When working with complex machinery, having a clear overview of how each element is organized is essential for ensuring smooth repairs and upkeep. Properly identifying each section and its associated elements helps streamline troubleshooting and part replacement, making the entire process much more efficient.

Visual representation of each system’s components offers users an easier way to familiarize themselves with key elements, improving productivity and reducing downtime. This approach ensures that all necessary pieces are correctly placed, promoting the longevity and reliability of the equipment.

Regular maintenance and understanding the exact layout of different sections are key factors in preventing unexpected breakdowns and ensuring long-term operational success. Having access to detailed visual guidance is invaluable in this context.

Component Overview of the Z Series Commercial Mower

This section provides a general understanding of the key mechanical elements found in professional-grade mowing equipment. Designed for efficient performance and durability, these machines rely on a robust combination of engine components, control systems, and structural elements to deliver optimal cutting power and user experience.

Engine and Power System

- High-capacity engine ensures reliable and continuous operation under demanding conditions.

- Fuel system optimized for long runtime and reduced emissions.

- Cooling system designed to prevent overheating and maintain peak efficiency.

Control and Maneuverability Features

- Advanced steering and hydraulic controls allow precise navigation.

- Ergonomic controls and adjustable seating enhance operator comfort during long working hours.

- Sturdy frame and suspension system improve stability and smooth operation on uneven terrain.

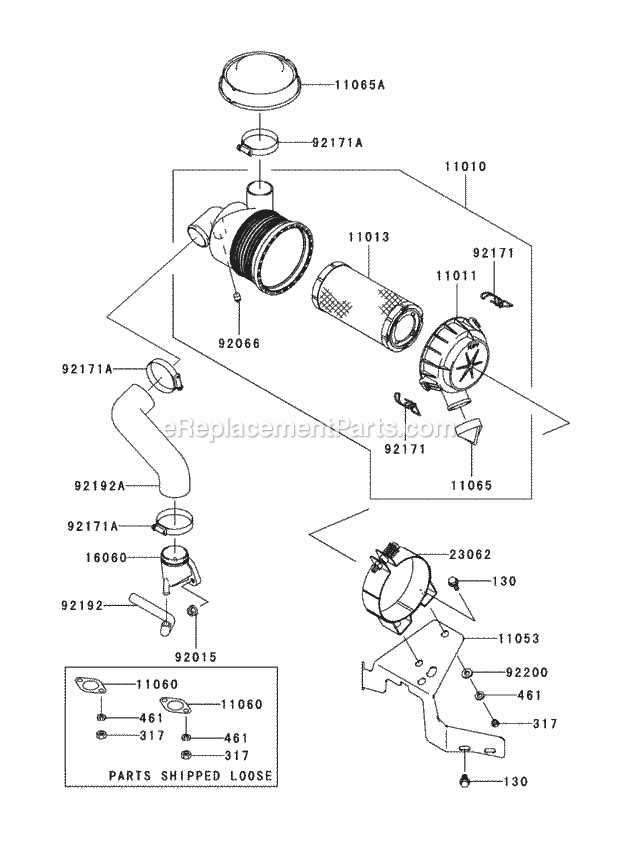

Key Engine Elements Breakdown

The internal combustion engine relies on several crucial components that work together to ensure efficient operation. Each element plays a specific role, contributing to the overall performance and longevity of the engine. In this section, we will explore the most essential parts that are responsible for powering and maintaining the engine’s functionality.

The first critical element is the cylinder, where fuel combustion occurs. It is accompanied by the piston, which moves within the cylinder to convert combustion energy into mechanical force. This energy transfer is managed by the crankshaft, a key component that transforms linear motion into rotational energy.

Another essential feat

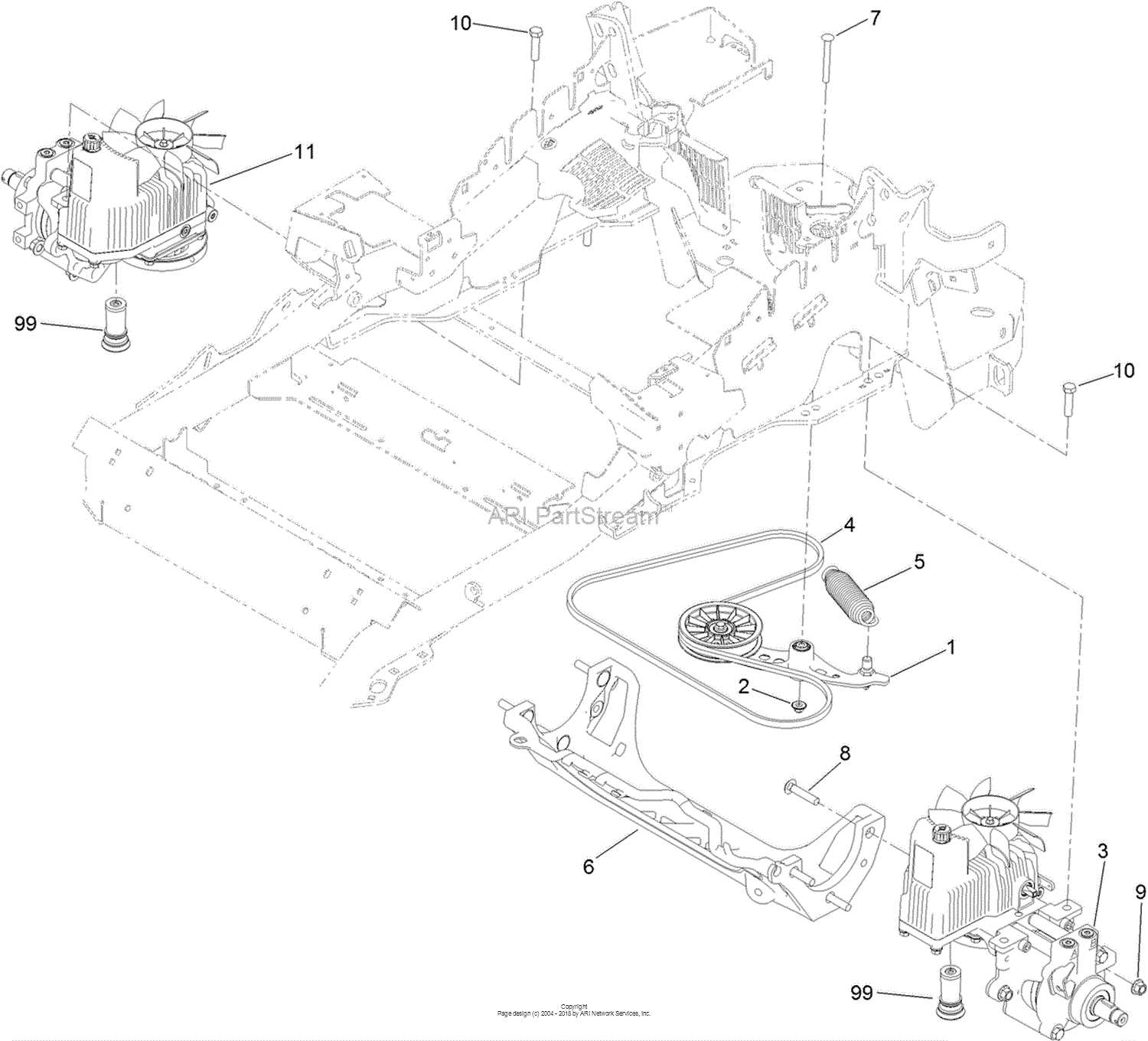

Hydraulic System Structure and Function

The hydraulic system plays a crucial role in the overall operation of modern machinery, providing the necessary power for various components. It utilizes fluid pressure to create movement and force, making it essential for smooth and efficient operation. The system’s design ensures seamless control and reliable performance across different functions.

Core Components: The main elements of this system include the hydraulic pump, which generates pressure, the reservoir that stores the fluid, and the valves that regulate flow. These parts work in harmony to ensure precision and responsiveness during operation.

Functionality: Hydraulic fluid is circulated through the system under pressure, allowing it to transmit power efficiently. This enables the machine to handle demanding tasks with high levels of control and reliability, making it suitable for various applications that require robust performance.

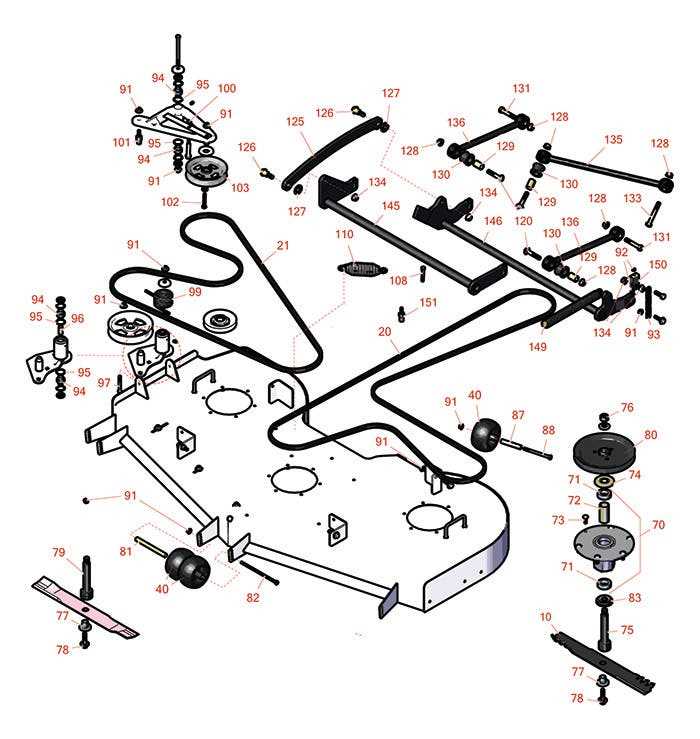

Cutting Deck Parts Layout

The cutting deck is a critical component responsible for the machine’s efficient grass cutting. Understanding the arrangement and how different elements work together ensures smooth performance and longer equipment life. This section outlines the key elements that form the overall structure of the cutting deck, providing a clear overview of

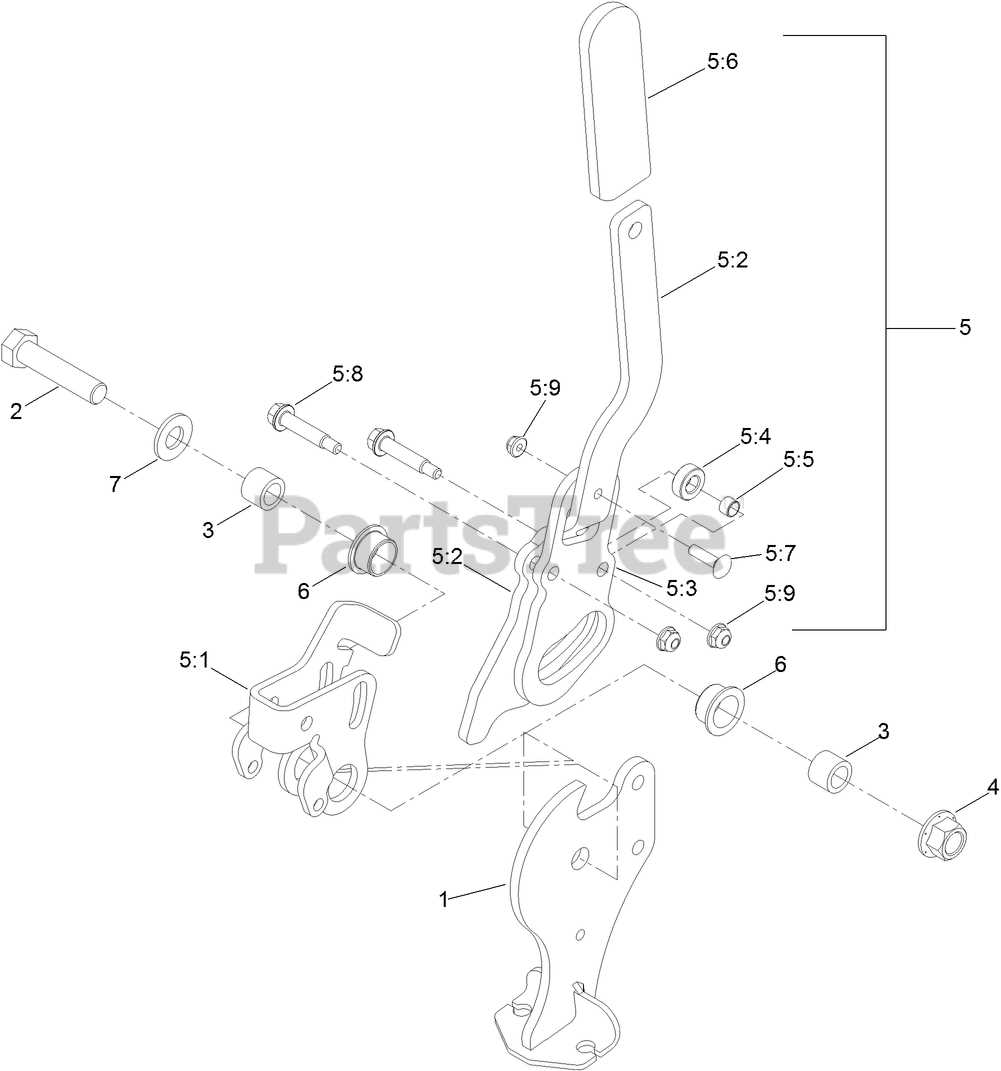

Steering Mechanism Components Guide

The steering system plays a crucial role in ensuring smooth and precise control of your equipment. Understanding its components can help maintain functionality and extend the lifespan of your vehicle. This guide will explore the essential elements of the steering mechanism and how they interact to provide accurate navigation and handling.

Key Components Overview

The steering system consists of various interconnected parts, each playing a vital role in translating the operator’s inputs into controlled movement. These components work together to provide stability and directional control, ensuring that the vehicle responds effectively to steering commands.

Component Breakdown

| Component | Function |

|---|

| Component | Description | Function |

|---|---|---|

| Battery | Stores electrical energy for starting and operating the engine | Provides the necessary power to start the engine and run electrical systems |

| Ignition Switch | Controls the electrical flow to the engine and accessories | Enables starting and shutting down of the engine |

| Wiring Harness | A collection of wires and connectors | Distributes electrical power to various components throughout the system |

| Fuses | Protective devices that prevent overloads | Safeguard components by breaking the circuit in case of excessive current |

| Relays | Electromechanical switches | Control higher voltage components with low voltage signals |

Blades and Spindle Assembly Details

The assembly of cutting implements and their rotational support is crucial for the effective operation of any lawn maintenance equipment. Understanding the components involved in this system helps ensure optimal performance and longevity of the machine.

Key elements of the cutting and spindle assembly include:

- Cutting Blades: These are the primary components responsible for trimming grass and achieving a clean finish.

- Spindle Housing: This structure supports the spindle and houses the bearings, allowing smooth rotation.

- Bearings: Essential for reducing friction, these components facilitate the smooth movement of the spindle.

- Blade Bolts: These secure the blades to the spindle, ensuring they remain attached during operation.

- Spindle Shaft: This part connects the spindle to the engine, transferring power for rotation.

Regular maintenance of the cutting implements and spindle assembly is necessary to prevent wear and tear, which can affect performance. Inspecting these components periodically ensures they function optimally and prolongs the lifespan of the equipment.

Seat and Control Panel Components

The seat and control interface are crucial elements of any machinery, providing both comfort and functionality. These components not only ensure a secure and pleasant experience for the operator but also facilitate ease of use through intuitive design.

Operator Seat: A well-designed operator seat enhances comfort during prolonged use. It typically features adjustable settings to accommodate various body types and preferences, ensuring optimal support and positioning.

Control Interface: The control panel is where operators interact with the machine. This area includes levers, buttons, and displays that control various functions, allowing for efficient operation. The layout is designed for user-friendliness, enabling quick access to essential controls.

Maintenance Considerations: Regular checks and maintenance of these components are essential for ensuring longevity and proper function. Operators should inspect the seat for wear and tear and ensure that the control panel remains responsive and free from obstructions.

Wheel and Tire Assembly Diagram

This section provides an overview of the components involved in the wheel and tire setup for a specific type of outdoor equipment. Understanding the assembly is essential for maintenance and ensuring optimal performance during operation. Each element plays a critical role in the overall functionality and stability of the machine.

Key Components

- Wheel Rim

- Tire Tread

- Inner Tube

- Valve Stem

- Wheel Hub

Assembly Steps

- Inspect all components for wear and damage.

- Place the inner tube inside the tire, ensuring it fits correctly.

- Align the tire with the wheel rim and secure it in place.

- Attach the valve stem to the designated hole in the rim.

- Inflate the tire to the recommended pressure.

Chassis and Frame Structure Overview

The chassis and frame play a crucial role in the overall performance and stability of outdoor machinery. This fundamental structure supports various components, ensuring durability and resilience during operation. Understanding its design and function is essential for effective maintenance and repair.

The chassis serves as the backbone of the equipment, providing a solid foundation for the engine, transmission, and other integral systems. Its robust construction enables the machinery to withstand the rigors of demanding tasks, while also contributing to weight distribution and balance.

The frame structure is intricately designed to absorb vibrations and shocks, enhancing operator comfort and prolonging the lifespan of vital parts. By focusing on the materials used and the design principles employed, one can appreciate the importance of this assembly in achieving optimal performance and reliability.

Maintenance Kit Components Reference

The maintenance kit is an essential collection of items designed to ensure optimal performance and longevity of your equipment. Each component within this set plays a crucial role in enhancing the functionality and reliability of the machinery. Understanding the various elements included in the kit can help users effectively maintain their equipment and avoid potential issues.

Key Elements of the Maintenance Kit

Typically, the kit consists of various filters, oils, and belts, all meticulously selected to meet the specific needs of the machinery. Filters are vital for keeping contaminants at bay, while oils contribute to smooth operation and reduce wear. Additionally, belts ensure the efficient transfer of power, maintaining the seamless functioning of the equipment.

Benefits of Using the Complete Kit

Utilizing the complete maintenance kit not only saves time but also enhances the overall performance of the machinery. Regular replacement of components as suggested can lead to improved efficiency and reduced downtime, ultimately extending the lifespan of the equipment.