The maintenance of a well-functioning lawn tractor relies on a clear understanding of its key mechanical elements. Regular upkeep not only ensures smooth operation but also extends the lifespan of your machine. Familiarizing yourself with its inner workings can help you diagnose issues and perform repairs with confidence.

In this guide, we’ll explore the various elements that make up the engine and other essential systems. By gaining knowledge about each component, you’ll be better equipped to handle minor adjustments or replacements that may be needed over time.

Whether you’re conducting routine maintenance or tackling a specific issue, having a clear reference of your machine’s inner structure is crucial. This will allow for efficient repairs and optimal performance throughout the years.

Key Components Overview

This section provides a detailed look at the essential elements that make up this specific lawn care machine. Understanding the structure and functionality of these components is crucial for efficient maintenance and troubleshooting.

- Engine: The powerhouse of the machine, designed to deliver reliable performance across different terrains.

- Transmission: Ensures smooth power delivery, allowing the user to easily control speed and direction.

- Cutting Deck: A vital part responsible for the precise cutting of grass, with adjustable height settings for customization.

- Blades: Sharp, durable blades that handle tough grass and provide clean cuts for a neat finish.

- Steering System: Offers precise maneuverability, enabling easy navigation around obstacles.

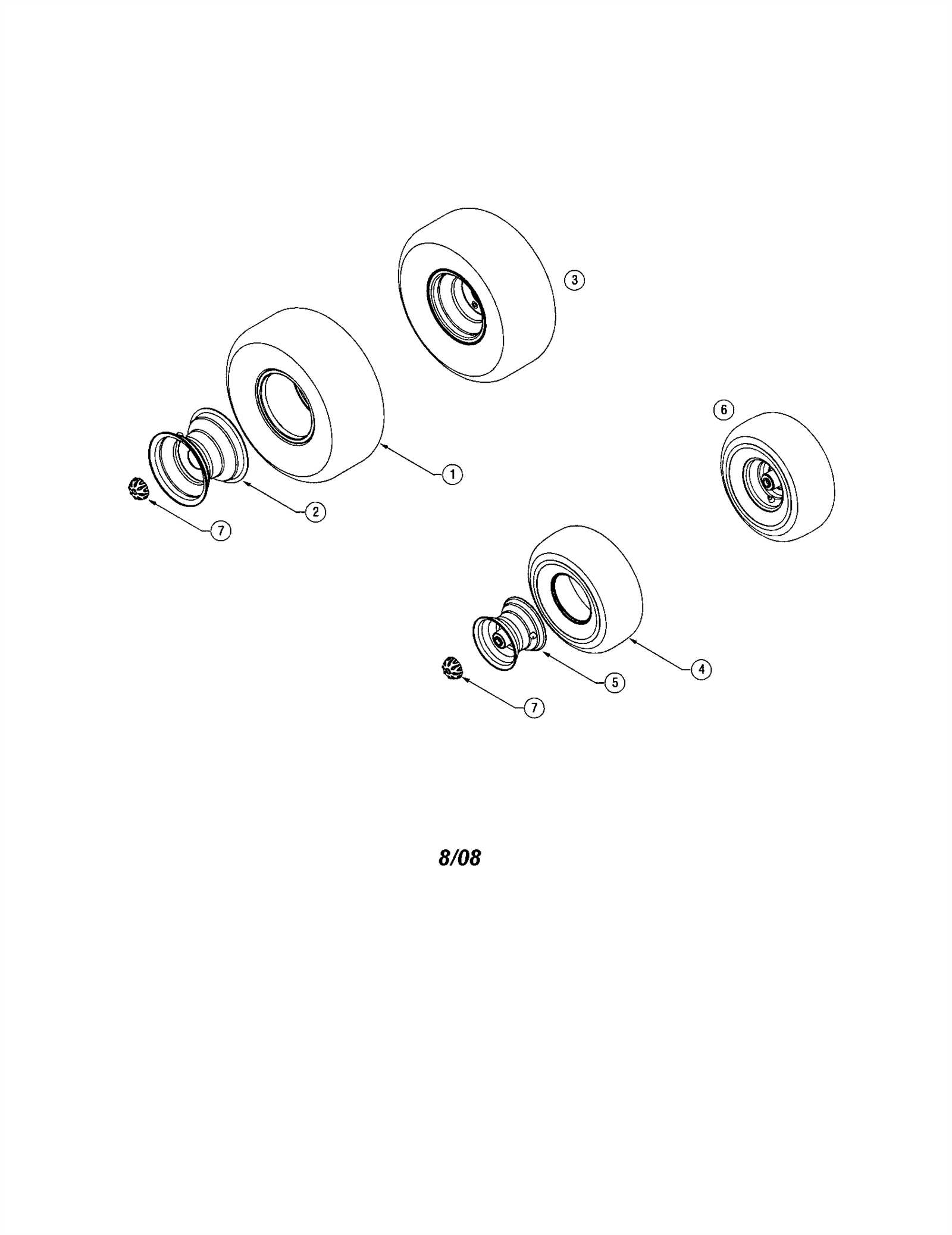

- Tires: Sturdy, well-gripped wheels designed to offer stability and smooth movement over various surfaces.

Each of these

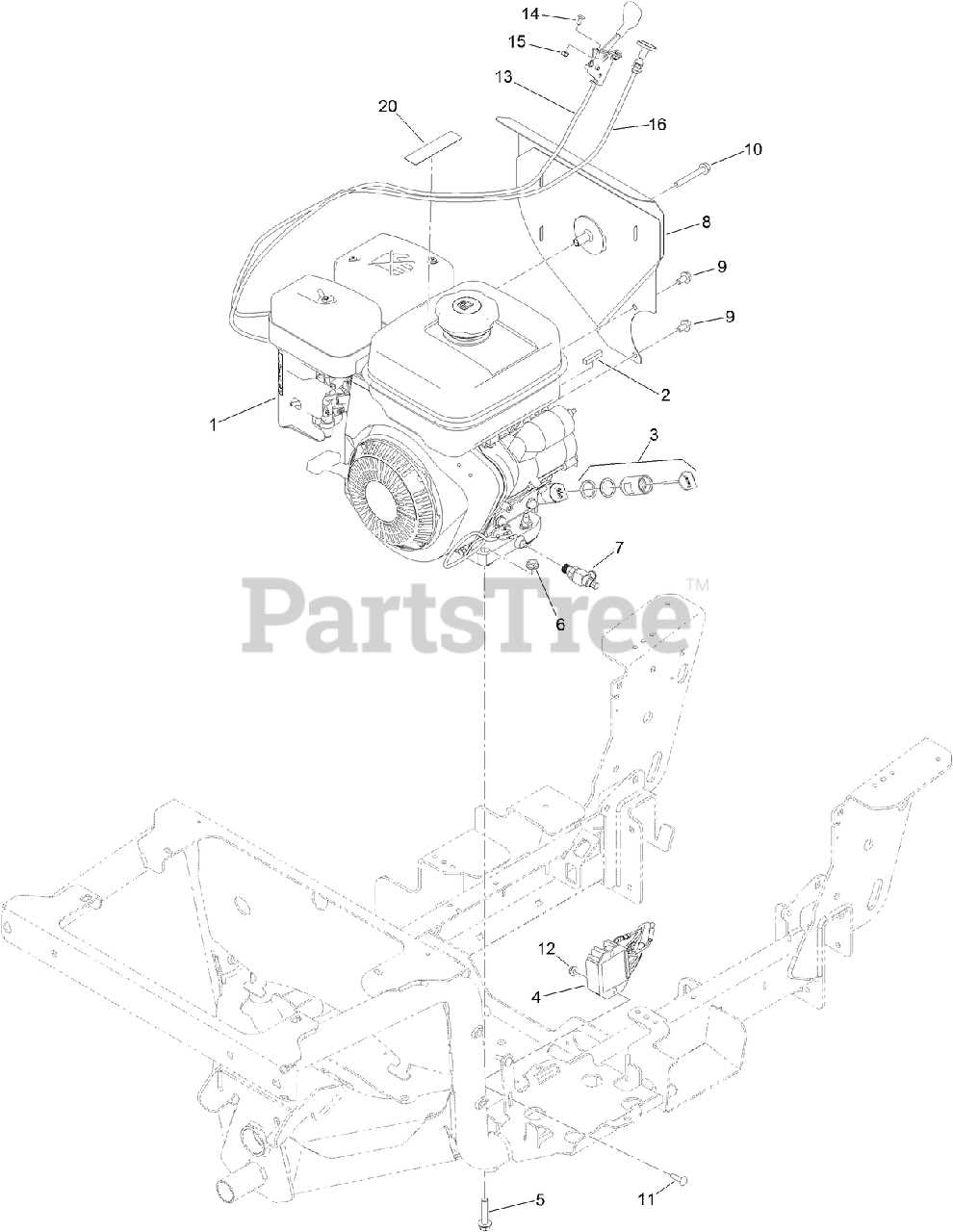

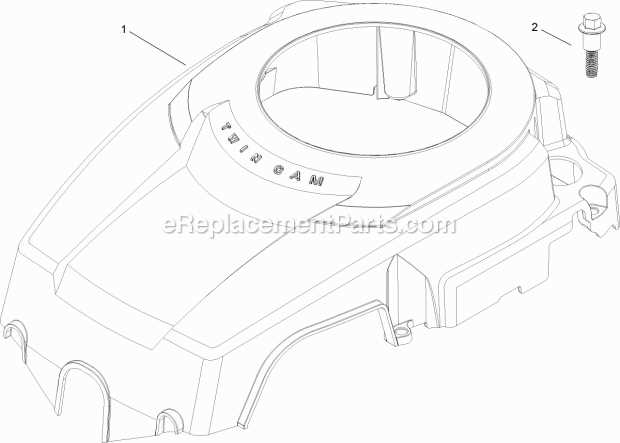

Engine Parts Breakdown for Toro LX420

Understanding the internal components of your lawn tractor’s engine is essential for proper maintenance and repair. Each section of the engine plays a critical role in ensuring smooth operation and longevity. In this guide, we’ll explore the various elements that make up the heart of your machine, focusing on their function and importance.

Main Components Overview

The engine consists of several key components, including the crankshaft, pistons, and cylinder block. These elements work together to convert fuel into mechanical power, driving the vehicle’s motion. Maintaining these parts in good condition is crucial for optimal performance.

Essential Moving Elements

The pistons and crankshaft are the driving force behind the engine’s operation. They move in sync to create the rotational energy necessary to power the machine. Regular inspection and timely replacement of these moving elements can prevent more significant mechanical issues down the line.

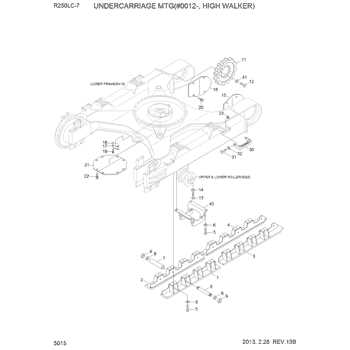

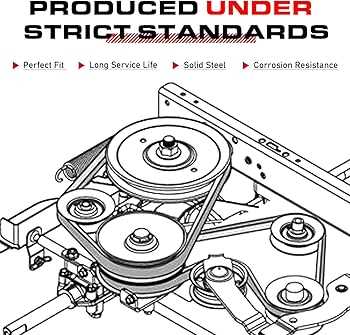

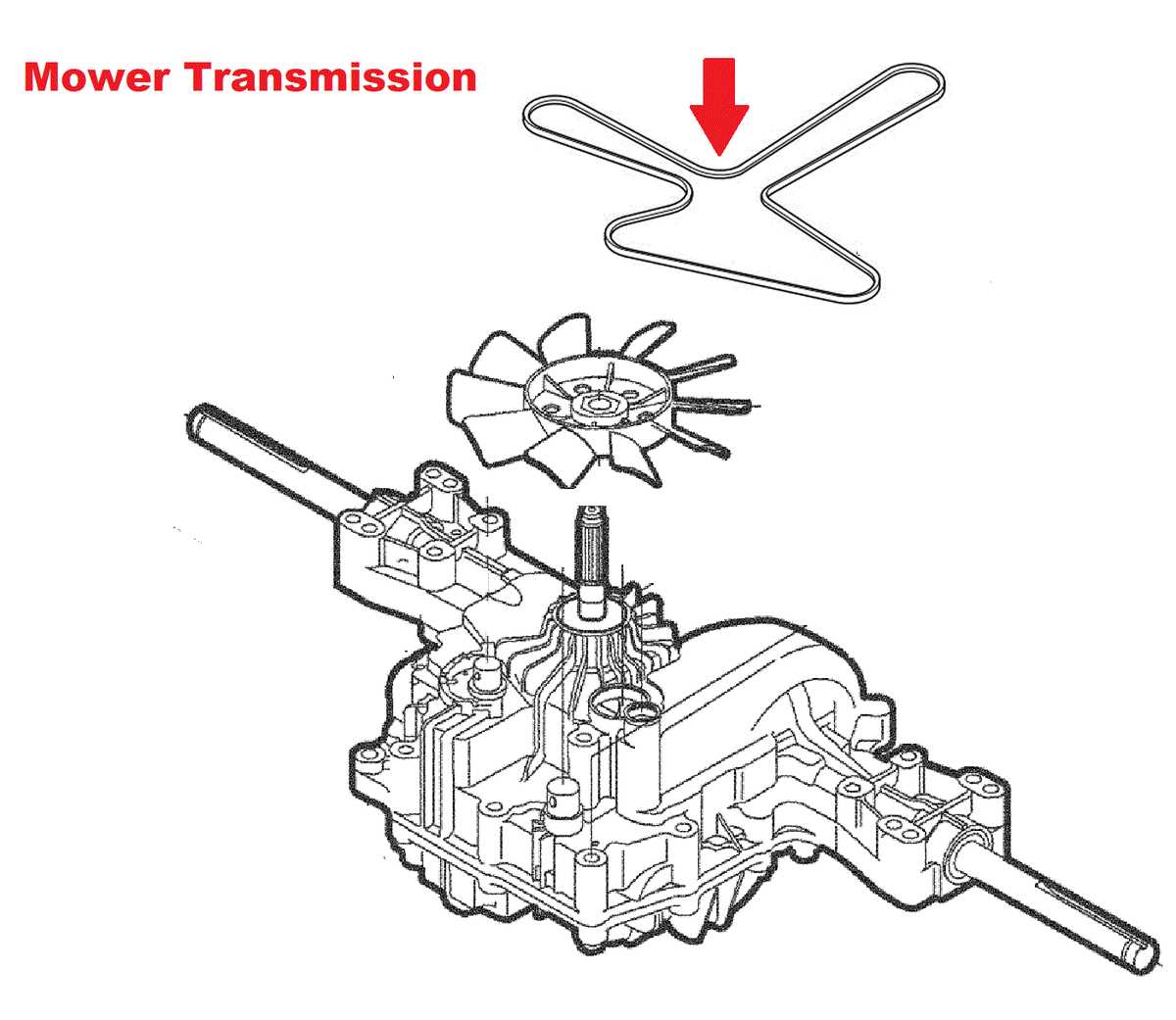

Understanding the Transmission Assembly

The transmission system plays a vital role in ensuring the efficient operation of your equipment by transferring power from the engine to the wheels. Proper comprehension of how it works can greatly enhance your ability to maintain and troubleshoot mechanical issues.

Let’s explore the key components that form this assembly:

- Gearbox: A crucial part that adjusts the speed and torque of the machine depending on the task at hand.

- Drive belt: Transmits power from the engine to the transmission, enabling smooth movement.

- Axle: Connects to the wheels, allowing them to rotate and move forward or backward based on the transmission’s output.

- Clutch system: Engages and disengages the transmission, giving the operator control over movement.

Each of these components works together, making sure your equipment runs smoothly and effectively

Steering Mechanism Detailed Layout

The steering system plays a critical role in ensuring the smooth and precise control of movement. Understanding its components and how they interact allows for better maintenance and troubleshooting when necessary. This section provides a closer look at the structure and key elements involved in the mechanism.

Main Components

The main elements of the steering system include various interconnected parts that work together to enable directional control. Below is an overview of the primary components and their functions.

| Component | Description |

|---|---|

| Steering Wheel | Used by the operator to control the direction of the vehicle. |

| Steering Shaft | Connects the steering wheel to the linkage, transmitting rotational movement. |

| Steering Linkage | A series of rods and joints that transfer motion from the steering shaft to the wheels. |

| Component | Description |

|---|---|

| Axle Shaft | Transfers power from the engine to the wheels, enabling movement. |

| Bearings | Facilitate smooth rotation of the axle, reducing friction. |

| Spindles | Connect the wheels to the axle, allowing for steering and turning. |

| Differential | Distributes power to the wheels while allowing them to rotate at different speeds. |

| Hubs | House the wheel bearings and provide a mounting point for the wheels. |

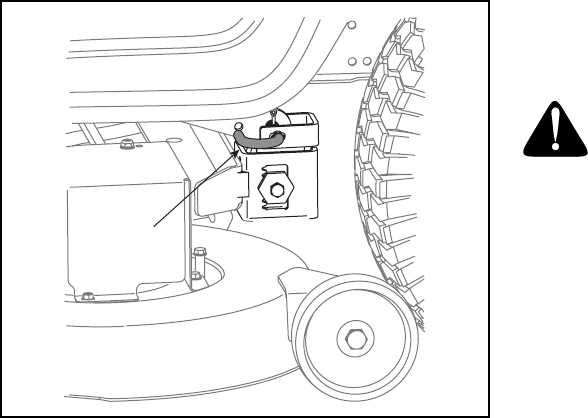

Brake System Parts and Configuration

The braking system of a lawn care machine is essential for safe operation and effective control. Understanding the components involved and their arrangement helps ensure optimal performance and maintenance. This section will delve into the various elements that constitute the braking mechanism and their respective functions.

Key Components of the Braking Mechanism

- Brake Pedal: The primary control for activating the braking system.

- Brake Pads: Friction materials that engage with the rotors to slow down or stop the machine.

- Brake Rotors: Circular discs that the pads press against to create stopping force.

- Calipers: Devices that house the brake pads and apply pressure to the rotors.

- Brake Lines: Tubes that transport hydraulic fluid to the calipers, facilitating movement.

- Master Cylinder: Converts the force from the brake pedal into hydraulic pressure.

Configuration and Functionality

In the braking system, the arrangement of components is crucial for efficiency. The master cylinder creates hydraulic pressure when the brake pedal is pressed. This pressure travels through the brake lines to the calipers, causing them to squeeze the brake pads against the rotors. As the pads grip the rotors, friction is generated, resulting in deceleration. Regular inspection and maintenance of each component are vital for ensuring that the system operates smoothly and reliably.

Maintenance Guide for LX420 Parts

Regular upkeep is essential for ensuring the longevity and optimal performance of your equipment. Understanding the components and their functions allows for more effective maintenance practices. This guide outlines key maintenance tasks to keep your machinery running smoothly and efficiently.

Start by regularly inspecting all essential components for wear and tear. Look for any signs of damage or degradation that could affect functionality. Cleaning the parts is equally important; debris and dirt can hinder performance and lead to more significant issues over time.

Lubrication is critical for moving parts to prevent friction and overheating. Ensure that you use the recommended lubricants and apply them according to the manufacturer’s specifications. Additionally, monitor the fluid levels and replace any fluids as needed to maintain proper operation.

Finally, keep an eye on the overall condition of your machine. If you notice any unusual noises or performance drops, address these issues promptly to avoid further damage. Regular maintenance checks will help extend the lifespan of your equipment and enhance its efficiency.