In the realm of small engine maintenance, grasping the intricate arrangements of components is essential for optimal performance. A comprehensive view of these assemblies enables enthusiasts and technicians to diagnose issues effectively and enhance operational efficiency. Such knowledge serves as a foundation for both troubleshooting and routine upkeep, ensuring longevity and reliability.

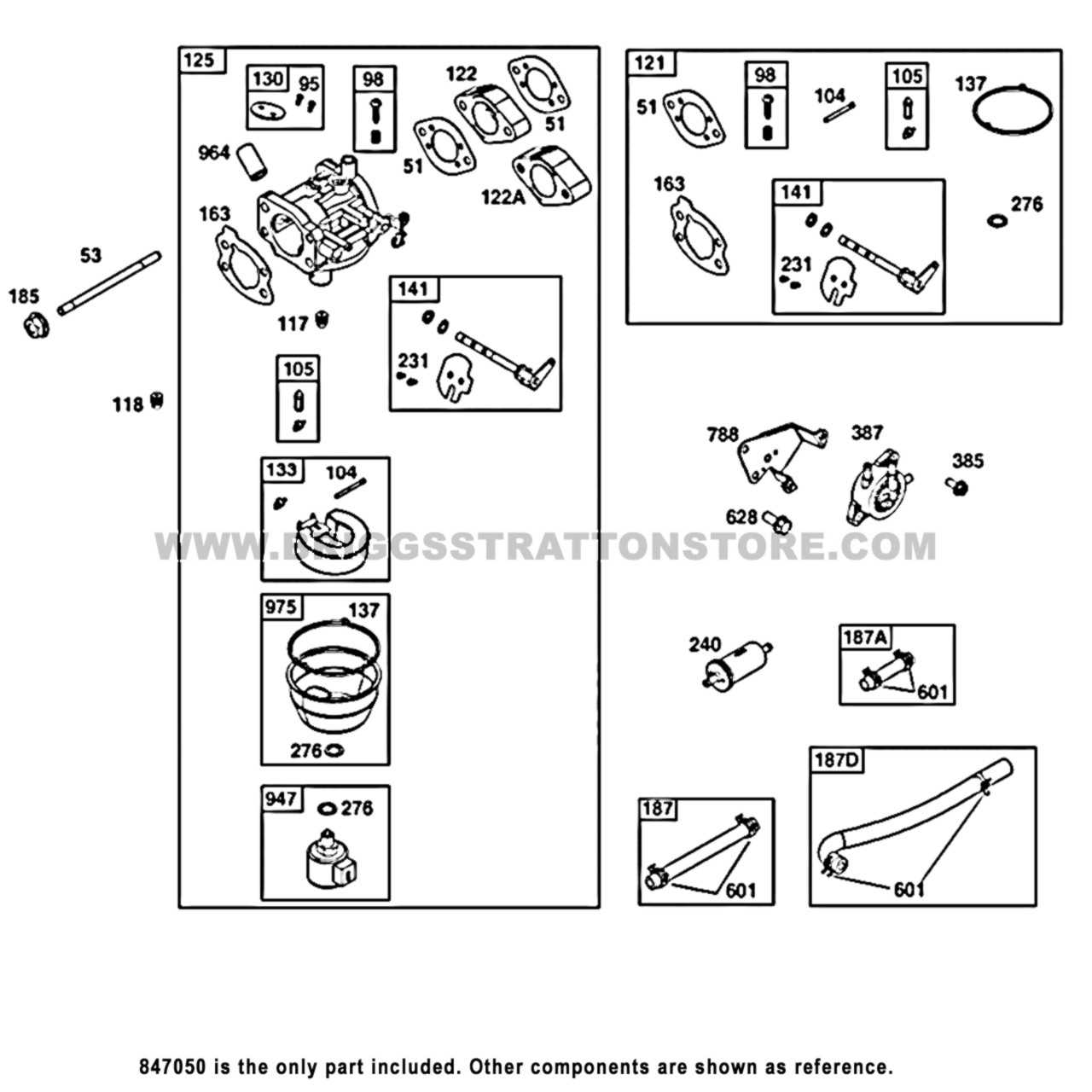

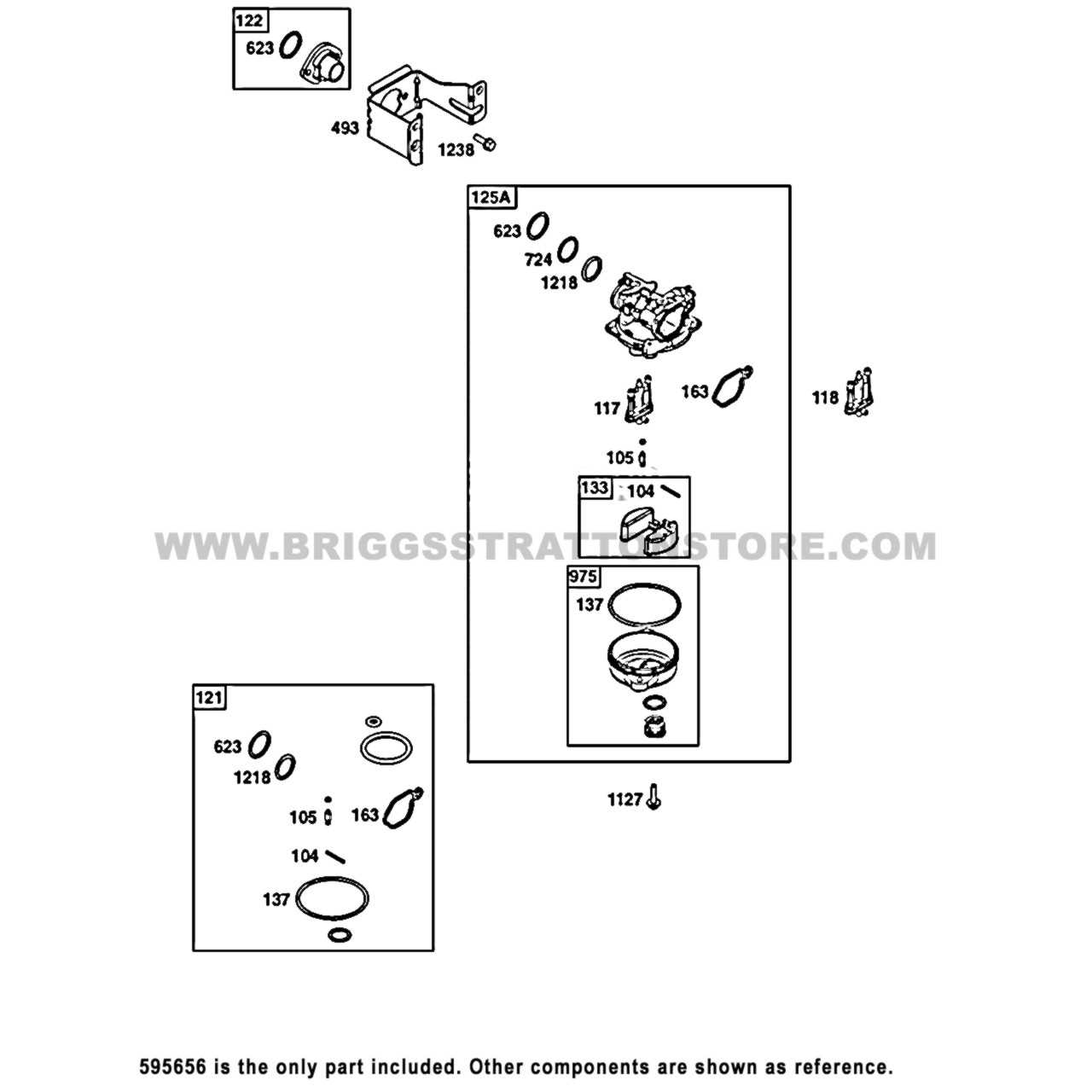

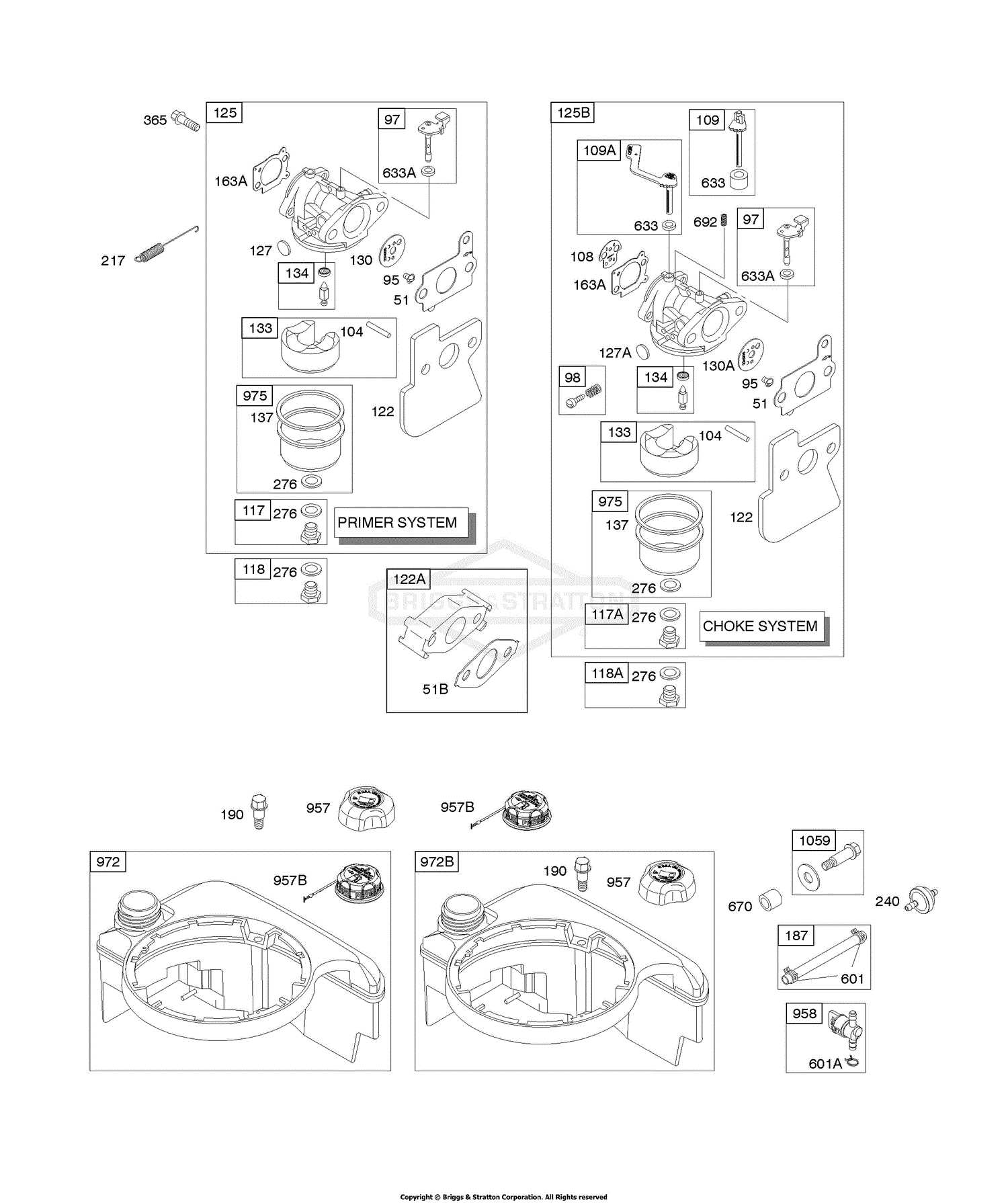

One particularly vital aspect involves the breakdown of specific elements that contribute to the overall functionality of fuel delivery mechanisms. Recognizing the roles and interconnections of these various components is crucial for anyone involved in engine repair or restoration. A detailed representation aids in visualizing how these parts interact, allowing for a clearer understanding of their purpose.

Furthermore, familiarity with these configurations equips users with the skills necessary to perform repairs or replacements confidently. Whether for hobbyists or professionals, this knowledge fosters a deeper appreciation for the engineering behind small engines. By examining these layouts, individuals can make informed decisions that ultimately lead to better maintenance practices.

Understanding Briggs and Stratton Carburetors

Gaining insight into small engine fuel delivery systems is essential for optimal performance and maintenance. These mechanisms play a crucial role in mixing air and fuel, ensuring efficient combustion.

Key components of these systems include:

- Float chamber

- Throttle valve

- Jet assembly

- Choke plate

Proper function is vital for various reasons:

- Ensures smooth engine operation

- Improves fuel efficiency

- Reduces emissions

- Enhances power output

Regular inspection and maintenance of these elements can significantly impact overall engine health. Understanding their roles aids in troubleshooting common issues and optimizing performance.

Key Components of Plastic Carburetors

The essential elements of a fuel delivery system are crucial for optimal engine performance. Understanding these components allows for better maintenance and troubleshooting, ultimately enhancing the lifespan of the equipment.

Fuel Intake Mechanism

This component is responsible for drawing in fuel from the tank. Its design impacts the efficiency of fuel flow and ensures proper mixing with air, which is vital for combustion.

Air-Fuel Mixture Adjustment

The ability to modify the ratio of air to fuel is critical. This adjustment affects engine responsiveness and power output. Proper calibration can lead to improved performance and reduced emissions.

Importance of Proper Maintenance

Ensuring the longevity and efficiency of mechanical equipment hinges on regular upkeep. Without attention to detail, even the most reliable devices can falter, leading to decreased performance and potential failures. Proper care not only enhances functionality but also prevents costly repairs in the long run.

Regular inspection is crucial for identifying wear and tear early on. Small issues can escalate into major problems if neglected, causing significant downtime. Moreover, maintaining cleanliness helps in preventing blockages and ensures smooth operation.

Ultimately, consistent maintenance practices foster reliability and enhance the lifespan of equipment, providing peace of mind to users and improving overall efficiency.

Common Issues with Carburetor Parts

In the realm of small engine maintenance, certain challenges frequently arise, affecting performance and efficiency. Understanding these common complications can aid in effective troubleshooting and enhance the longevity of your machinery.

Clogged Jets

One prevalent issue is the blockage of fuel jets, which can restrict the flow of fuel, leading to poor engine performance. This often results from residue buildup due to old fuel or contaminants, necessitating thorough cleaning or replacement.

Leaking Seals

Another significant problem involves the deterioration of seals, which can lead to leaks and erratic operation. Aging materials may fail to maintain their integrity, making regular inspections essential for optimal function.

How to Identify Replacement Needs

Understanding when components require replacement is crucial for maintaining optimal performance of your equipment. Several signs may indicate that certain elements are worn out or damaged, leading to potential inefficiencies or failures. Regular inspections and familiarity with common issues can help in timely replacements, ensuring smooth operation.

Common Indicators of Wear

Look for visible signs of damage such as cracks, corrosion, or excessive wear. Unusual noises during operation can also signal underlying problems. Additionally, performance issues, like inconsistent power delivery or difficulty in starting, may suggest that specific elements need to be replaced. Addressing these issues promptly can prevent further complications.

Routine Maintenance Practices

Implementing a regular maintenance schedule can aid in identifying when components may need attention. Clean all accessible areas and check for debris buildup, which can hinder functionality. Consulting your user manual for guidance on inspection intervals can also be beneficial. Keeping detailed records of maintenance activities will help you track when replacements are necessary.

Tools Required for Repairs

Having the right instruments is crucial for effectively addressing any mechanical issues. Utilizing appropriate tools ensures accuracy, safety, and efficiency during maintenance tasks.

| Tool | Purpose |

|---|---|

| Screwdriver Set | For loosening and tightening various screws. |

| Wrench | Essential for securing or releasing nuts and bolts. |

| Pliers | Helpful for gripping and manipulating components. |

| Fuel Line Cutter | Used to accurately cut fuel lines without damage. |

| Cleaning Brush | For removing dirt and debris from surfaces. |

Step-by-Step Repair Process

This section provides a clear and concise guide for effectively addressing common issues encountered with a specific engine component. Following a systematic approach will ensure that each step is performed correctly, minimizing the risk of further complications.

Begin by gathering all necessary tools and materials. A clean workspace will enhance focus and facilitate an efficient repair process. Once everything is prepared, carefully detach the component from the engine, taking note of its positioning and any connections.

Next, inspect the assembly for signs of wear, damage, or blockage. Cleaning any residue with appropriate solvents is crucial for optimal performance. Afterward, replace any damaged or worn-out elements, ensuring compatibility with the existing setup.

Once the new components are installed, reassemble the unit according to the original configuration. Tighten all connections securely, but avoid overtightening to prevent damage. Finally, perform a thorough test to confirm that the system operates smoothly and effectively.

Using Diagrams for Better Understanding

Visual representations serve as powerful tools for grasping complex information. They simplify intricate concepts, allowing individuals to visualize relationships and functions that might otherwise remain abstract. By engaging with these illustrations, users can enhance their comprehension and retention of the subject matter.

Enhanced Clarity

Diagrams provide clarity by breaking down components into manageable sections. This segmentation helps users pinpoint specific areas of interest, facilitating a deeper understanding of the overall structure.

Practical Application

Utilizing visual aids not only aids in theoretical knowledge but also translates into practical skills. Engaging with these visuals empowers individuals to apply their understanding in real-world situations, making learning more relevant and effective.

Comparing Plastic and Metal Carburetors

In the world of small engine technology, the choice between two predominant materials often influences performance, durability, and maintenance. Each material brings its unique characteristics to the table, affecting not only the efficiency of fuel delivery but also the overall longevity of the engine components.

Durability and Longevity

Metal components are generally recognized for their resilience and ability to withstand high temperatures and pressures. They often provide a robust solution for engines operating under strenuous conditions. In contrast, synthetic alternatives may face challenges such as warping or degradation over time, especially when exposed to harsh chemicals or extreme heat. However, advancements in manufacturing have improved the durability of these modern options significantly.

Weight and Installation

When it comes to weight, synthetic variants tend to be lighter, making installation easier and potentially enhancing the overall maneuverability of the equipment. This can be particularly beneficial in applications where weight reduction is crucial. On the other hand, the heft of metal options may contribute to a more stable setup, reducing vibrations during operation and leading to a smoother performance.

Where to Find Quality Replacement Parts

Finding reliable components for your small engine equipment is crucial for maintaining performance and longevity. Quality replacements ensure smooth operation and minimize the risk of future issues, allowing you to keep your machinery running efficiently.

Online Retailers

Numerous online platforms specialize in aftermarket components, offering a vast selection at competitive prices. When choosing a retailer, look for customer reviews and ratings to ensure credibility and satisfaction.

Local Dealers

Visiting local dealers can provide direct access to authentic components. This option often allows for personalized service and expert advice, making it easier to find the right solution for your needs. Ask for recommendations to locate the best options in your area.

Tips for Long-lasting Carburetor Performance

Maintaining optimal functionality of your engine’s fuel delivery system is essential for efficiency and longevity. Proper care and timely maintenance can significantly enhance performance and reduce the likelihood of issues.

Regular Cleaning

Keeping the system free from debris and buildup is crucial. Regularly inspect and clean components to prevent clogs that can hinder operation. Use appropriate solvents and tools to ensure thorough cleaning.

Quality Fuel Usage

Utilizing high-quality fuel can make a noticeable difference. Fuel with additives can help minimize deposits and improve combustion efficiency. Always store fuel in clean, dry containers to avoid contamination.

Emphasizing regular maintenance and the use of quality materials will ultimately lead to a more reliable and efficient performance.