Keep the blade free of debris and buildup by cleaning it a

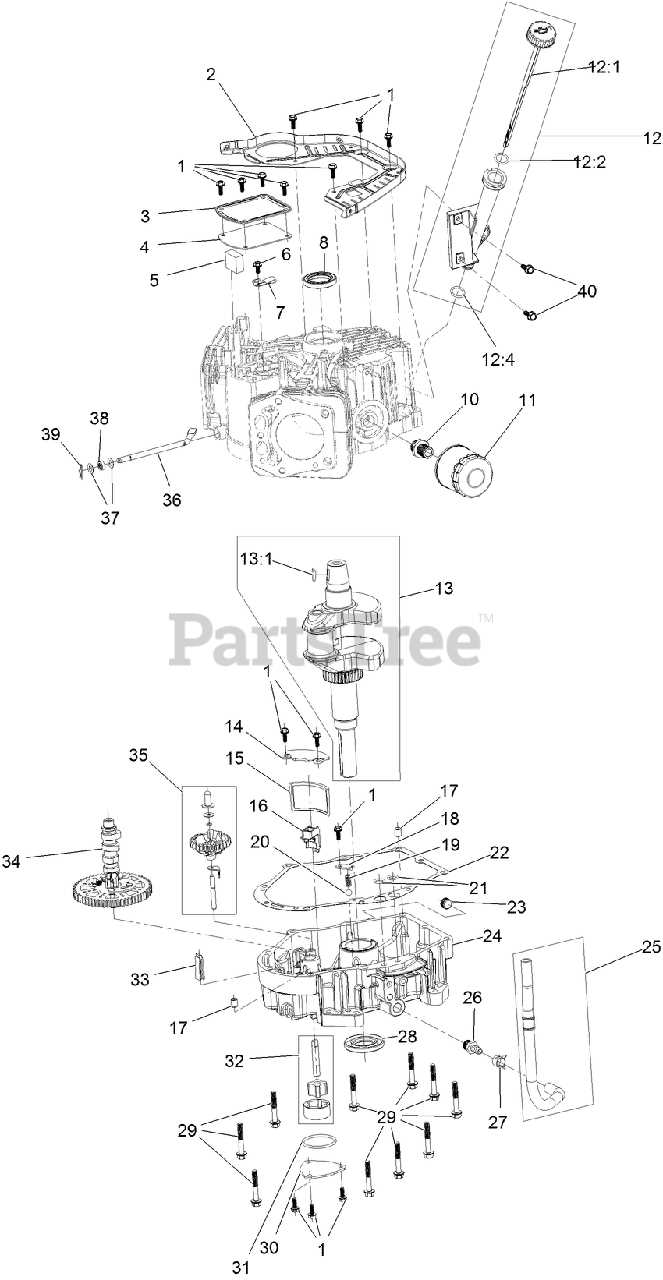

Understanding the Engine and Fuel System

The engine and fuel system play a crucial role in powering outdoor equipment designed for cutting and maintaining large areas of grass. By ensuring a steady flow of fuel and air, the motor can operate efficiently and deliver consistent performance. It is essential to understand how these components work together to maintain functionality and optimize power output.

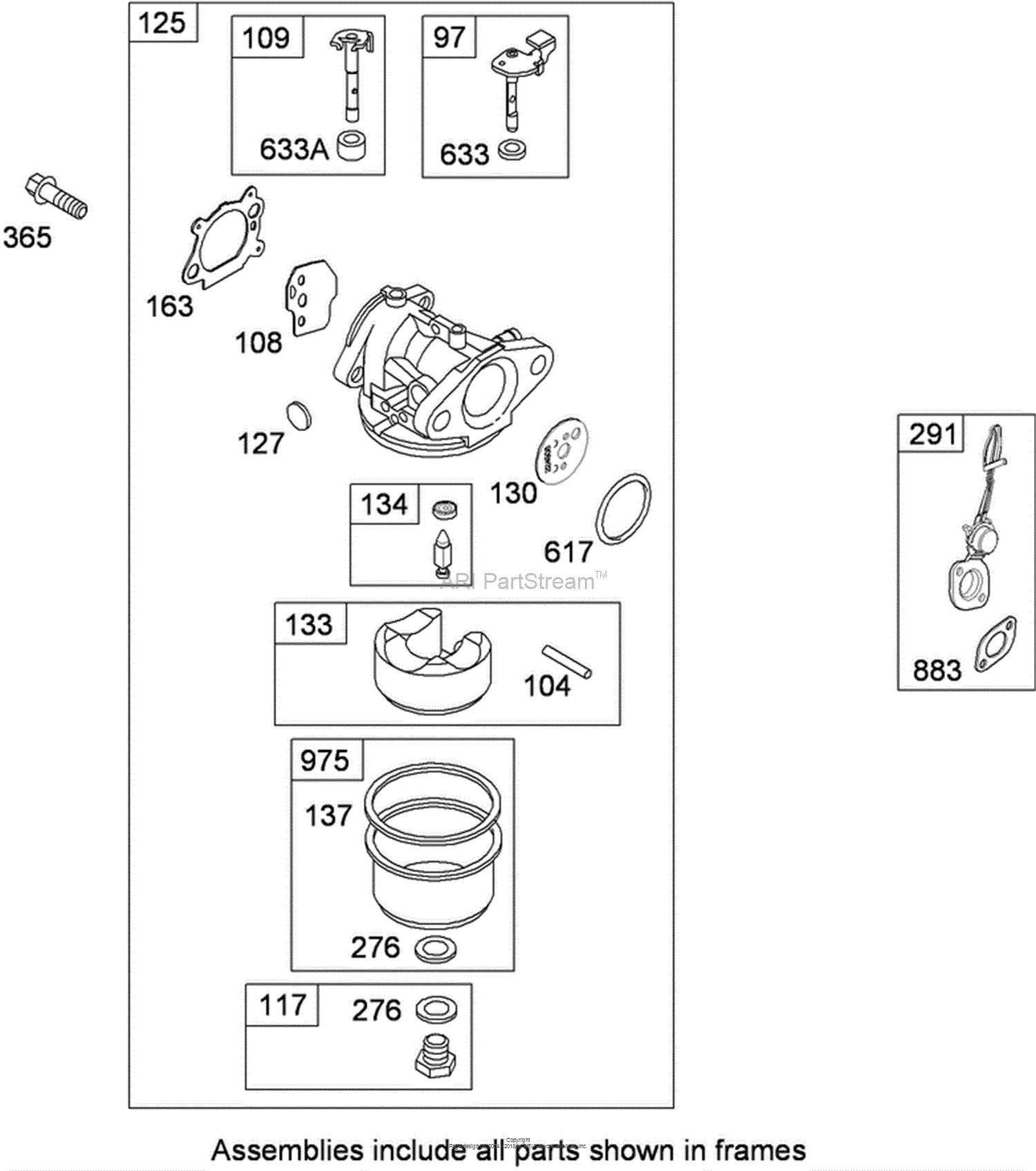

Key Components of the Engine

The heart of the equipment lies in its combustion mechanism, which relies on a combination of air, fuel, and spark to generate energy. This energy drives the blades and ensures smooth operation. Key parts of the system include the carburetor, which mixes air and fuel, the spark plug, responsible for ignition, and the piston, which converts energy into mechanical motion.

Fuel Delivery and Management

The fuel system is responsible for supplying the correct amount of gasoline to the engine. Components like the fuel tank, lines, and filter ensure clean and uninterrupted fuel flow. Regular maintenance, such as cleaning the filter and checking the fuel lines for leaks, is crucial for preventing engine issues and ensuring a long-lasting and efficient machine.

How the Cutting Deck Works

The cutting deck is an essential component designed to handle the primary task of trimming vegetation. Its role revolves around holding and guiding the blades that perform the cutting action. This mechanism is crucial for ensuring a smooth and efficient trimming process, allowing the user to achieve consistent results with minimal effort.

Blade Mechanism

The blades inside the cutting deck rotate at high speeds, generating enough force to slice through various types of grass and other plants. The deck not only protects the user from debris but also creates an airflow that helps lift the vegetation for a more even trim. This ensures an optimal cutting height and cleaner finish.

Deck Height Adjustment

One of the key features of the cutting deck is the ability to adjust its height. By altering the distance between the ground and the blades, the user can control the length of the cut. This adjustment feature makes it easier to tackle different terrains and vegetation types, enhancing both the efficiency and flexibility of the machine.

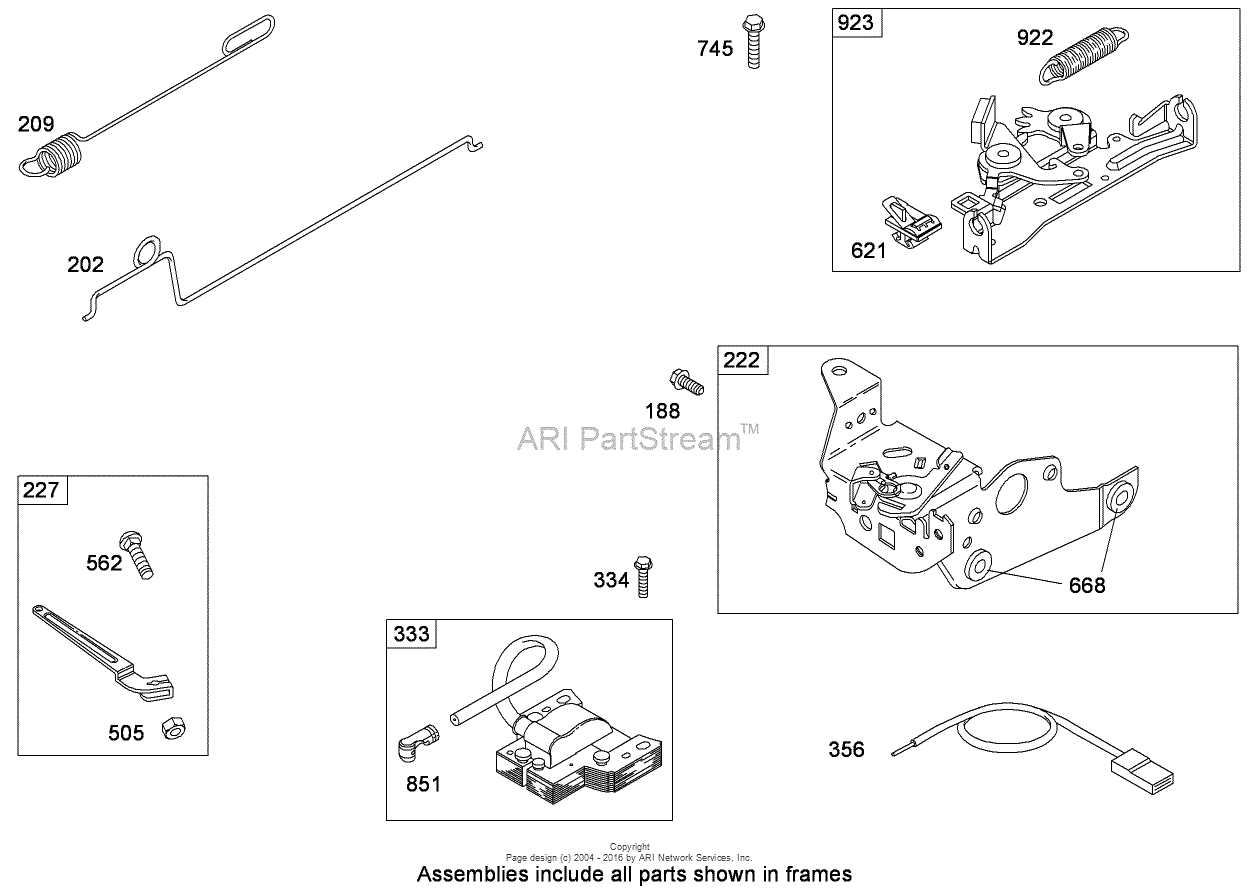

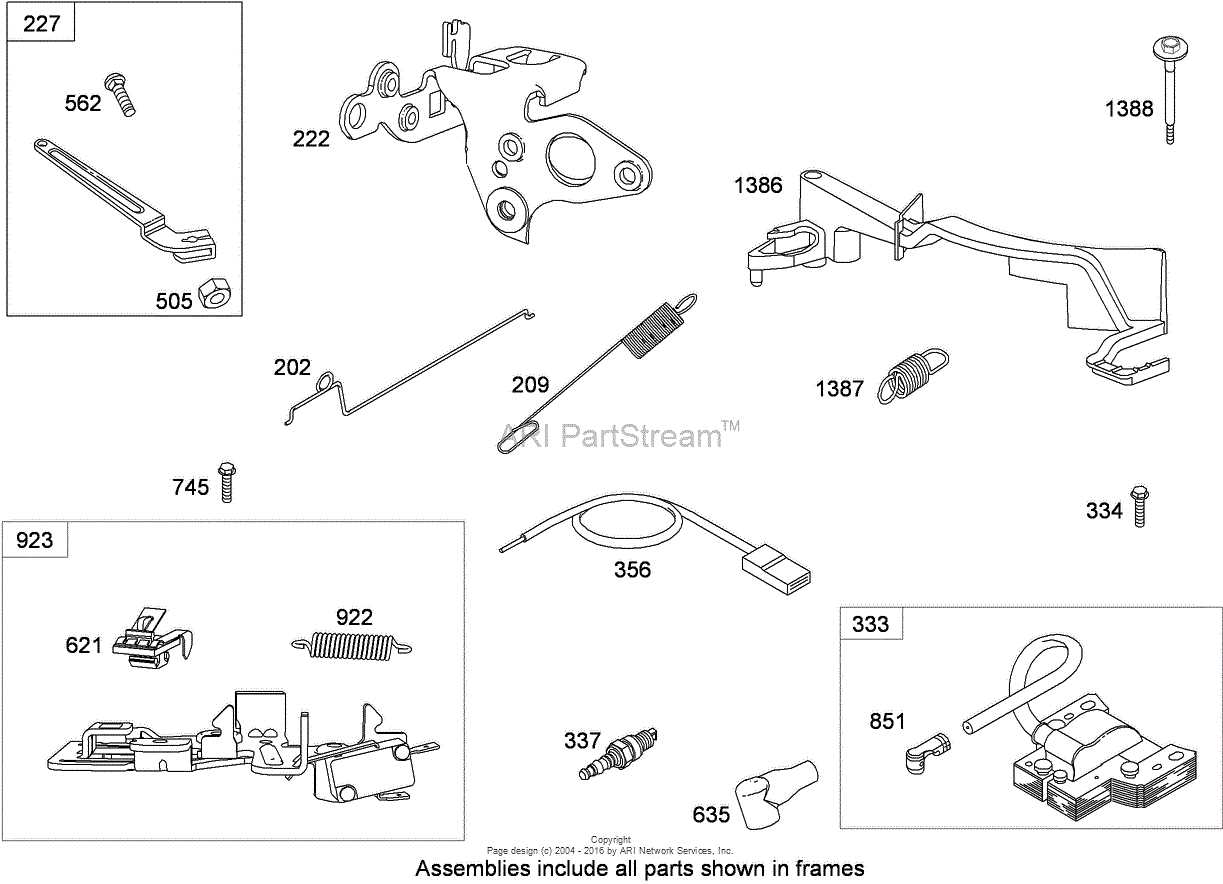

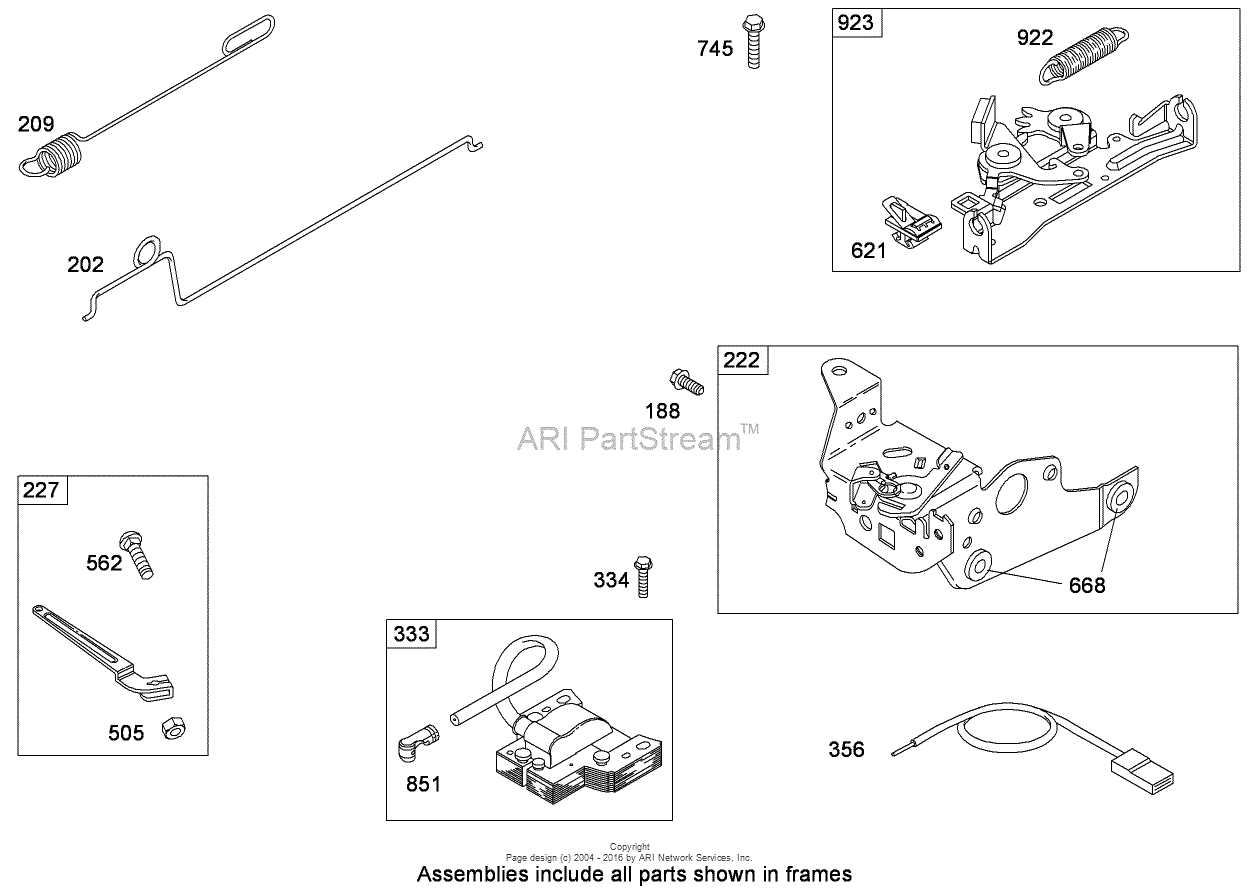

Throttle and Control Mechanism Breakdown

The throttle and control system is a crucial component that governs the operation and performance of the equipment. Understanding the intricacies of this mechanism can enhance user experience and improve maintenance practices. This section delves into the various elements that comprise this system, emphasizing their functions and interrelationships.

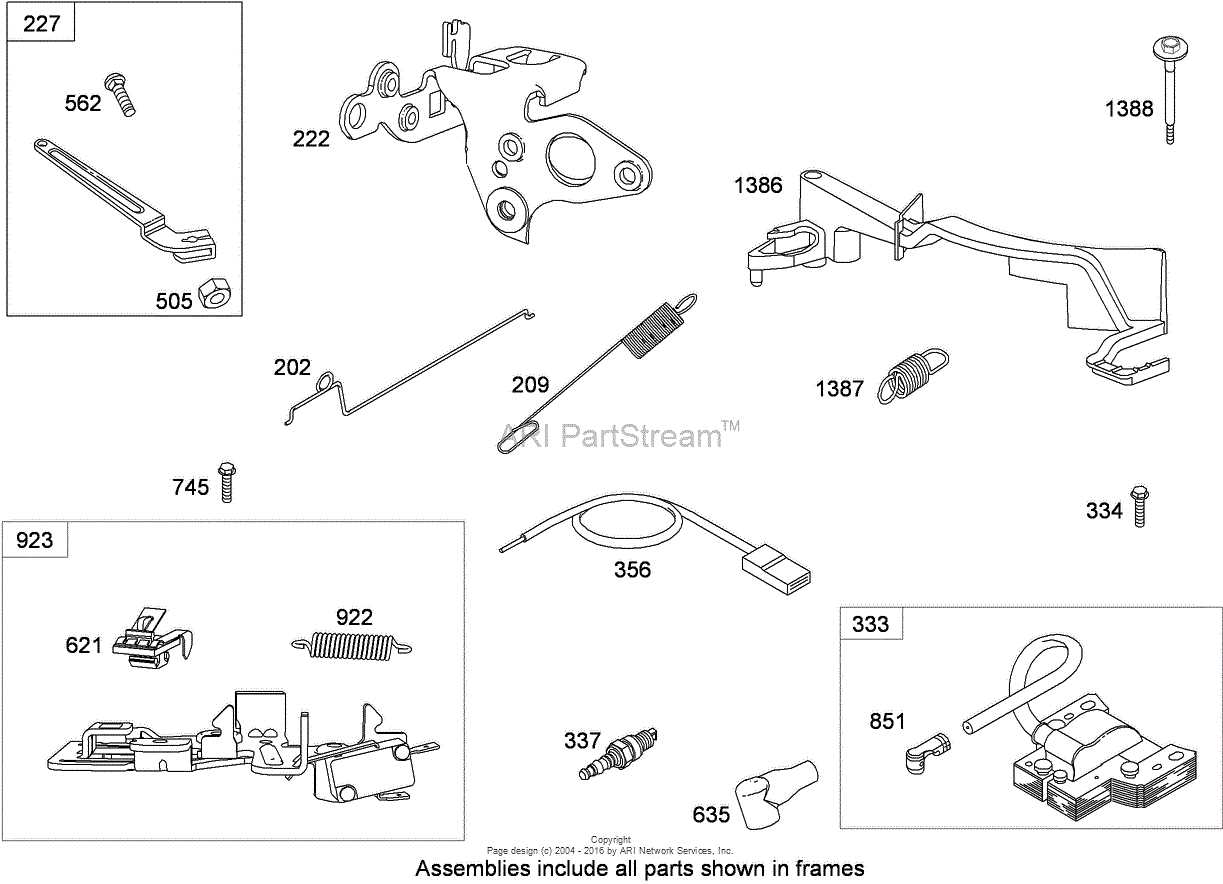

Components of the Throttle System

The throttle mechanism typically includes a cable, lever, and spring assembly that work together to regulate engine speed. The cable connects the control lever to the throttle valve, allowing the operator to adjust power output effortlessly. Regular inspection of these components is essential to ensure smooth operation and prevent potential issues.

Control Mechanism Functionality

The control mechanism serves as the interface between the user and the engine. By manipulating the lever, the operator can influence the speed and efficiency of the machine. This interaction not only enhances maneuverability but also allows for precise handling in various environments. Maintaining the integrity of this system is vital for optimal performance and longevity of the equipment.

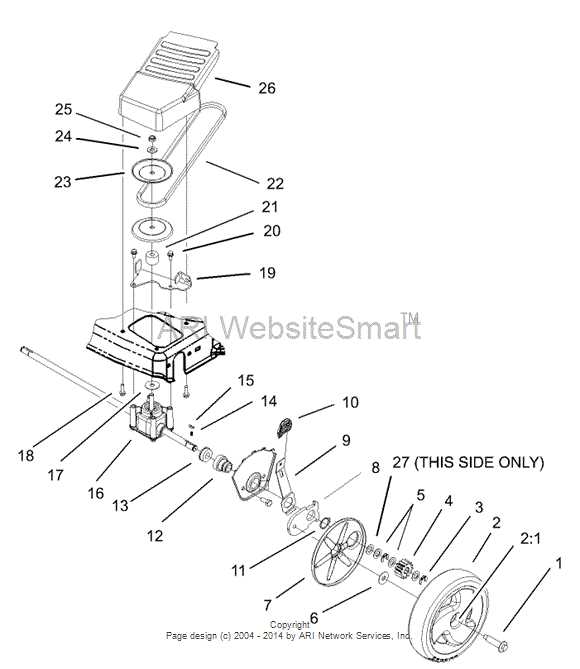

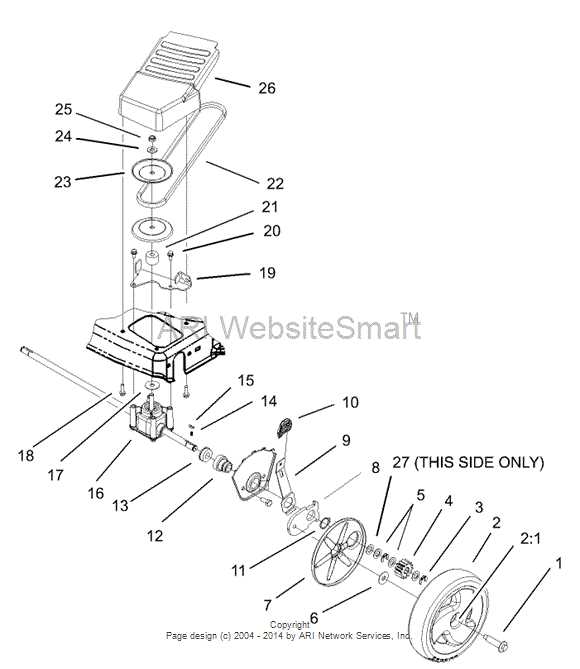

Inspecting the Mower’s Wheel System

Regular examination of the wheel assembly is essential for ensuring optimal functionality and safety during operation. A well-maintained wheel system not only enhances performance but also contributes to the longevity of the equipment.

To effectively assess the wheel mechanism, follow these steps:

- Visual Inspection: Check for any visible damage or wear on the wheels. Look for cracks, deformation, or signs of excessive wear on the tread.

- Wheel Attachment: Ensure that the wheels are securely attached to the axles. Tighten any loose screws or bolts as needed.

- Movement Test: Rotate each wheel to confirm smooth motion. Any resistance or unusual sounds may indicate a problem.

- Check Bearings: Inspect the bearings for any signs of damage or wear. Replace them if they are worn out to maintain smooth operation.

- Cleaning: Remove any debris or grass clippings that may have accumulated around the wheel area to prevent blockage and maintain functionality.

By following these inspection guidelines, users can ensure that the wheel system operates efficiently, reducing the risk of breakdowns and enhancing the overall experience.

Electrical System and Safety Features

The electrical framework of modern grass-cutting machines plays a crucial role in their functionality and safety. A well-designed system not only ensures efficient operation but also incorporates several safety measures to protect the user during operation. Understanding these components can enhance user experience and promote safer handling.

Key Components of the Electrical Framework

At the heart of the electrical system are the battery and motor, which work together to provide power to the unit. The battery supplies energy, while the motor converts this energy into mechanical force. Additionally, wiring harnesses connect these elements, allowing for seamless communication between the various parts. Fuses and relays are also integral, serving as protective elements that prevent overload and short circuits, ultimately ensuring reliable performance.

Safety Mechanisms

Safety features are essential in any cutting device to minimize risks. These machines typically include mechanisms such as emergency shut-off switches that can instantly stop the operation if necessary. Furthermore, protective covers shield users from moving components, reducing the likelihood of accidents. Regular maintenance and inspections of these safety features are vital to ensure they function correctly, contributing to a safer working environment.

Function of the Grass Clipping Bag System

The grass clipping collection system plays a vital role in maintaining a clean and tidy outdoor area. This mechanism efficiently gathers cut grass, ensuring that the area remains neat and reduces the need for additional cleanup after mowing. By effectively managing the clippings, it enhances both the aesthetic appeal and health of the turf.

Key Features of the Collection System

- Efficiency: The system is designed to capture clippings promptly, minimizing the chance of them spreading across the lawn.

- Convenience: With an attached bag, users can easily dispose of the collected material, making the mowing process more streamlined.

- Enhanced Lawn Health: Collecting clippings prevents thatch buildup, promoting better air circulation and nutrient absorption for the grass.

Maintenance Tips

- Regularly check for blockages in the collection chute to ensure optimal performance.

- Clean the bag frequently to prevent odors and maintain hygiene.

- Inspect for wear and tear, replacing any damaged components to ensure continued efficiency.

Commonly Replaced Parts and Upgrades

When maintaining a gardening machine, certain components often require attention due to wear or performance improvement needs. Understanding which elements are frequently substituted can enhance efficiency and prolong the device’s lifespan.

Frequent Component Replacements

The most commonly swapped elements typically include blades, filters, and drive belts. These components experience significant wear over time, impacting the overall functionality. Regularly checking these items ensures optimal performance and a smoother operation.

Upgrades for Enhanced Performance

Upgrading certain features can also lead to better results. Consider investing in high-performance blades or advanced filter systems. These enhancements not only improve cutting efficiency but can also contribute to fuel savings and reduced maintenance requirements, making the device more reliable.

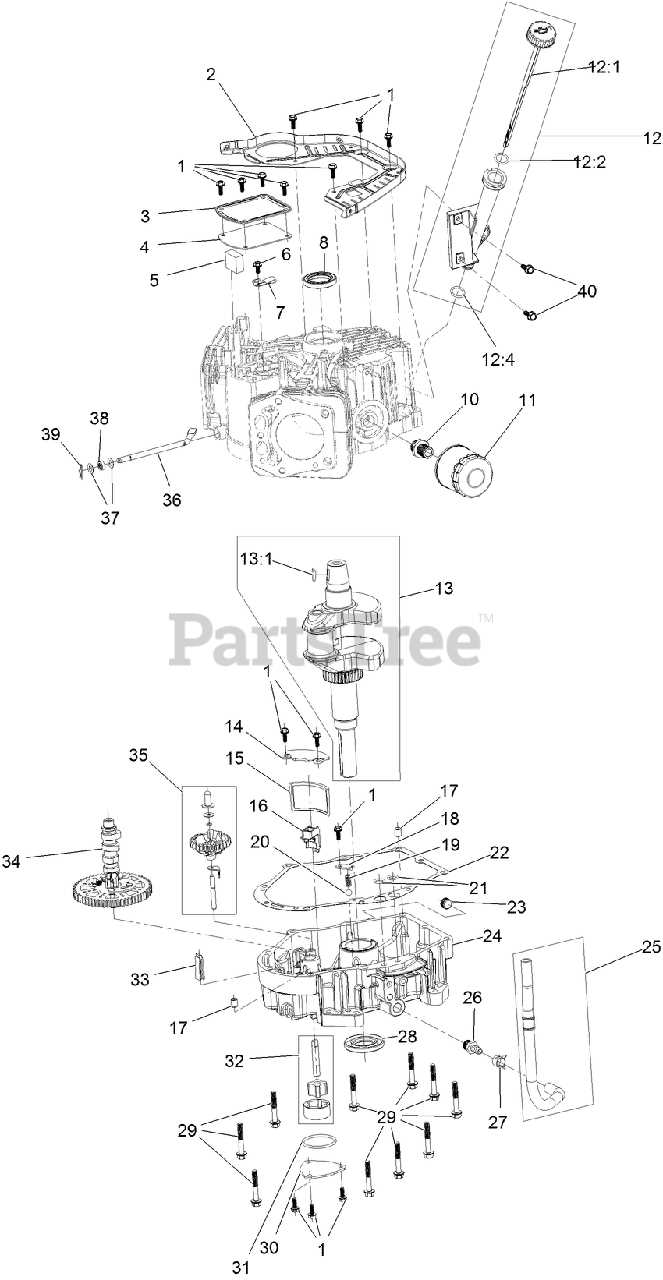

How to Maintain Self-Propelled Functionality

Ensuring the optimal operation of a wheeled cutting machine involves regular upkeep and attention to specific components that facilitate movement. By following a few essential practices, users can enhance performance and prolong the lifespan of their equipment. Proper care not only improves efficiency but also contributes to a smoother experience during use.

Regular Inspection and Cleaning

It is crucial to conduct periodic checks of the equipment to identify any wear and tear. Regularly cleaning the exterior and the drive mechanism prevents debris accumulation, which can hinder movement. This practice ensures that all parts function smoothly and efficiently.

Lubrication of Moving Components

Applying the right lubricant to moving elements is vital for maintaining functionality. Lubrication reduces friction and prevents overheating, which can lead to mechanical failure. Ensure that all joints and pivots are adequately greased to maintain fluid motion.

| Component |

Maintenance Task |

Frequency |

| Drive Wheels |

Check for wear and clean |

Monthly |

| Transmission Belt |

Inspect tension and condition |

Every season |

| Gearbox |

Check lubricant level |

Every 6 months |

| Handle Controls |

Clean and test responsiveness |

Monthly |

Troubleshooting Tips for Performance Issues

When a machine experiences performance challenges, it can be frustrating. Understanding common issues and their solutions is essential for maintaining optimal functionality. This section provides practical advice to help identify and resolve problems that may arise during operation.

1. Inspect the Power Source: A weak or inconsistent power supply can hinder performance. Ensure that the battery is fully charged or that the electrical outlet is functioning properly. If using gasoline, check the fuel quality and level.

2. Check the Cutting Mechanism: Dull or damaged blades can lead to uneven cutting. Regularly inspect and sharpen blades, and replace them if necessary. Also, ensure that the cutting height is set correctly for the type of grass.

3. Clean the Undercarriage: Grass clippings and debris can accumulate beneath the unit, affecting its efficiency. Periodically clean the underside to prevent buildup and maintain airflow.

4. Examine the Air Filter: A clogged air filter can restrict airflow, leading to decreased power. Regularly check and clean or replace the filter as needed to ensure optimal engine performance.

5. Review the Belts and Cables: Worn or frayed belts and cables can cause operational issues. Inspect these components regularly for signs of wear and replace them if any damage is found.

By following these troubleshooting tips, users can effectively address performance issues, ensuring their equipment operates efficiently and reliably.

|