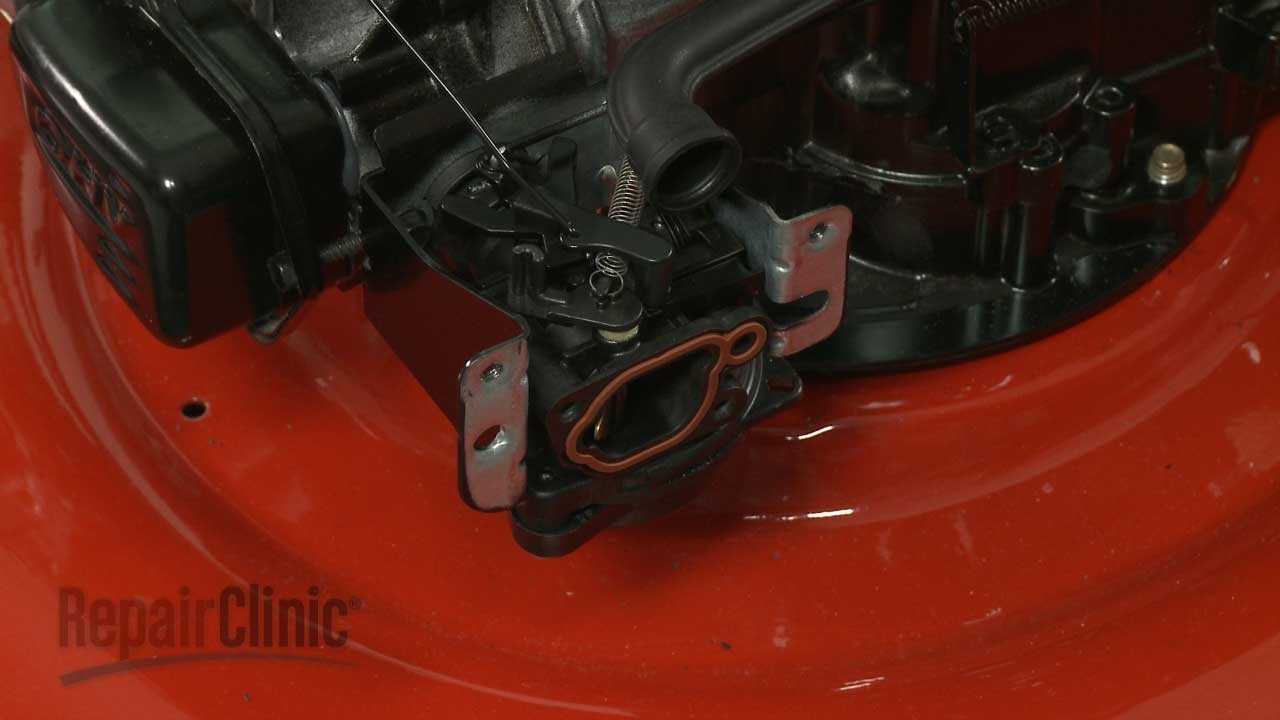

First, the engine block serves as the core structure, housing various mechanisms essential for operation. Secondly, the carburetor is integral for fuel-air mixture regulation, directly impacting combustion efficiency. Additionally, the spark plug ignites the fuel mixture, making it indispensable for starting the engine.

Lastly, the fuel tank stores the necessary fuel for operation, while the air filter ensures clean airflow, promoting engine health. Grasping the function of these components is the first step toward successful maintenance.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended life of any engine. Regular attention to maintenance tasks not only enhances performance but also prevents costly repairs down the line. By adhering to a few straightforward guidelines, you can keep your machinery operating efficiently for years to come.

Regular Oil Changes

Changing the oil regularly is crucial for optimal engine function. Fresh oil helps lubricate components and reduce wear.

Clean Air Filters

Maintaining clean air filters is vital for airflow and performance. Clogged filters can lead to reduced efficiency and increased fuel consumption.

| Maintenance Task | Frequency |

|---|---|

| Oil Change | Every 25 hours of use |

| Air Filter Check | Every 10 hours of use |

| Spark Plug Inspection | Every 50 hours of use |

Where to Find Replacement Parts

Locating suitable components for maintenance can be essential for optimal performance. There are several reliable sources where one can procure the necessary items to ensure your equipment operates smoothly.

- Authorized Dealers: Visiting official dealers guarantees authenticity and quality.

- Online Retailers: Websites dedicated to outdoor equipment often have a wide selection and competitive pricing.

- Local Hardware Stores: Many neighborhood shops carry essential components for popular machinery.

- Manufacturer’s Website: Checking the official site can provide direct access to the latest offerings and specifications.

Before purchasing, it’s wise to verify compatibility and quality to ensure longevity and reliability in your machinery.

Step-by-Step Repair Guide

This guide offers a comprehensive approach to fixing small engine issues effectively. By following these clear steps, you can restore your equipment to optimal performance without unnecessary complications.

Step 1: Begin by gathering all necessary tools and replacement components. A well-organized workspace is crucial for efficiency.

Step 2: Carefully examine the engine for any visible damage or wear. Make notes of any areas that require special attention during the repair process.

Step 3: Disassemble the relevant sections, ensuring you keep track of all screws and parts. Utilize a labeled container to avoid confusion.

Step 4: Inspect each component for functionality. Clean or replace any parts that show signs of deterioration.

Step 5: Reassemble the engine meticulously, ensuring all pieces fit snugly and securely. Refer back to your notes to confirm correct placement.

Step 6: Conduct a final check for any loose fittings or leftover tools. Test the engine to confirm it operates smoothly.

Step 7: Document the repair process for future reference, noting any challenges faced and solutions discovered.

Troubleshooting Common Issues

When working with small engines, it’s essential to identify and resolve frequent problems that can hinder performance. Understanding typical symptoms can help in diagnosing issues efficiently, leading to quicker repairs and a smoother operation.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Engine won’t start | No fuel, clogged filter, dead battery | Check fuel level, replace filter, recharge or replace battery |

| Engine runs rough | Dirty carburetor, faulty spark plug | Clean carburetor, inspect and replace spark plug |

| Excessive vibration | Loose parts, unbalanced blade | Tighten loose components, balance or replace blade |

| Overheating | Low oil level, blocked air intake | Check and refill oil, clear air intake |

| Poor performance | Old fuel, air filter blockage | Replace old fuel, clean or replace air filter |

By addressing these common problems, users can ensure their engines function effectively and enjoy a longer lifespan. Regular maintenance is key to preventing these issues from arising.

Safety Precautions During Repairs

Ensuring safety while performing maintenance on small engines is crucial. Adopting proper measures can significantly reduce the risk of accidents and injuries. Being aware of the environment and using appropriate tools and techniques helps create a secure workspace.

Essential Safety Gear

Before starting any repair work, it’s important to equip yourself with the right protective gear. This includes items that safeguard against potential hazards associated with engine maintenance.

| Safety Equipment | Purpose |

|---|---|

| Safety Goggles | Protect eyes from debris and chemicals |

| Gloves | Prevent cuts and chemical exposure |

| Ear Protection | Reduce noise exposure during operation |

| Steel-Toed Boots | Protect feet from heavy equipment |

Work Area Safety

Maintaining a clean and organized workspace is vital for minimizing risks. Ensure that tools are stored properly and any spills are cleaned immediately. Additionally, always work in a well-ventilated area to avoid inhaling harmful fumes.

Benefits of Using Genuine Parts

Opting for authentic components in maintenance and repair tasks offers a multitude of advantages that significantly enhance performance and longevity. These original items are specifically designed to fit and function seamlessly with the equipment, ensuring optimal operation and reliability.

Quality Assurance: Genuine components undergo rigorous testing and meet strict manufacturing standards, which ensures they perform efficiently under various conditions. This reliability reduces the likelihood of breakdowns and costly repairs in the long run.

Compatibility: Original items are crafted to match the exact specifications of the equipment, ensuring a perfect fit. This compatibility minimizes the risk of malfunctions that can occur with generic alternatives.

Longevity: Using authentic components often results in a longer lifespan for your equipment. These parts are built with high-quality materials that withstand wear and tear, leading to less frequent replacements.

Warranty Protection: Many manufacturers provide warranties on their products when authentic items are used for repairs. This protection gives users peace of mind and can save money on future repairs.

Resale Value: Maintaining equipment with genuine components can positively impact its resale value. Prospective buyers often prefer machines that have been kept in optimal condition with original parts.

In summary, choosing authentic components not only enhances the performance and durability of equipment but also provides significant long-term benefits for users.