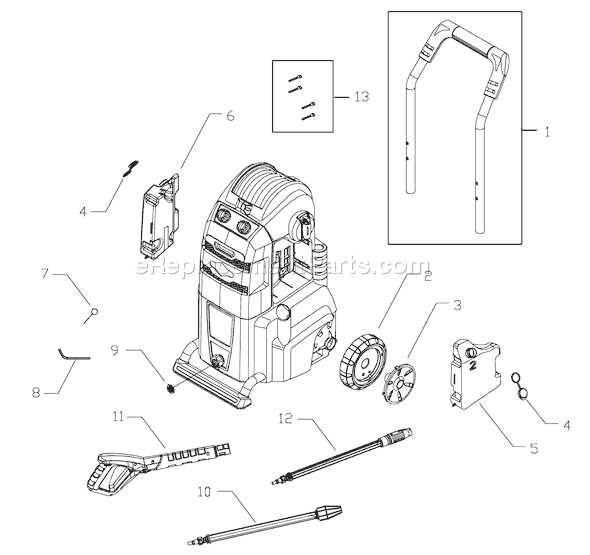

Maintaining outdoor machinery is essential for optimal performance and longevity. When issues arise, having a clear visual reference can greatly assist in identifying and resolving problems. This section aims to provide insight into the various elements that make up your cleaning apparatus, ensuring you can effectively manage repairs and replacements.

In any mechanical device, each component plays a vital role in overall functionality. Recognizing these individual parts not only simplifies troubleshooting but also enhances your understanding of how the system operates. By familiarizing yourself with the structure of your equipment, you can take proactive steps to ensure its efficient use and maintenance.

This guide offers an organized view of the different segments involved in your cleaning machine. Whether you’re a seasoned technician or a casual user, having access to a comprehensive outline of the components can empower you to tackle issues with confidence. Delve into the intricate world of your machinery’s makeup, and equip yourself with the knowledge to keep it running smoothly.

Understanding Power Washer Components

Having a clear grasp of the various elements that make up a cleaning machine is essential for effective maintenance and operation. Each component plays a vital role in ensuring optimal functionality and efficiency, contributing to the overall performance of the device. Familiarity with these parts not only aids in troubleshooting but also enhances the user experience.

Key Elements of the Cleaning Equipment

The main components of a cleaning device include the engine, pump, and nozzle. The engine serves as the powerhouse, converting fuel into mechanical energy. This energy is then transferred to the pump, which generates the necessary pressure for spraying water. The nozzle, often adjustable, allows users to control the flow and intensity of the spray, making it adaptable for various cleaning tasks.

Maintenance and Care

Regular upkeep of these essential components is crucial for longevity and efficiency. For instance, checking the engine oil levels, inspecting the pump seals, and cleaning the nozzle can prevent issues that may lead to more significant repairs. Understanding how each part functions not only empowers users to maintain their equipment better but also enhances overall satisfaction with the cleaning process.

Importance of Proper Maintenance

Ensuring the longevity and efficiency of your equipment hinges on regular upkeep. Neglecting maintenance can lead to decreased performance, increased wear, and even costly repairs. A proactive approach not only safeguards your investment but also enhances safety and operational effectiveness.

Benefits of Regular Care

Consistent maintenance helps identify potential issues before they escalate into major problems. Regular checks can optimize functionality, ensuring that every component operates as intended. This not only extends the lifespan of the machine but also maintains its peak performance, making tasks easier and more efficient.

Cost-Effectiveness

Investing time and resources in routine care can significantly reduce long-term expenses. Preventive measures are often less costly than emergency repairs. By avoiding sudden breakdowns, you can save on service costs and avoid the disruption of having to replace your equipment unexpectedly.

Identifying Common Issues

When using a cleaning device, users may encounter various problems that can affect its performance. Recognizing these challenges early can save time and prevent further complications. Familiarity with typical symptoms can guide users toward effective solutions.

Unusual Noises: If the equipment produces unexpected sounds, it may indicate a mechanical issue. Listen for grinding or rattling noises, which could signal loose components or wear.

Reduced Pressure: A significant drop in cleaning efficiency is often due to clogs or leaks. Check hoses and nozzles for blockages that could impede flow.

Starting Difficulties: Trouble initiating the device may arise from fuel problems or electrical issues. Ensure proper fuel levels and inspect the ignition system for faults.

Excessive Vibrations: If the unit shakes more than usual during operation, it could point to an unbalanced assembly. Verify that all parts are securely attached and properly aligned.

Overheating: High temperatures can lead to performance decline. Monitor for signs of overheating and ensure that cooling systems are functioning adequately.

By understanding these common issues, users can troubleshoot effectively, ensuring their equipment operates smoothly and efficiently.

Parts of a Briggs and Stratton Washer

Understanding the components of a cleaning machine is essential for maintenance and effective operation. Each element plays a crucial role in the overall functionality and efficiency of the equipment. Familiarity with these components ensures better care and longevity.

Key components include:

- Engine: The heart of the machine, responsible for generating power.

- Pump: This vital component pressurizes the water, allowing for effective cleaning.

- Hose: Connects the unit to the water source, facilitating the flow of water.

- Nozzle: Directs the pressurized water stream, adjustable for various cleaning tasks.

- Handle: Provides control and maneuverability, essential for user comfort.

- Frame: The structure that holds everything together, ensuring stability.

Regular inspection of these components can help identify wear or damage, leading to timely replacements and repairs.

- Check the engine for any signs of malfunction.

- Inspect the pump for leaks or unusual noises.

- Ensure the hose is free of kinks or cracks.

- Test the nozzle to confirm it adjusts properly.

By maintaining awareness of these elements, users can enhance the performance and durability of their equipment.

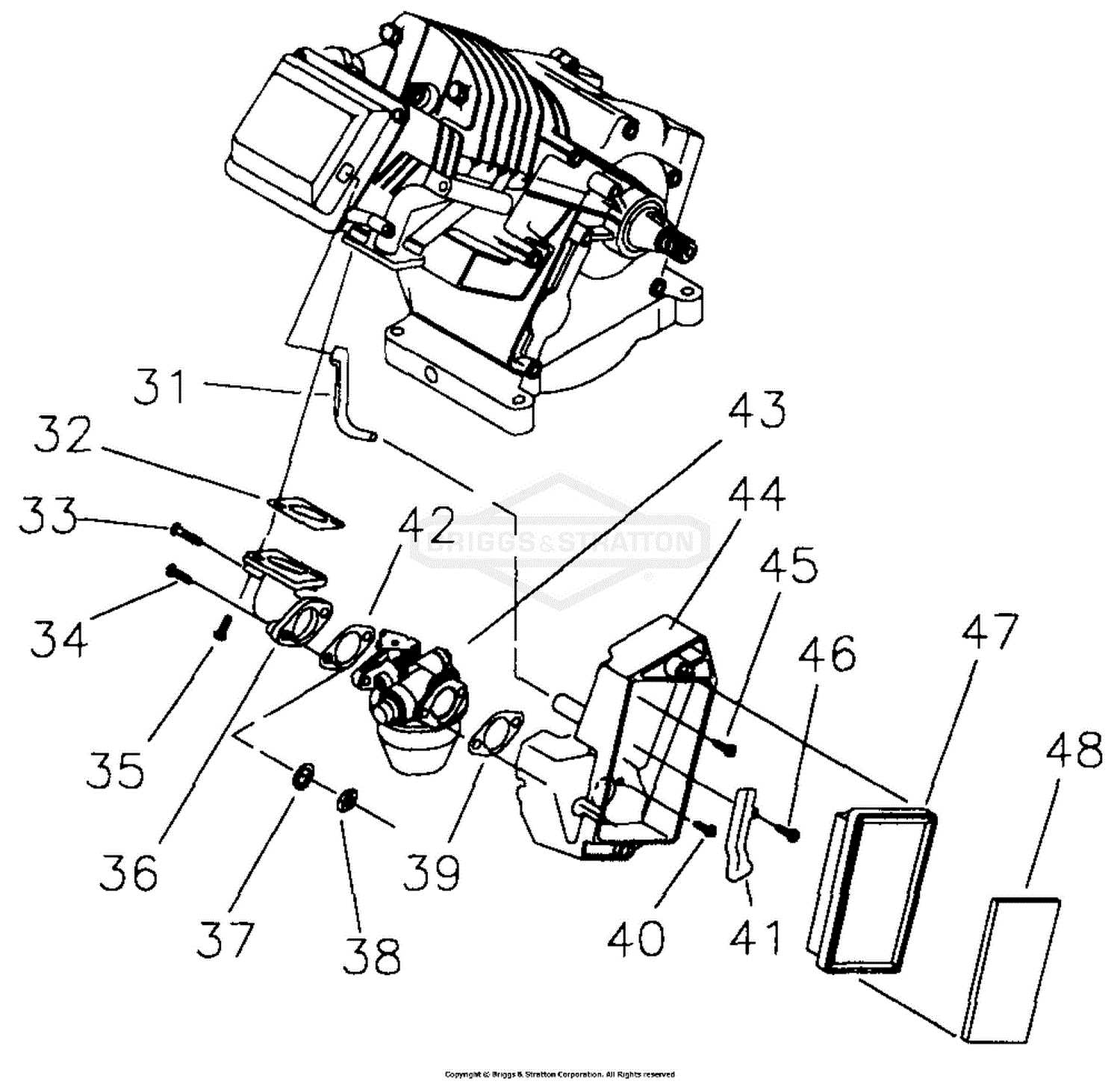

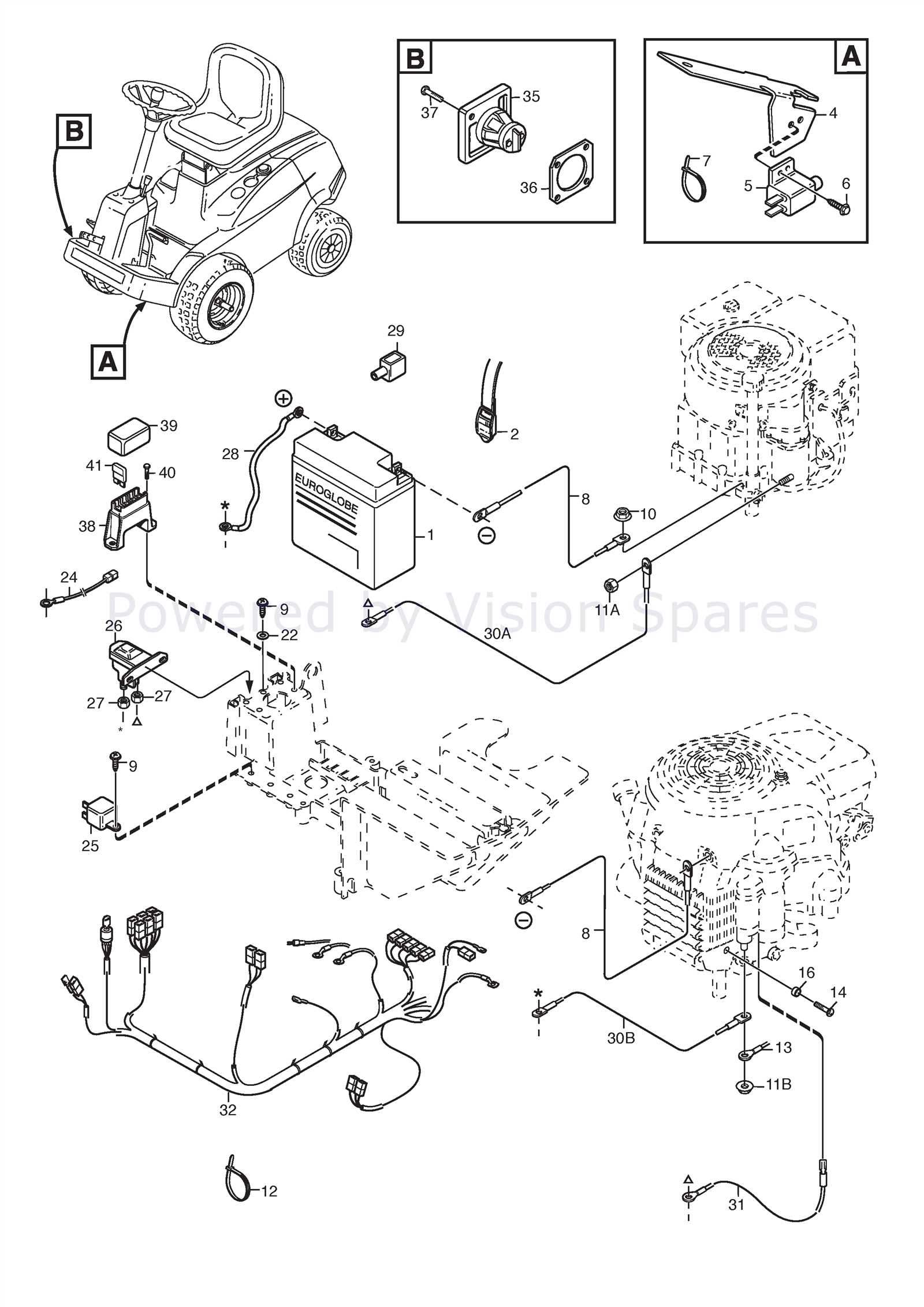

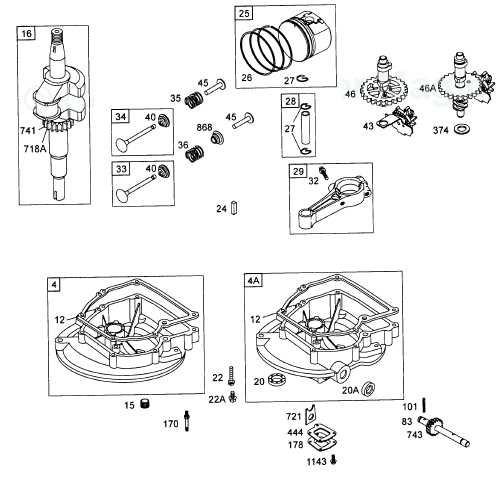

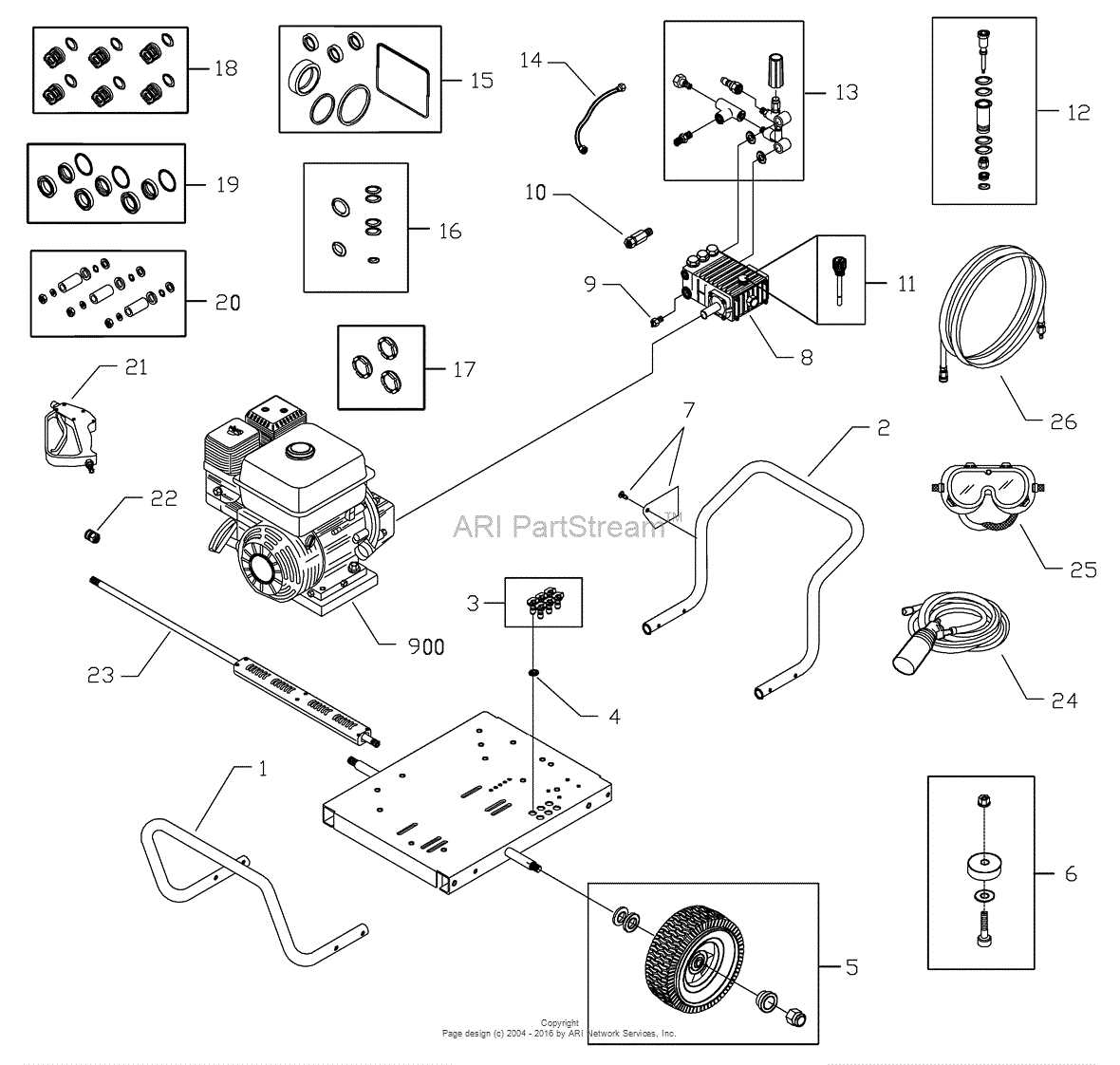

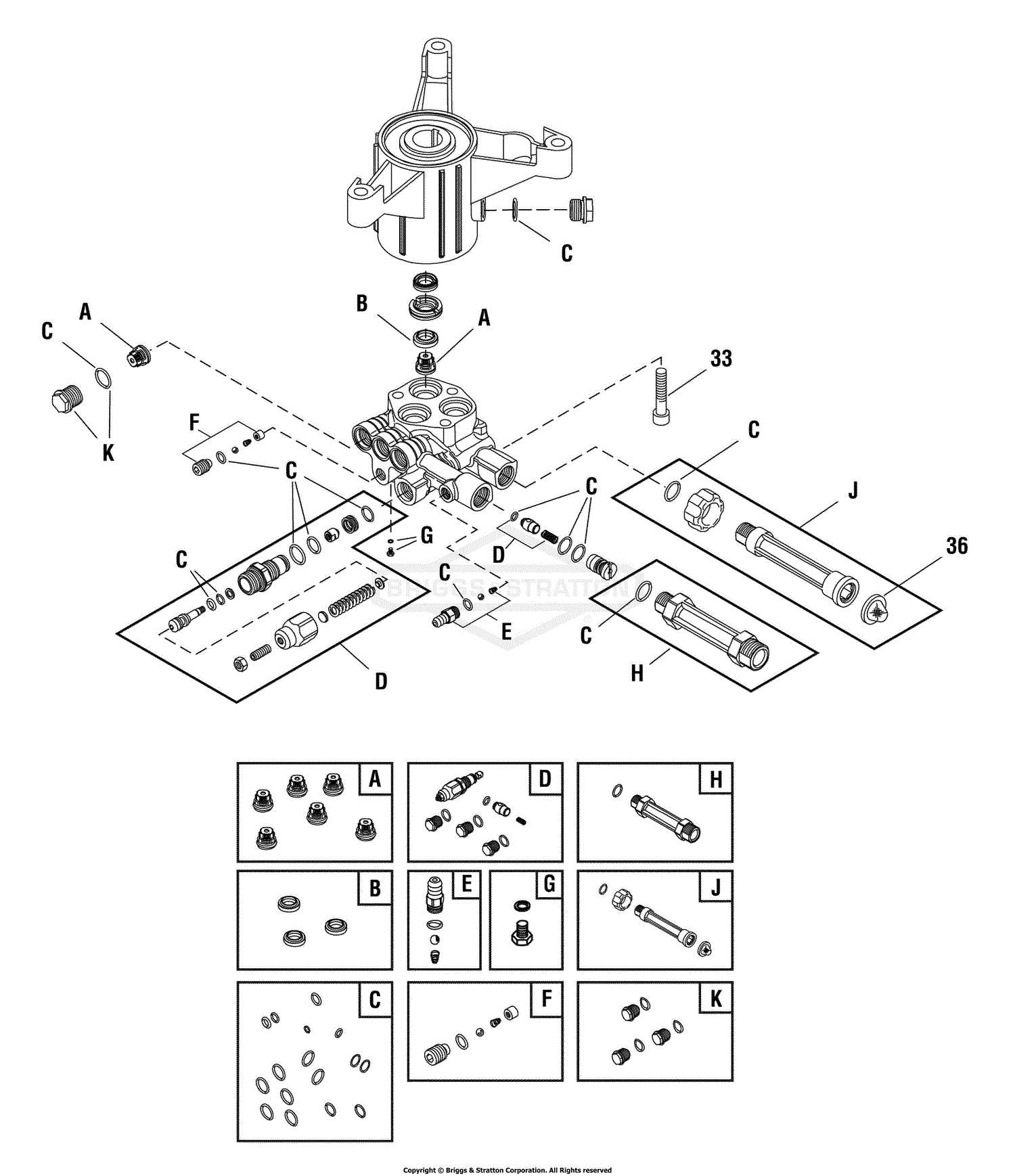

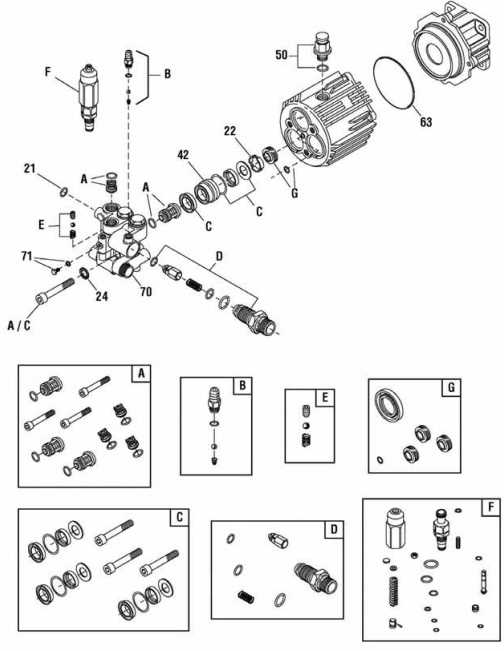

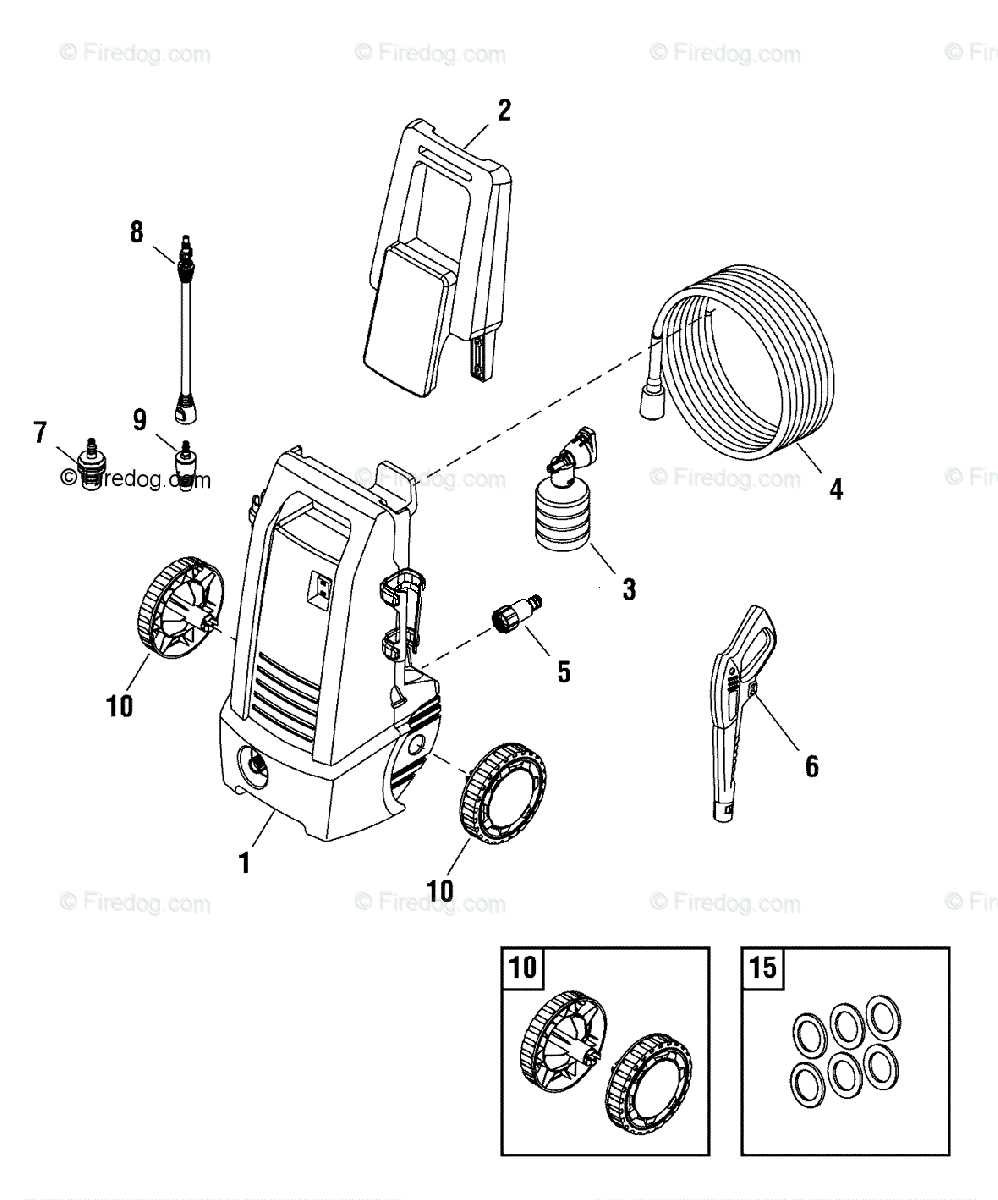

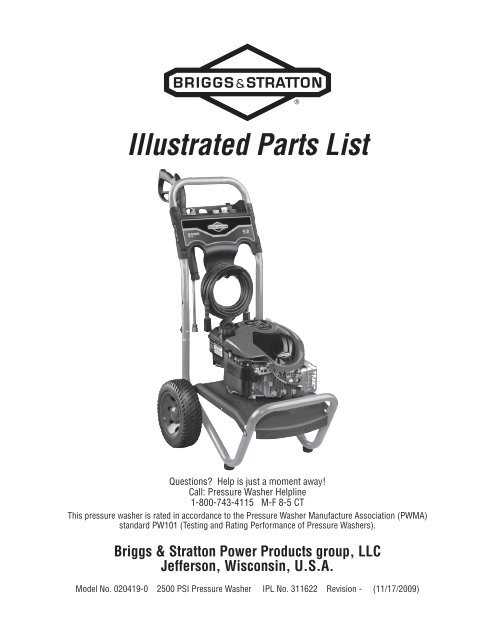

Reading the Parts Diagram

Understanding a visual representation of components is essential for efficient maintenance and repairs. Such illustrations provide a clear layout of each element, allowing users to identify and locate specific sections easily. This knowledge is crucial for anyone looking to troubleshoot or replace any necessary items effectively.

First, familiarize yourself with the overall structure depicted in the illustration. Take note of the labels assigned to each segment, as these will guide you through the various functionalities and connections. Recognizing how the elements interact with one another can significantly enhance your understanding of the entire mechanism.

Secondly, pay attention to the numbering or coding system often used in these visuals. This organization helps in pinpointing the exact pieces you may need to order or inspect. By correlating the numbers with a detailed list, you can streamline your approach to repairs, ensuring that no crucial component is overlooked.

Lastly, always keep in mind that referring back to the visual can aid in reassembly after performing any maintenance work. By revisiting the layout, you ensure that everything is correctly positioned, minimizing the risk of malfunctions in the future.

How to Replace Worn Parts

Maintaining the efficiency of your cleaning equipment is essential for optimal performance. Over time, components may degrade and require replacement to ensure smooth operation. Understanding the replacement process can enhance longevity and functionality.

Follow these steps to effectively replace worn components:

- Identify the Worn Components

- Inspect the unit thoroughly.

- Look for signs of wear, such as cracks or discoloration.

- Refer to the manual for a list of critical elements.

- Collect tools such as wrenches, screwdrivers, and pliers.

- Obtain compatible replacement items from a reliable supplier.

- Ensure the unit is powered off and disconnected from any source.

- Drain any remaining fluids if applicable.

- Carefully detach the old parts, noting their arrangement.

- Keep all screws and fasteners organized for reassembly.

- Position the new items in their designated places.

- Secure all parts using the original fasteners.

- Reconnect to the power source and refill any fluids.

- Run a test cycle to ensure everything functions correctly.

Regular inspections and timely replacements can prevent larger issues and keep your equipment in top condition. Stay proactive for the best results.

Tools Needed for Repairs

When undertaking maintenance tasks on your cleaning equipment, having the right instruments is crucial for a smooth and effective repair process. These essential tools not only facilitate efficient work but also enhance safety and precision during the operation.

Wrenches are fundamental for loosening and tightening nuts and bolts, ensuring that components are securely fastened. A set of screwdrivers, including both flathead and Phillips, is also necessary for accessing various screws throughout the machinery.

In addition, a reliable socket set allows for quick removal of larger fasteners, while a multimeter is invaluable for diagnosing electrical issues. For those tricky parts that may require a bit more grip, pliers can provide the extra leverage needed to make adjustments.

Don’t forget to keep a utility knife on hand for cutting through stubborn materials or packaging. Finally, having a good work surface and appropriate safety gear, such as gloves and goggles, will ensure a secure and organized repair environment.

Safety Tips During Maintenance

Ensuring safety while conducting upkeep tasks is paramount to prevent accidents and injuries. Proper precautions should be taken to create a secure working environment. Adhering to recommended practices not only protects the individual but also prolongs the lifespan of the equipment.

| Safety Tip | Description |

|---|---|

| Wear Protective Gear | Always use safety goggles, gloves, and sturdy footwear to shield yourself from debris and chemicals. |

| Disconnect Power Source | Before starting any maintenance, ensure that the unit is unplugged or that the fuel supply is turned off. |

| Work in a Ventilated Area | Perform tasks in a well-ventilated space to avoid inhaling fumes or harmful particles. |

| Keep Workspace Organized | A clutter-free environment reduces the risk of tripping or losing essential tools during maintenance. |

| Follow Manufacturer Guidelines | Refer to the user manual for specific maintenance instructions to ensure safe and effective upkeep. |

By implementing these guidelines, individuals can effectively reduce risks and enhance safety during maintenance activities. Awareness and preparation are key components of a successful and secure upkeep process.

Where to Find Replacement Parts

Finding the right components for your equipment is essential to ensure optimal performance and longevity. Whether you are looking for specific items for repairs or maintenance, there are various avenues to explore that cater to your needs.

Authorized Dealers

One of the most reliable sources for acquiring quality items is through authorized dealers. These outlets often carry a wide range of original components and can provide assistance in identifying the correct parts for your model.

Online Retailers

The internet offers a vast selection of options for obtaining components. Many websites specialize in equipment accessories, allowing for easy searches based on model numbers. Additionally, user reviews can guide you in making informed choices.

| Source Type | Benefits |

|---|---|

| Authorized Dealers | Quality assurance and expert guidance |

| Online Retailers | Convenience and variety |

| Local Hardware Stores | Immediate access and support |

| Manufacturer’s Website | Direct purchases and comprehensive catalogs |

Comparing OEM and Aftermarket Parts

When it comes to maintaining equipment, consumers often face the choice between original manufacturer components and those produced by third-party companies. Each option presents its own set of advantages and drawbacks, influencing decisions based on factors such as cost, quality, and availability.

Original manufacturer components, often referred to as OEM, are specifically designed to meet the original specifications of the equipment. These components are typically made from high-quality materials and undergo rigorous testing to ensure optimal performance and longevity. Buyers can often expect a seamless fit and reliable operation when using these parts, which can enhance the overall reliability of the machinery.

On the other hand, third-party alternatives can provide a more budget-friendly solution. These components may vary in quality and performance, but many reputable brands offer reliable options that can compete with OEM items. While the lower cost is appealing, it’s crucial to research and select high-quality alternatives to avoid potential issues down the line.

Ultimately, the decision between OEM and aftermarket options should be based on individual needs, preferences, and the specific requirements of the equipment. Assessing the trade-offs of cost versus quality can help ensure that the best choice is made for both performance and value.

Assembly Process of Key Components

Understanding the assembly procedure of essential elements is crucial for maintaining and optimizing equipment performance. Each component plays a significant role in the overall functionality, requiring precise integration and attention to detail during the assembly phase.

Essential Steps in the Assembly Process

To ensure a successful assembly, follow these key steps:

- Prepare all necessary tools and components.

- Review the assembly instructions thoroughly to familiarize yourself with the process.

- Begin with the foundational parts, ensuring they are securely fastened.

- Assemble auxiliary elements, taking care to align them properly.

- Perform a quality check at each stage to prevent issues later on.

Common Challenges and Solutions

While assembling, you may encounter some challenges. Here are a few common issues and their solutions:

- Misalignment: Ensure components are positioned accurately before tightening.

- Loose fittings: Double-check connections and fasteners after initial assembly.

- Missing parts: Always verify that all components are present before starting the assembly.

By following these guidelines, you can effectively assemble the crucial elements, ensuring optimal performance and longevity of your equipment.

Troubleshooting Power Washer Problems

When dealing with issues related to high-pressure cleaning devices, understanding the common challenges can significantly enhance the troubleshooting process. This section aims to guide users through typical malfunctions, offering insights into their potential causes and solutions.

1. Low Pressure: If the output pressure is not as expected, check for any blockages in the nozzle or hose. Additionally, ensure that the water supply is adequate and that the filter is clean. An improper nozzle size can also lead to diminished performance.

2. Unusual Noises: Listen for any strange sounds during operation. Rattling or grinding may indicate loose components or worn-out parts. Inspect the motor and pump for any signs of damage or wear that could contribute to these sounds.

3. Engine Won’t Start: If the motor fails to initiate, start by verifying the fuel levels and ensuring the choke is properly positioned. Check the spark plug for cleanliness and function; replacing it may resolve ignition issues.

4. Leaking Fluid: Fluid leaks can arise from various seals or connections. Examine hoses and fittings for cracks or looseness. Tightening or replacing faulty components will often eliminate the leakage.

5. Overheating: If the unit overheats, it may be due to prolonged use without breaks or a lack of water flow. Allow the device to cool down and inspect the inlet filter for any obstructions that might restrict water entry.

By systematically addressing these common problems, users can restore functionality and extend the lifespan of their cleaning equipment. Regular maintenance and prompt attention to issues will ensure optimal performance.

Enhancing Performance with Upgrades

Improving efficiency and functionality is essential for maximizing the potential of any equipment. Upgrades can significantly enhance the overall experience, leading to better results and extended longevity. By focusing on key components, users can achieve superior performance tailored to their specific needs.

Key Components for Improvement

Identifying which elements to upgrade can make a substantial difference. Here are some critical components that often benefit from enhancements:

| Component | Potential Upgrade | Benefits |

|---|---|---|

| Engine | High-performance model | Increased power output and efficiency |

| Pump | Advanced pressure system | Improved water flow and pressure |

| Hoses | Reinforced material | Greater durability and resistance to wear |

| Nozzles | Interchangeable types | Versatile applications for various tasks |

Conclusion

Upgrading specific components not only enhances functionality but also ensures a more enjoyable and effective experience. By selecting the right enhancements, users can tailor their equipment to meet individual demands, resulting in optimal performance and satisfaction.