The efficient operation of farming equipment relies on a comprehensive understanding of its various elements. This section aims to provide insights into the essential components that make up a specific model of agricultural machinery, facilitating better maintenance and repair practices. By exploring these elements, operators can enhance their skills in troubleshooting and optimizing performance.

Each machinery model consists of distinct assemblies, which contribute to its overall functionality. Recognizing how these segments interrelate allows for informed decision-making when addressing issues or upgrading components. Moreover, having a clear grasp of the configurations involved can significantly reduce downtime, ultimately leading to improved productivity on the field.

In this guide, we will delve into the intricate structures that define the machinery in question. Understanding the arrangement and function of these critical segments empowers users to make knowledgeable choices regarding service and replacement. With this information, operators can ensure the longevity and efficiency of their equipment.

Overview of International 484 Tractor Parts

This section provides a comprehensive examination of the essential components and assemblies that contribute to the functionality and performance of a popular agricultural machine. Understanding these elements is crucial for efficient operation and maintenance.

Key Components

- Engine: The powerhouse that drives the machine, providing the necessary torque and horsepower.

- Transmission: This assembly transfers power from the engine to the wheels, allowing for smooth operation.

- Hydraulics: Essential for operating implements and attachments, enhancing versatility.

- Chassis: The framework that supports various systems and components, ensuring structural integrity.

Maintenance Considerations

- Regularly inspect all components for wear and tear.

- Change fluids as per the manufacturer’s recommendations to ensure optimal performance.

- Replace worn-out parts promptly to prevent further damage.

- Keep the machine clean to avoid debris accumulation that can affect functionality.

Key Components of the Tractor

The efficient operation of agricultural machinery relies on several essential elements that work in harmony. Understanding these components is vital for maintaining functionality and ensuring optimal performance in the field.

Engine: The heart of the machinery, this component provides the necessary power to drive all operations. A robust engine translates to greater efficiency and productivity during agricultural tasks.

Transmission: This system plays a crucial role in transferring power from the engine to the wheels. It allows the operator to select different speeds and torque levels, making it adaptable for various applications.

Hydraulic System: This feature enables the operation of attachments and implements, facilitating tasks such as lifting and digging. A reliable hydraulic system is essential for enhancing the versatility of the equipment.

Chassis: The framework supports all other components, providing stability and durability. A strong chassis is vital for the machine’s longevity, allowing it to withstand harsh working conditions.

Wheels and Tires: These elements are critical for mobility, influencing traction and control on various terrains. Choosing the right wheels and tires ensures better performance and reduces the risk of getting stuck in challenging conditions.

Familiarity with these integral components allows operators to make informed decisions regarding maintenance and upgrades, ultimately enhancing the overall effectiveness of the machinery.

Identifying Essential Spare Parts

Understanding the necessary components for maintaining machinery is crucial for ensuring its efficient operation. Recognizing these vital elements can help prevent unexpected breakdowns and prolong the lifespan of the equipment. By knowing what to look for, operators can effectively manage their inventory and ensure that they have access to the required items when needed.

Common Components to Consider

Several key elements are typically associated with heavy machinery maintenance. Engine components, such as filters and belts, are essential for optimal performance. Additionally, hydraulic systems play a significant role in the functioning of various mechanisms, so ensuring the availability of seals and hoses is vital. Regular inspection of these components can help identify potential wear and tear before it leads to larger issues.

Benefits of Proper Identification

Accurately identifying necessary components not only enhances operational efficiency but also reduces downtime caused by equipment failure. Keeping a well-organized inventory of these essentials ensures that repairs can be made swiftly, minimizing disruption to daily operations. Moreover, a proactive approach to maintenance contributes to cost savings by preventing the need for extensive repairs in the future.

Maintenance and Repair Tips

Proper upkeep and troubleshooting are essential for ensuring the longevity and efficiency of your machinery. Regular inspections, timely repairs, and a keen understanding of operational requirements can significantly enhance performance and prevent unexpected breakdowns.

Routine Checks: Conduct frequent examinations of critical components, such as fluid levels, belts, and filters. This practice helps identify potential issues early, reducing the risk of major malfunctions.

Lubrication: Keeping moving parts well-lubricated is vital. Utilize the appropriate grease and oils to minimize friction and wear, contributing to smoother operation and extending the lifespan of your equipment.

Cleaning: Regular cleaning of the exterior and interior surfaces prevents the buildup of dirt and debris that can impair functionality. Pay special attention to air intakes and cooling systems to maintain optimal performance.

Parts Replacement: Be proactive in replacing worn or damaged components. Always consult your user manual for specifications on compatible replacements, ensuring seamless integration and functionality.

Professional Assistance: For complex repairs or maintenance tasks beyond your expertise, consider seeking help from qualified technicians. Their experience can provide valuable insights and ensure the job is done correctly.

By adhering to these guidelines, you can maintain the efficiency of your machinery and mitigate the risk of costly repairs down the line.

Understanding the Parts Layout

The arrangement of components in machinery plays a crucial role in its functionality and efficiency. Grasping the layout allows operators to familiarize themselves with the various elements, ensuring smooth operation and maintenance. Each section of the machine serves a specific purpose, contributing to the overall performance and reliability.

Key Components Overview

Each essential element can be categorized into systems that work in harmony. For instance, the engine assembly provides the necessary power, while the transmission system enables movement. Recognizing how these sections interconnect helps in troubleshooting and optimizing the equipment’s performance.

Maintenance and Repair Insights

A clear understanding of the layout aids in effective upkeep and repairs. By identifying each segment, operators can quickly locate issues, replace worn-out elements, and ensure the machine operates at its best. Regular inspections and familiarity with the arrangement can significantly extend the lifespan of the equipment.

Common Issues with Parts Usage

When dealing with machinery components, users often encounter various challenges that can affect performance and longevity. Understanding these common issues can help in maintaining optimal functionality and ensuring a smoother operation.

Compatibility Concerns

One of the primary problems is the compatibility of components. Mismatched parts can lead to inefficiencies and potential damage. Ensuring that all elements are designed to work together is crucial for smooth operation.

Quality Variability

The quality of components can vary significantly. Using substandard materials may result in frequent breakdowns and increased maintenance costs. It’s important to invest in high-quality replacements to enhance reliability.

| Issue | Description | Solution |

|---|---|---|

| Compatibility | Mismatched components leading to performance issues. | Verify specifications before purchase. |

| Quality | Inferior materials causing frequent failures. | Choose reputable manufacturers for replacements. |

| Installation | Improperly installed components can lead to malfunction. | Follow manufacturer guidelines during installation. |

Parts Replacement Guidelines

Ensuring the proper functioning of your machinery is vital for optimal performance and longevity. When components wear out or malfunction, timely replacement is essential to maintain efficiency and prevent further damage. This section provides essential advice for replacing elements effectively and safely.

Identification of Components

Before initiating any replacement process, it’s important to accurately identify the necessary components. Here are some steps to help with the identification:

- Consult the owner’s manual for specifications.

- Use reference materials to locate part numbers.

- Examine the existing parts for wear patterns or damage.

Replacement Process

Follow these guidelines for a successful replacement:

- Gather the required tools and new components.

- Ensure the machinery is turned off and safely secured.

- Carefully remove the damaged components, noting their arrangement.

- Install the new components, ensuring they fit correctly.

- Conduct a thorough inspection to confirm proper installation.

- Test the machinery to verify functionality.

Importance of Genuine Components

Utilizing authentic components is crucial for ensuring optimal performance and longevity of machinery. These original elements are specifically designed to fit seamlessly and function effectively within the equipment, providing reliability and efficiency that imitation alternatives often lack.

One significant advantage of choosing genuine components is the assurance of quality. Original items are manufactured to strict standards, which helps prevent potential failures and costly repairs. Additionally, using authentic parts can maintain the warranty of the machinery, safeguarding the owner’s investment.

| Benefit | Description |

|---|---|

| Quality Assurance | Original components are produced to meet specific standards, ensuring durability and performance. |

| Warranty Protection | Using authentic parts often preserves the warranty of the machinery, protecting your investment. |

| Optimal Performance | Genuine components are engineered for precise fit and function, enhancing overall efficiency. |

| Long-Term Savings | Investing in original parts can reduce the likelihood of breakdowns, saving on repairs and downtime. |

In conclusion, opting for authentic components not only enhances the functionality of equipment but also contributes to its longevity and efficiency. By prioritizing quality and reliability, owners can ensure their machinery operates at its best.

Locating Parts Suppliers

Finding reliable suppliers for machinery components can significantly enhance the efficiency of maintenance and repairs. The right resources ensure that operators have access to high-quality items necessary for optimal performance.

Researching Local Resources

Begin your search by exploring local options. Many communities have dedicated establishments that specialize in machinery components. Here are some tips for effective research:

- Visit local hardware stores that may stock essential items.

- Check agricultural supply shops, as they often cater to equipment needs.

- Network with other equipment owners for recommendations.

Exploring Online Platforms

The internet offers a vast array of suppliers that can provide various components. Utilize online resources effectively by:

- Searching for specialized websites that focus on machinery.

- Reading reviews and ratings to ensure supplier reliability.

- Comparing prices and availability across multiple platforms.

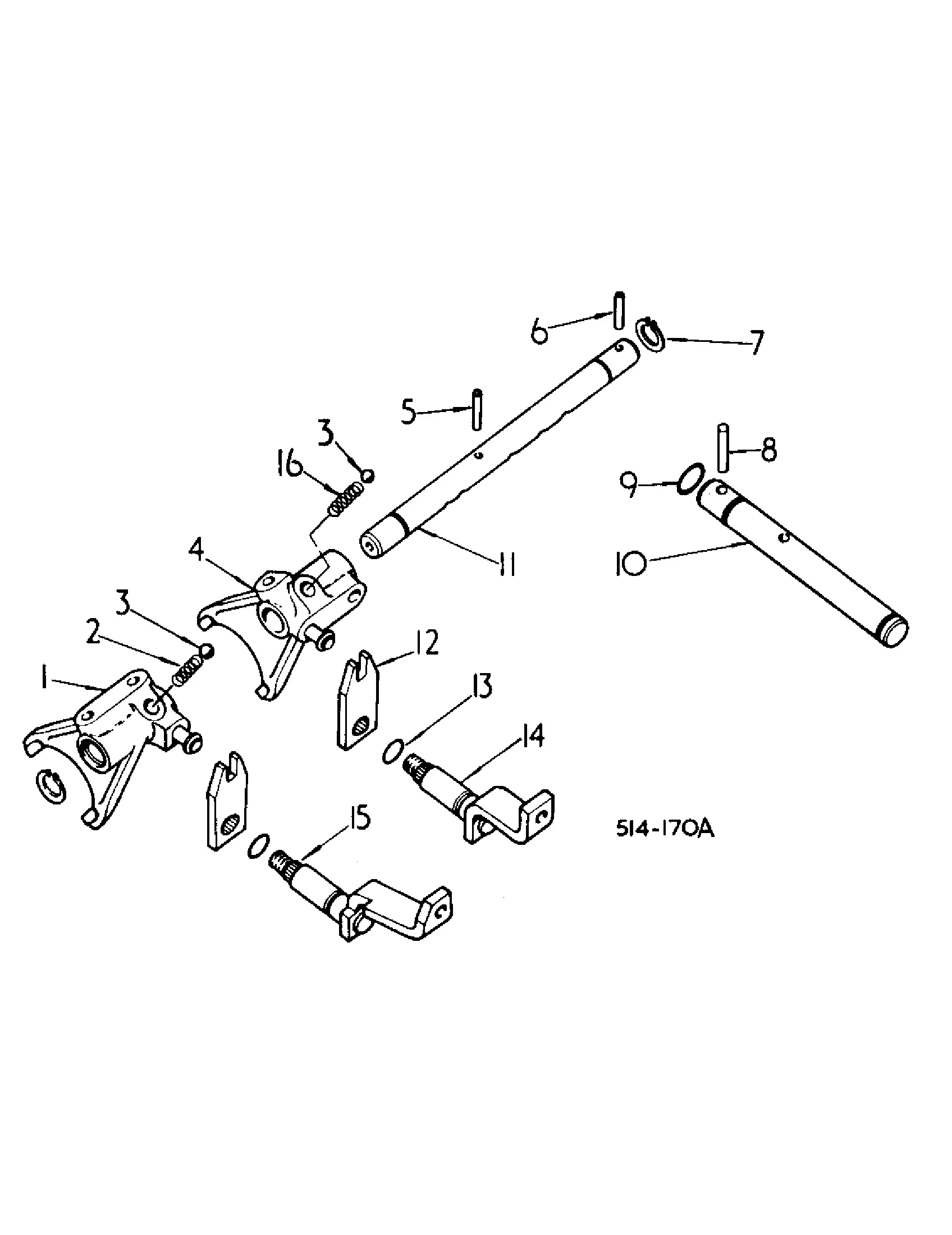

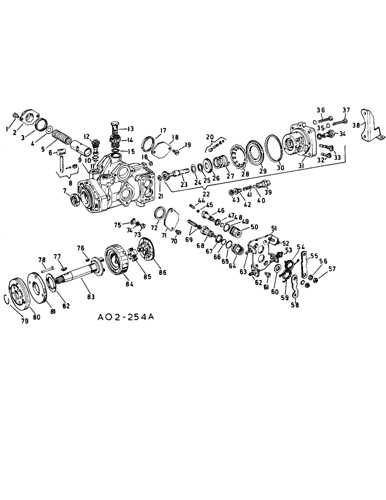

Using Diagrams for Efficient Repairs

Visual aids play a crucial role in enhancing the repair process, enabling mechanics and enthusiasts to understand complex systems quickly. By providing a clear representation of components and their relationships, these illustrations facilitate a more organized approach to maintenance tasks.

Streamlining Troubleshooting

When faced with mechanical issues, a visual reference allows for faster identification of problematic areas. Instead of relying solely on textual descriptions, one can refer to these images to pinpoint specific elements that may require attention. This method not only saves time but also reduces the likelihood of errors during the diagnostic phase.

Enhancing Assembly and Disassembly

Utilizing visual guides simplifies the process of both assembling and disassembling various components. With a clear outline of how parts fit together, individuals can work methodically, ensuring that nothing is overlooked. This approach minimizes the risk of damaging sensitive components and promotes a smoother workflow.

Safety Precautions during Repairs

When undertaking maintenance or repairs on heavy machinery, it is crucial to prioritize safety to prevent accidents and injuries. Proper precautions can help ensure a safe working environment and protect both the equipment and the technician.

Here are some essential safety measures to consider:

- Always wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and steel-toed boots.

- Ensure the machine is turned off and disconnected from any power source before starting repairs.

- Utilize proper tools and equipment designed for specific tasks to avoid injuries.

- Maintain a clean and organized workspace to minimize the risk of slips and falls.

- Be aware of your surroundings, including other workers and machinery in the area.

In addition to the above measures, it is essential to follow manufacturer guidelines and recommendations for maintenance procedures. Regular training and safety briefings can also enhance awareness and preparedness among technicians.

By adhering to these safety precautions, individuals can significantly reduce the likelihood of accidents and ensure a more efficient and secure repair process.

Resources for Further Learning

Exploring additional materials can greatly enhance your understanding and proficiency in handling various machinery components. Whether you are a novice or an experienced user, the following resources will provide valuable insights and practical knowledge.

- Online Forums: Engaging with communities of enthusiasts can offer practical advice and solutions to common challenges.

- Manufacturer Websites: Many manufacturers provide extensive documentation and manuals, helping you familiarize yourself with specific models and features.

- Instructional Videos: Platforms like YouTube have numerous tutorials that demonstrate maintenance techniques and troubleshooting methods.

- Books and Manuals: Printed literature can serve as comprehensive references for repairs and enhancements, covering a wide range of topics.

- Workshops and Seminars: Participating in hands-on training sessions can improve your skills through direct instruction and practice.

Utilizing these resources will enable you to gain deeper insights and practical skills necessary for effective equipment management.