When maintaining outdoor machinery, a clear overview of its individual elements is essential. Familiarity with each component can enhance performance, extend lifespan, and facilitate effective repairs. A comprehensive guide can significantly aid users in navigating the complexities of their equipment.

Having access to a detailed representation of the various elements involved not only simplifies troubleshooting but also empowers users to undertake maintenance tasks confidently. This insight allows for a more informed approach to both repairs and upgrades, ensuring that every piece works harmoniously within the system.

By examining the structure and function of each section, one can appreciate the intricacies involved in the overall operation. A thorough understanding of these components fosters a proactive attitude towards upkeep, ultimately leading to more efficient usage and greater satisfaction in outdoor projects.

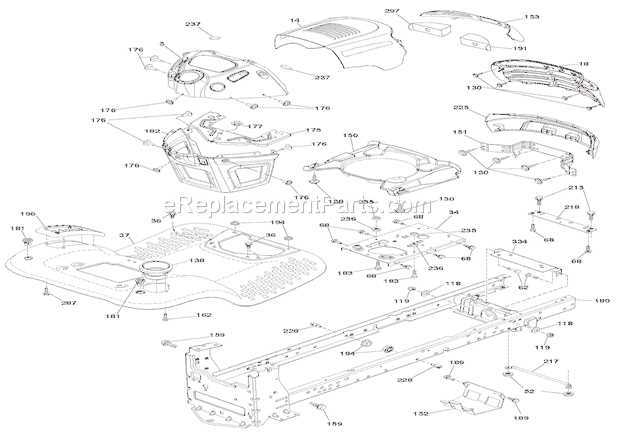

Ariens Lawn Tractor Parts Overview

This section provides an insightful look into the essential components of a specific garden maintenance vehicle. Understanding each element is crucial for effective upkeep and repair.

- Engine: The powerhouse that drives performance.

- Transmission: Facilitates smooth movement and speed adjustments.

- Deck: The structure that houses the cutting mechanism.

- Wheels: Provide mobility and stability across various terrains.

- Steering System: Ensures precise maneuvering and control.

Familiarity with these components enables users to maintain optimal functionality and prolong the lifespan of their equipment.

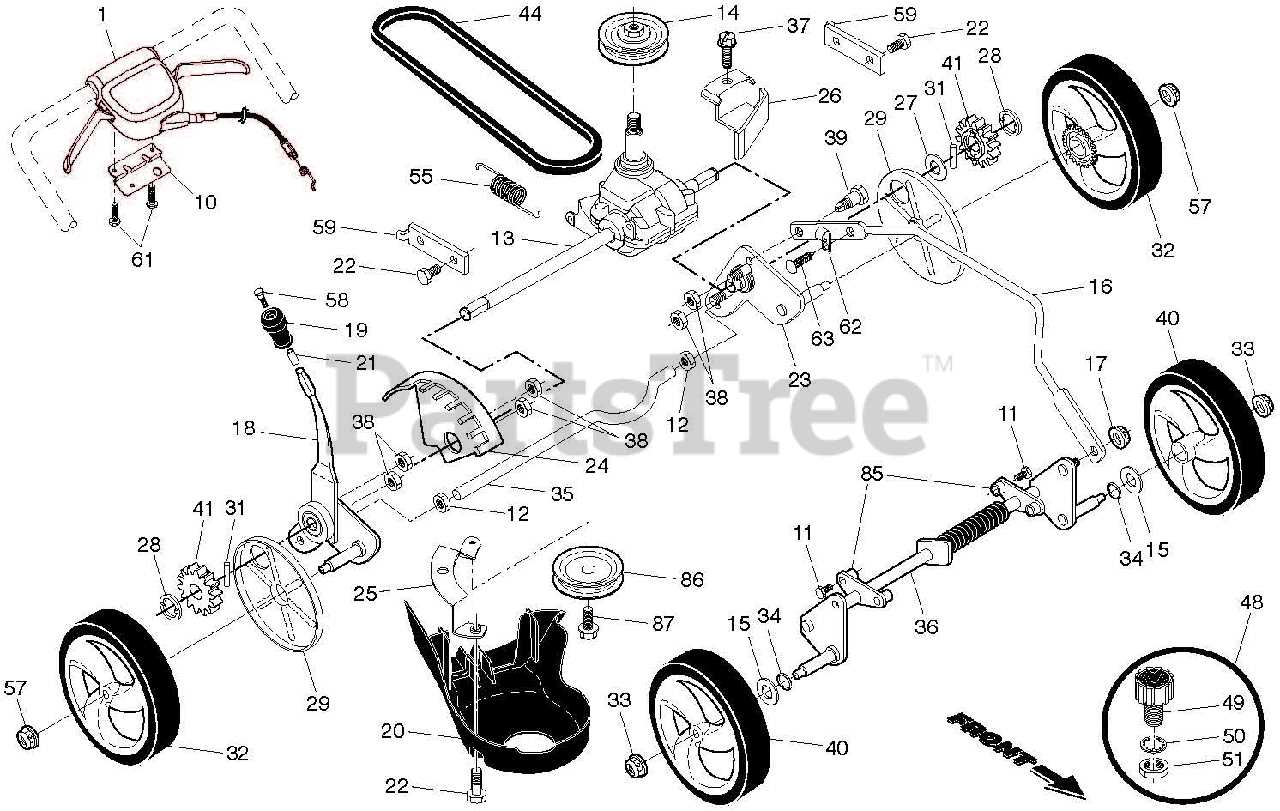

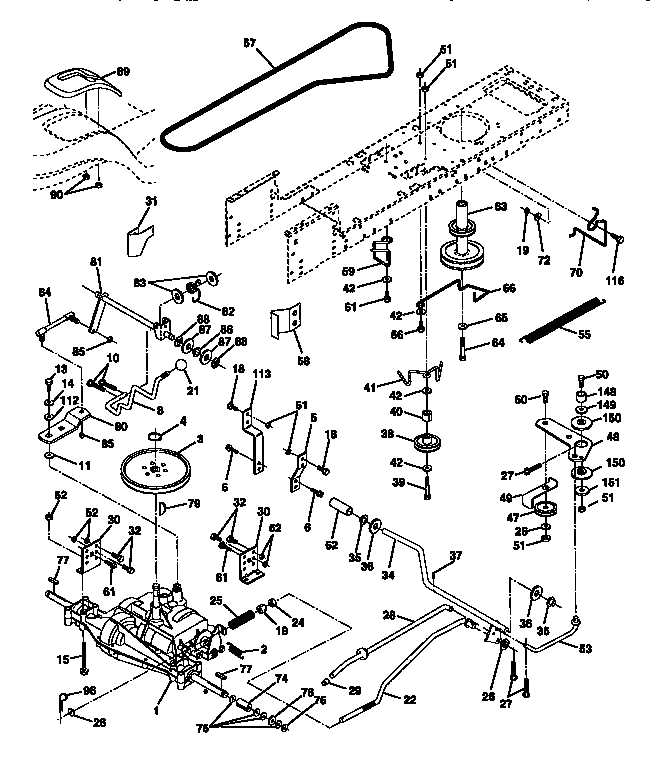

Understanding the Parts Diagram

Familiarizing oneself with the layout and components of any mechanical device is essential for effective maintenance and troubleshooting. A detailed illustration serves as a valuable guide, allowing users to identify and locate various elements within the machinery. By grasping the structure and organization, operators can enhance their understanding and perform necessary repairs more efficiently.

Each section of the illustration represents a specific assembly, providing insight into the functionality and interrelationships of different components. Recognizing how these parts work together is crucial for effective management and upkeep. Below is a simplified representation to illustrate the typical sections found in such a schematic.

| Component | Description |

|---|---|

| Engine | The power source that drives the entire mechanism. |

| Transmission | Responsible for transferring power from the engine to the wheels. |

| Deck | The housing that protects and supports the cutting apparatus. |

| Wheels | Provide mobility and stability for the machine. |

| Controls | Interface elements for operating the various functions. |

By studying this visual representation, users can develop a clearer understanding of their machinery, leading to improved performance and longevity. Proper knowledge of the components will empower operators to take proactive steps in maintenance and repair tasks.

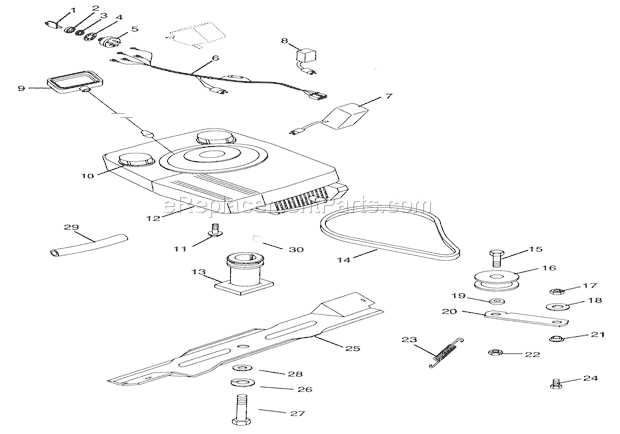

Essential Components of Lawn Tractors

Understanding the key elements that make up outdoor mowing machines is crucial for maintenance and optimal performance. Each component plays a specific role in ensuring efficiency and longevity, contributing to the overall functionality of the equipment.

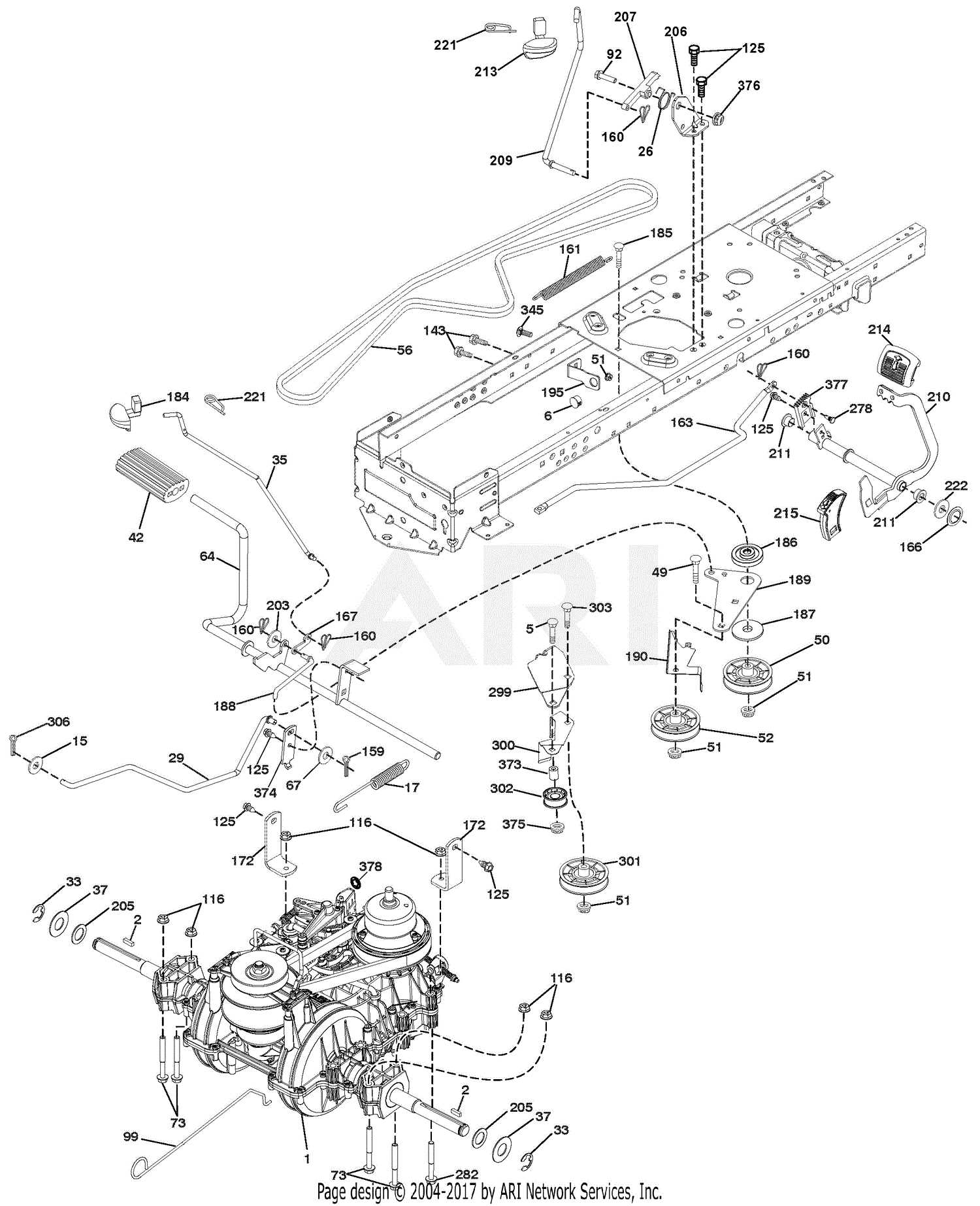

Power System

The power system serves as the heart of the machinery, providing the necessary energy for operation. Typically, this consists of a robust engine, which may vary in size and horsepower depending on the model. A reliable ignition system is also essential, ensuring smooth starts and consistent performance.

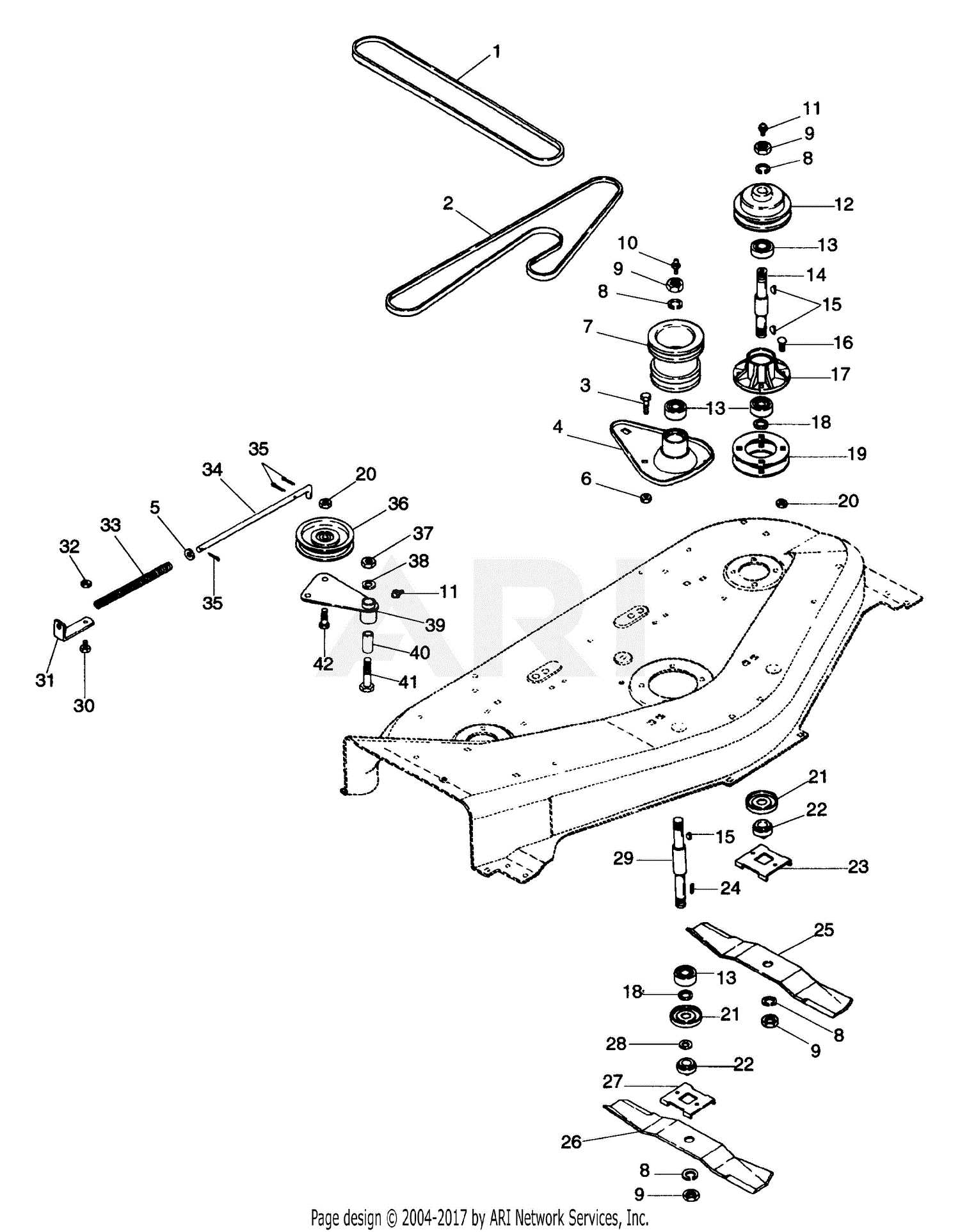

Cutting Mechanism

The cutting mechanism is a pivotal feature, designed to achieve a precise and even trim. This often includes sharp blades, which may be adjustable to accommodate different grass lengths. Additionally, the cutting deck’s construction influences maneuverability and the quality of the finished job.

Maintenance of these components is vital; regular checks and replacements can prevent larger issues and enhance the lifespan of the equipment. Understanding these essentials allows operators to perform effective troubleshooting and care.

How to Read the Diagram Effectively

Understanding a schematic representation is essential for efficient maintenance and troubleshooting. Familiarizing yourself with the layout can streamline repairs and ensure that each component functions correctly. Here are some tips to enhance your comprehension of the visual guide.

- Familiarize Yourself with Symbols: Each icon represents a specific element. Knowing these symbols will help you quickly identify parts and their functions.

- Follow the Flow: Diagrams often illustrate the direction of operation. Trace the connections to see how components interact within the system.

- Refer to the Legend: Most illustrations include a key that explains the symbols and colors used. Consult this reference to clarify any confusion.

- Identify Groups: Components are usually grouped by function. Recognizing these clusters can simplify the repair process.

- Take Notes: Jot down any observations or questions as you study the representation. This practice can aid in problem-solving later on.

By applying these strategies, you can effectively decode the visual representation and enhance your understanding of the machinery’s intricacies.

Common Replacement Parts for Ariens

Maintenance is essential for ensuring optimal performance and longevity of outdoor equipment. Various components may require replacement over time due to wear and tear, enabling users to maintain efficiency and reliability. Understanding which elements typically need attention can help in making informed decisions for repairs and upkeep.

Engine Components

The engine is the heart of any machine, and specific elements such as filters, spark plugs, and belts often need replacement. Regular checks on these components can prevent larger issues and ensure smooth operation.

Cutting Mechanism

For those using machinery equipped with cutting blades, sharpness and integrity are crucial. Blades, spindles, and pulleys frequently wear out and should be inspected regularly. Keeping these parts in good condition helps achieve the best cutting performance.

Maintaining Your Lawn Tractor Parts

Regular upkeep of your outdoor machinery components is essential for ensuring optimal performance and longevity. By adhering to a consistent maintenance routine, you can prevent costly repairs and enhance efficiency.

Here are some fundamental practices to keep in mind:

- Inspect Regularly: Examine all components for signs of wear or damage.

- Clean Thoroughly: Remove dirt and debris from surfaces to prevent buildup.

- Lubricate Moving Parts: Apply appropriate lubricants to reduce friction and wear.

Additionally, consider the following specific tasks:

- Check Belts and Cables: Ensure they are tight and free of frays.

- Sharpen Blades: Keep cutting edges sharp for effective performance.

- Change Fluids: Replace oil and other fluids as recommended by the manufacturer.

By implementing these strategies, you can maintain your machinery in peak condition, ensuring it runs efficiently throughout its lifespan.

Where to Find Quality Parts

When it comes to maintaining outdoor equipment, sourcing reliable components is essential for optimal performance. Ensuring that you use high-grade replacements can significantly enhance the longevity and functionality of your machinery. This section outlines various avenues where you can procure these crucial items effectively.

Online Retailers

The internet offers a plethora of options for purchasing components. Renowned e-commerce platforms host a wide variety of suppliers, providing a convenient way to compare prices and reviews. Look for sellers with established reputations and customer feedback to ensure that you are acquiring quality merchandise. Always verify compatibility with your specific model before completing a purchase.

Local Dealers and Service Centers

Visiting nearby dealerships can yield valuable results. These establishments often carry authentic merchandise that meets the manufacturer’s standards. Engaging with knowledgeable staff can also provide insights into installation and maintenance practices. Additionally, local repair shops may have access to aftermarket solutions that could serve as economical alternatives without compromising on quality.

DIY Repairs Using the Diagram

Understanding the layout and components of your equipment can significantly simplify the repair process. With a detailed illustration, you can easily identify each element, making it easier to troubleshoot issues and perform maintenance tasks. This empowers users to tackle repairs confidently, reducing dependency on professional services and saving time and money.

Identifying Components

Before diving into repairs, familiarize yourself with the various components depicted in the illustration. Each part is labeled clearly, allowing you to quickly locate specific items that may need attention. This clarity is essential for effective troubleshooting and ensures that you don’t waste time guessing which component requires replacement or adjustment.

Step-by-Step Repair Process

Once you’ve identified the necessary components, follow a systematic approach to execute repairs. Start by gathering the required tools and any replacement items. Refer to the illustration as you disassemble the equipment, taking care to document your progress. This method not only streamlines the process but also minimizes the risk of losing or misplacing parts.

In summary, utilizing a well-structured illustration can greatly enhance your DIY repair skills, leading to successful maintenance and extended equipment lifespan. With practice, you’ll become adept at identifying and resolving issues independently.

Upgrading Components for Better Performance

Enhancing the efficiency of outdoor machinery can lead to a significant improvement in overall functionality. By focusing on specific elements, users can achieve a smoother operation, greater power output, and increased longevity. This section explores various strategies to elevate the performance of your equipment through selective upgrades.

Engine Enhancements: Upgrading the engine is often the most impactful change. Consider opting for a high-performance variant or enhancing the existing one with modifications like improved air filters and exhaust systems. These alterations can boost horsepower and torque, providing a noticeable increase in power during operation.

Transmission Improvements: Another key area for enhancement lies in the transmission. Upgrading to a more efficient system can facilitate smoother gear shifts and better power transfer. This can be particularly beneficial for handling diverse terrains, ensuring that your machinery remains agile and responsive.

Deck Modifications: The cutting deck plays a crucial role in the performance of your equipment. Investing in a more robust deck or optimizing the existing one with sharper blades can improve cutting efficiency. This not only enhances the quality of the work but also reduces the time spent on tasks.

Tire Upgrades: Finally, considering the right tires can significantly affect performance. Selecting tires designed for specific conditions can enhance traction, stability, and maneuverability, making your machinery more versatile and effective in various environments.

In conclusion, thoughtful upgrades across these components can lead to remarkable improvements in performance, making your outdoor equipment more reliable and efficient.

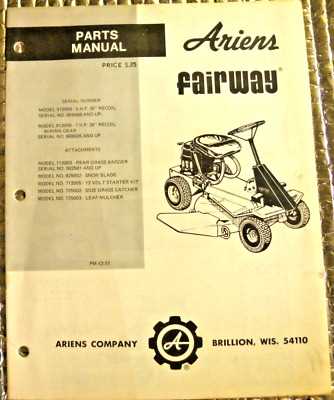

Identifying Parts by Model Number

Understanding how to accurately determine components by their model identifier is essential for maintenance and repairs. This process not only streamlines the search for necessary elements but also ensures compatibility and efficiency in handling any machinery issues.

Finding the Model Number

The first step in this identification process is locating the specific model number. This identifier is typically found on a label or tag affixed to the unit. Knowing where to look can save time and frustration when searching for replacements or information.

Using the Model Number for Identification

Once the model number is obtained, it can be cross-referenced with manufacturer catalogs or online databases. These resources provide detailed listings of available elements and their specifications. This method not only confirms the exact components needed but also enhances the likelihood of acquiring the right items for repairs.

Safety Tips for Working on Tractors

Ensuring safety while maintaining outdoor machinery is crucial for preventing accidents and injuries. By following certain guidelines, operators can create a secure environment that minimizes risks during maintenance and repairs. Here are essential tips to keep in mind while working on your equipment.

| Tip | Description |

|---|---|

| Wear Appropriate Gear | Always use protective clothing, gloves, and eyewear to shield yourself from debris and potential hazards. |

| Read the Manual | Familiarize yourself with the equipment’s manual to understand specific safety precautions and operational guidelines. |

| Work in a Well-Lit Area | Ensure your workspace is adequately illuminated to avoid accidents caused by poor visibility. |

| Disconnect the Battery | Before performing any maintenance, always disconnect the battery to prevent accidental starts. |

| Keep Tools Organized | Store tools properly to avoid tripping hazards and ensure that everything is within reach during repairs. |

| Check for Leaks | Regularly inspect for fuel or oil leaks to prevent slips and maintain a clean working environment. |

| Use Proper Lifting Techniques | When lifting heavy components, use your legs to lift rather than your back to prevent injuries. |

By adhering to these safety tips, operators can effectively reduce the likelihood of accidents and ensure a smoother maintenance experience.

Common Issues and Solutions

When operating outdoor machinery, users often encounter a variety of challenges that can affect performance and efficiency. Understanding these common problems and their respective solutions is crucial for maintaining optimal functionality. Below are some frequent issues and practical remedies to enhance your experience.

Engine Won’t Start

If the engine fails to ignite, first check the fuel level and ensure it’s fresh. A clogged fuel line or a faulty spark plug can also be culprits. Replacing the spark plug and clearing any blockages may resolve the issue.

Uneven Cutting

Uneven cutting can be attributed to dull blades or improper deck height settings. Regularly inspect and sharpen the blades, and adjust the cutting height to achieve a consistent finish.

Overheating

Overheating often results from inadequate airflow or a dirty cooling system. Cleaning debris from around the engine and ensuring that air vents are unobstructed can help maintain appropriate temperatures.

Strange Noises

Unusual sounds may indicate loose components or worn bearings. Conduct a thorough inspection to tighten any loose parts and consider replacing bearings if they show signs of wear.

Difficulty Maneuvering

If steering becomes challenging, check the tire pressure and inspect the steering components for wear. Proper inflation and timely replacement of worn parts can restore ease of movement.