When it comes to maintaining outdoor power equipment, having a clear understanding of engine assemblies is essential. Each machine is made up of numerous elements that work together to ensure optimal performance. By exploring the arrangement and functionality of these components, users can enhance their troubleshooting skills and improve maintenance practices.

Visual representations of these components play a vital role in simplifying the repair process. They allow operators to identify individual pieces and their respective functions within the engine. Whether for routine maintenance or major repairs, a detailed view of the engine’s structure helps in recognizing potential issues before they escalate.

Furthermore, familiarizing oneself with the layout of the engine parts can lead to better decision-making when it comes to replacements and upgrades. Understanding how each element interacts with others not only extends the life of the equipment but also enhances its overall efficiency. Proper knowledge equips users with the confidence needed to undertake repairs with ease.

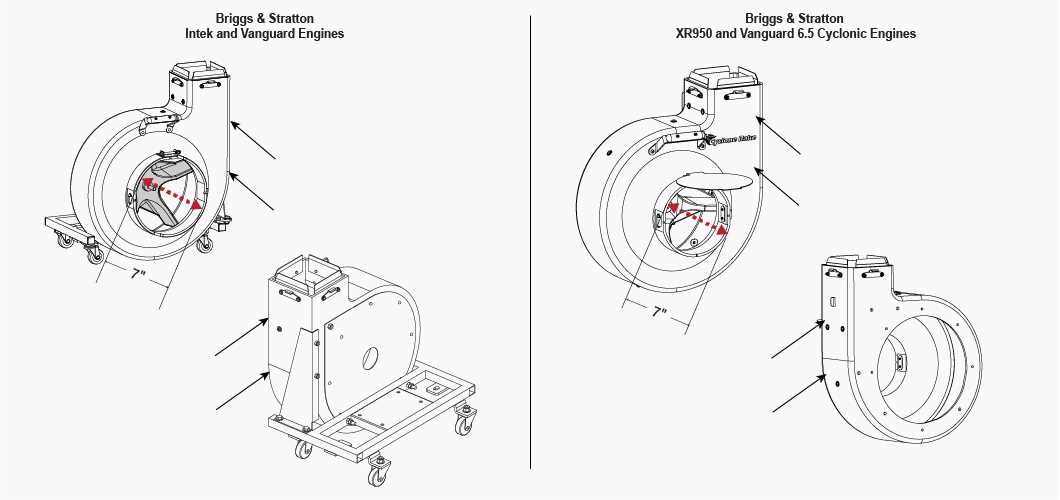

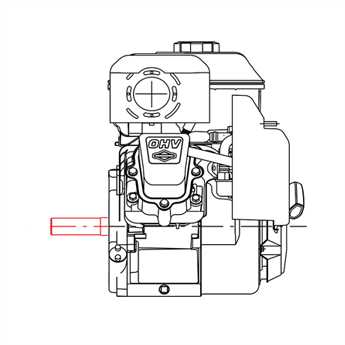

Overview of Briggs and Stratton Intek 206

The Intek series represents a range of small engines designed for various outdoor applications, combining efficiency with durability. These power units are engineered to meet the demands of both residential and commercial users, offering reliable performance in tasks ranging from lawn maintenance to other heavy-duty operations.

One notable aspect of this engine series is its user-friendly design, which simplifies maintenance and enhances longevity. The construction incorporates high-quality materials, ensuring that each component works seamlessly to provide optimal power output and operational smoothness.

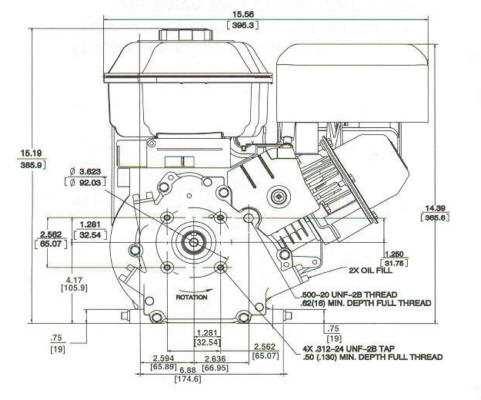

| Feature | Description |

|---|---|

| Engine Type | Four-stroke air-cooled engine |

| Cylinder Configuration | Single-cylinder |

| Displacement | Approximately 206cc |

| Power Output | Varies by model; typically ranges from 6 to 7.25 horsepower |

| Fuel Type | Gasoline |

| Oil Capacity | Approximately 18 oz |

This engine line is recognized for its robust performance and ability to handle various workloads, making it a preferred choice among many users. The efficient design not only provides high power but also promotes fuel efficiency, further enhancing its appeal in a competitive market.

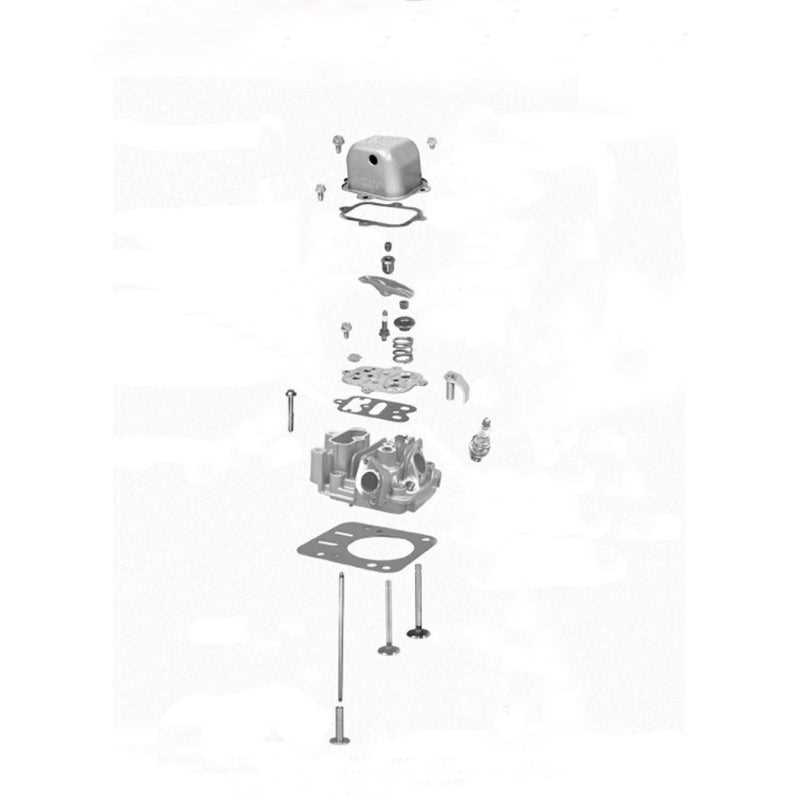

Understanding Engine Components and Functions

Engines are intricate machines composed of various elements, each serving a distinct role in the overall operation. Familiarizing oneself with these components is crucial for effective maintenance and troubleshooting. By grasping how these elements work together, one can enhance the performance and longevity of the engine.

The primary components of an engine can be categorized into several groups:

- Power Generation: This category includes the parts that convert fuel into energy.

- Air Management: These components control the intake and exhaust of air, ensuring efficient combustion.

- Fuel Delivery: This system is responsible for transporting fuel to the combustion chamber.

- Ignition System: This includes elements that create a spark to ignite the fuel-air mixture.

- Cooling Mechanisms: These parts help maintain optimal operating temperatures, preventing overheating.

Each component interacts with the others to ensure smooth functioning. For instance, the power generation elements rely on efficient air management to create a powerful explosion, while the cooling mechanisms help maintain an ideal temperature for performance. Understanding these interactions allows for better troubleshooting and repair.

By familiarizing oneself with these components and their functions, one can ensure that the machine operates efficiently, ultimately leading to better performance and reliability.

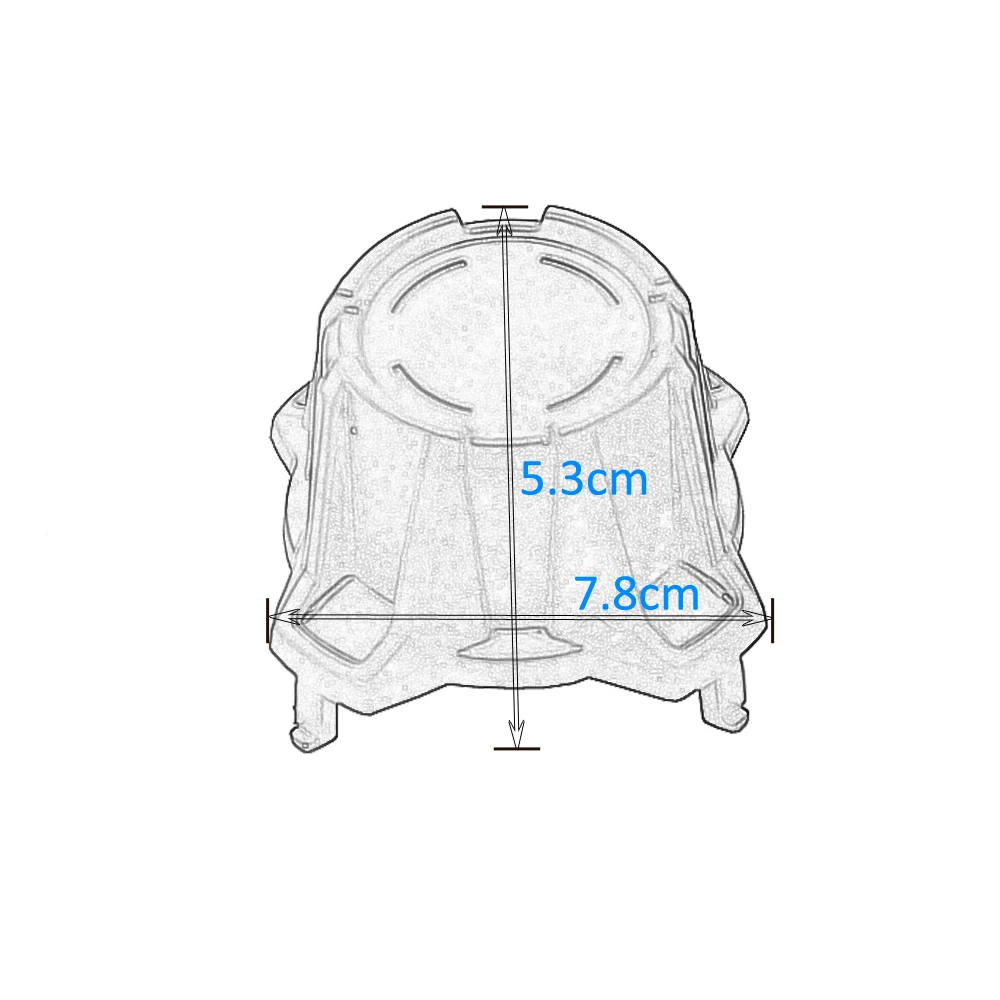

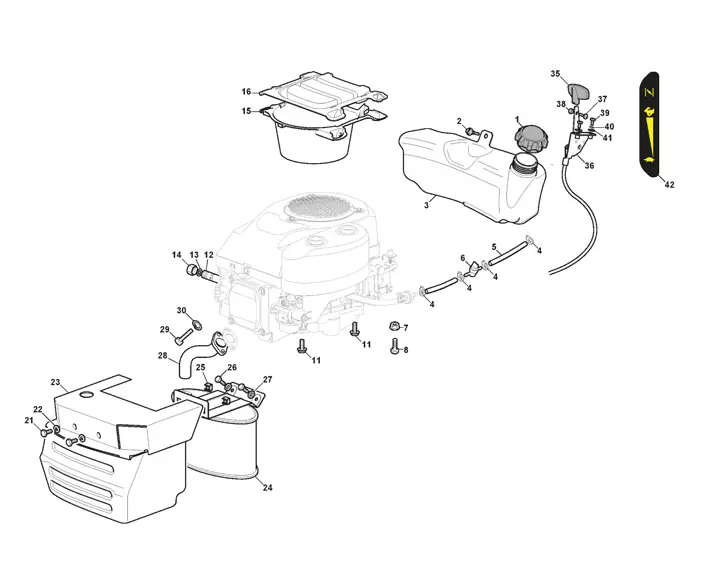

Parts Identification for Easy Reference

Understanding the various components of your engine is crucial for efficient maintenance and troubleshooting. This section aims to provide an overview that allows users to quickly recognize essential elements, ensuring a smoother experience when working with the machinery. By familiarizing yourself with the various components, you can easily navigate repairs and replacements, optimizing the performance of your equipment.

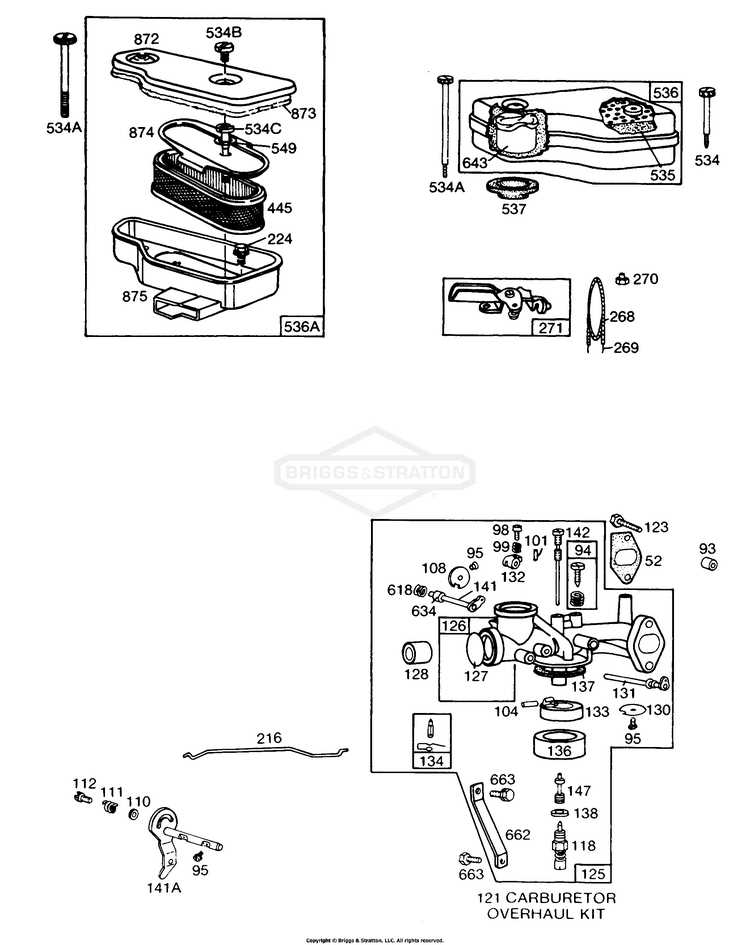

Common Components Overview

When dealing with engine repairs, it is important to know the common elements involved. Key parts include the cylinder head, crankshaft, fuel system, and ignition components. Each of these plays a vital role in the overall functionality and efficiency of the engine. Recognizing these elements will aid in quick assessments during maintenance.

Identification Tips

To effectively identify the components, consider using a reference guide or checklist that outlines the function and appearance of each part. Visual aids can significantly enhance your understanding, making it easier to locate and assess individual pieces. Additionally, labeling parts during disassembly can prevent confusion and ensure that reassembly is straightforward.

Common Issues with Intek 206 Engines

Engines from this series are popular for their reliability and efficiency; however, they are not without their challenges. Understanding the typical problems encountered can help users troubleshoot and maintain their machinery more effectively. This section outlines some prevalent issues that may arise during operation and offers insights into their potential causes and solutions.

Starting Difficulties

One of the most common complaints involves difficulties in starting the engine. This issue can stem from various factors, including fuel delivery problems, a weak ignition system, or a clogged air filter. Ensuring that the fuel is fresh and that the fuel lines are clear can significantly improve starting performance. Additionally, checking the spark plug for wear and ensuring proper connections in the ignition system are essential steps in resolving this problem.

Overheating

Overheating is another frequent concern that can lead to significant engine damage if not addressed promptly. Insufficient cooling due to a malfunctioning fan or blocked cooling fins often causes this issue. Regularly inspecting and cleaning the cooling system can prevent overheating. Additionally, monitoring the oil level and quality is crucial, as low or dirty oil can hinder effective lubrication, leading to excessive heat generation.

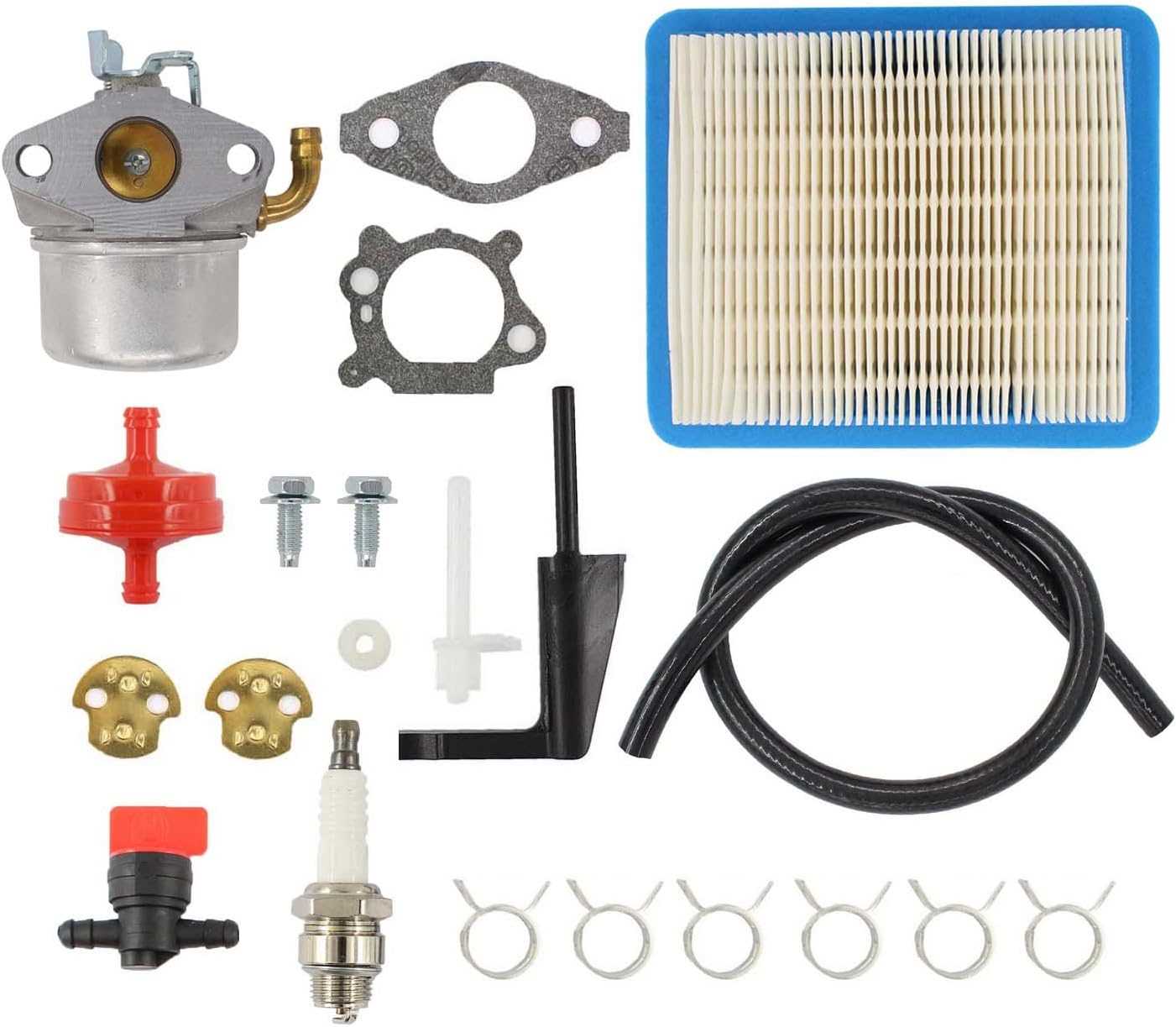

Replacement Parts and Availability

When maintaining and repairing small engines, having access to high-quality components is essential for optimal performance and longevity. Understanding the availability of various elements is crucial for enthusiasts and professionals alike, ensuring that machinery runs smoothly without unnecessary downtime. This section outlines the key considerations for sourcing replacement items for these engines, including options for procurement and factors affecting accessibility.

Where to Find Components

Numerous retailers, both online and brick-and-mortar, specialize in engine components. Websites dedicated to outdoor equipment often provide an extensive selection of aftermarket and original items. Local hardware stores may also stock essential replacements, catering to the needs of immediate repairs. Additionally, manufacturers typically maintain a catalog of parts for order through their authorized dealers.

Factors Influencing Availability

Several factors can impact the accessibility of replacement items. Supply chain issues, seasonal demand, and regional preferences can lead to fluctuations in stock levels. It’s advisable to check inventory regularly and consider ordering components in advance, especially for critical elements that may not be readily available. Furthermore, consulting with fellow users and online forums can offer insights into reliable suppliers and potential alternatives.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your engine requires regular upkeep and attention to detail. By following a few essential practices, you can keep your machinery running smoothly and efficiently, minimizing the need for costly repairs or replacements.

Regular Cleaning

Maintaining cleanliness is vital for optimal performance. Here are some key points to consider:

- Remove debris from air filters and cooling fins.

- Clean the exterior surfaces to prevent rust and corrosion.

- Inspect and clean fuel lines to avoid clogs.

Routine Inspections

Frequent checks can help identify potential issues before they escalate. Focus on these areas:

- Examine spark plugs for wear and replace as needed.

- Check the oil level and quality, changing it according to the manufacturer’s recommendations.

- Inspect belts and hoses for signs of wear or damage.

Implementing these practices will contribute to the longevity of your engine, ensuring it operates efficiently and reliably for years to come.

Tools Needed for Repairs

Successful maintenance and repair of small engines require a specific set of instruments to ensure efficiency and accuracy. Having the right equipment not only speeds up the process but also minimizes the risk of damage to components. Below is a comprehensive list of essential tools that will facilitate smooth repairs.

| Tool | Description |

|---|---|

| Wrench Set | A variety of wrenches for loosening and tightening bolts and nuts. |

| Screwdriver Set | Includes various sizes and types, such as Phillips and flathead, for removing screws. |

| Pliers | Useful for gripping and bending components during repairs. |

| Socket Set | Allows for easy removal of bolts in tight spaces. |

| Torque Wrench | Ensures bolts are tightened to the manufacturer’s specified torque. |

| Oil Filter Wrench | Specifically designed for removing oil filters easily. |

| Fuel Line Pliers | Helps to disconnect fuel lines without damaging them. |

| Work Gloves | Protects hands from sharp edges and chemicals during maintenance. |

| Safety Glasses | Protects eyes from debris while working on the engine. |

Step-by-Step Disassembly Process

This section provides a comprehensive guide to the systematic breakdown of an engine assembly. Following a meticulous approach ensures that each component is carefully removed, preventing damage and facilitating easier reassembly.

Step 1: Prepare Your Workspace

Begin by organizing your tools and workspace. Ensure that you have adequate lighting and a clean area to work. A clutter-free environment helps in locating parts easily and reduces the risk of losing small components.

Step 2: Disconnect the Power Source

Before commencing the disassembly, ensure that the power source is disconnected. This is a crucial safety measure to avoid any accidental starts during the process. Remove the spark plug to prevent any ignition.

Step 3: Remove External Components

Start by detaching any external elements, such as the air filter and muffler. Use appropriate tools to loosen screws and clips, making sure to keep track of all fasteners for reinstallation.

Step 4: Access the Engine Housing

Next, remove the cover of the engine housing. Typically secured by screws or bolts, gently lift off the cover to reveal the internal mechanisms. Take care not to force any parts, as this can lead to damage.

Step 5: Detach Internal Parts

With the housing exposed, proceed to disconnect internal components systematically. Begin with the carburetor and fuel lines, followed by the ignition system. Keep all removed parts organized to simplify the reassembly process.

Step 6: Document the Process

As you disassemble each part, consider documenting the process. Taking notes or photographs can be invaluable when it’s time to put everything back together, ensuring that nothing is overlooked.

Step 7: Clean and Inspect Components

Once the assembly is fully disassembled, clean all parts thoroughly. Inspect for wear or damage, replacing any components as necessary before reassembly. This proactive step will enhance performance and longevity.

Reassembly Guidelines for Efficiency

Proper reassembly of mechanical components is crucial for ensuring optimal functionality and longevity. By following systematic procedures, users can significantly reduce the likelihood of errors and enhance performance. This section outlines effective practices for reassembling engine elements with precision and care.

Preparation Steps

- Gather all necessary tools and equipment before beginning the reassembly process.

- Organize components in a logical manner to facilitate easy access during assembly.

- Review the service manual for specific guidelines regarding the reassembly of each part.

Reassembly Process

- Start by inspecting each component for wear or damage before reassembly.

- Apply appropriate lubricants to moving parts to ensure smooth operation.

- Follow the sequence outlined in the service manual, tightening fasteners gradually and in the correct order to avoid misalignment.

- Double-check the alignment of all components as they are fitted together.

- Once reassembly is complete, conduct a thorough test to confirm proper functionality before the engine is put back into use.

Safety Precautions During Repairs

When undertaking maintenance tasks on mechanical equipment, it is crucial to prioritize safety. Understanding potential hazards and implementing appropriate measures can significantly reduce the risk of accidents and injuries. Proper preparation and awareness of one’s surroundings play vital roles in ensuring a secure work environment.

Before starting any repair work, it is essential to equip yourself with the right tools and protective gear. These measures can help prevent injuries caused by sharp objects, chemical exposure, or equipment malfunctions. Below are some key safety tips to keep in mind:

| Safety Tip | Description |

|---|---|

| Wear Protective Gear | Always use gloves, goggles, and appropriate clothing to shield against potential hazards. |

| Work in a Well-Ventilated Area | Ensure good airflow to avoid inhaling harmful fumes from fuel or chemicals. |

| Disconnect Power Sources | Before beginning repairs, ensure that all power sources are disconnected to prevent accidental starts. |

| Use Tools Properly | Utilize tools according to their intended purpose to avoid damage and injury. |

| Keep Workspace Organized | Maintain a tidy workspace to minimize tripping hazards and improve efficiency. |

By adhering to these safety precautions, individuals can create a safer environment while performing repairs, ultimately leading to successful and accident-free maintenance.

Upgrading Parts for Performance

Enhancing the efficiency and capability of small engines often involves selecting high-quality components designed to boost overall performance. By focusing on the right modifications, enthusiasts can achieve noticeable improvements in power output and operational reliability.

Key Upgrades to Consider

- Air Intake System: Improving airflow can significantly increase combustion efficiency. Consider installing a high-performance air filter or an upgraded intake manifold.

- Exhaust System: A less restrictive exhaust system helps to expel gases more efficiently, enhancing engine output. Look for aftermarket options that optimize flow.

- Fuel Delivery: Upgrading the carburetor or fuel injectors can improve fuel atomization and flow, contributing to better engine performance.

- Ignition System: A high-performance ignition module can provide a stronger spark, leading to more complete combustion and increased power.

Benefits of Upgrading

- Improved horsepower and torque

- Enhanced fuel efficiency

- Better throttle response

- Increased longevity of engine components

Choosing the right modifications can transform the capabilities of your engine, leading to a more satisfying experience during operation. Always ensure that upgrades are compatible and installed correctly for optimal results.

Customer Reviews and Feedback

This section provides an overview of user experiences and opinions regarding the product in question. It highlights various perspectives and insights shared by consumers, which can assist potential buyers in making informed decisions.

Overall Satisfaction

Many users have expressed their contentment with the reliability and performance of the unit. Positive reviews often emphasize the ease of operation and maintenance, making it a favorable choice for both novice and experienced users. Customers frequently mention that the product meets their expectations and serves its intended purpose effectively.

Common Concerns

While the majority of feedback is positive, some users have raised concerns regarding specific aspects of the device. Issues such as difficulty in sourcing replacement components or occasional operational hiccups have been noted. However, these concerns do not overshadow the overall positive sentiment surrounding the product.

| Rating | Review Count |

|---|---|

| 5 Stars | 120 |

| 4 Stars | 75 |

| 3 Stars | 30 |

| 2 Stars | 10 |

| 1 Star | 5 |