The study of small combustion systems reveals a complex arrangement of elements that work together to produce reliable performance. Each component plays a crucial role in ensuring efficiency and longevity, making it essential to familiarize oneself with their arrangement and function. By examining the layout of these various components, users can gain insights into maintenance and troubleshooting, enhancing their overall experience with the machinery.

Furthermore, a comprehensive overview of the different sections and mechanisms within these systems provides a clearer understanding of how they interact. Recognizing the individual elements and their respective roles helps in diagnosing issues and performing effective repairs. This knowledge empowers users to engage with their machines more confidently, ultimately leading to better upkeep and functionality.

Whether one is a seasoned mechanic or a novice enthusiast, grasping the intricacies of these systems can lead to significant improvements in both operation and maintenance. This exploration serves not only as a reference but also as an opportunity to deepen one’s appreciation for the craftsmanship behind these remarkable devices.

Understanding Briggs and Stratton Engines

This section explores the fundamental aspects of small power units, focusing on their components, functionality, and applications. Such systems are widely recognized for their reliability and efficiency, making them popular choices in various machinery and equipment. By delving into the key features and operational principles, one can appreciate the craftsmanship and engineering that go into these power solutions.

Key Components and Their Functions

The main assembly comprises several crucial elements that work together seamlessly. These include the combustion chamber, fuel delivery system, ignition mechanism, and cooling apparatus. Each component plays a vital role in ensuring optimal performance and longevity. Understanding the interaction between these parts helps users maintain and troubleshoot effectively.

Applications and Versatility

These small power units find use in numerous applications, ranging from lawn maintenance tools to portable generators. Their adaptability is evident in various environments, whether residential or commercial. Users benefit from their compact design and ease of use, making them suitable for both casual and professional tasks.

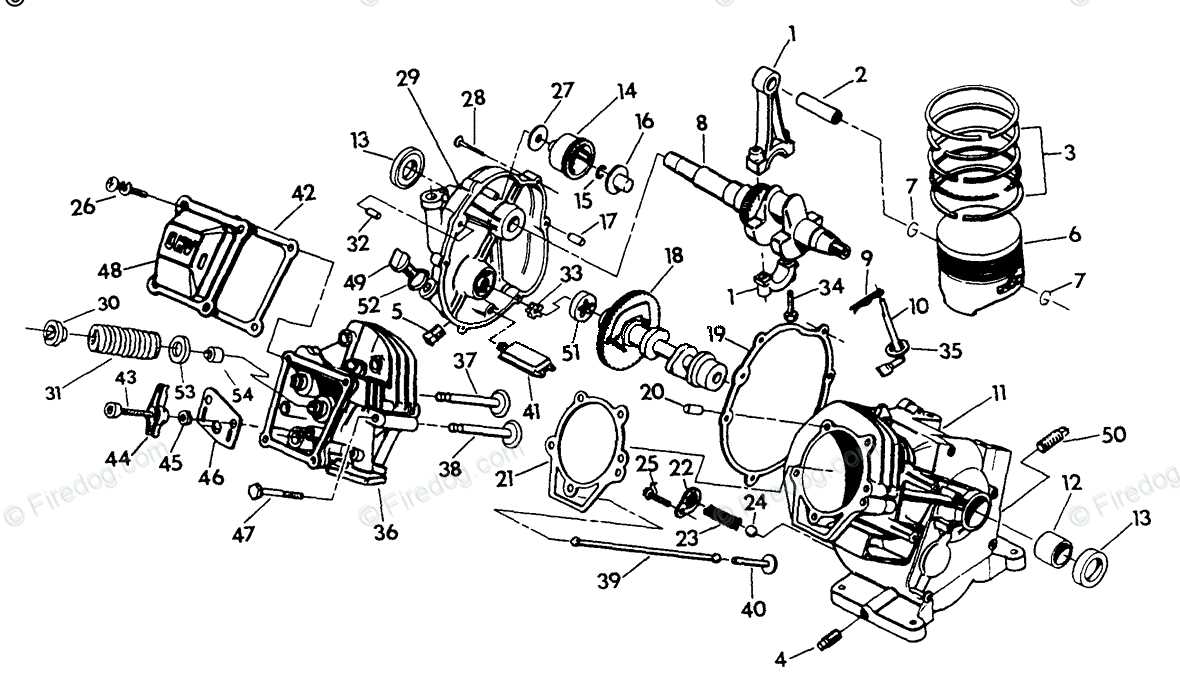

Common Components of Small Engines

Understanding the fundamental elements of compact power units is essential for anyone involved in their maintenance or repair. These essential parts work in harmony to ensure reliable operation, efficiency, and longevity. Each component plays a critical role in the functionality of the machinery, allowing it to perform a variety of tasks effectively.

Fuel Delivery System

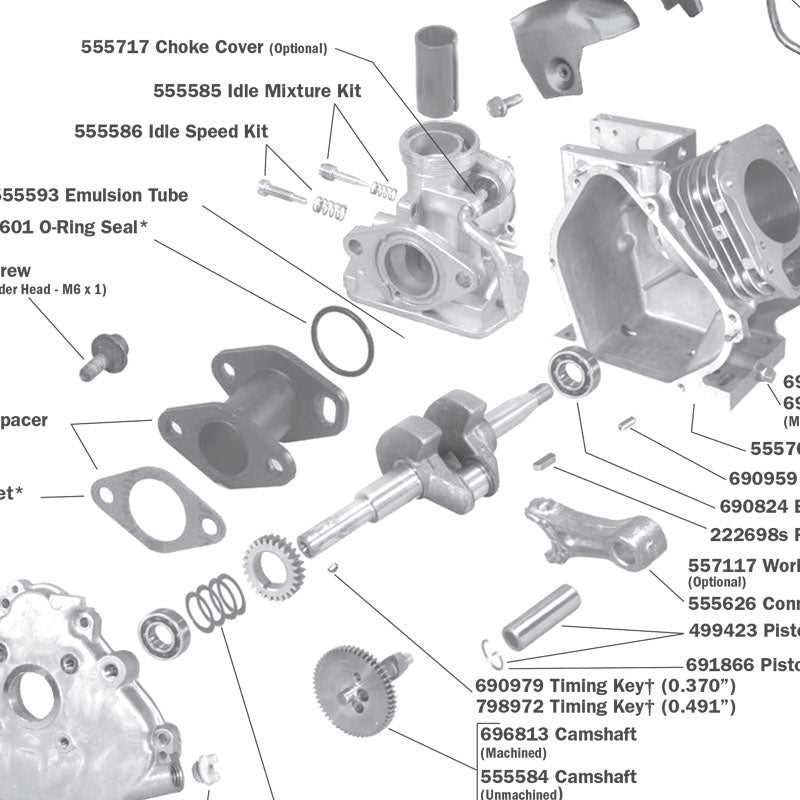

The fuel delivery system is crucial for supplying the necessary fuel to the combustion chamber. It includes elements such as the carburetor, which mixes air and fuel in the correct proportions, and the fuel pump, which ensures a steady flow. Proper maintenance of this system is vital for optimal performance.

Ignition Mechanism

The ignition mechanism is responsible for initiating the combustion process. This includes components like the spark plug, which generates a spark to ignite the air-fuel mixture, and the ignition coil, which amplifies voltage to create a strong spark. A well-functioning ignition system is essential for efficient power generation.

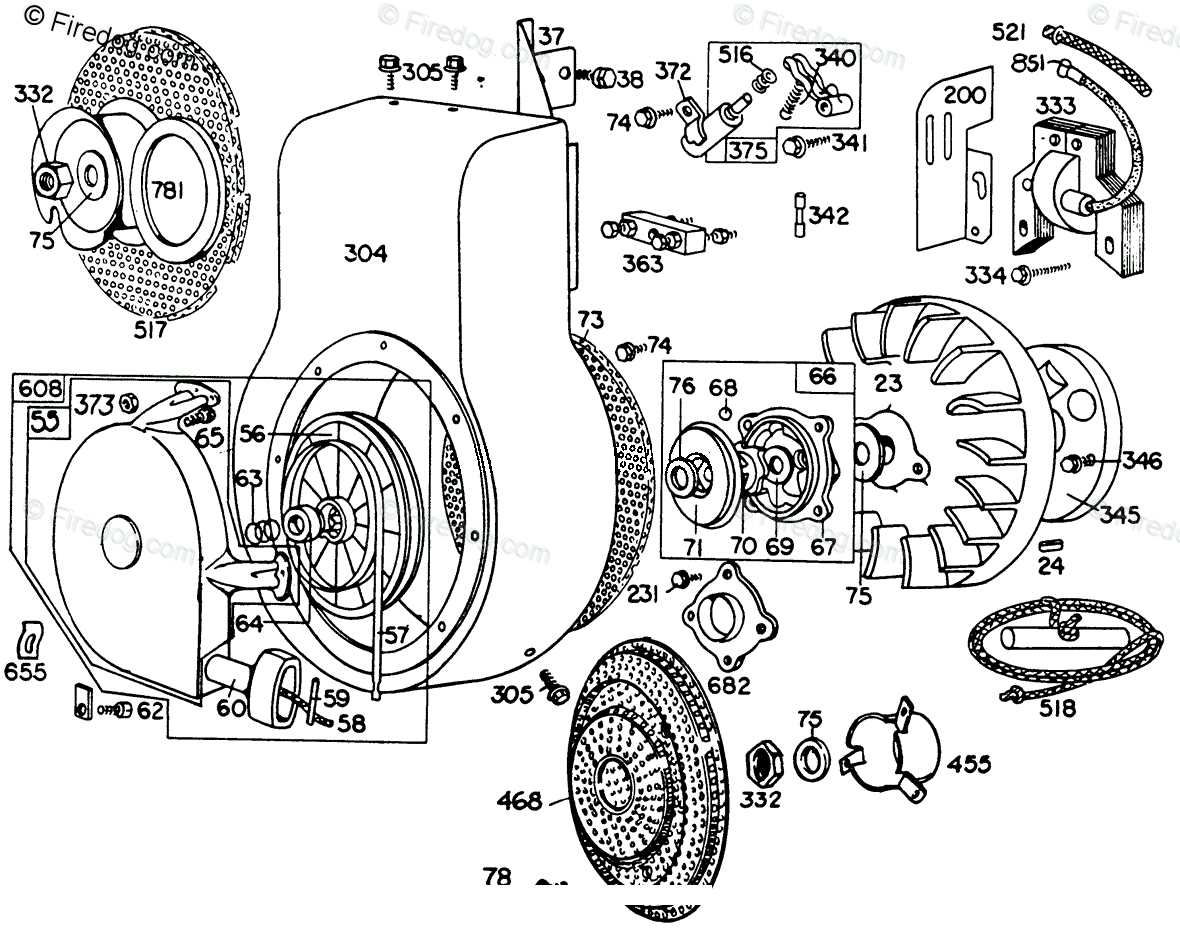

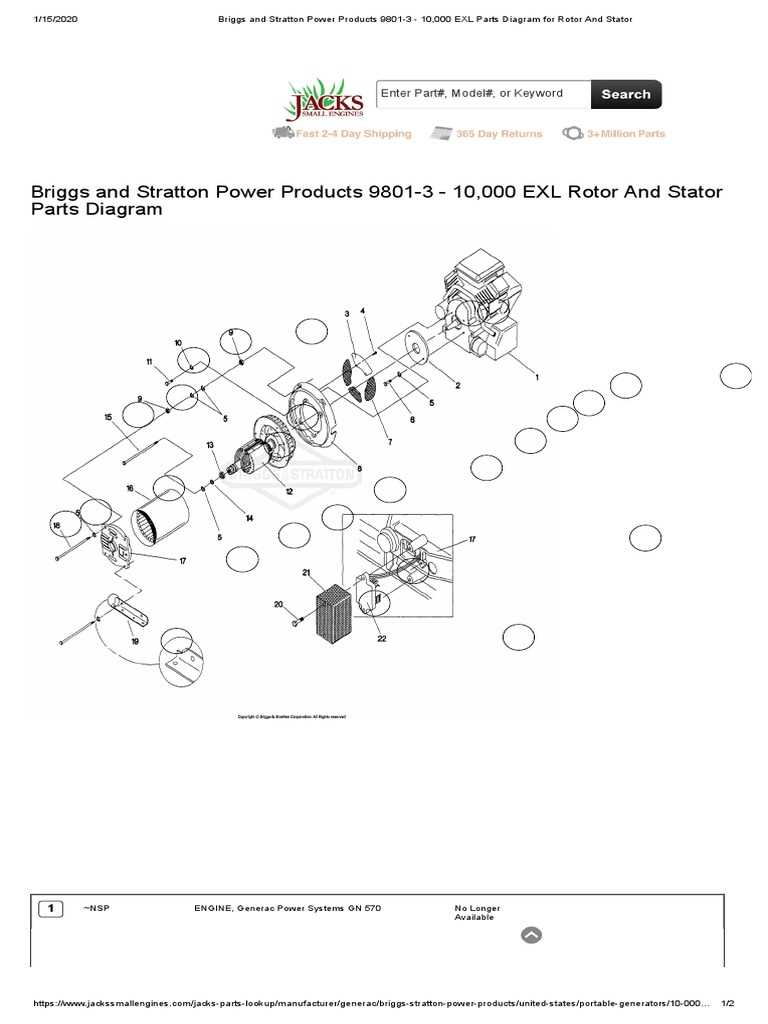

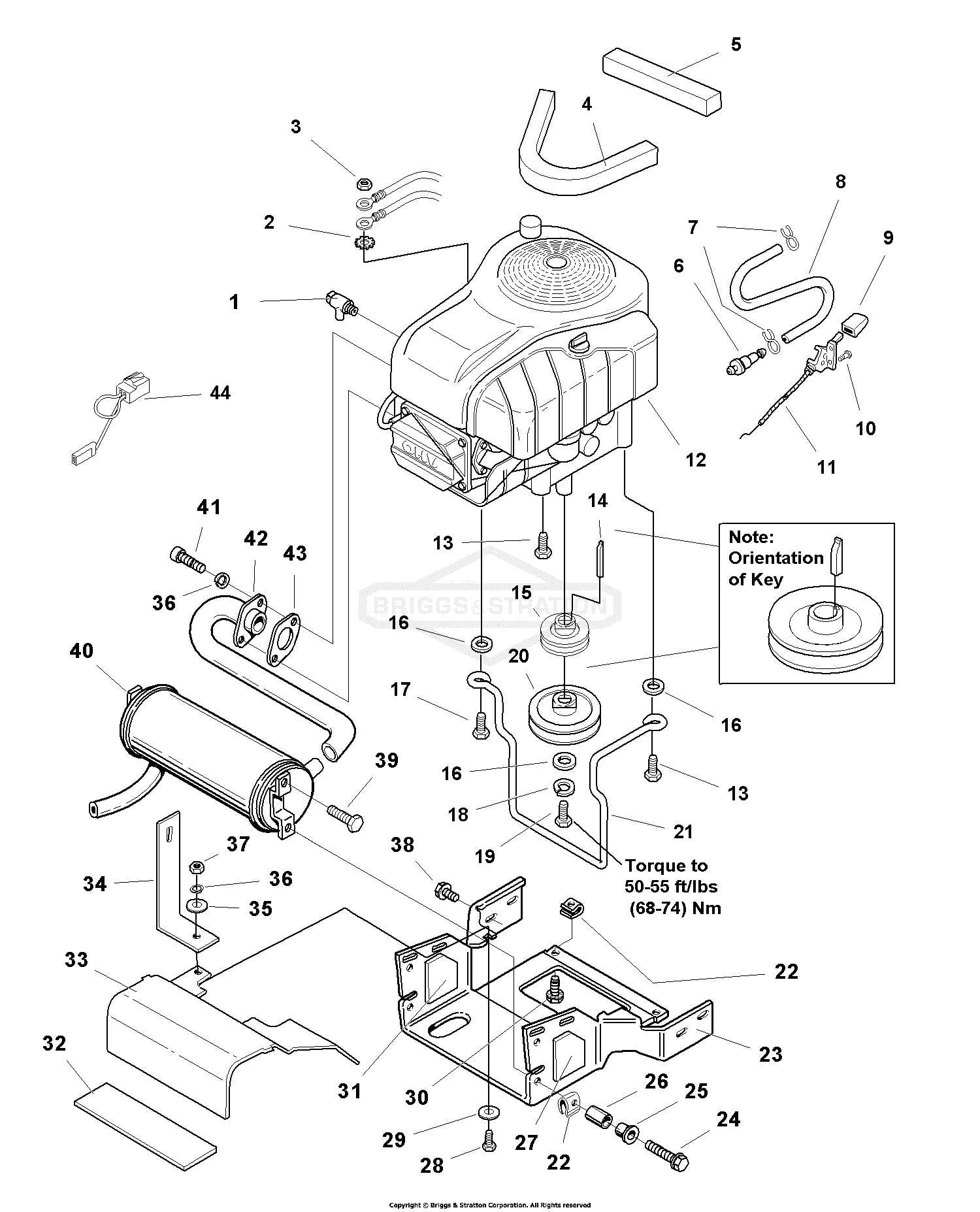

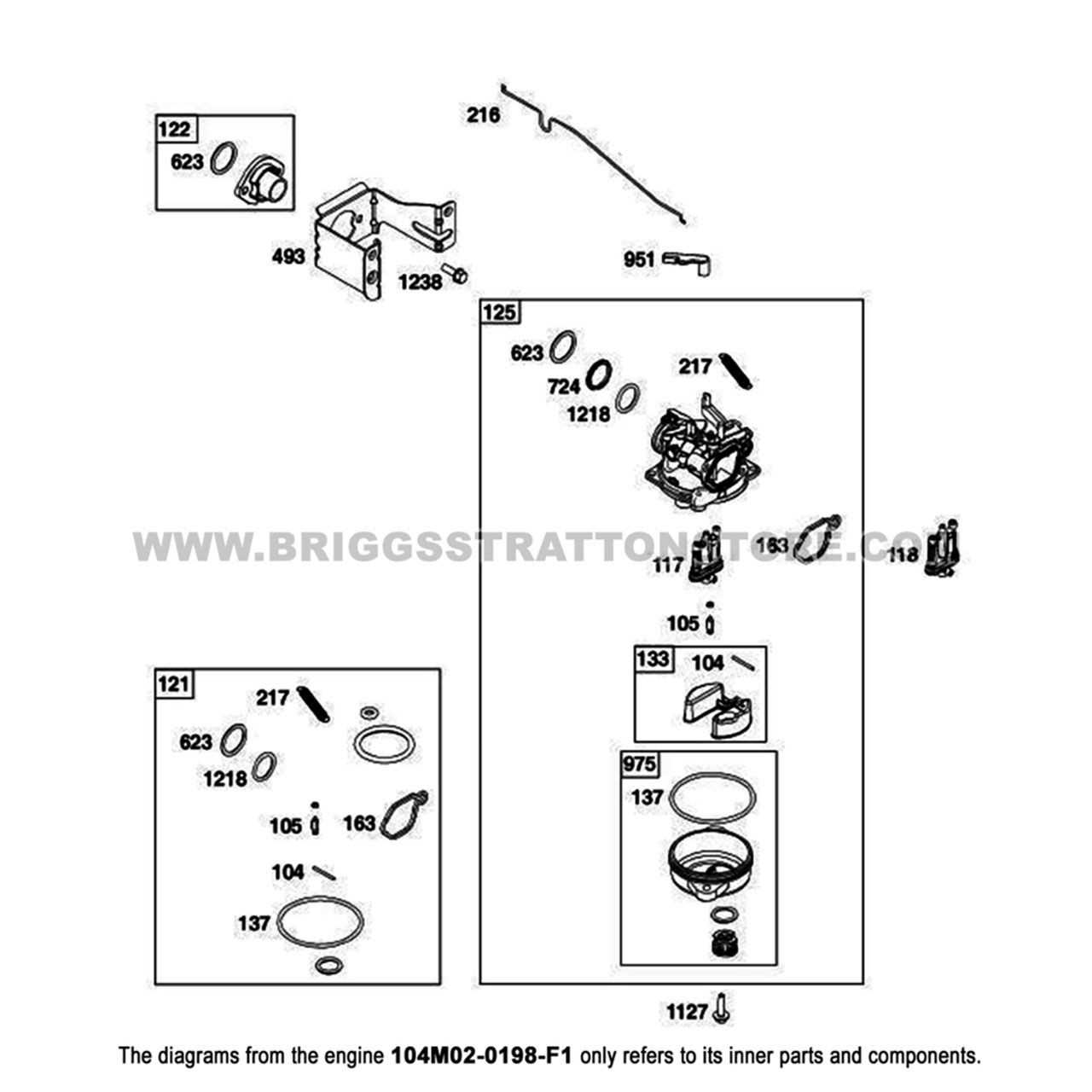

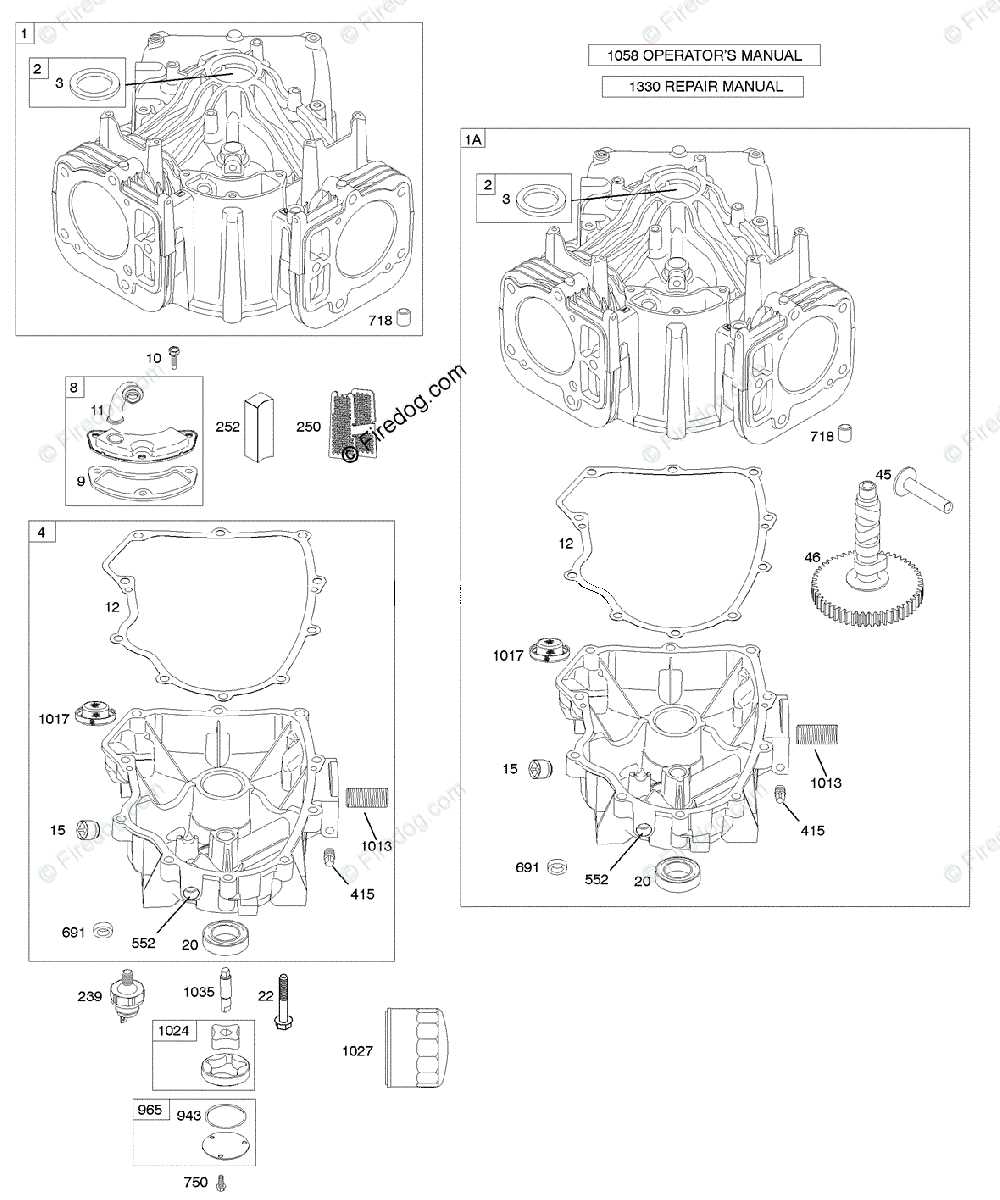

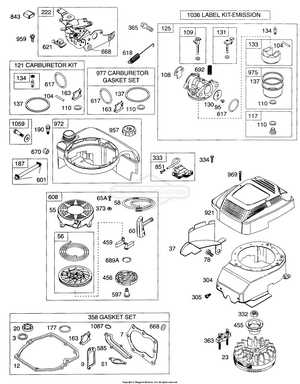

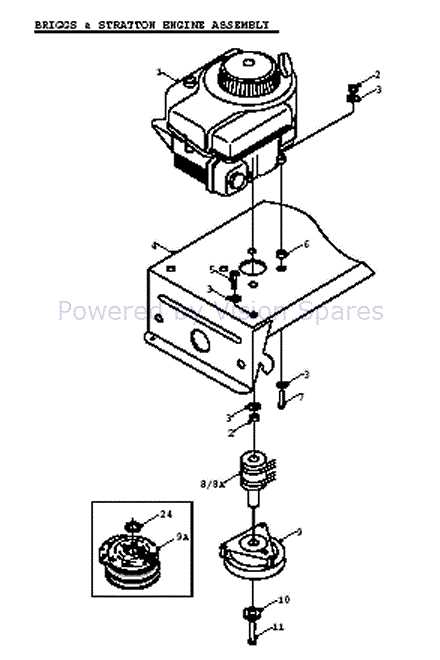

Identifying Parts in Engine Diagrams

Understanding the components of a motor schematic is essential for effective maintenance and repair. Recognizing each element helps in diagnosing issues and implementing solutions efficiently. Familiarity with the visual representation of mechanical systems enables operators and technicians to grasp the layout and functionality of various segments within the unit.

To successfully interpret these visuals, begin by familiarizing yourself with common symbols and shapes used to represent different elements. Circles often indicate rotating components, while rectangles typically represent static elements. Furthermore, arrows denote movement or flow, guiding users through the mechanics of the setup.

Additionally, pay attention to labels and numbers that accompany each illustration. These notations often correspond to a reference list or manual that provides detailed descriptions of each component. By systematically cross-referencing these details, one can accurately identify and understand the roles of various sections in the schematic.

Maintenance Tips for Engine Longevity

Ensuring the durability of your motor relies heavily on regular care and attention. By following a few essential practices, you can significantly extend its lifespan and maintain optimal performance.

- Regular Oil Changes: Replacing oil at recommended intervals keeps components lubricated, reducing wear and tear.

- Air Filter Maintenance: Keeping the air filter clean prevents debris from entering the system, promoting efficient combustion.

- Spark Plug Inspection: Periodically checking and replacing spark plugs ensures reliable ignition and smooth operation.

- Fuel Quality: Using high-quality fuel can improve efficiency and prevent issues related to contamination.

- Cooling System Check: Maintaining proper cooling helps avoid overheating, a common cause of serious damage.

Incorporating these practices into your routine will help safeguard your motor from potential problems and enhance its performance over time.

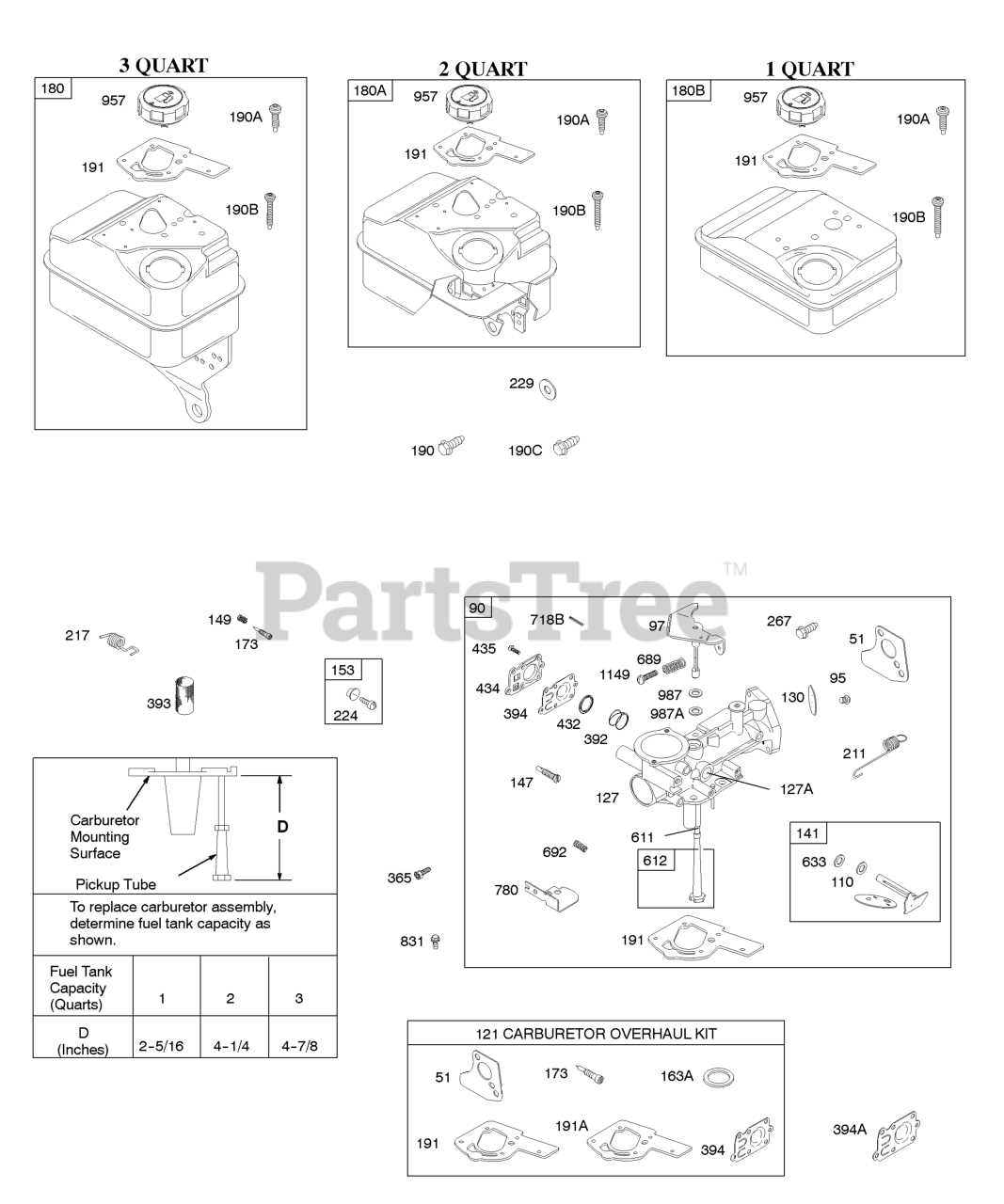

Fuel System Components Explained

The fuel system is crucial for the efficient operation of small power units, ensuring the proper delivery and management of fuel. Each component plays a vital role in maintaining optimal performance and reliability.

The primary element is the fuel tank, where the fuel is stored before it is delivered to the combustion chamber. Connected to the tank is a fuel line that transports the liquid to the carburetor, which mixes the fuel with air to create a combustible mixture. This mixture is then drawn into the combustion area, where it ignites to produce power.

A vital component within the system is the fuel filter, which prevents impurities from reaching the carburetor, safeguarding the unit’s internal mechanisms. Additionally, the fuel pump is responsible for supplying the necessary pressure to move the fuel through the system efficiently. Understanding these components and their functions can help in troubleshooting issues and performing maintenance effectively.

Electrical Components and Their Functions

This section delves into the various electrical components commonly found in small motors, exploring their crucial roles in ensuring efficient operation. Understanding these elements is essential for effective maintenance and troubleshooting.

Key Electrical Components

- Ignition Coil: Converts low voltage from the battery to a high voltage needed to create a spark for combustion.

- Starter Motor: Responsible for initiating the engine’s operation by rotating the crankshaft.

- Battery: Stores electrical energy to power the ignition system and starter motor.

- Voltage Regulator: Maintains a consistent voltage level, preventing overcharging and ensuring proper electrical flow.

- Magneto: Generates electrical energy needed for ignition without the reliance on a battery.

Functions of Electrical Elements

- Facilitating the ignition process to ensure timely combustion.

- Providing the necessary power to start the machine.

- Regulating voltage to protect sensitive components.

- Generating electricity independently for models without a battery.

- Enhancing overall efficiency by ensuring consistent electrical supply.

Importance of the Ignition System

The ignition mechanism plays a crucial role in the operation of any power unit. It is responsible for initiating the combustion process, which in turn generates the necessary power for functionality. Without a reliable ignition system, the overall performance and efficiency of the machine can be significantly compromised.

Functionality and Reliability

A well-functioning ignition system ensures that the combustion occurs at the optimal time and under the right conditions. This precision is vital for maximizing performance and reducing fuel consumption. Moreover, a dependable ignition mechanism minimizes the risk of misfires and stalls, contributing to the longevity of the entire system.

Maintenance and Troubleshooting

Lubrication System and Its Role

The lubrication mechanism is crucial for ensuring the smooth operation of small machinery. It serves to minimize friction between moving components, enhancing performance and longevity. Proper lubrication not only prevents wear and tear but also facilitates efficient heat dissipation, allowing the system to function optimally under various conditions.

Key Functions of the Lubrication Mechanism

- Friction Reduction: By creating a protective layer between moving surfaces, the system significantly decreases friction, promoting efficient operation.

- Heat Management: Lubricants help in absorbing and transferring heat away from critical areas, preventing overheating.

- Contaminant Removal: The flow of lubricant assists in carrying away dirt and debris, maintaining cleanliness within the machinery.

- Corrosion Prevention: Certain lubricants contain additives that protect metal surfaces from corrosion, extending the lifespan of components.

Types of Lubricants Used

- Oil: Commonly used due to its excellent flow properties and ability to penetrate small gaps.

- Grease: Thicker than oil, grease provides long-lasting protection and is ideal for applications where lubrication frequency is low.

- Synthetic Lubricants: These modern alternatives offer enhanced performance in extreme conditions, reducing breakdown and evaporation.

Analyzing the Cooling Mechanism

The cooling system of a combustion unit plays a crucial role in maintaining optimal performance and longevity. By regulating the temperature during operation, it ensures that components function efficiently and prevents overheating, which can lead to severe damage. Understanding how this system works is essential for effective maintenance and troubleshooting.

In most units, air or liquid is utilized to dissipate heat generated by the combustion process. Air-cooled systems typically rely on a fan to circulate air around hot components, drawing heat away and promoting cooling. This method is commonly found in smaller units due to its simplicity and ease of maintenance.

On the other hand, liquid-cooled systems involve a more complex setup where coolant circulates through passages in the assembly. This liquid absorbs heat and is then cooled in a radiator or similar device before being recirculated. This method is often preferred for larger applications, as it provides more effective temperature control under heavy workloads.

Additionally, the placement of cooling fins and shrouds can significantly influence airflow and heat dissipation. Optimizing these features is critical for maximizing the efficiency of the cooling mechanism. Regular inspection and cleaning of these components can prevent debris buildup, ensuring consistent airflow and cooling performance.

Replacing Worn Parts Efficiently

Maintaining optimal performance in mechanical systems involves timely substitutions of degraded components. Efficiently managing this process not only enhances functionality but also extends the lifespan of the machinery. Understanding how to identify, source, and install replacements can significantly reduce downtime and improve overall productivity.

Identifying Signs of Wear

Recognizing when components are approaching the end of their useful life is crucial. Look for indicators such as unusual noises, decreased performance, or visible damage. Regular inspections can help pinpoint specific areas needing attention, ensuring timely interventions.

Effective Replacement Strategies

Once worn components have been identified, sourcing quality replacements should be a priority. Utilize reputable suppliers to ensure you obtain durable options. Follow detailed guidelines during installation to avoid complications. Additionally, keeping a stock of common replacements can save time and prevent unnecessary delays in operations.

Tools Required for Engine Repair

When it comes to repairing machinery, having the right tools is essential for achieving successful outcomes. A variety of instruments are needed to address different aspects of maintenance, ensuring that each component functions optimally. This section outlines the necessary tools that facilitate effective repairs and enhance overall performance.

| Tool Type | Description |

|---|---|

| Wrenches | Used for loosening or tightening bolts and nuts, available in various sizes. |

| Screwdrivers | Essential for inserting or removing screws, typically featuring flat and Phillips heads. |

| Pliers | Helpful for gripping, bending, or cutting wire and other materials. |

| Socket Set | Includes multiple socket sizes for fast and efficient fastening and loosening. |

| Torque Wrench | Ensures proper tightness of fasteners by applying a specific torque. |

| Multimeter | Used for diagnosing electrical issues by measuring voltage, current, and resistance. |

| Oil Filter Wrench | Designed to remove and install oil filters easily. |

| Work Light | Provides illumination to ensure visibility during repairs. |