Exploring the intricate world of agricultural machinery reveals a wealth of information about its essential elements. Each component plays a crucial role in ensuring optimal performance and efficiency in various tasks.

When delving into the specifics, it becomes clear that visual aids are invaluable. They not only enhance comprehension but also provide a clear representation of how individual elements interact within the larger system.

For those seeking the ultimate understanding, a detailed overview can lead to better maintenance practices and informed decision-making. By familiarizing oneself with these schematics, operators can enhance their skills and ensure longevity in their equipment.

Understanding Branson Tractors

This section explores the essential features and functionalities of a renowned brand in the agricultural machinery sector. It provides insights into their engineering, reliability, and user-friendly designs that cater to various farming needs.

Key Features

- Robust construction for durability

- Efficient engines that enhance performance

- User-friendly controls for easy operation

- Versatile attachments for multiple tasks

Benefits of Using This Brand

- Cost-effective solutions for farming

- Excellent customer support and service

- Innovative technology that improves productivity

- Strong resale value in the market

Key Components of Branson Tractors

Understanding the essential elements of agricultural machinery is crucial for optimal performance and maintenance. Each component plays a vital role in ensuring that the equipment operates efficiently, making it easier for operators to complete their tasks effectively.

Core Elements

- Engine: The powerhouse that drives all operations, providing the necessary horsepower for various tasks.

- Transmission: This system transfers power from the engine to the wheels, allowing for smooth movement across different terrains.

- Hydraulic System: Essential for powering attachments and implements, this system enhances versatility in handling various jobs.

- Chassis: The framework that supports all components, ensuring durability and stability during operation.

Functional Attachments

- Loader: A front-mounted tool designed for lifting and moving materials, increasing productivity on the farm.

- Backhoe: An attachment that allows for digging and excavation, making it invaluable for landscaping and construction tasks.

- Mowers: Ideal for maintaining grass and crops, providing efficient cutting and clearing capabilities.

Each of these components contributes significantly to the overall functionality of agricultural machinery, ensuring that operators can rely on their equipment for a wide range of tasks.

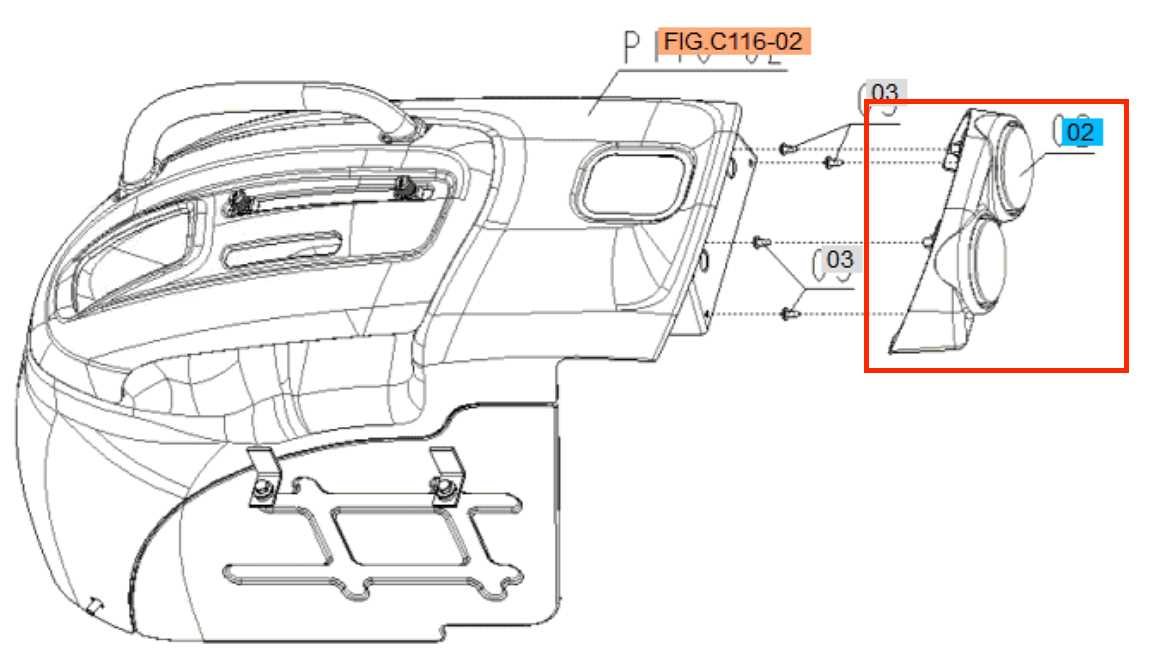

Importance of Tractor Parts Diagrams

Understanding the intricate layout and components of agricultural machinery is crucial for effective maintenance and repair. Visual representations provide clarity, enabling operators to identify individual elements and their functions easily. This knowledge is essential for troubleshooting issues and ensuring optimal performance.

Moreover, these illustrations serve as invaluable resources during the assembly and disassembly processes. They guide technicians through complex tasks, reducing the likelihood of errors and saving time. Additionally, clear visuals can enhance training programs for new operators, providing them with the confidence to handle machinery responsibly.

| Benefits | Description |

|---|---|

| Clarity | Facilitates understanding of component functions. |

| Efficiency | Streamlines repair and maintenance processes. |

| Training | Aids in educating new operators on machinery. |

| Accuracy | Minimizes mistakes during assembly or repair. |

In summary, these visual guides play a vital role in the longevity and reliability of agricultural equipment. They empower users with the knowledge necessary for effective operation and upkeep, ultimately leading to better productivity in the field.

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations provide crucial insights into the arrangement and function of various elements within machinery. Familiarizing yourself with the symbols and layouts will enhance your ability to locate and identify the necessary items swiftly.

Key Elements to Recognize

- Symbols: Each symbol corresponds to a specific component, often varying between manufacturers.

- Numbers: Numerical references typically indicate part numbers or categories.

- Connections: Arrows and lines illustrate how components are interconnected.

Steps for Effective Interpretation

- Start by examining the legend or key, which explains the symbols used.

- Identify the main sections of the visual aid to understand the overall structure.

- Cross-reference the numbers with the parts list to find detailed descriptions.

Common Issues with Tractor Parts

In the world of agricultural machinery, various components can encounter challenges that impact performance and reliability. Understanding these issues is crucial for efficient maintenance and operation.

Frequent Challenges

Among the most prevalent concerns are wear and tear, improper installation, and environmental factors. These elements can lead to decreased efficiency and increased downtime.

Signs of Trouble

Identifying symptoms early can prevent costly repairs. Common indicators include unusual noises, decreased power, and fluid leaks. Regular inspections help in early detection.

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Wear and Tear | Reduced efficiency | Regular replacements |

| Improper Installation | Unusual noises | Professional assessment |

| Environmental Factors | Fluid leaks | Protective measures |

Finding Replacement Parts for Branson

When it comes to maintaining heavy machinery, locating the right components is essential for optimal performance. Identifying suitable substitutes can enhance efficiency and prolong the lifespan of your equipment. Whether you’re a professional or a hobbyist, knowing where to find these crucial elements is key to successful repairs.

Resources for Locating Components

- Manufacturer’s Website: Start by visiting the official site for detailed information on available items.

- Authorized Dealers: Connect with licensed distributors for genuine options and expert advice.

- Online Marketplaces: Explore e-commerce platforms that specialize in machinery accessories.

- Local Retailers: Check nearby stores that cater to agricultural and industrial needs.

Tips for Ensuring Compatibility

- Reference Manuals: Always consult user manuals for specific information regarding compatible items.

- Part Numbers: Keep part numbers handy to streamline your search and avoid confusion.

- Community Forums: Engage with online groups for insights from fellow users who may have faced similar challenges.

- Consult Experts: When in doubt, seek advice from professionals who can guide you toward the right solutions.

Maintenance Tips for Branson Tractors

Regular upkeep is essential for ensuring optimal performance and longevity of your machinery. Proper care not only enhances efficiency but also minimizes unexpected breakdowns and costly repairs. Adopting a proactive approach to maintenance can lead to a smoother operation and increased productivity.

Routine Inspections

Conducting regular checks on your equipment is vital. Look for signs of wear and tear, such as leaks or unusual noises. Ensure that all fluids, including oil and coolant, are at appropriate levels. Inspect belts and hoses for fraying or cracks, as these components are crucial for seamless operation.

Scheduled Servicing

Adhering to a scheduled servicing plan is crucial for sustaining performance. Follow the manufacturer’s recommendations for service intervals and replace filters and fluids as needed. Keeping a maintenance log can help track what has been done and when, providing a clear history that can be useful for future reference.

Aftermarket vs. OEM Parts Explained

When it comes to maintaining and repairing machinery, understanding the difference between two main categories of components is essential. Each type offers unique advantages and considerations that can significantly impact performance, longevity, and cost-effectiveness. This distinction is particularly important for those seeking reliable solutions for their equipment needs.

Original equipment manufacturer components are crafted to meet the specifications set by the original maker. These items ensure compatibility and often come with warranties that can provide peace of mind. Conversely, alternative components are produced by third-party manufacturers and may offer more competitive pricing or improved performance characteristics. However, they can vary in quality and may not always guarantee a perfect fit.

Choosing between these options involves weighing factors such as budget, performance expectations, and the intended use of the machinery. While OEM options often provide assurance in quality and reliability, aftermarket choices can be appealing for those looking to save money or enhance functionality. Ultimately, understanding these differences allows users to make informed decisions tailored to their specific needs.

Using Online Resources for Parts

Accessing digital platforms has revolutionized the way individuals find components for their machinery. The internet offers a plethora of tools and websites that streamline the search process, making it easier to identify and procure the necessary items for maintenance and repair tasks.

Here are some benefits of utilizing online resources:

- Comprehensive Catalogs: Many websites provide extensive inventories, allowing users to browse a wide range of components in one place.

- User-Friendly Search Functions: Advanced filters and search options help quickly locate specific items based on various criteria.

- Detailed Specifications: Online platforms often include detailed descriptions, compatibility information, and images, aiding in informed decision-making.

When exploring these resources, consider the following tips:

- Check Reviews: Look for user feedback to gauge the reliability and quality of the items offered.

- Compare Prices: Take time to compare prices across different sites to ensure you get the best deal.

- Verify Return Policies: Understand the return policies to avoid issues if a component does not meet your expectations.

By leveraging these digital tools, individuals can enhance their maintenance efforts and ensure their machinery operates smoothly.

Identifying Your Tractor Model

Understanding the specific model of your agricultural machinery is crucial for effective maintenance and optimal performance. Each variant may have unique features and specifications that distinguish it from others. Accurately determining your equipment’s model not only aids in finding the right components but also enhances your overall experience.

Start by checking the manufacturer’s label, typically located on the frame or near the engine. This label usually contains essential information, including the model number and serial number. Take note of these details as they will guide you in your search for the appropriate components and resources.

Additionally, consult the owner’s manual if available. This document often includes a section dedicated to model identification, offering insights into various configurations and options. Familiarizing yourself with this manual can significantly streamline the identification process.

Finally, consider online resources and forums where fellow users share their experiences. These communities can provide valuable tips on identifying models based on specific characteristics and features. Diving into these discussions can reveal helpful information that might not be found elsewhere.

Tools Needed for Repairing Tractors

Effective maintenance of agricultural machinery requires a well-equipped workspace and the right instruments. Whether you’re conducting routine checks or tackling significant repairs, having the necessary tools on hand can make all the difference in achieving successful outcomes. This section outlines the essential equipment that every operator should consider for efficient servicing of their machinery.

Basic hand tools like wrenches, screwdrivers, and pliers are fundamental for any repair job. These instruments enable precise adjustments and replacements, ensuring that components are securely fastened. Additionally, a set of sockets can greatly enhance efficiency when working on various bolts and fasteners.

Power tools, such as drills and impact wrenches, streamline the repair process, particularly when dealing with stubborn or rusted fasteners. A quality air compressor can also be invaluable for powering pneumatic tools, making tasks quicker and easier.

Safety equipment, including gloves, goggles, and ear protection, is crucial to protect oneself while working. Ensuring a safe environment should always be a priority, especially when using heavy machinery or tools that can cause injury.

Finally, diagnostic tools like multimeters and engine analyzers provide valuable insights into the machinery’s performance, helping to identify issues before they escalate. Keeping these instruments readily available can save time and resources in the long run.

Connecting with Branson Tractor Communities

Engaging with fellow enthusiasts creates a vibrant network where knowledge and experiences can be shared. This collective support fosters a deeper understanding and appreciation of machinery, allowing members to learn from one another and enhance their skills.

| Platform | Description |

|---|---|

| Online Forums | A space for discussions, troubleshooting, and advice from experienced users. |

| Social Media Groups | Connect with like-minded individuals, share photos, and ask questions in real-time. |

| Local Clubs | Meet face-to-face, participate in events, and build lasting friendships. |

| Workshops | Hands-on experiences to delve into maintenance and enhancements with experts. |

Benefits of Regular Parts Inspection

Consistent evaluation of machinery components plays a crucial role in maintaining optimal performance and longevity. By routinely checking these elements, one can identify potential issues before they escalate, ensuring smooth operations and reducing unexpected downtimes.

Enhanced Performance

Regular assessments contribute significantly to the efficiency of equipment. Ensuring all components function correctly leads to better fuel efficiency and improved output. This proactive approach helps in maximizing productivity while minimizing costs.

Cost Savings

Investing time in inspections can lead to substantial financial benefits. Early detection of wear and tear can prevent costly repairs and extend the lifespan of essential machinery. Below is a table illustrating potential savings from routine evaluations:

| Inspection Frequency | Estimated Annual Savings |

|---|---|

| Monthly | $2,000 |

| Quarterly | $1,200 |

| Yearly | $500 |