When it comes to maintaining your lawn care equipment, having a clear overview of its elements is essential. A comprehensive understanding of each section can enhance efficiency and ensure longevity. This knowledge empowers users to tackle repairs and upgrades with confidence.

Visual aids play a crucial role in comprehending the intricate mechanisms at play. By examining a detailed representation, one can easily identify various sections and their functions. This clarity simplifies the maintenance process and helps in troubleshooting potential issues.

Moreover, being familiar with these components allows for informed decision-making when it comes to replacements or enhancements. Whether you’re an experienced operator or a newcomer, diving into the specifics can ultimately improve your overall experience and performance.

Toro Zero-Turn Parts Overview

This section provides a comprehensive look at the essential components of a specific type of mowing machine, highlighting their functions and importance in maintaining optimal performance. Understanding these elements can significantly enhance the user experience and prolong the lifespan of the equipment.

Key Components: Various elements play critical roles, from the engine to the cutting mechanism. Each part works in harmony to ensure efficiency and effectiveness during operation.

Maintenance Importance: Regular checks and timely replacements are crucial for keeping the machinery running smoothly. Neglecting any component may lead to decreased functionality or unexpected breakdowns.

Conclusion: A solid grasp of the various components not only aids in proper maintenance but also empowers users to make informed decisions regarding repairs and upgrades.

Understanding Zero-Turn Mowers

In the realm of lawn maintenance, certain machines stand out due to their maneuverability and efficiency. These cutting-edge devices enable users to navigate complex landscapes with ease, transforming the task of lawn care into a streamlined process.

Key Features

- Exceptional agility allowing tight turns.

- Enhanced cutting performance with dual blades.

- User-friendly controls for intuitive operation.

Benefits of Using These Machines

- Significantly reduces mowing time.

- Minimizes lawn damage due to precise handling.

- Offers a smooth ride over uneven terrain.

Key Components of Toro Models

Understanding the essential elements of these innovative mowing machines is crucial for optimal performance and maintenance. Each unit is designed with specific features that enhance maneuverability and efficiency, catering to both residential and commercial users.

- Engine: The power source that drives the entire system, influencing speed and cutting capacity.

- Transmission: The mechanism responsible for transferring power from the engine to the wheels, allowing for smooth operation and control.

- Deck: The cutting chamber where grass is trimmed, designed for durability and precise cutting height adjustments.

- Chassis: The frame that supports all components, providing stability and structural integrity during operation.

- Wheels: Specialized tires that ensure traction and agility, enabling sharp turns and effective maneuvering in tight spaces.

- Control System: User interfaces such as levers or steering wheels that facilitate operation and adjustments on the go.

Each component plays a pivotal role in the overall functionality, contributing to the seamless operation of these advanced gardening tools.

Benefits of Toro Zero-Turn Design

The innovative layout of these mowers offers significant advantages for users seeking efficiency and precision in their lawn care. By allowing for exceptional maneuverability, these machines streamline the mowing process, making it quicker and more effective.

One of the ultimate benefits is the time saved during lawn maintenance. Users can navigate around obstacles with ease, reducing the need for additional trimming.

| Benefit | Description |

|---|---|

| Enhanced Maneuverability | Offers superior control and agility, allowing for tight turns and precise cuts. |

| Time Efficiency | Reduces mowing time by enabling faster navigation around obstacles. |

| Improved Comfort | Ergonomic designs lead to less fatigue during extended use. |

Common Parts and Their Functions

This section explores essential components found in lawn care machinery, highlighting their roles and importance. Understanding these elements is crucial for effective maintenance and operation, ensuring optimal performance and longevity of the equipment.

Engine

The engine serves as the powerhouse of the machine, converting fuel into mechanical energy. A well-functioning engine is vital for achieving the ultimate efficiency in cutting and maneuvering.

Blade Assembly

The blade assembly is responsible for trimming grass and achieving a clean cut. Regular inspection and maintenance of this component enhance the quality of the lawn and reduce wear over time. Proper alignment and sharpness are key for optimal results.

Maintenance Tips for Longevity

Ensuring the durability and performance of your equipment requires consistent attention and care. Regular maintenance practices not only extend the lifespan of your machine but also enhance its efficiency. By following some essential guidelines, you can keep your device running smoothly for years to come.

Regular Inspections: Schedule periodic checks to identify any wear or damage early on. Look for signs of rust, loose components, or leaks, as addressing these issues promptly can prevent more significant problems down the line.

Proper Cleaning: Keeping your machine clean is crucial. Remove grass clippings, dirt, and debris after each use. This practice prevents corrosion and ensures optimal performance during operation.

Fluid Checks: Regularly inspect and change fluids as recommended by the manufacturer. Engine oil, hydraulic fluid, and fuel levels should be monitored to maintain functionality and prevent breakdowns.

Sharpening Blades: Dull blades can damage your equipment and lead to uneven cuts. Make it a habit to sharpen the blades frequently, ensuring a clean and efficient cutting experience.

Storage Considerations: When not in use, store your equipment in a dry, sheltered area. Protecting it from the elements can significantly reduce wear and tear and keep it in optimal condition.

By implementing these maintenance tips, you can significantly enhance the lifespan of your equipment, ensuring it remains reliable and effective for all your landscaping needs.

Finding Replacement Parts Easily

Locating components for maintenance can be a straightforward process if approached methodically. With the right resources and tools, you can identify the necessary items to keep your equipment in optimal condition. Understanding where to search and how to navigate the available options will save time and effort.

Utilizing Online Resources

One of the most effective methods is leveraging online platforms dedicated to outdoor equipment. Websites often feature extensive catalogs, complete with specifications and images, which facilitate easier identification of the required components. User reviews and ratings can also provide insights into the quality and compatibility of items.

Consulting Manuals and Guides

Another reliable approach is to refer to the user manuals or maintenance guides that accompany your machinery. These documents typically include lists of recommended components and may even provide assembly instructions, ensuring you select the correct replacements.

| Resource Type | Description |

|---|---|

| Online Catalogs | Comprehensive listings of components with images and details. |

| User Manuals | Guides that offer specific information on compatible items. |

| Community Forums | Platforms for sharing experiences and recommendations. |

| Local Retailers | Physical stores that may carry popular components. |

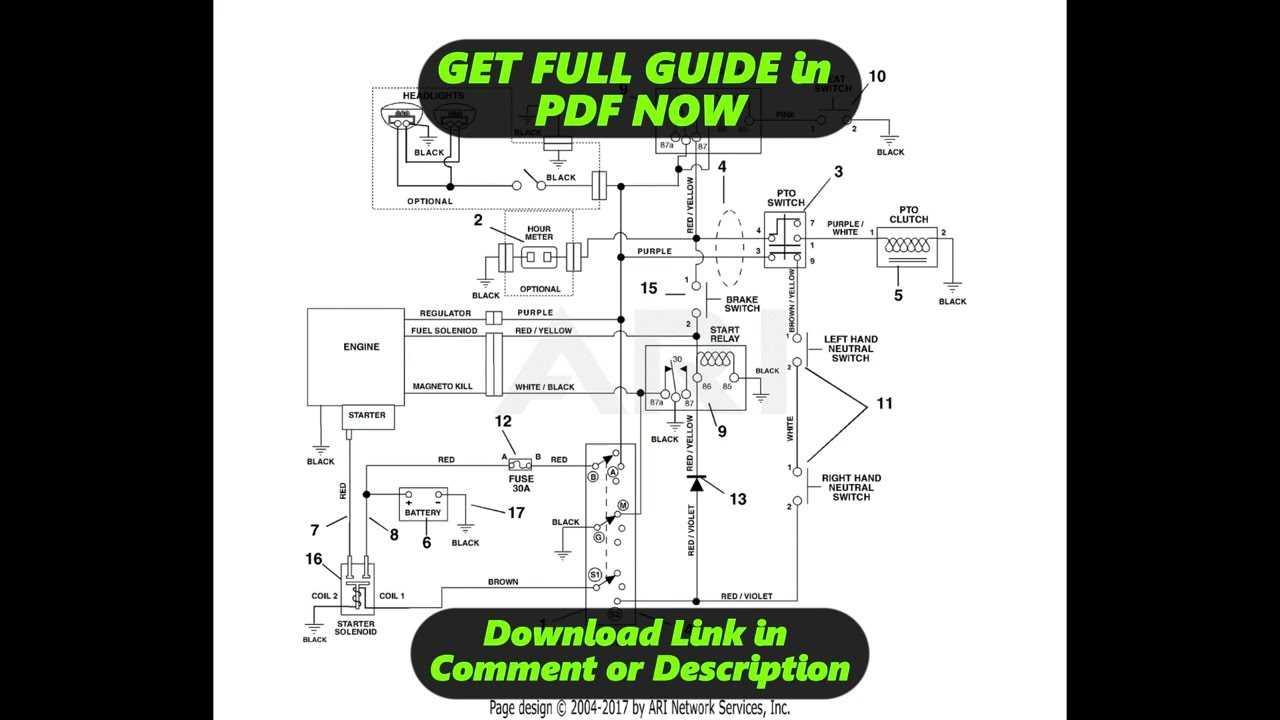

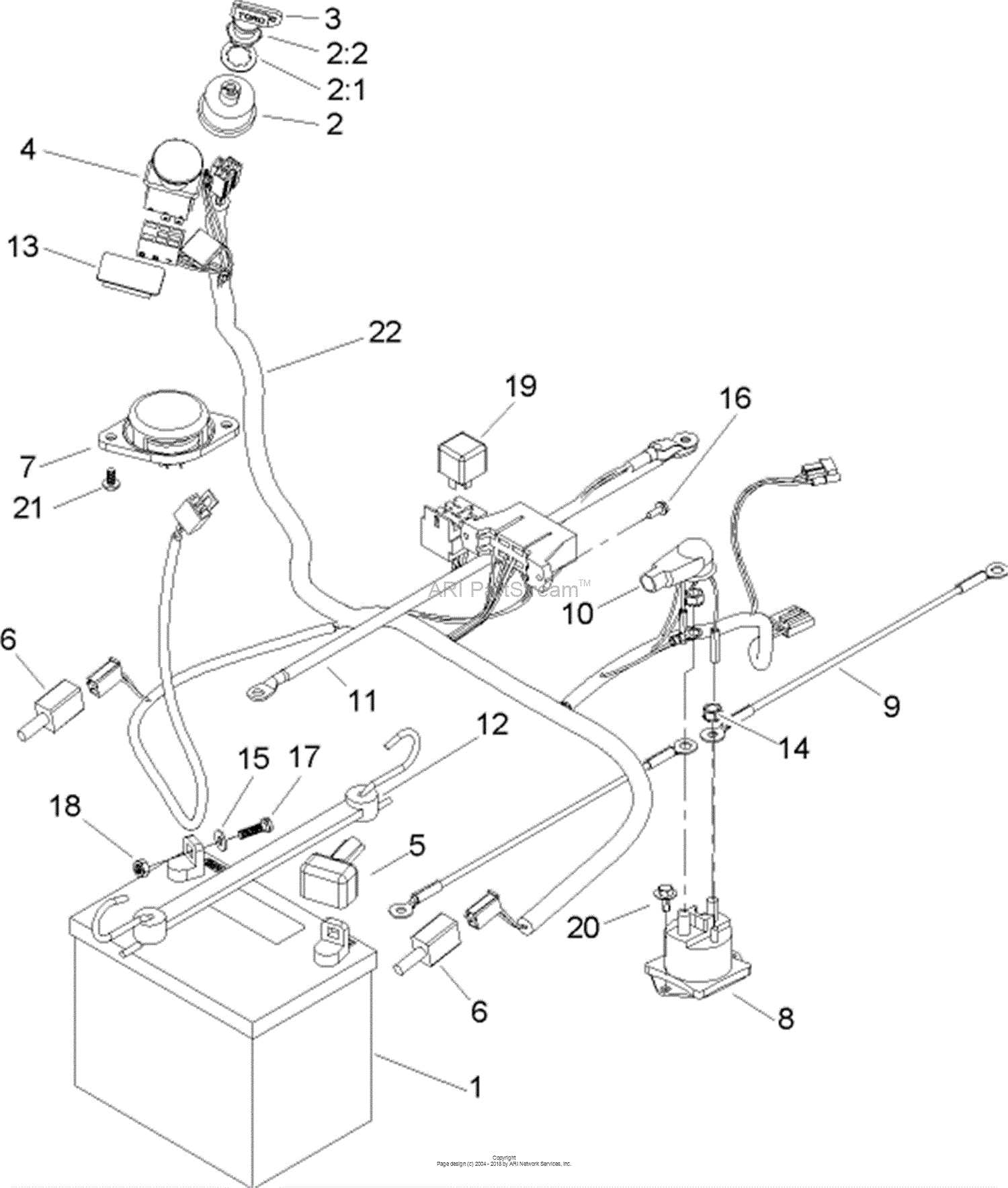

Using the Parts Diagram Effectively

Understanding the components of your equipment is crucial for maintenance and repairs. Utilizing a visual representation of these elements can streamline the process, ensuring that each piece is correctly identified and handled. This approach not only enhances efficiency but also minimizes the risk of errors during assembly or disassembly.

To maximize the benefits of this visual guide, start by familiarizing yourself with its layout. Identify key sections and understand how different parts interact. Pay attention to any labels or notes that accompany the illustration, as they often provide valuable information regarding compatibility and installation.

When performing maintenance, reference the illustration regularly. This will help you track your progress and ensure you don’t overlook any necessary steps. If you encounter difficulties, consult the guide to pinpoint the specific area causing issues, allowing for targeted troubleshooting.

Additionally, keep the diagram accessible for future projects. Regularly reviewing it can deepen your understanding of the equipment, leading to more efficient repairs and maintenance. This proactive approach not only saves time but also extends the lifespan of your machinery.

Identifying Wear and Tear Signs

Recognizing the indicators of deterioration in machinery is crucial for maintaining optimal performance. Regular inspection can help in identifying issues early, preventing further damage and ensuring longevity. Understanding these signs allows for timely interventions that can save both time and resources.

Common Indicators

Look for fraying belts, unusual noises, and visible cracks in components. These signs often suggest that parts are nearing the end of their lifespan. Additionally, leaking fluids can be a strong indication of malfunctioning seals or gaskets.

Importance of Regular Maintenance

Implementing a routine maintenance schedule helps in spotting wear and tear before it escalates. Regular checks not only enhance the efficiency of the equipment but also contribute to safety, ensuring that all operations run smoothly and without unexpected interruptions.

Tools Needed for Repairs

Having the right equipment is essential for any maintenance task. The proper tools not only facilitate efficient repairs but also ensure safety and effectiveness in restoring machinery to optimal performance. Below is a list of essential instruments required for effective maintenance work.

- Wrenches: A variety of sizes is crucial for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips screwdrivers are necessary for different fasteners.

- Pliers: Useful for gripping, twisting, and cutting wires or small components.

- Socket Set: Provides a range of sockets to fit various bolt sizes for quick adjustments.

- Torque Wrench: Ensures that fasteners are tightened to the correct specifications.

In addition to the basic tools, having a few specialized items can enhance your repair capabilities:

- Grease Gun: Essential for lubricating moving parts to reduce wear and tear.

- Multimeter: Useful for diagnosing electrical issues by measuring voltage, current, and resistance.

- Parts Cleaner: Helps maintain cleanliness and functionality of components.

By equipping yourself with these tools, you can effectively tackle various maintenance challenges and keep machinery running smoothly.

Comparing Toro to Other Brands

When evaluating different manufacturers in the lawn care equipment industry, it’s essential to consider various factors that contribute to performance, durability, and user experience. This comparison aims to highlight the strengths and weaknesses of a leading brand relative to its competitors, helping consumers make informed decisions.

Performance and Efficiency

In terms of performance, many users appreciate how certain brands deliver exceptional maneuverability and cutting precision. This allows for a more efficient mowing experience, particularly in complex landscapes. However, some alternatives may offer comparable power but fall short in terms of speed and ease of use, making them less appealing for those with large or intricate properties.

Durability and Maintenance

Durability is another critical aspect where brand comparisons come into play. Some manufacturers utilize high-quality materials that withstand harsh conditions, requiring minimal upkeep. On the other hand, others might use cost-effective options that, while initially attractive, may lead to increased maintenance efforts and replacement costs over time. Ultimately, understanding the long-term implications of these choices can significantly impact overall satisfaction with the equipment.

Where to Purchase Toro Parts Online

Finding quality components for your outdoor equipment has never been easier. Numerous online retailers offer a wide selection of items to ensure your machinery operates efficiently. Here’s how to navigate the online marketplace for your needs.

- Official Manufacturer Websites: Start with the official site of the manufacturer. They often provide an extensive catalog of available items, ensuring authenticity and compatibility.

- Specialized Online Retailers: Many websites focus specifically on outdoor machinery. These retailers typically have knowledgeable staff and can guide you in selecting the right components.

- General E-commerce Platforms: Popular online marketplaces like Amazon or eBay feature a variety of products. Always check seller ratings and product reviews to ensure quality.

- Local Dealerships with Online Presence: Many local dealers offer online ordering services. Supporting them can also benefit your community.

Before making a purchase, consider comparing prices and checking return policies. This diligence will help you secure the best deal while ensuring you receive the right components for your equipment.