When it comes to maintaining outdoor machinery, having a clear overview of its individual elements is crucial for optimal performance. Knowing how each component interacts can significantly enhance the longevity and efficiency of your device.

In this guide, we will explore a comprehensive layout of essential features, offering insights into their functions and interconnections. By familiarizing yourself with these elements, you can make informed decisions regarding repairs and upgrades.

Ultimately, this knowledge empowers users to delve deeper into the mechanics of their equipment, ensuring it operates at peak efficiency while minimizing potential issues. Understanding these intricacies not only saves time but also resources in the long run.

Toro Power Max 726 OE Overview

This section provides a comprehensive look at a renowned snow removal machine, highlighting its design, features, and overall performance. Known for its efficiency and reliability, this equipment is ideal for both residential and commercial use, ensuring that winter challenges are handled with ease. Users can expect robust construction and innovative technology that make clearing snow a seamless task.

Key Features

With a blend of functionality and user-friendly design, this snow blower offers several standout features:

| Feature | Description |

|---|---|

| Engine Power | Equipped with a powerful engine that ensures optimal performance in various snow conditions. |

| Clearing Width | A generous clearing width allows for quick and efficient snow removal from driveways and sidewalks. |

| Adjustable Chute | The chute can be adjusted easily to direct snow where needed, enhancing control during operation. |

| Ergonomic Design | Designed for comfort, the controls are positioned for easy access, reducing user fatigue. |

Performance and Reliability

This equipment is built to withstand harsh winter conditions, featuring durable materials and advanced engineering. Users can rely on consistent performance year after year, making it a trusted choice for tackling heavy snowfall. The combination of power and versatility ensures that it meets the demands of various environments, from suburban driveways to expansive commercial areas.

Key Features of Toro Power Max

When it comes to snow removal equipment, certain characteristics stand out, enhancing performance and usability. These features are designed to ensure efficiency and ease of operation, making winter tasks more manageable.

Robust Build Quality: The equipment boasts a durable construction, ensuring longevity and reliability in harsh weather conditions.

Intuitive Controls: User-friendly controls allow for seamless operation, even for those unfamiliar with similar machinery.

Powerful Engine: Equipped with a high-performance engine, this model delivers impressive clearing capabilities, making short work of heavy snow.

Advanced Traction: Enhanced traction systems provide stability and control, enabling users to navigate various terrains effortlessly.

Adjustable Settings: With customizable settings, operators can tailor the machine’s performance to suit specific tasks and conditions.

Compact Design: Its sleek design facilitates easy storage and maneuverability, even in tight spaces.

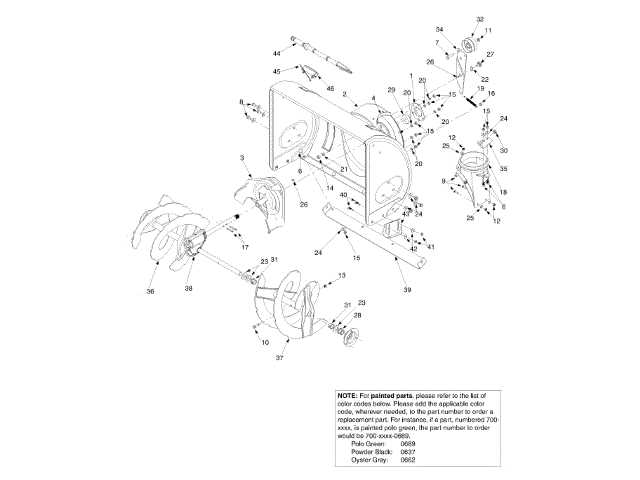

Understanding the Parts Diagram

Grasping the layout of components is essential for effective maintenance and troubleshooting. A clear representation allows users to identify various sections and elements, ensuring proper assembly and function.

Importance of Component Clarity

Having a well-organized visual guide enhances understanding and facilitates repairs. It enables users to quickly locate parts, minimizing downtime during maintenance tasks.

Key Features of a Component Layout

| Feature | Description |

|---|---|

| Identification | Each section is labeled for easy reference. |

| Arrangement | Components are grouped logically, reflecting their interaction. |

| Detailing | Includes specifications and dimensions for precise replacements. |

Importance of Proper Maintenance

Regular upkeep is essential for ensuring optimal performance and longevity of any mechanical equipment. Neglecting this crucial aspect can lead to diminished efficiency, increased wear, and ultimately, costly repairs. By committing to a consistent maintenance routine, users can not only enhance the functionality of their devices but also extend their operational life significantly.

Benefits of Routine Care

Implementing a systematic maintenance schedule yields numerous advantages, including improved reliability and safety. Well-maintained machinery operates more smoothly, reducing the likelihood of unexpected breakdowns. Additionally, it helps in identifying potential issues before they escalate, allowing for timely interventions.

Cost-Effectiveness

Investing time and resources in maintenance can lead to significant cost savings in the long run. Regular inspections and servicing can prevent major failures that require expensive repairs or replacements. This proactive approach not only protects your investment but also ensures uninterrupted productivity.

Common Replacement Parts Explained

Maintaining equipment often requires understanding the various components that may need substitution over time. These essential elements play a crucial role in ensuring optimal performance and longevity. Knowing the typical parts that might require replacement can help users stay proactive in their upkeep.

Blades are among the most frequently replaced items, as they experience significant wear during operation. Dull or damaged blades can compromise efficiency and effectiveness.

Filters, such as air and fuel types, are vital for maintaining proper function. Regularly changing these can prevent debris buildup and ensure smooth operation.

Batteries often have a limited lifespan and may need replacement to guarantee reliable performance. Checking battery health regularly can save time and prevent unexpected failures.

Belt systems may also require attention, as they are crucial for transferring power. Over time, belts can wear down or become misaligned, leading to reduced performance.

Lastly, sprockets and gears may require replacement due to wear and tear, ensuring smooth operation and preventing breakdowns. Understanding these components can enhance equipment reliability and performance.

Identifying Component Functions

Understanding the roles of various elements within a mechanical system is crucial for effective maintenance and repair. Each component is designed with a specific purpose, contributing to the overall functionality and efficiency of the machine. By familiarizing oneself with these individual roles, operators can troubleshoot issues more effectively and ensure the longevity of the equipment.

Key Components and Their Roles

Every system consists of critical parts that serve distinct functions. For instance, the engine is responsible for generating power, while the transmission system facilitates movement. Additionally, the electrical components control operations and enhance user interaction. Recognizing these elements enables users to pinpoint problems and implement appropriate solutions.

Importance of Proper Identification

Accurate identification of component functions not only aids in repairs but also enhances performance optimization. When operators know how each part contributes to the system, they can make informed decisions regarding upgrades and modifications. This knowledge ultimately leads to improved efficiency and reduced downtime.

Tools Needed for Repairs

Effective maintenance requires the right equipment to ensure efficiency and precision. Having a well-stocked toolbox can significantly simplify the repair process and enhance overall results.

Essential Tools

- Wrenches: For loosening and tightening various components.

- Screwdrivers: Both flathead and Phillips types for versatile applications.

- Pliers: Useful for gripping, twisting, and cutting.

- Socket Set: Ideal for quick removal and installation of nuts and bolts.

Additional Supplies

- Lubricants: To minimize friction and wear on moving parts.

- Cleaning Agents: For maintaining a clean working environment.

- Safety Gear: Such as gloves and goggles to protect while working.

Step-by-Step Repair Guide

This section aims to provide a comprehensive approach to restoring and maintaining your equipment effectively. Following these instructions will help ensure a smooth process and optimal performance.

Preparation Phase

Before starting any repair work, gather all necessary tools and materials. Make sure to have a clean workspace to facilitate the task. It’s essential to refer to the manual for specific instructions related to your model, ensuring you understand each component’s function.

Repair Process

Begin by disassembling the unit carefully, taking note of how each part fits together. Use labels or photographs to document the arrangement. Once disassembled, inspect each component for wear or damage, replacing any faulty parts. After repairs, reassemble the unit in the reverse order, ensuring everything is secure before testing the functionality.

Where to Find OEM Parts

Locating original equipment manufacturer components can be crucial for maintaining the performance and reliability of your machinery. These authentic items ensure compatibility and longevity, providing peace of mind for users who value quality.

One of the most reliable sources is the official website of the manufacturer, where you can often browse a catalog or utilize a search function for specific items. Additionally, authorized dealers and service centers specialize in genuine components, offering expert advice and support.

Online marketplaces can also be a good option, but it’s essential to verify the seller’s reputation to avoid counterfeit goods. Lastly, consider local repair shops; they may stock or be able to order authentic items, often with the added benefit of expert installation.

Tips for Efficient Troubleshooting

Effective problem-solving is crucial when dealing with machinery or equipment issues. A systematic approach can save time and reduce frustration. By following a few essential guidelines, you can enhance your diagnostic skills and tackle challenges with confidence.

| Tip | Description |

|---|---|

| Understand the Basics | Familiarize yourself with the fundamental principles of how the equipment operates. This knowledge lays the groundwork for effective troubleshooting. |

| Consult the Manual | Always refer to the user manual for specific instructions and troubleshooting procedures. Manuals often contain valuable insights into common issues. |

| Visual Inspection | Conduct a thorough visual examination of the equipment. Look for signs of wear, damage, or loose connections that could indicate problems. |

| Check for Obstructions | Ensure that all moving parts are free of debris and that there are no blockages affecting performance. Clearing any obstructions can often resolve issues. |

| Test Components | Isolate and test individual components to identify malfunctioning parts. This methodical approach can help pinpoint the source of the issue more effectively. |

| Keep Records | Document any issues encountered and the steps taken to resolve them. This record can serve as a reference for future troubleshooting efforts. |

Comparing Toro Models and Variants

Understanding the distinctions between various models and their variants can significantly enhance the user’s experience and maintenance choices. Each design caters to different needs, performance levels, and user preferences.

Key Features Across Models

- Engine Types: Options range from gas-powered to electric.

- Cutting Widths: Varying sizes accommodate different yard dimensions.

- Durability: Materials used can impact longevity and robustness.

Choosing the Right Variant

- Assess your yard size and terrain type.

- Determine your preferred fuel source and maintenance level.

- Consider additional features like self-propulsion or adjustable heights.

Customer Reviews and Feedback

This section aims to provide insights into the experiences of users with a specific outdoor equipment model. Customer reviews serve as valuable testimonials that highlight both the strengths and weaknesses of the product, helping potential buyers make informed decisions.

Many users have praised the reliability and performance of the equipment, noting its efficiency in handling various tasks. Comments often highlight ease of use and the effectiveness of its features, making it a favorite among homeowners and professionals alike. Several reviews mention the durability of the machine, emphasizing its ability to withstand tough conditions.

However, some feedback has pointed out areas for improvement. A few customers experienced challenges with assembly or maintenance, suggesting that clearer instructions could enhance user satisfaction. Others have noted the weight of the equipment as a potential drawback, particularly for those seeking more portability.

Overall, the collection of feedback offers a balanced view, showcasing a mix of commendations and constructive critiques. This helps prospective buyers gauge whether the product aligns with their needs and expectations.