Understanding the individual elements that make up your machine is essential for ensuring its long-term performance and reliability. Each element plays a crucial role in maintaining the overall functionality and efficiency of the system. When it comes to keeping your equipment running smoothly, it’s important to familiarize yourself with the layout and structure of its various components.

Having a clear visual guide to the inner workings of your machinery can significantly simplify maintenance and repairs. By identifying each element and its function, you can make informed decisions when it comes to replacing or servicing any malfunctioning parts. Whether you’re conducting routine maintenance or dealing with an unexpected issue, a well-organized reference can save you time and effort.

In this section, we’ll explore the layout of various key elements and how they interact to ensure optimal performance. Detailed illustrations and explanations will help you better understand the inner workings of your equipment, making it easier to maintain and repair when necessary.

Components Overview

The structure of this equipment is built from various key elements, each playing a crucial role in ensuring smooth operation. Understanding how these individual components work together can greatly aid in maintaining and troubleshooting the system. In this section, we’ll explore the primary features and their functions, helping you to grasp the essentials of the machine’s internal configuration.

Engine Assembly: The power source, designed for optimal performance, serves as the heart of the system, providing the necessary force to drive all operations.

Drive System: This mechanism ensures the smooth movement and control, allowing for efficient handling across different terrains. It’s essential for maintaining stability and precision.

Cutting Unit: The cutting section is engineered for accuracy, responsible for the primary function of trimming and shaping. Its efficiency directly impacts the overall performance of the equipment.

Control Panel: The command center of the unit, where all settings and adjustments can be managed. This area provides operators with easy access to the machine’s operational modes and fine-tuning options.

Regular inspection and care of these components can significantly extend the longevity of the system and improve overall functionality.

Exploring the Mower’s Main Sections

The mower is composed of several key sections that work together to ensure smooth operation and efficient grass cutting. Each area has its own specific role, contributing to the overall functionality of the machine. In this section, we will take a closer look at these essential components and how they interact to deliver optimal performance.

Engine Compartment

The heart of the mower lies in its engine compartment. This section houses the motor, fuel system, and other vital mechanisms that provide the power necessary for the machine to operate. Ensuring proper maintenance of this area is crucial for reliable and long-lasting performance.

- Motor block

- Fuel tank

- Cooling system

Cutting Deck

Another fundamental part is the cutting deck, which directly handles the grass trimming. Equipped with blades and a height adjustment system, this section is responsible for delivering a precise cut while navigating different terrains.

- Blades

- Height adjustment mechanism

- Deck shell

Key Engine Parts for Toro 74633

The functionality of any lawn mower engine relies heavily on several essential components that ensure smooth and reliable performance. Each of these elements plays a crucial role in maintaining efficiency and prolonging the machine’s lifespan.

Motor block serves as the core structure, providing the necessary foundation for all other elements. It houses various mechanisms that enable the machine to function effectively.

Air filtration system is another critical component, responsible for ensuring that the engine receives clean air, free from dust and debris. This part helps optimize fuel combustion and prevents potential damage from contaminants.

Another important element is the ignition system, which sparks the fuel-air mixture, initiating the combustion process. It ensures that the engine starts promptly and operates efficiently.

Understanding the Fuel System Layout

The fuel system is a critical component that ensures efficient operation by delivering gasoline from the tank to the engine. Its layout is designed for optimal fuel delivery, allowing smooth performance under various conditions. Understanding how the system is structured will help in maintaining its functionality and addressing any potential issues.

Below is a simplified overview of the key elements involved in the fuel system, showing how each part interacts to ensure proper fuel flow:

| Component | Function | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fuel Tank | Stores the gasoline

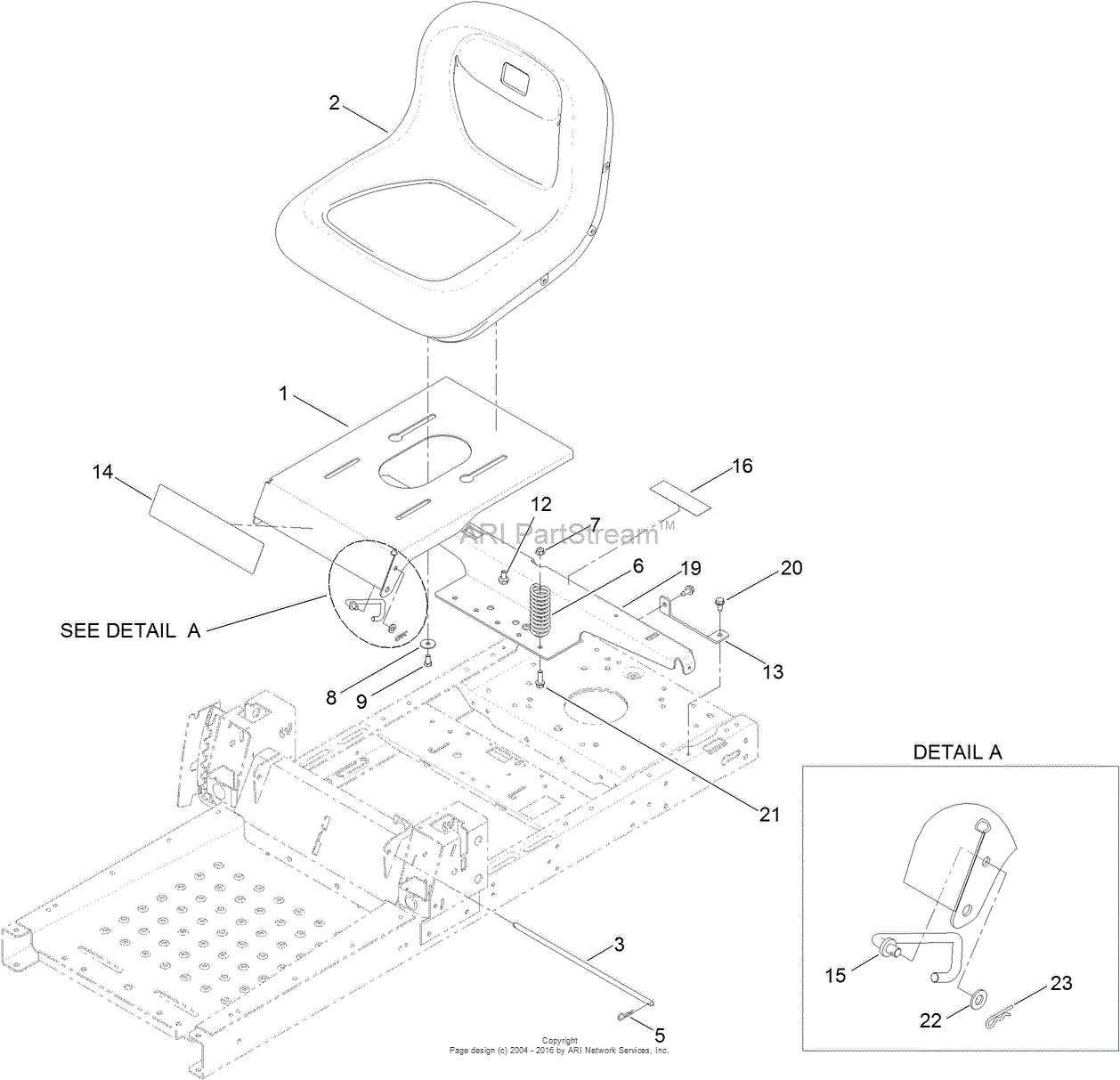

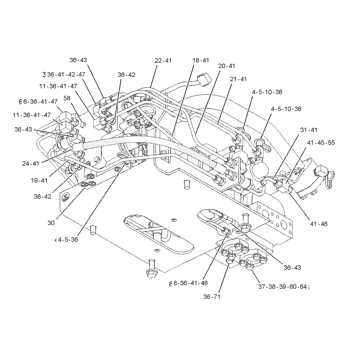

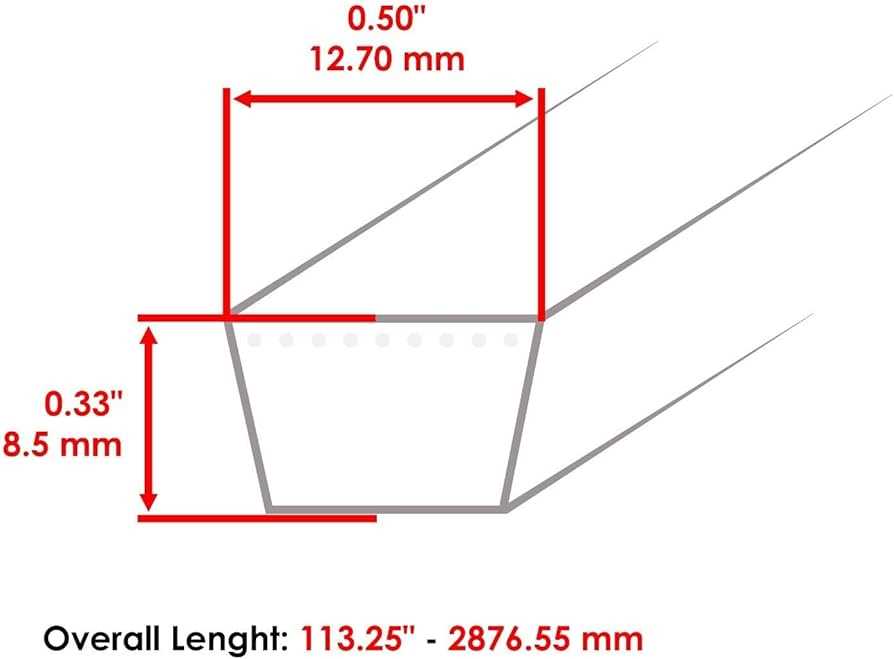

Essential Transmission Components BreakdownThe transmission system is vital for the smooth operation and control of any machine. Understanding the key elements within this system allows for better maintenance and troubleshooting. In this section, we will explore the primary mechanical structures that play a crucial role in ensuring the proper function of the transmission mechanism. Clutch MechanismThe clutch serves as the mediator between the engine and the transmission. It allows the machine to engage and disengage from the power source, providing flexibility in speed control and shifting. Proper function of the clutch is essential to prevent wear and ensure longevity. Gear AssemblyThe gear assembly is responsible for transferring power efficiently by adjusting the torque and speed ratio. Each gear is precisely designed to handle varying loads, ensuring the transmission operates under optimal conditions. Regular inspection of the gears can prevent misalignment and potential breakdowns. Blade and Deck Assembly DetailsThe assembly of the cutting blade and the deck is crucial for optimal performance and durability of any lawn maintenance equipment. Understanding how these components interact can significantly enhance the machine’s efficiency and lifespan. In this section, we will explore the various elements involved in the assembly, focusing on the placement and alignment of the blade, as well as the deck’s structural integrity. Proper installation ensures that the cutting mechanism operates smoothly, minimizing wear and tear while maximizing cutting precision. Blade Assembly: The blade typically attaches to the deck via a central spindle. It is essential to ensure that the blade is secured tightly to prevent any wobbling during operation. Regularly checking for wear can also help in maintaining effective cutting performance. Deck Structure: The deck serves as the housing for the blade, providing protection and support. It is important to inspect the deck for any signs of damage or corrosion, as these issues can compromise the overall functionality. Maintaining a clean and debris-free deck allows for better airflow, contributing to a more efficient cutting process. Regular maintenance of both the blade and the deck assembly is essential. Periodic checks and timely replacements of worn components can help ensure that the lawn equipment operates at its best, delivering a well-manicured lawn while prolonging the life of the machine. Steering Mechanism and Linkages

The steering mechanism is a vital component that ensures precise maneuverability of machinery. This system comprises various linkages that facilitate the transmission of motion from the steering wheel or control lever to the wheels. Understanding how these elements interact is crucial for maintaining optimal performance and ensuring safety during operation. Key Components

Maintenance Considerations

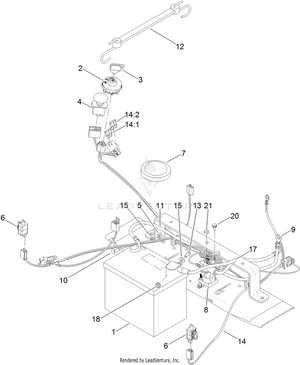

Electrical System LayoutThis section provides a comprehensive overview of the electrical configuration utilized in the specified model, emphasizing the arrangement and function of various components. Understanding this layout is crucial for effective maintenance and troubleshooting. Key elements of the electrical configuration include:

To effectively navigate the electrical layout, consider the following steps:

A thorough understanding of the electrical configuration not only aids in routine checks but also enhances troubleshooting capabilities during repairs. Identifying Key Safety FeaturesUnderstanding the essential safety characteristics of machinery is crucial for ensuring user protection and efficient operation. These features are designed to minimize risks and enhance the overall safety of equipment during use. Recognizing these components can significantly contribute to safe handling and maintenance practices. Here are some critical safety features commonly found in various machinery:

Implementing and understanding these safety features is essential for all users to ensure a secure working environment. Regular inspections and maintenance of these components can help preserve their effectiveness and reliability. Wheels and Axles Structure ExplainedThe structure of wheels and axles plays a crucial role in the overall functionality and efficiency of various machinery. These components work together to facilitate movement, support weight, and ensure stability during operation. Understanding the intricate design of these elements is essential for maintenance and optimization. Components of WheelsWheels are not just simple circular objects; they consist of multiple parts that contribute to their performance. The primary elements include the rim, tread, and hub. Each of these components serves a specific function, enhancing the wheel’s ability to navigate different terrains and handle varying loads. Understanding Axles

Axles act as the backbone of the wheel assembly, connecting the wheels and supporting the weight of the equipment. They are typically classified into two main types: live and dead axles. Live axles transmit power to the wheels, while dead axles provide structural support without rotational movement.

Detailed Look at the Exhaust SystemThe exhaust system plays a crucial role in the efficient operation of any machinery, facilitating the safe expulsion of gases produced during combustion. Understanding its components and functionality can significantly enhance performance and prolong the lifespan of the equipment. Key Components: This system typically comprises several vital parts, including the muffler, pipes, and catalytic converter. Each of these elements works in harmony to reduce noise, control emissions, and ensure optimal gas flow. The muffler, for instance, is designed to minimize sound while allowing gases to exit smoothly. Functionality: Properly functioning exhaust systems are essential for maintaining engine efficiency. They help manage back pressure, which can affect power output if not adequately addressed. Additionally, the system aids in cooling the exhaust gases before they are released, reducing the overall temperature and enhancing safety. Maintenance Tips: Regular inspection of the exhaust system can prevent costly repairs down the line. Look for signs of wear, such as rust or leaks, and address any issues promptly to maintain peak performance. Replacing damaged components quickly can ensure that the equipment operates smoothly and efficiently. Hydraulic Systems and ControlsThe effectiveness of machinery heavily relies on its hydraulic mechanisms, which are crucial for controlling various functions and ensuring smooth operations. These systems utilize fluid power to transmit force, providing the necessary strength to handle heavy tasks. By converting mechanical energy into hydraulic energy, these systems enhance the overall efficiency of equipment. Components of Hydraulic SystemsAt the core of hydraulic systems are several key elements that work together seamlessly. Pumps play a vital role in generating flow, while cylinders and motors translate this flow into motion. Additionally, valves regulate the fluid flow, directing it to specific components as needed. This intricate interplay ensures precise control over the machinery’s functions. Importance of Proper MaintenanceTo maintain optimal performance, regular inspection and upkeep of hydraulic systems are essential. Fluid quality should be monitored, as contaminants can severely impact functionality. Furthermore, checking for leaks and ensuring that components are in good working order will help prevent costly breakdowns and prolong the life of the equipment. Maintenance Points and Part Locations

Regular upkeep is essential for optimal performance and longevity of your equipment. Understanding the various components and their specific locations can significantly enhance maintenance efficiency. This section highlights crucial areas that require attention and describes the positioning of essential elements to facilitate easy access during service tasks. Key Areas for UpkeepFocus on several vital points to ensure proper functioning. Lubrication points, for instance, should be regularly serviced to minimize wear and tear. Inspecting filters and air intakes is also critical, as these areas can accumulate debris and affect overall efficiency. Regular checks will prevent potential issues and maintain peak operational standards. Component Locations

Knowing where to find key components can save time during maintenance procedures. Drive belts and spark plugs are often located near the engine compartment, providing straightforward access for inspection and replacement. Additionally, oil reservoirs are typically situated in a designated area, allowing for easy monitoring of fluid levels. Familiarizing yourself with these locations will streamline maintenance tasks and ensure timely interventions. |