In the realm of farming machinery, a thorough comprehension of individual components is essential for optimal performance and maintenance. Each element plays a pivotal role in the overall functionality, contributing to the efficiency and reliability of the equipment. Proper knowledge of these components aids in troubleshooting issues and ensuring smooth operation.

Visual representations of these elements can serve as valuable tools for both seasoned professionals and newcomers alike. By familiarizing oneself with the layout and function of each component, operators can make informed decisions regarding repairs and replacements. This understanding not only enhances productivity but also prolongs the lifespan of the machinery.

In addition, recognizing the specific features of various models empowers users to select the appropriate upgrades and enhancements. With a clearer view of how each part interacts within the system, individuals can optimize their equipment for diverse agricultural tasks, thus achieving greater success in their endeavors.

This section aims to provide insights into the various elements that make up a specific agricultural machine, focusing on their roles and interactions. A clear understanding of these components is essential for efficient operation and maintenance. Knowing how each part contributes to the overall functionality can enhance performance and prolong the lifespan of the equipment.

Key Elements of the Machinery

Several critical components work together to ensure optimal operation of the equipment. Familiarity with these elements can help in troubleshooting issues and performing necessary repairs. Each section of the machine serves a distinct purpose, contributing to its overall efficiency.

Common Components Overview

The following table outlines some of the common components found in the machinery, along with their functions:

| Component Name | Function |

|---|---|

| Engine | Provides the power necessary for operation |

| Transmission | Transmits power from the engine to the wheels |

| Hydraulic System | Facilitates the operation of various attachments |

| Chassis | Serves as the base structure for all components |

| Cooling System | Prevents overheating by regulating temperature |

Key Features of the Tractor

This versatile machine is designed to provide exceptional performance across a wide range of agricultural tasks. Its robust construction, combined with efficient power delivery, ensures reliability and efficiency for various operations in the field. Offering precision and control, it meets the demands of both small and large-scale farming needs.

Engine and Power

Equipped with a high-performing engine, this model ensures optimal fuel efficiency while delivering strong horsepower. The advanced engineering of the motor allows for smooth operation, even under heavy load, ensuring consistency in demanding conditions.

Hydraulic System

The hydraulic system offers enhanced control over implements, enabling smooth handling of attachments. The responsive system ensures the machine can handle various tools with precision

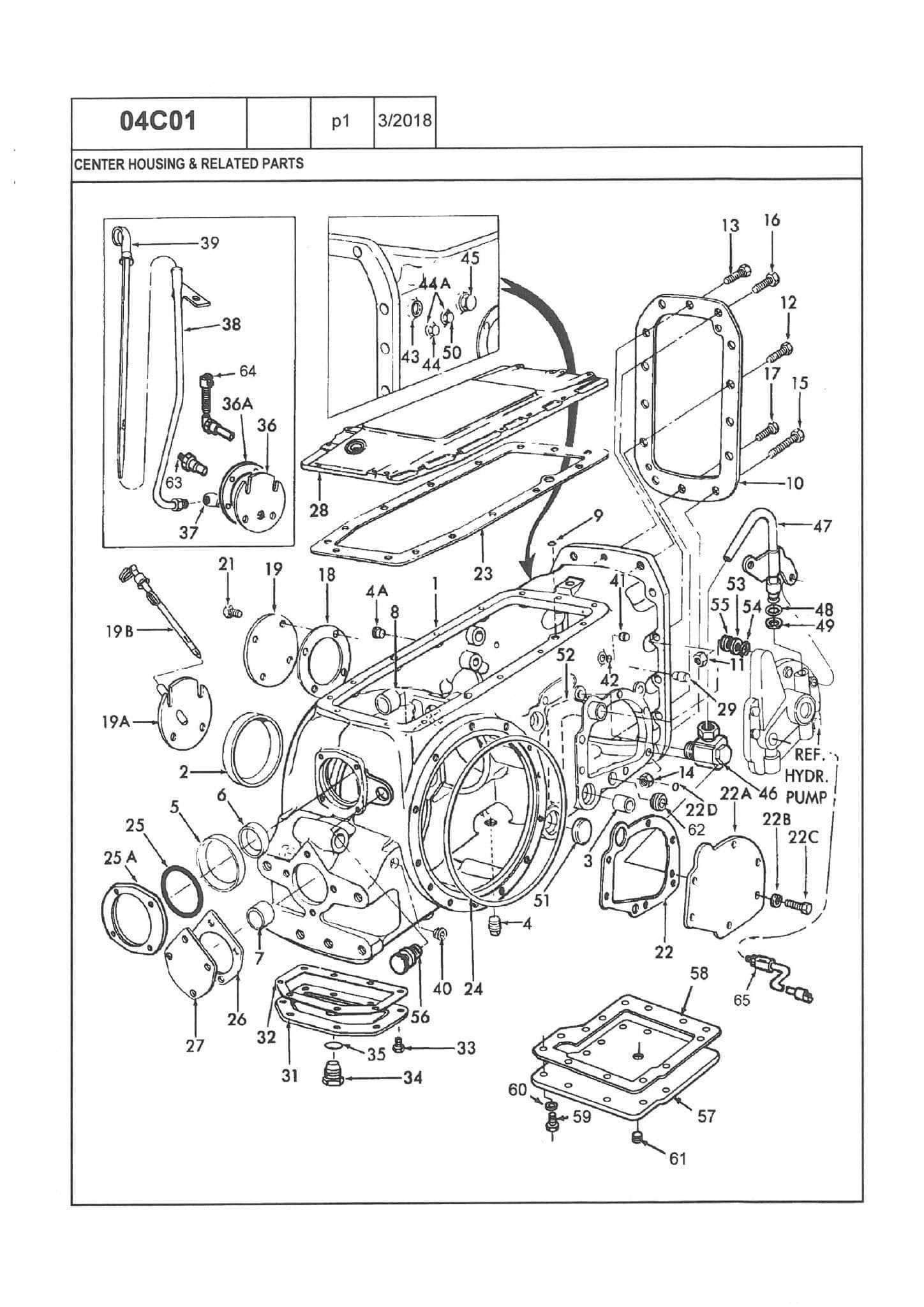

Identifying Major Parts

Understanding the structure and key components of complex machinery is essential for maintaining optimal performance. By recognizing the most critical elements, users can ensure proper upkeep and repair when necessary, minimizing downtime and enhancing functionality.

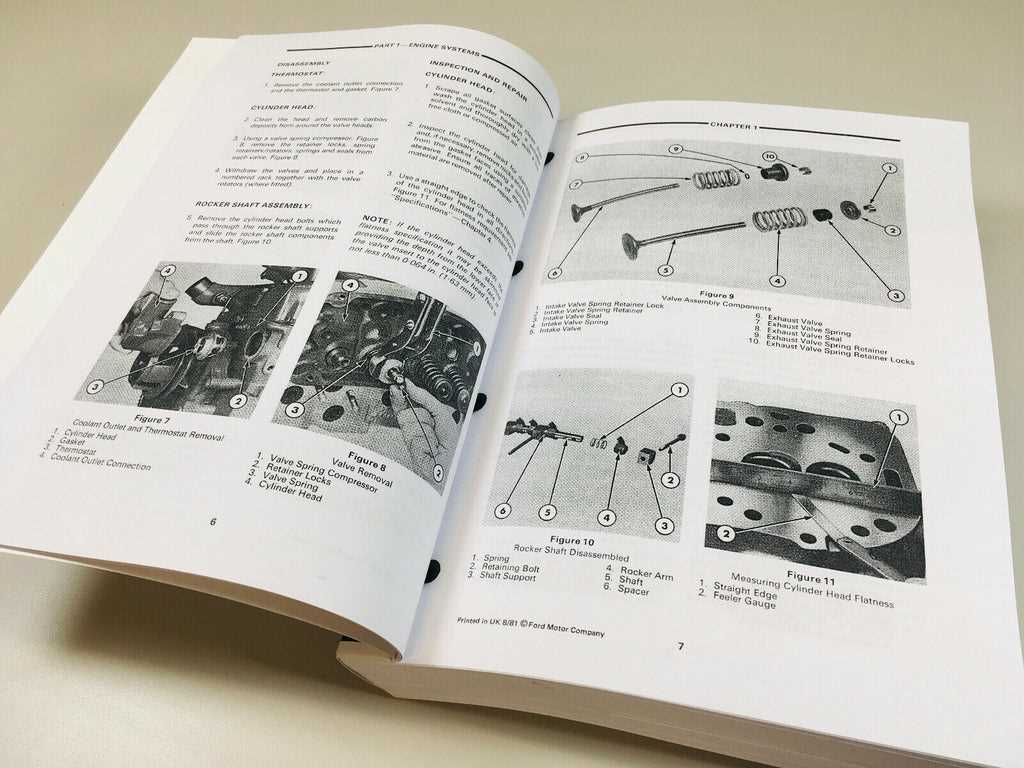

Engine Assembly

The core of any machine lies in its power source. The engine, composed of numerous intricate components, is responsible for converting energy into motion. Regular inspection and maintenance of this section can prevent major issues and prolong the equipment’s lifespan.

Transmission System

This system ensures smooth operation by managing the transfer of energy from the power source to the moving parts. It consists of various gears and linkages, which must work in harmony to allow controlled movement and power distribution

Importance of Maintenance Schedules

Regular upkeep is crucial for ensuring the longevity and optimal performance of any machinery. Establishing a structured plan for servicing can prevent unexpected issues, reduce long-term costs, and extend the life of the equipment. A well-maintained machine operates more efficiently and minimizes downtime, which is vital for productivity.

Preventative Care

Routine checks and timely servicing help identify potential problems before they escalate into major failures. This proactive approach ensures that the machinery remains in peak condition, ultimately saving time and money by avoiding costly repairs.

- Early detection of wear and tear

- Prevention of major breakdowns

- Improved efficiency and performance

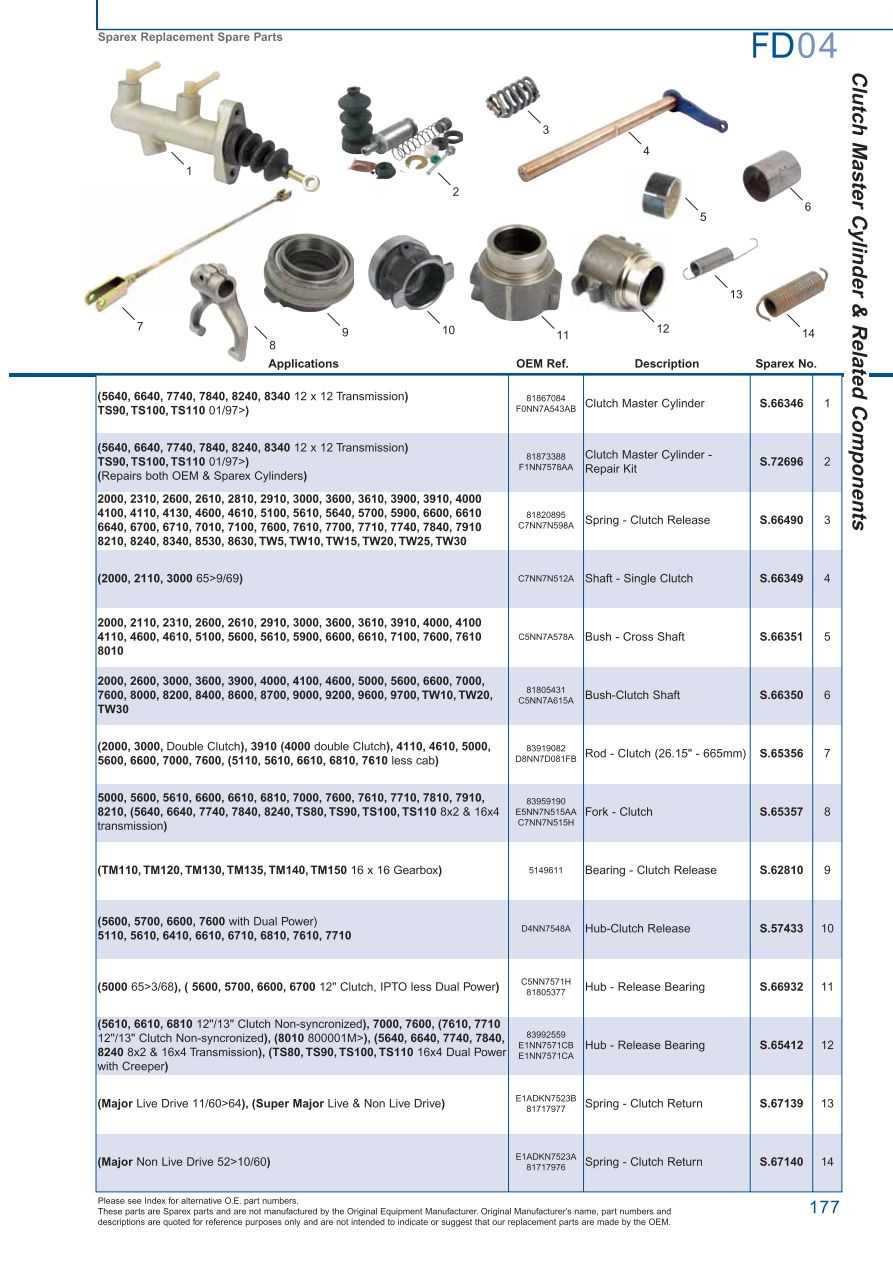

Common Replacement Parts Overview

Maintaining the functionality of agricultural equipment often requires the replacement of certain components. Over time, various elements wear out due to constant use, and identifying key areas that frequently need attention can help ensure smooth operation.

Frequently Replaced Components

- Filters: These include air, fuel, and oil filters that play a crucial role in keeping the system clean and preventing damage.

- Belts: Drive belts often experience wear and may require replacement to maintain proper power transmission.

- Batteries: As the electrical system ages, the battery may lose its charge capacity, affecting the overall functionality.

- Hoses: Hydraulic and coolant hoses are subject to cracking and leaks over time, leading to

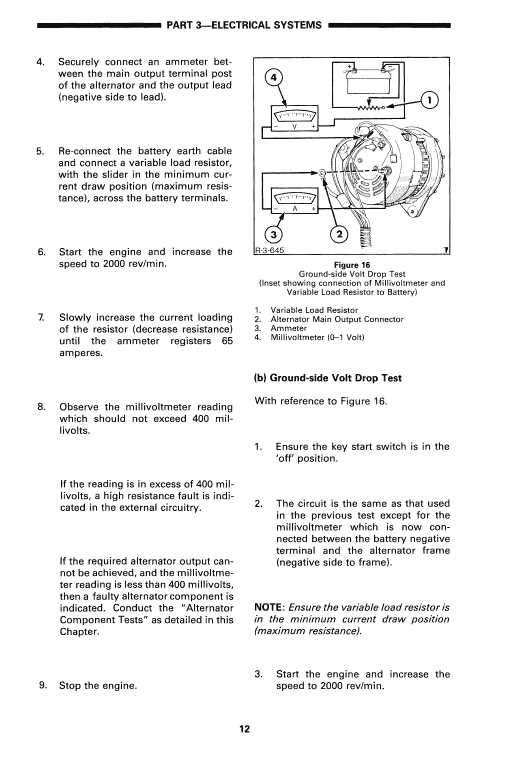

Wiring Diagram Basics Explained

Understanding the fundamentals of electrical wiring visuals is crucial for anyone working with electrical systems. These illustrations provide a clear representation of the electrical connections and components within a system, offering insight into how circuits are laid out and function together.

Key Components of a Wiring Visual

In any schematic, several core elements play a vital role in conveying the structure of the system. These include symbols that represent electrical devices, lines that illustrate connections, and labels to specify the function of each part. Knowing these elements makes it easier to read and interpret the connections.

How to Read Wiring Illustrations

Reading a schematic begins by identifying the power source and following the pathways from the source to the various

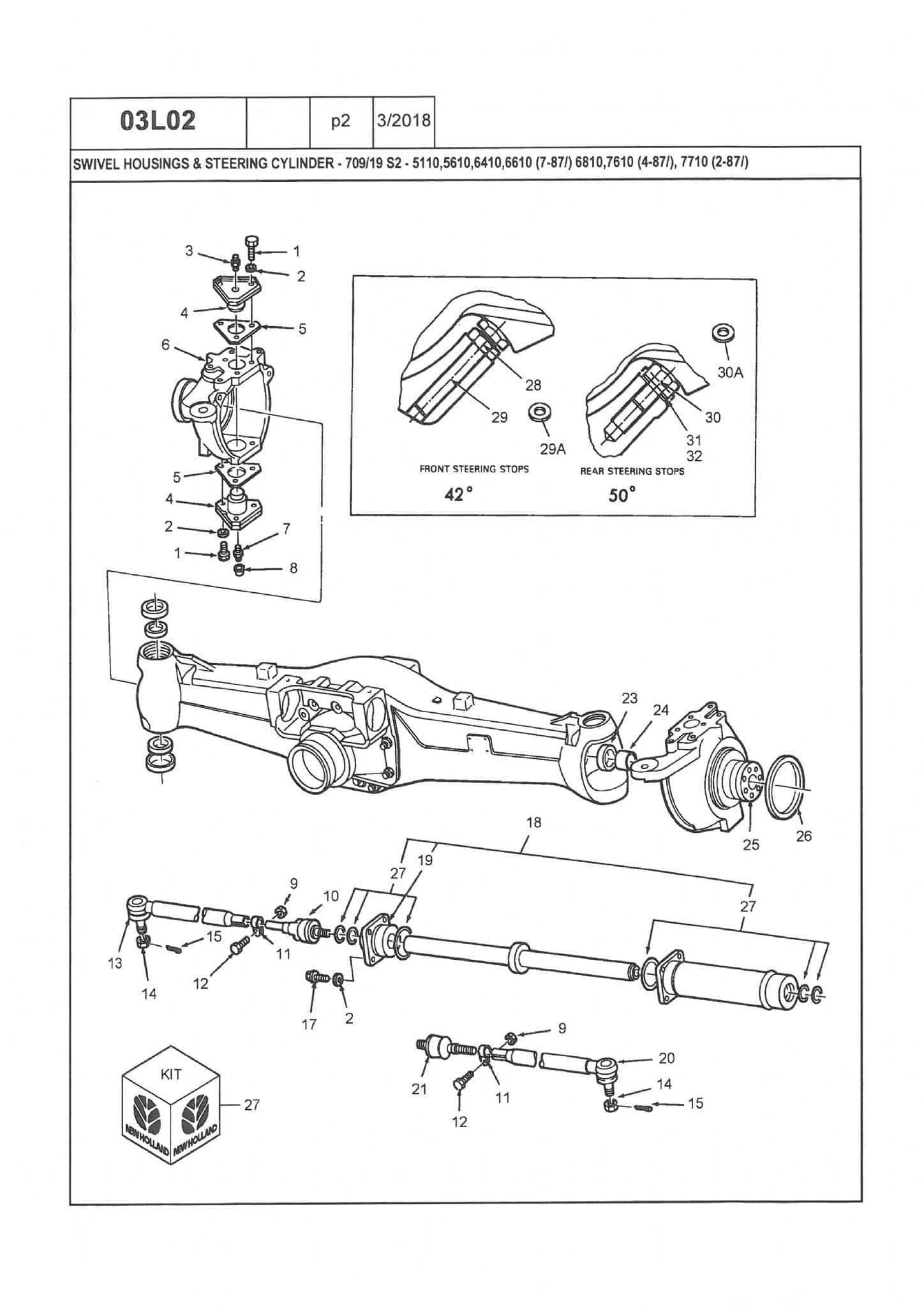

Hydraulic System Functionality

The hydraulic mechanism operates as a critical component, ensuring the movement and control of various attachments and implements. It functions by transmitting power through pressurized fluid, which allows for precise lifting, lowering, and adjusting actions. This system is crucial for maintaining efficient and smooth operation across a wide range of tasks.

Main Components of the Hydraulic System

- Pump: Responsible for generating fluid flow.

- Valves: Control the direction and pressure of the fluid.

- Reservoir: Stores hydraulic fluid and ensures consistent supply.

- Cylinders: Convert fluid pressure into mechanical movement.

Engine Specifications and Details

The power unit is known for its robust performance and reliability. This section outlines key features and technical characteristics, giving a clear understanding of the engine’s design and operation. The information provided here helps to comprehend its core components and performance parameters.

- Displacement: The engine has a large displacement, ensuring efficient fuel combustion and optimal power output.

- Horsepower: Known for its strong horsepower, the engine delivers excellent torque, making it suitable for heavy-duty applications.

- Cooling System: It features a liquid-cooled mechanism that prevents overheating, contributing to the engine’s longevity and consistent operation under demanding conditions.

- Cylinder Configuration: The multi-cylinder layout allows for smoother operation, balancing power with fuel efficiency.

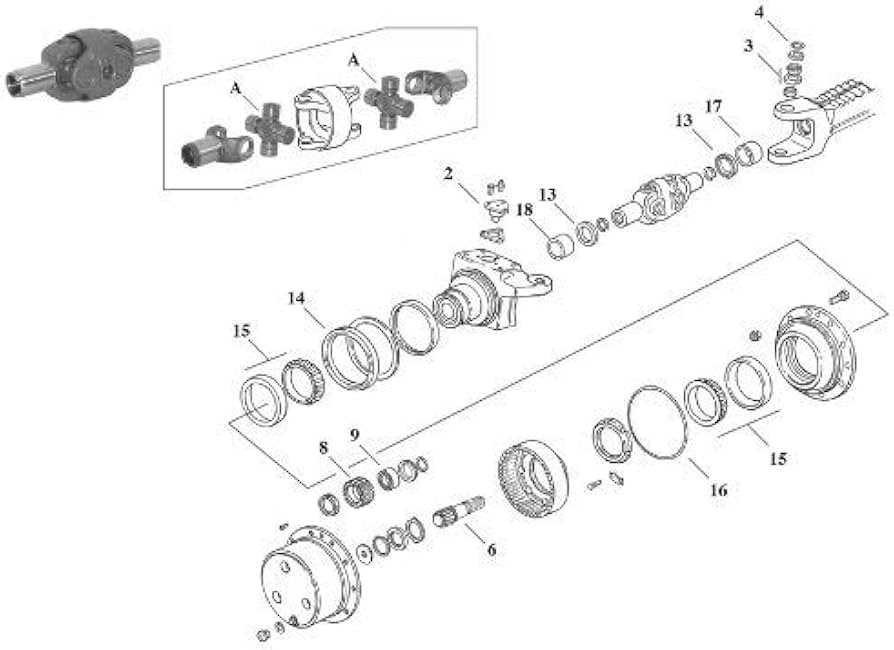

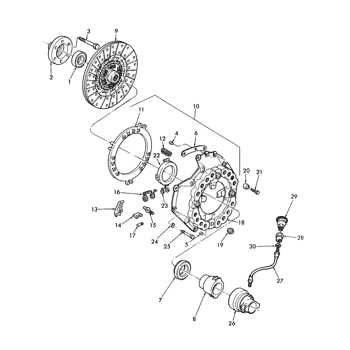

Transmission Components Breakdown

The transmission system plays a crucial role in ensuring the smooth operation of machinery by transferring power from the engine to the wheels. It consists of several interconnected elements, each performing specific tasks to regulate speed, torque, and overall performance. Understanding the breakdown of these components helps in identifying potential issues and maintaining optimal functionality.

The main sections within the transmission include gear sets, shafts, and clutches, all working together to adjust speed and power according to operational needs. These parts are meticulously designed to handle varying loads and mechanical stress, ensuring that the machine can adapt to different conditions.

Regular inspection and maintenance of the transmission components are essential to avoid unexpected malfunctions. Recognizing the symptoms of wear and tear in gears, bearings, and other essential parts can prevent costly repairs and ensure long-lasting performance.

Understanding the Cooling System

The cooling mechanism is essential for maintaining the operational temperature of an engine, preventing overheating and ensuring efficient performance. It works by circulating a coolant through various components to dissipate heat generated during operation.

Key Components

- Radiator – A device responsible for cooling the liquid that absorbs heat from the engine. It allows the heat to dissipate into the surrounding air.

- Water Pump – This pump ensures that the coolant circulates through the system, maintaining a consistent flow.

- Thermostat – A valve that regulates the flow of coolant based on the

Electrical System Components

The electrical system of machinery is responsible for powering various essential functions, ensuring reliable performance and operational efficiency. Understanding the different elements within this system allows for effective maintenance and troubleshooting, which helps prevent unexpected issues.

Power Source: The main energy source supplies electricity to the system, providing power for ignition, lighting, and other crucial functions. Regular checks of this component ensure steady and uninterrupted performance.

Wiring and Connectors: The network of wires and connectors is vital for transmitting electrical signals between different parts of the machinery. These elements must be properly maintained to avoid issues like short circuits or power loss.

Control Units: These

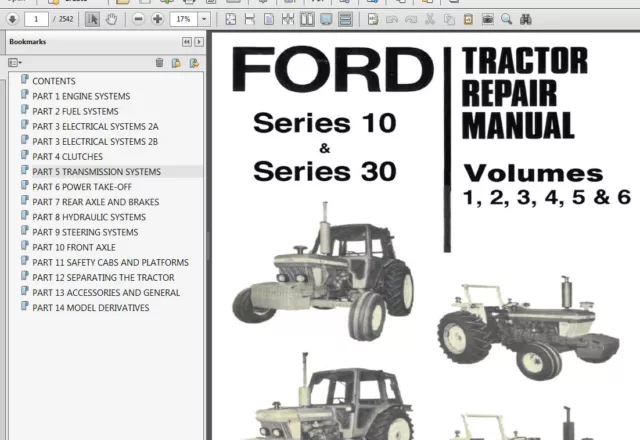

Accessing Service Manuals

Obtaining service manuals is crucial for maintaining and repairing machinery effectively. These manuals provide detailed instructions and essential information, ensuring proper functionality and longevity of equipment.

Service manuals can typically be accessed through various channels, including official manufacturer websites, authorized dealers, or specialized online platforms. Digital versions are often available for easy download, while printed copies can be ordered if preferred. Utilizing these resources ensures that operators and technicians have the necessary guidelines at their fingertips.

When seeking a manual, it’s beneficial to verify the version to ensure it corresponds with the specific model. Accurate documentation can prevent mistakes during repairs and maintenance, ultimately saving time and resources. Consulting multiple sources can also enhance understanding and provide different perspectives on troubleshooting and servicing equipment.

Tips for Efficient Repairs

Ensuring that maintenance and restoration tasks are carried out effectively can significantly enhance the longevity and performance of your machinery. By following a few strategic approaches, you can streamline the repair process and minimize downtime.

Assessing the Issue

Begin by thoroughly evaluating the problem at hand. Take the time to inspect the equipment carefully, noting any unusual sounds, movements, or fluid leaks. Creating a checklist of symptoms will help you pinpoint the root cause more efficiently.

Gathering Necessary Tools

Before starting any repair, ensure that you have all required tools and replacement components readily available. Having everything organized will prevent interruptions during the process. Consider investing in quality tools that are suited for your specific tasks, as they can greatly improve your efficiency and accuracy.

Lastly, always refer to a comprehensive guide or manual when available, as it can provide invaluable insights into the assembly and disassembly processes.