Every lawn maintenance device is a sophisticated system made up of various interconnected elements, each playing a crucial role in ensuring smooth and efficient operation. The specific arrangement and interaction between these elements determine the overall functionality and performance of the machine. In this section, we will explore the essential components that make up a well-engineered outdoor tool designed for effective yard care.

The device under discussion is built with numerous mechanical elements, each with a specific function. These elements work together to create a seamless operation, from powering the tool to managing its movement and precision. Understanding how these individual parts fit together will give users a clearer idea of how to maintain, repair, or upgrade the equipment when needed.

By learning more about the internal structure and layout of this equipment, users can enhance its longevity, improve performance, and ensure it continues to provide optimal results for lawn care tasks. Exploring each element in detail will allow users to perform necessary adjustments and ensure efficient upkeep.

Mower Components Overview

This section provides a comprehensive look at the essential elements that contribute to the functionality of the lawn equipment. Understanding these components is crucial for effective maintenance and optimal performance.

Key parts include the cutting system, which plays a vital role in achieving precise grass trimming. Additionally, the power source ensures reliable operation, while the chassis supports stability and maneuverability. Each element works in harmony to deliver an efficient mowing experience.

Key Features of Toro 20371 Model

This section explores the notable characteristics of a specific lawn care device, emphasizing its design and functionality. Understanding these attributes can enhance user experience and maintenance efficiency.

Design and Build Quality

The construction of this model ensures durability and resilience, making it suitable for various outdoor tasks. The ergonomic design provides ease of use, promoting a comfortable handling experience during operation.

Performance and Efficiency

Equipped with advanced technology, this device delivers impressive performance while maintaining fuel efficiency. Users can expect consistent results, enabling effective lawn management throughout the season.

| Feature | Description |

|---|---|

| Durability | Built to withstand tough conditions. |

| Ergonomics | Designed for user comfort. |

| Fuel Efficiency | Minimizes fuel consumption. |

| Performance | Consistent results for lawn care. |

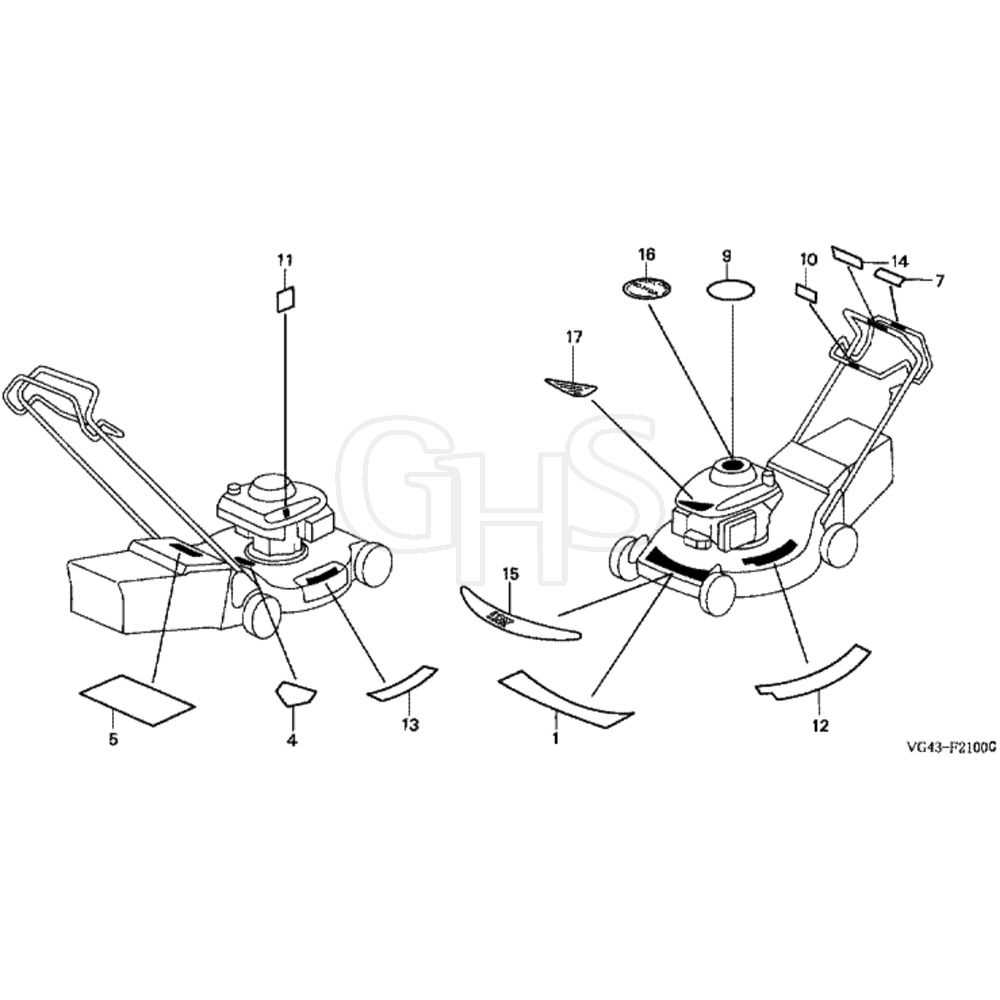

Blade Assembly and Maintenance Guide

This section provides essential information on the assembly and upkeep of the cutting component, ensuring optimal performance and longevity. Proper handling and maintenance can significantly enhance the efficiency of your equipment.

To effectively manage the cutting assembly, follow these steps:

| Task | Frequency | Description |

|---|---|---|

| Inspection | Before Each Use | Check for damage or wear on the blades and secure attachments. |

| Sharpening | Every 10 Uses | Maintain sharpness for effective cutting; use appropriate tools for sharpening. |

| Cleaning | After Each Use | Remove debris and grass clippings to prevent rust and buildup. |

| Replacement | As Needed | Replace blades when they show significant wear or damage. |

By adhering to this guide, you can ensure the cutting assembly operates efficiently, enhancing your overall experience.

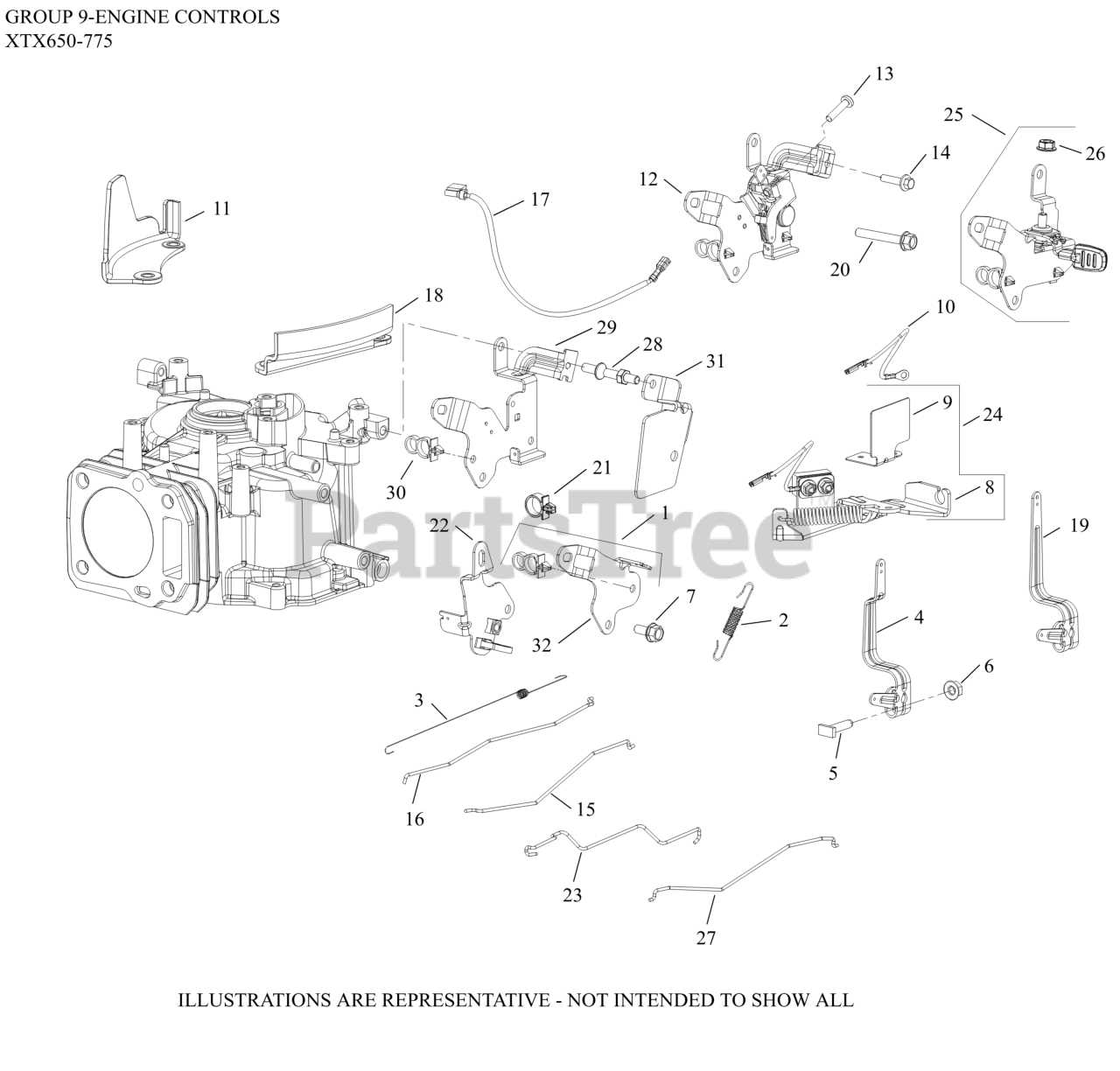

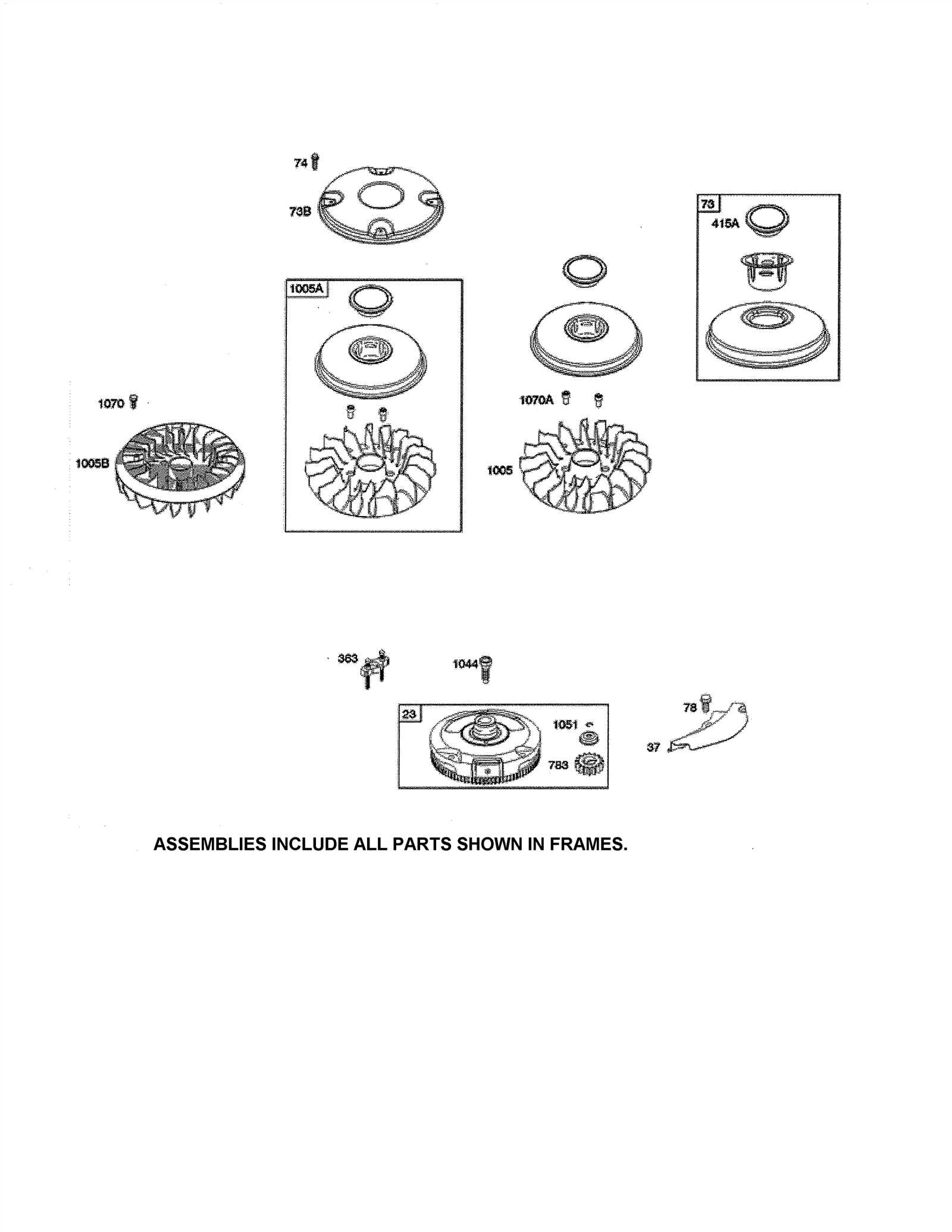

Understanding the Toro 20371 Engine System

The engine system in lawn care equipment plays a crucial role in ensuring optimal performance and efficiency. It comprises various components that work together to deliver power and reliability during operation. A clear understanding of this system can enhance maintenance practices and improve the longevity of the machine.

Key Components of the Engine System

- Power Unit: The primary source of energy that drives all other components.

- Fuel Delivery: System responsible for supplying the necessary fuel to the engine.

- Ignition System: Initiates combustion, ensuring the engine starts and runs smoothly.

- Cooling Mechanism: Maintains optimal operating temperature, preventing overheating.

- Exhaust System: Manages emissions and enhances engine performance.

Importance of Regular Maintenance

Regular upkeep of the engine system is vital for ensuring that all parts function harmoniously. Neglecting maintenance can lead to reduced efficiency and potential breakdowns. Routine checks on components, such as the fuel system and ignition parts, can prevent costly repairs and enhance the overall lifespan of the equipment.

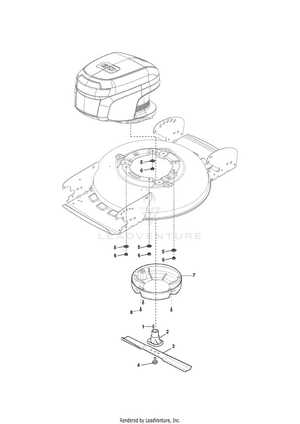

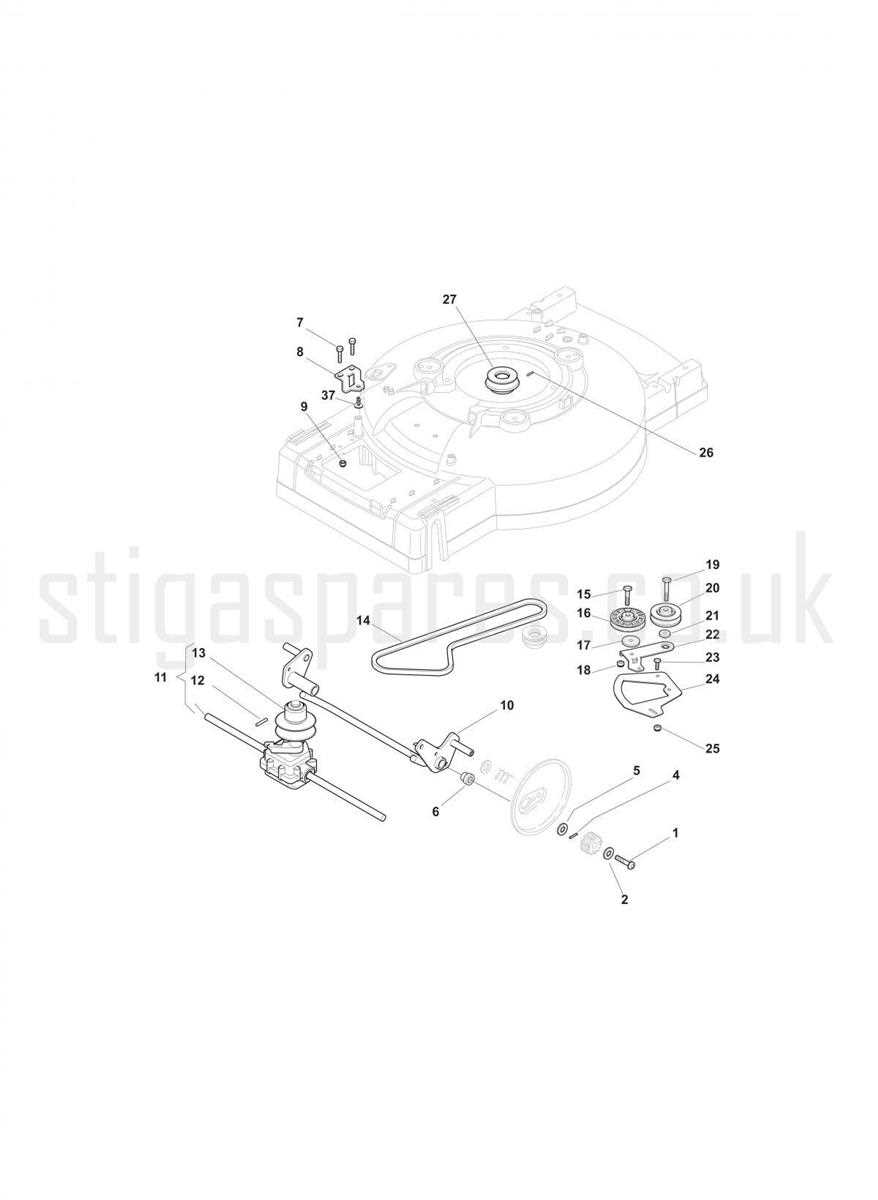

Deck Design and Structural Elements

The design of a lawn mower deck plays a crucial role in its overall performance and durability. Understanding the various structural components helps ensure efficiency and longevity.

Material selection is vital, as it affects the weight and resilience of the deck. Common materials include high-quality steel and reinforced plastics, each offering distinct benefits.

Another essential aspect is the shape and configuration of the deck. A well-designed contour promotes effective grass cutting and reduces clumping, enhancing the mowing experience. Additionally, strategically placed supports and reinforcements provide stability, preventing wear and tear over time.

Replacing the Drive System Components

Maintaining the functionality of the drive system is essential for optimal performance. Over time, various elements may wear out or become damaged, necessitating their replacement. This section will guide you through the process of updating these crucial components to ensure smooth operation.

Identifying Components for Replacement

Begin by examining the system to pinpoint any parts that show signs of wear or malfunction. Common indicators include unusual noises, reduced efficiency, or visible damage. Make a list of these components for easy reference when procuring new ones.

Steps for Replacement

Once you have the necessary components, follow these steps: first, ensure that the machine is powered off and safely secured. Next, remove any protective covers to access the drive assembly. Carefully detach the worn components and replace them with the new ones, making sure to follow the manufacturer’s guidelines. Finally, reassemble everything and perform a test run to confirm that the system operates as intended.

How to Service the Mower Wheels

Maintaining the wheels of your lawn mower is crucial for ensuring smooth operation and optimal performance. Regular servicing helps to prolong the lifespan of the wheels and enhances the overall efficiency of the equipment.

Follow these steps to effectively service the mower wheels:

- Inspect the Wheels:

Check for any signs of wear, cracks, or damage. Ensure that the wheels are securely attached and free of debris.

- Clean the Wheels:

Remove any dirt or grass buildup using a brush or cloth. Ensure the wheel area is clear for proper functionality.

- Lubricate Moving Parts:

Apply appropriate lubricant to the axle and other moving parts to reduce friction and ensure smooth rotation.

- Check Tire Pressure:

Ensure that the tires are inflated to the recommended pressure. Under or over-inflated tires can affect performance.

- Replace Worn Parts:

If any components are excessively worn or damaged, consider replacing them to maintain optimal performance.

By following these steps, you can ensure your mower wheels are well-maintained, leading to improved performance and longevity of your equipment.

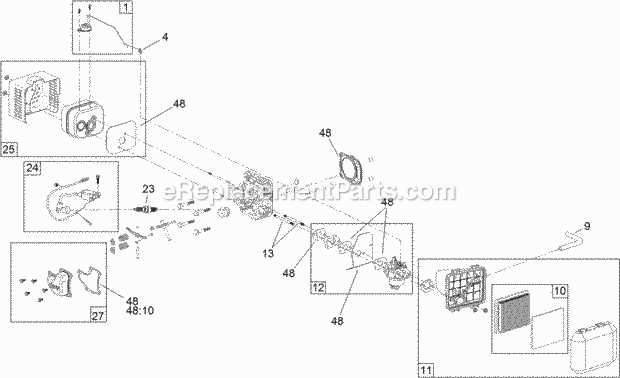

Fuel System Parts and Their Functions

The fuel system is crucial for the efficient operation of any engine, providing the necessary energy for performance. Understanding its components and their roles can help in maintaining and troubleshooting the machinery effectively.

| Component | Function |

|---|---|

| Fuel Tank | Stores fuel until needed for combustion. |

| Fuel Pump | Delivers fuel from the tank to the engine. |

| Fuel Filter | Removes impurities and contaminants from the fuel. |

| Carburetor | Mixes air and fuel in the correct ratio for combustion. |

| Fuel Lines | Transport fuel between components of the system. |

Air Filter Replacement and Care Tips

Maintaining optimal performance of your equipment involves regular upkeep of the air filtration system. A clean air filter is essential for ensuring efficient operation and prolonging the lifespan of your machine.

When to Replace the Filter

Identifying the right time for a filter change is crucial. Consider the following indicators:

- Visual dirt and debris accumulation

- Reduced engine performance or efficiency

- Frequent maintenance intervals

Care Instructions

To ensure longevity and functionality of the air filter, follow these care guidelines:

- Inspect regularly for signs of wear or damage.

- Clean reusable filters as per manufacturer recommendations.

- Store filters in a dry place to prevent moisture damage.

Exploring the Electrical Wiring Diagram

Understanding the intricacies of electrical connections is vital for efficient operation and maintenance of machinery. This section delves into the fundamental aspects of wiring schematics, providing insights into how components interconnect and function together. A clear comprehension of these layouts not only facilitates troubleshooting but also enhances overall performance.

Key Components and Their Functions

Every electrical setup consists of various elements, each playing a crucial role. Power sources, such as batteries or generators, supply the necessary energy, while conductors facilitate the flow of electricity. Switches and relays control the operation, allowing users to manage the system effectively. Familiarity with these components is essential for anyone looking to maintain or repair equipment.

Interpreting the Schematic

Reading a wiring schematic requires attention to detail and an understanding of symbols. Lines indicate connections, while various shapes represent different components. By interpreting these symbols accurately, technicians can trace circuits, identify issues, and implement effective solutions. This knowledge not only aids in repairs but also empowers users to optimize their machines for improved efficiency.

Handle and Control Mechanisms Breakdown

The handle and control systems of equipment play a crucial role in ensuring operational efficiency and user comfort. Understanding the various components involved in these mechanisms can enhance maintenance practices and improve overall functionality. This section delves into the specific elements that constitute the handle and control assembly, offering insights into their purposes and interrelationships.

Key Components

- Grip Handles: Provide the primary point of contact for the user, designed for ergonomic comfort and optimal control.

- Control Levers: Allow for the manipulation of various functions, essential for fine-tuning performance during operation.

- Throttle Controls: Enable the adjustment of speed, ensuring responsive operation based on user requirements.

- Brake Mechanisms: Critical for safety, these systems allow for immediate halting of the equipment when necessary.

- Cables and Linkages: Facilitate communication between the handles and the operational components, translating user inputs into actions.

Maintenance Considerations

- Regularly inspect grip handles for wear and tear to ensure a secure hold.

- Check control levers for responsiveness and proper alignment to prevent malfunction.

- Lubricate throttle controls and cables to ensure smooth operation and reduce friction.

- Examine brake mechanisms for effectiveness, replacing worn parts as needed.

- Keep all components free of debris to maintain optimal functionality.

By understanding the various parts and their maintenance needs, users can enhance the reliability and performance of their equipment, ensuring a seamless operational experience.

Essential Tips for Prolonging Part Life

Maintaining the longevity of your equipment components is crucial for optimal performance and cost efficiency. By following a few key strategies, you can ensure that each element functions effectively for an extended period, minimizing the need for replacements and repairs.

Regular Maintenance

Consistent upkeep is essential. Clean and inspect your components regularly to identify wear and tear early. This proactive approach helps prevent major issues and extends the life of each part.

Proper Storage

When not in use, store components in a dry, cool environment to avoid rust and degradation. Using protective covers can also shield them from dust and moisture, further enhancing their durability.