In the world of industrial equipment, a thorough comprehension of each element’s functionality is essential for optimal performance. Knowledge about the intricate systems that drive these machines can significantly enhance maintenance practices and operational efficiency.

Visual representations of these complex assemblies provide invaluable insight, allowing operators and technicians to identify specific elements and their interconnections. This understanding not only aids in troubleshooting but also promotes a proactive approach to equipment care.

As we delve into the specifics of these mechanisms, we will explore how each component contributes to the ultimate effectiveness of the machinery, ensuring that your operations run smoothly and reliably.

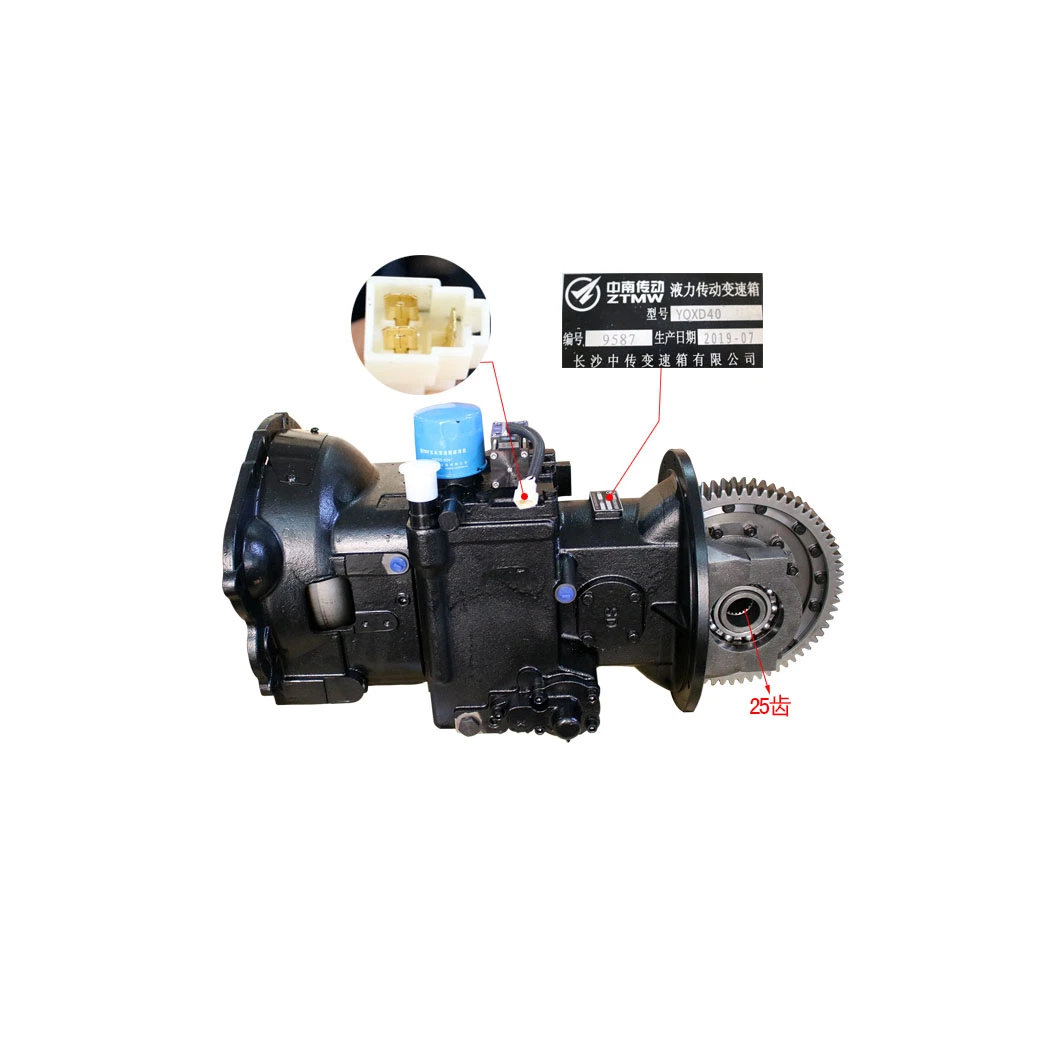

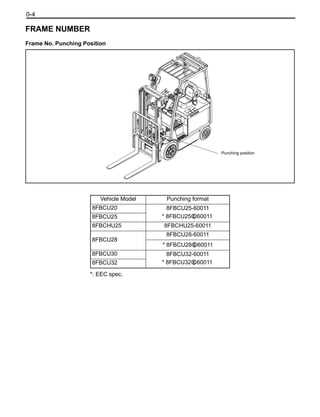

Understanding Toyota Forklift Transmission

The operation of heavy machinery relies heavily on a robust system that transfers power efficiently to ensure optimal performance. In this section, we will explore the essential elements that contribute to the seamless movement and functionality of these industrial vehicles. A thorough comprehension of how these systems work is crucial for maintenance and troubleshooting.

Key Components: The core components include gears, clutches, and hydraulic elements, all of which work in harmony to facilitate smooth gear changes. Each element plays a vital role in ensuring that the vehicle responds accurately to the operator’s commands.

Maintenance Practices: Regular inspection and upkeep are necessary to prevent wear and tear. Understanding the signs of potential issues, such as unusual noises or sluggish performance, can help in identifying problems early on. Following the manufacturer’s guidelines for service intervals is essential for longevity.

Common Issues: Operators may encounter challenges such as slipping, overheating, or unexpected stalls. Being aware of these symptoms allows for timely intervention and can prevent more extensive damage.

In summary, grasping the mechanics behind this power transfer system is fundamental for anyone involved in the operation or maintenance of heavy equipment. With proper knowledge, one can ensure not only the longevity of the machinery but also its efficiency and reliability on the job site.

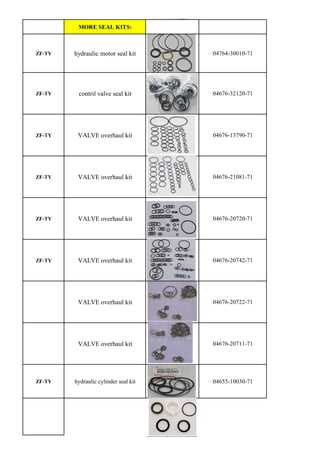

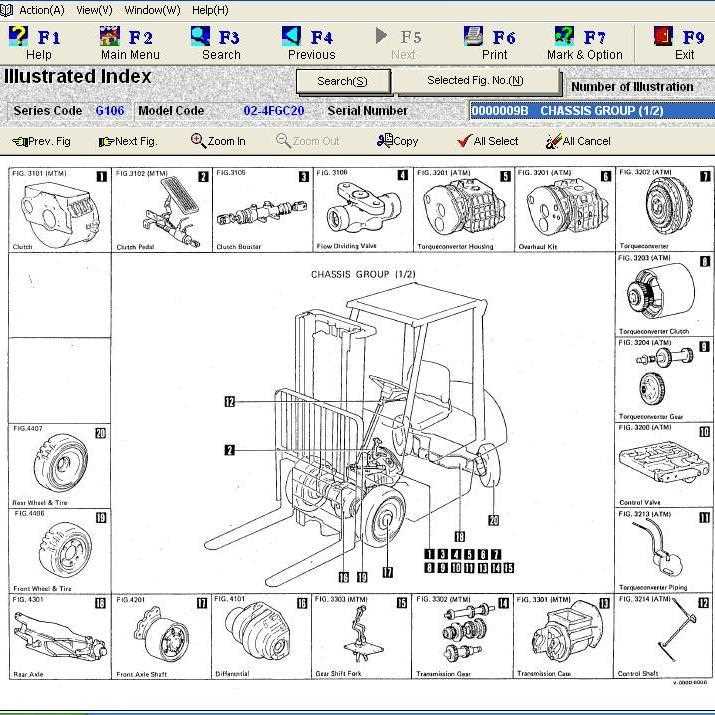

Key Components of Forklift Transmissions

This section explores the essential elements that contribute to the efficient operation of heavy machinery. Understanding these components is vital for maintenance and performance optimization.

- Hydraulic System: Responsible for the transfer of power, enabling smooth movement.

- Torque Converter: Facilitates the adjustment of power delivery and speed control.

- Gearbox: Adjusts the ratio of speed and torque to suit various operational demands.

- Clutch Mechanism: Engages and disengages power flow for seamless transitions.

- Control Valve: Manages fluid flow and directs power where needed.

Each of these components plays a crucial role in ensuring the machinery operates efficiently and effectively, enhancing overall productivity.

Common Issues in Transmission Systems

The functioning of complex machinery heavily relies on efficient systems that facilitate movement and power transfer. Understanding the frequent challenges encountered within these systems is crucial for maintaining optimal performance and ensuring longevity.

Frequent Problems

- Fluid Leaks: Loss of essential fluids can lead to inadequate lubrication and cooling, resulting in overheating and wear.

- Overheating: Excessive heat can cause components to expand and may result in failure.

- Slipping Gears: Difficulty in maintaining gear engagement can cause performance issues, making it hard to control machinery effectively.

- Noisy Operation: Unusual sounds can indicate internal wear or damage, requiring immediate attention.

Preventive Measures

- Regular fluid checks and replacements to prevent leaks and overheating.

- Routine inspections to identify wear and tear early.

- Monitoring for unusual sounds or behavior to address issues promptly.

- Keeping components clean to enhance efficiency and reduce strain.

Maintenance Tips for Forklift Parts

Regular upkeep is essential for ensuring the longevity and efficiency of machinery. Implementing a consistent maintenance routine can prevent unexpected breakdowns and improve performance.

- Perform routine inspections to identify wear and tear early.

- Keep all components clean to prevent dirt accumulation.

- Lubricate moving elements regularly to minimize friction.

- Replace worn components promptly to avoid further damage.

- Follow the manufacturer’s guidelines for maintenance schedules.

By adhering to these practices, operators can enhance reliability and extend the service life of their equipment.

Identifying Faulty Transmission Symptoms

Recognizing signs of mechanical failure is crucial for ensuring efficient operation. Several indicators can point to underlying issues that may require immediate attention to prevent further damage.

Unusual Noises: Listen for grinding, whining, or clunking sounds. These often suggest internal problems that need investigation.

Fluid Leaks: Check for any fluid spots beneath the machine. Leaks can signify damaged seals or components that require repair.

Slipping Gears: If the equipment hesitates or struggles to engage when shifting, it may indicate a failure in the system.

Unresponsive Controls: Difficulty in maneuvering can reflect issues with the control mechanisms, affecting performance.

Warning Lights: Pay attention to any dashboard indicators that illuminate, as they can provide early warnings of potential malfunctions.

Addressing these symptoms promptly can enhance safety and prolong the lifespan of your machinery.

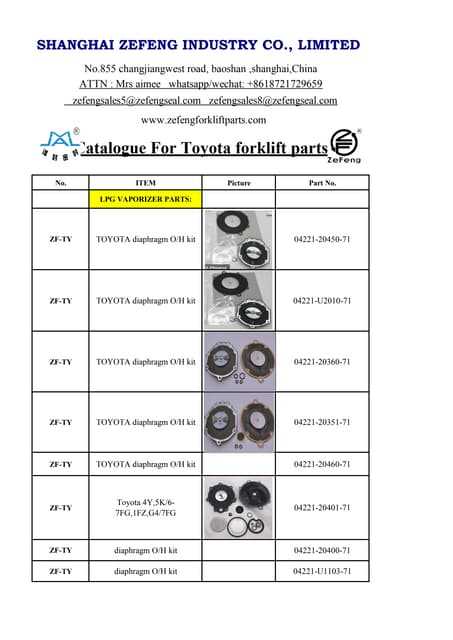

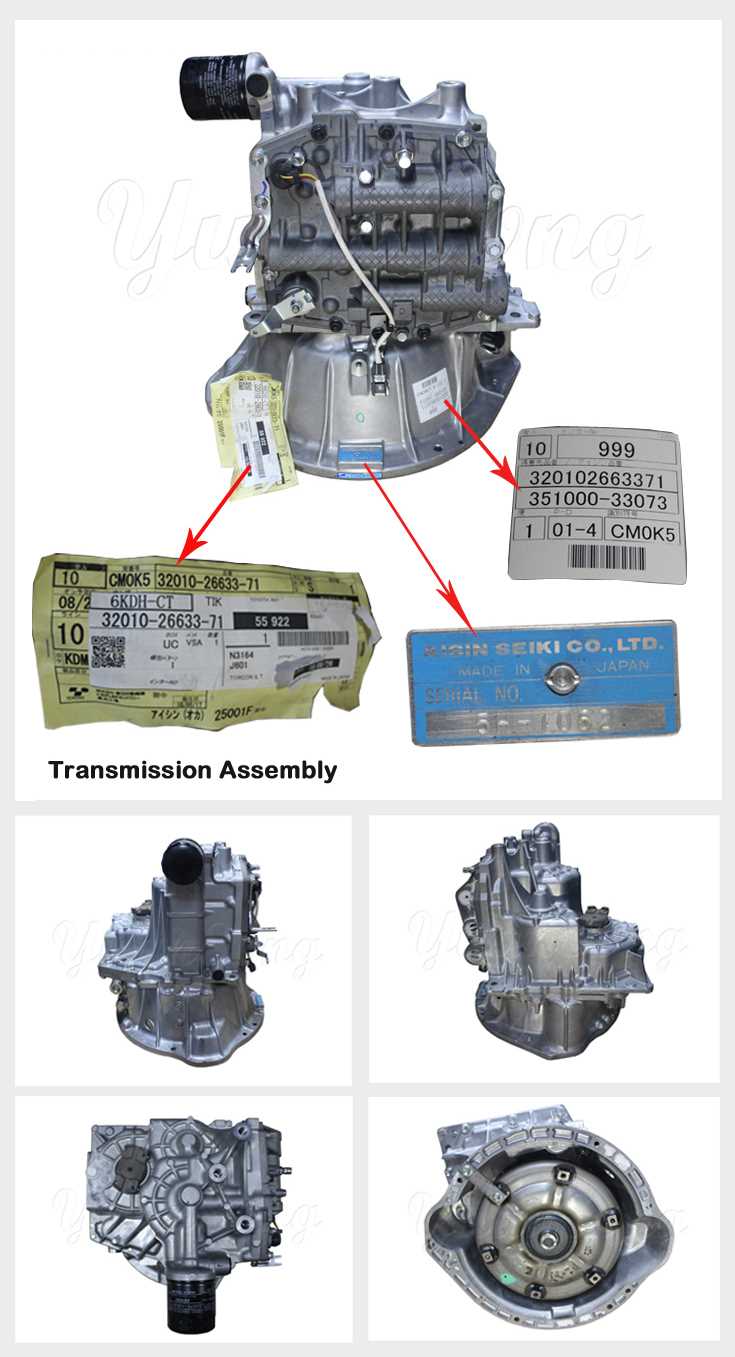

Benefits of Genuine Toyota Parts

Utilizing authentic components for machinery ensures optimal performance and longevity. When equipment is maintained with original items, users can experience enhanced reliability and safety, ultimately leading to increased productivity. The choice of genuine components can significantly impact operational efficiency and reduce the likelihood of unexpected breakdowns.

Quality Assurance

Original components are manufactured to meet strict standards, ensuring compatibility and superior performance. This quality control process minimizes the risk of failures that can arise from using inferior alternatives. By investing in authentic materials, operators can trust in the durability and effectiveness of their machinery.

Long-Term Cost Efficiency

While the initial investment in genuine components may be higher, the long-term savings can be substantial. Reduced maintenance costs, fewer repairs, and prolonged machinery lifespan contribute to overall financial benefits. Choosing authentic items helps avoid the recurring expenses often associated with counterfeit or substandard substitutes.

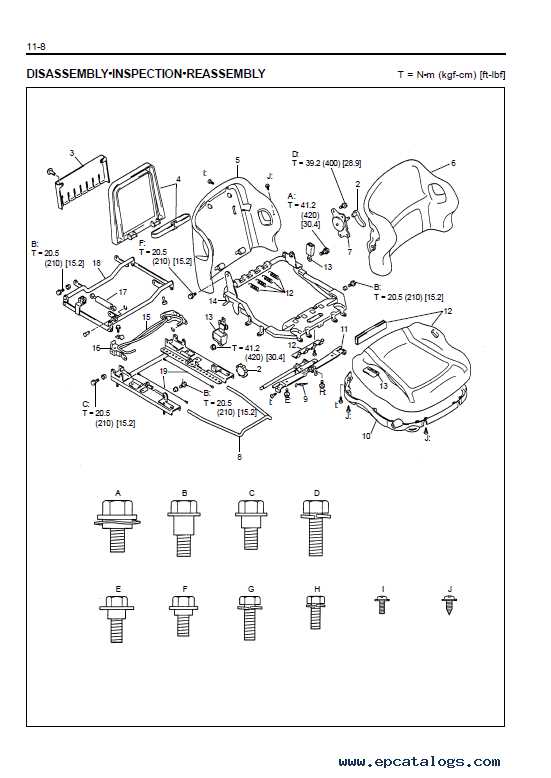

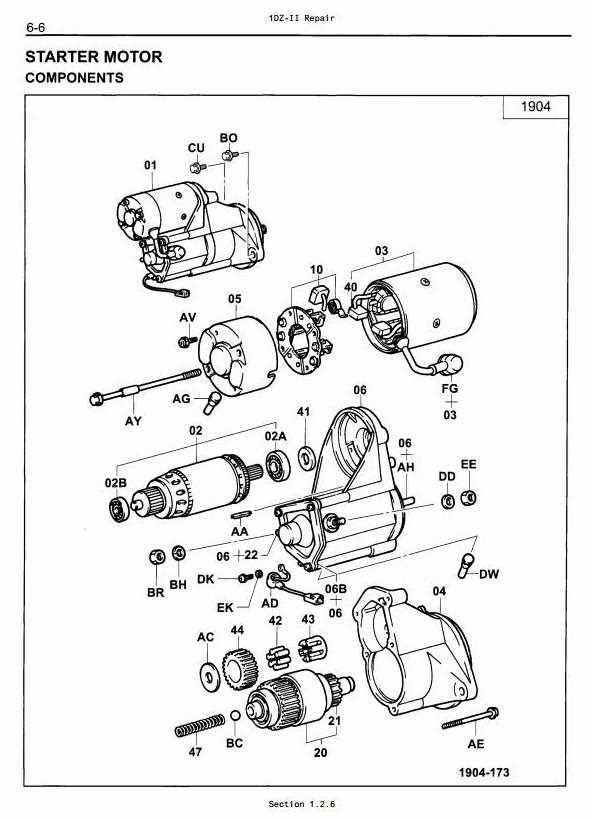

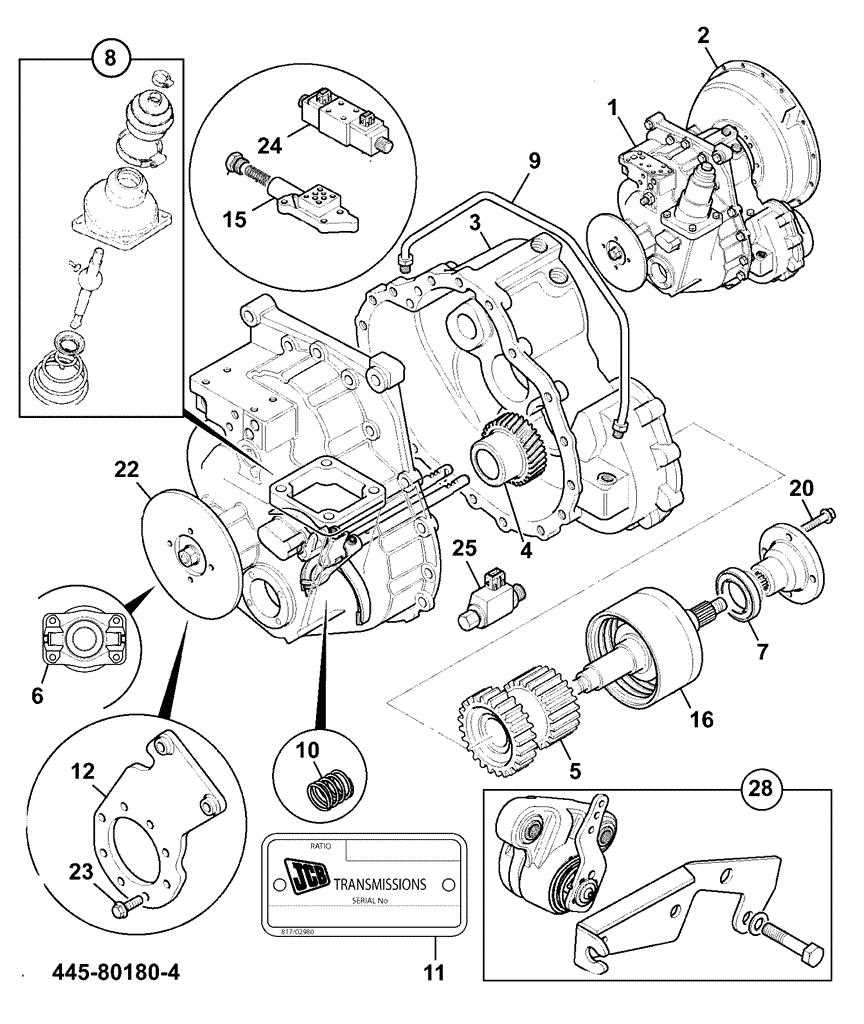

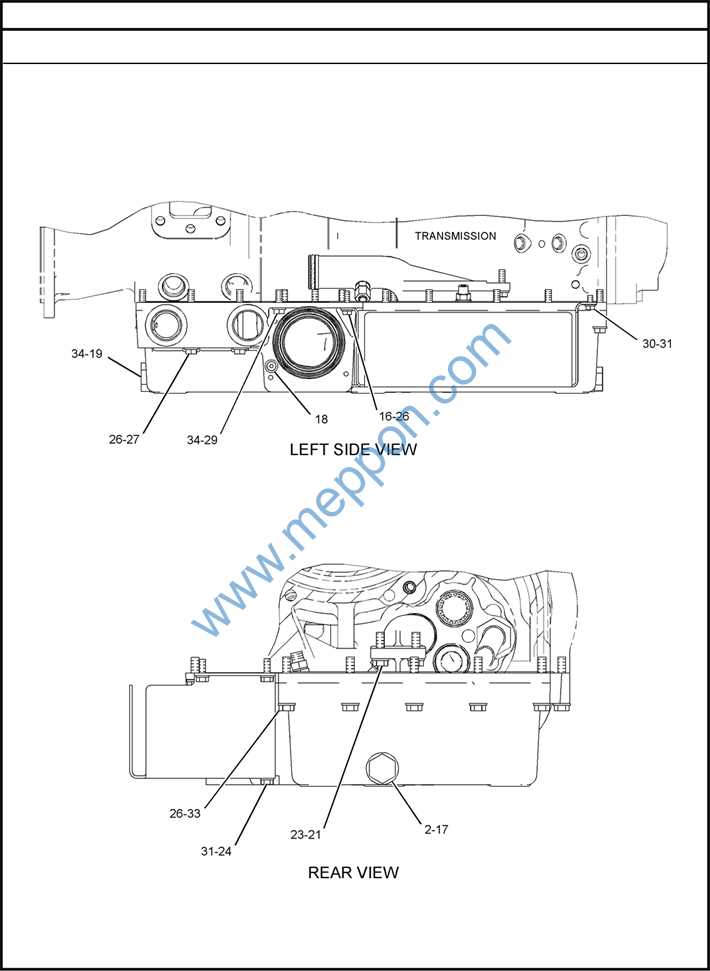

How to Read Parts Diagrams

Understanding visual representations of components is essential for efficient maintenance and repair tasks. These illustrations provide a clear view of how individual elements interact within a system, enabling users to identify and locate specific items easily.

1. Familiarize Yourself with Symbols: Each representation uses specific symbols to denote various components. Knowing what each symbol represents is crucial for accurate interpretation.

2. Follow the Numbering System: Often, these visuals incorporate a numbering system that corresponds to a list. This helps in quickly identifying the required elements.

3. Observe Relationships: Pay attention to how components are connected. Understanding the relationship between items is vital for effective assembly or disassembly.

4. Use Reference Materials: Keep manuals or guides handy that explain the details behind each symbol and connection. This additional information can clarify any confusion.

5. Practice Makes Perfect: Regularly engaging with these illustrations enhances your familiarity and confidence, making it easier to work with complex systems over time.

Steps for Replacing Transmission Parts

Replacing critical components in machinery requires careful planning and execution to ensure optimal performance. This guide outlines essential actions to facilitate a successful replacement process.

Preparation

- Gather necessary tools and equipment.

- Consult the manufacturer’s manual for specifications.

- Ensure a clean and organized workspace.

Replacement Process

- Disconnect the power source to prevent accidents.

- Remove any protective covers and access panels.

- Carefully detach the components that need replacement.

- Install the new components, ensuring proper alignment.

- Reassemble any removed covers and panels.

- Reconnect the power source and conduct a functionality test.

Importance of Regular Inspections

Conducting routine evaluations of machinery is crucial for ensuring optimal performance and longevity. These assessments help identify potential issues before they escalate, ultimately safeguarding both equipment and operator safety.

Preventative Maintenance

Regular check-ups facilitate early detection of wear and tear, allowing for timely repairs. This proactive approach minimizes downtime and extends the lifespan of the equipment.

Safety Assurance

Systematic inspections are essential for maintaining a safe working environment. By addressing any mechanical faults promptly, the risk of accidents is significantly reduced.

| Inspection Type | Frequency | Benefits |

|---|---|---|

| Visual Checks | Daily | Identifies obvious issues |

| Functional Tests | Weekly | Ensures operational efficiency |

| Comprehensive Reviews | Monthly | Addresses underlying problems |

Upgrading Transmission for Enhanced Performance

Improving the efficiency of a heavy-duty vehicle involves not only routine maintenance but also thoughtful enhancements to its core components. Upgrading the mechanism that controls power delivery can significantly boost operational capabilities, resulting in smoother performance and increased productivity. Understanding the nuances of these modifications can lead to a more responsive and powerful experience.

Key Benefits of Performance Enhancements

Enhancing the mechanism can lead to various advantages, such as improved fuel efficiency, better acceleration, and reduced wear on critical components. Upgraded systems can also provide enhanced adaptability to varying loads and conditions, ensuring that operators can achieve optimal performance in diverse environments. Furthermore, a more robust setup can contribute to lower long-term maintenance costs.

Considerations for Upgrades

Before proceeding with enhancements, it’s crucial to assess the specific needs of the vehicle. Factors such as operating conditions, load requirements, and existing performance issues should be carefully evaluated. Investing in quality components and ensuring compatibility with the current configuration are essential steps to avoid future complications. Collaborating with experienced professionals can also yield valuable insights and recommendations tailored to your operational goals.

Where to Find Replacement Parts

Finding suitable components for your machinery can be a crucial task to ensure smooth operation and longevity. Various sources offer these essential items, ranging from authorized dealers to online platforms, providing a wide selection to meet diverse needs.

Authorized Dealers

Authorized distributors are a reliable choice for high-quality components. They offer genuine products and expert advice, ensuring compatibility and performance.

Online Marketplaces

Online platforms have revolutionized the search for essential components. They provide convenience and often competitive pricing, making it easier to compare options.

| Source | Advantages |

|---|---|

| Authorized Dealers | Genuine quality, expert support |

| Online Marketplaces | Convenience, price comparisons |

| Local Salvage Yards | Cost-effective, unique finds |