For those working with specialized machinery, understanding the layout of various mechanisms is crucial. This article provides a detailed examination of key components and how they interact within larger systems. Whether you’re maintaining equipment or preparing for upgrades, having a clear understanding of the internal workings is essential for ensuring smooth operation.

In this guide, we’ll explore the layout of essential mechanisms, focusing on their functions and how they interconnect. By understanding the internal structures, you can make informed decisions on maintenance, troubleshooting, and enhancements.

This resource will also help you identify individual sections, making it easier to address any operational issues you may encounter. Whether you’re replacing elements or simply reviewing the configuration, a well-organized breakdown of these assemblies will ensure efficiency and longevity in your work.

John Deere 4400 Engine Components Overview

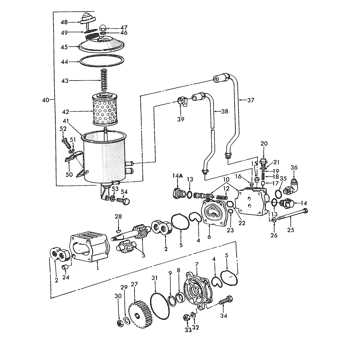

The heart of this robust machine is a precisely engineered system that powers various functions efficiently. Understanding its main mechanisms and how they work together is essential for ensuring optimal performance and longevity. The combination of carefully designed parts ensures smooth operation, making maintenance and troubleshooting much easier for users.

Cylinder block forms the foundation, housing crucial moving parts. It maintains the structural integrity needed to withstand extreme conditions. Paired with pistons, which move within the cylinders, they create the necessary force to drive the system.

Next, the fuel injection system delivers the right amount of energy source to ensure combustion, providing consistent power output. It is essential to inspect this system regularly to avoid inefficiencies.

At the core, the cooling mechanism ensures the engine doesn’t overheat during heavy workloads. This system includes the radiator and fluid passages, designed to keep temperatures within safe limits.

Finally, the exhaust assembly removes gases produced during operation, ensuring clean combustion and maintaining efficiency. Proper functioning of these elements is key to a well-performing system.

Identifying Key Elements of the Engine

The heart of any heavy-duty machine relies on several crucial components to ensure smooth and efficient performance. Understanding the primary elements that contribute to the engine’s operation is essential for maintaining longevity and reliability. This section outlines the major segments that require attention for proper upkeep and repair.

Core Components

- Power Generator: The primary source of energy, converting fuel into mechanical force, which drives the entire system.

- Cooling Mechanism: This system prevents overheating by dissipating heat generated during operation, ensuring optimal temperature levels.

- Lubrication System: Reduces friction between moving parts, extending the lifespan of the internal mechanisms.

Fuel Management and Air Intake

- Fuel Injector: Delivers precise amounts of fuel into the combustion chamber for maximum efficiency.

- Air Filter: Ensures clean air enters the system, preventing debris from causing internal damage.

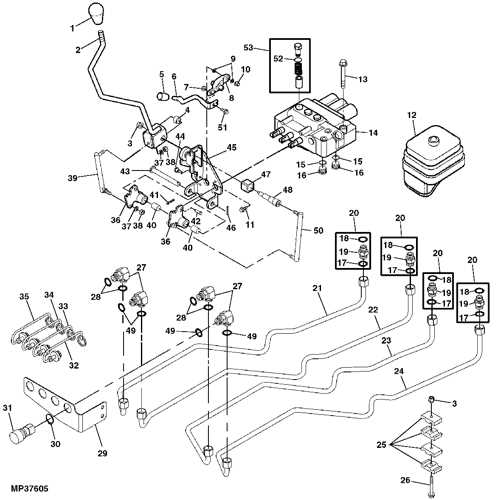

Hydraulic System Configuration on John Deere 4400

The fluid-based mechanism in this equipment model is designed for seamless integration with various attachments and operations, ensuring efficient performance. Its layout focuses on delivering consistent pressure and flow to support a range of functions. Understanding this setup is essential for maintenance and troubleshooting.

The arrangement consists of pumps, valves, and reservoirs working together to manage the distribution of fluid. These components are strategically positioned to maximize power transfer and response time. Control levers and actuators enable precise operation, ensuring the system adapts to diverse tasks while maintaining smooth operation.

Analyzing the Flow and Connections

Understanding the interrelations and dynamics of various components within a mechanical system is essential for effective maintenance and troubleshooting. By examining how different elements interact, one can gain insights into the overall efficiency and performance of the machine.

In this section, we will explore the critical pathways and connections that facilitate the operational flow of the equipment. This analysis will help identify key areas where attention may be required to enhance functionality.

- Fluid Pathways: Analyze how fluids circulate through the system, including oil, fuel, and coolant. Understanding these pathways is crucial for diagnosing leaks or blockages.

- Electrical Connections: Review the wiring and electrical circuits that connect various sensors and components. Proper functioning of these connections is vital for the overall operation of the machinery.

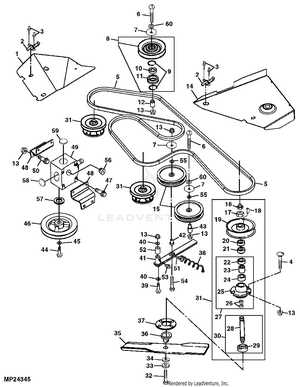

- Mechanical Linkages: Investigate the mechanical connections between different parts, such as gears and belts. Ensuring these linkages are intact and functioning smoothly is essential for optimal performance.

By focusing on these aspects, operators can make informed decisions regarding maintenance and repairs, ultimately leading to improved efficiency and longevity of the equipment.

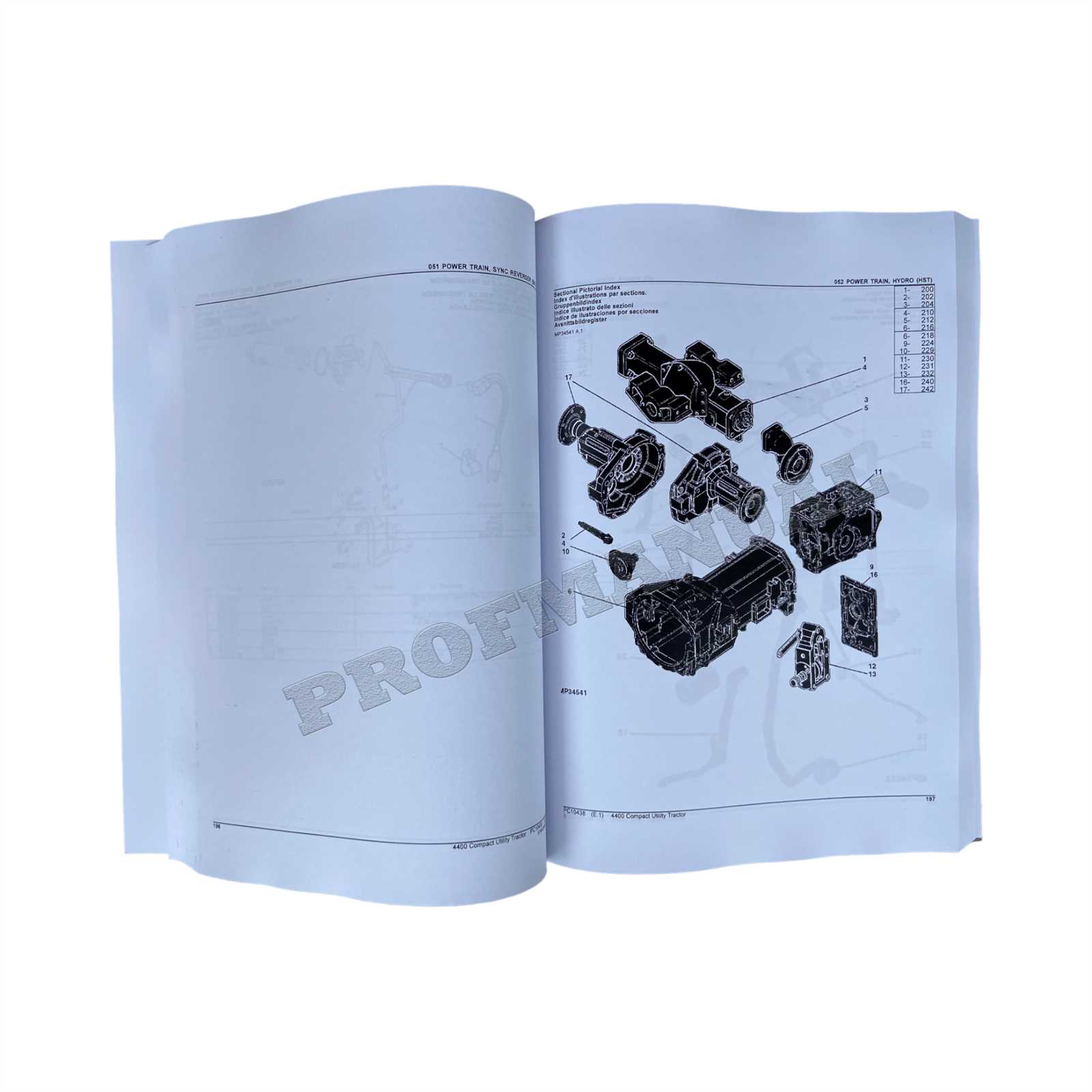

Transmission Assembly Breakdown for John Deere 4400

The transmission assembly serves as a crucial component in agricultural machinery, facilitating efficient power transfer from the engine to the wheels. Understanding the layout and function of this system is essential for effective maintenance and repair. This section provides an overview of the various elements that constitute the transmission mechanism, highlighting their roles and interconnections.

Components of the Transmission System

The transmission system comprises several key elements, each playing a vital role in ensuring smooth operation. These components include:

- Gear Sets: Responsible for adjusting the speed and torque delivered to the wheels.

- Shift Mechanism: Allows the operator to change gears easily, enhancing maneuverability.

- Hydraulic Pumps: Facilitate the movement of fluid, enabling the operation of various transmission functions.

Maintenance Considerations

Regular inspection and maintenance of the transmission assembly are essential to prolong its lifespan. Key maintenance practices include:

- Fluid Checks: Regularly verify the fluid levels and quality to ensure optimal performance.

- Component Inspection: Examine gears and seals for wear and tear, replacing them as necessary.

- Cleaning: Keep the transmission area free of debris to prevent contamination and ensure smooth operation.

Understanding the Internal Mechanisms

The inner workings of agricultural machinery are essential for efficient operation and overall performance. A thorough comprehension of these systems enhances maintenance and troubleshooting capabilities. By delving into the intricate components and their interrelationships, operators can better appreciate how each part contributes to the machinery’s functionality.

Engine systems play a pivotal role in generating the necessary power for operation. Understanding how fuel combustion translates into mechanical energy is crucial for optimizing performance and reducing wear. Additionally, the transmission components facilitate the transfer of power from the engine to the wheels, allowing for varying speeds and torque, tailored to specific tasks.

Another significant aspect is the suspension system, which ensures stability and comfort during operation. This system absorbs shocks and vibrations, contributing to better handling on uneven terrain. Furthermore, the hydraulic mechanisms enable precise control of implements, enhancing the versatility of the equipment.

Regular inspection and maintenance of these internal systems can prevent costly repairs and extend the lifespan of the machinery. Understanding the various mechanisms not only empowers operators but also fosters a more profound respect for the technology that underpins modern agricultural practices.

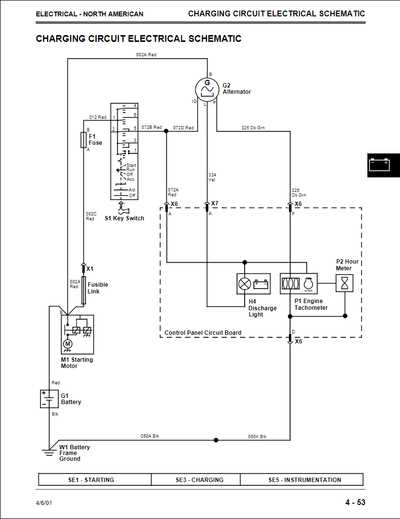

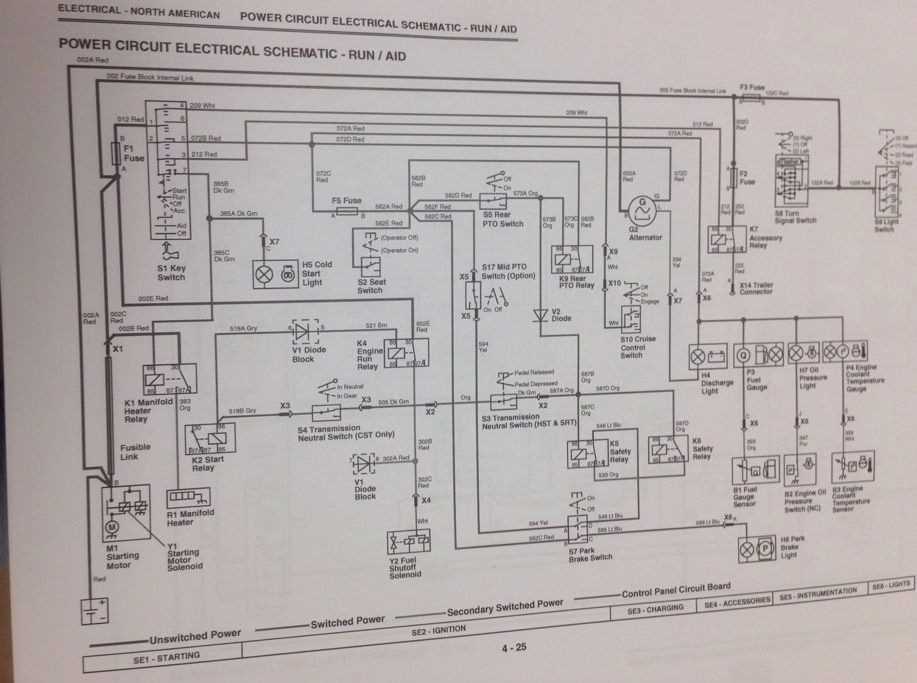

Electrical System Layout of the 4400 Model

The electrical framework of this specific agricultural vehicle is essential for its efficient operation. It encompasses various components that work together to ensure seamless functionality and reliability. Understanding the arrangement of these elements is crucial for maintenance and troubleshooting, as it allows operators to identify potential issues quickly.

Key Components and Their Functions

This system includes a battery, alternator, starter motor, and several switches and relays. The battery serves as the primary power source, while the alternator recharges it during operation. The starter motor is responsible for initiating the engine, and switches and relays control various electrical functions such as lights, ignition, and other accessories. Each component is strategically placed to optimize performance and accessibility.

Wiring and Connections

The wiring harness connects all electrical parts, facilitating communication and power distribution throughout the vehicle. Proper routing of these wires is vital to prevent wear and damage from movement or heat. Color-coded wires often denote specific functions, making it easier for technicians to navigate the system during repairs or modifications.

Exploring Wiring and Power Distribution

Understanding the electrical system of agricultural machinery is crucial for ensuring optimal performance and reliability. This section delves into the intricate wiring and energy allocation mechanisms that play a vital role in the operation of these powerful machines. By analyzing the layout and functionality of various components, one can gain valuable insights into troubleshooting and maintenance.

| Component | Description | Function |

|---|---|---|

| Battery | Stores electrical energy for starting and powering the system. | Provides the necessary voltage to initiate the engine and power electrical accessories. |

| Starter Motor | Converts electrical energy into mechanical energy to start the engine. | Engages the engine’s flywheel to initiate combustion. |

| Fuse Box | Houses fuses that protect the electrical circuits from overload. | Disconnects the circuit when excess current is detected, preventing damage. |

| Alternator | Generates electricity to recharge the battery and power electrical systems while the engine runs. | Maintains the battery’s charge and supplies power to essential components. |

| Wiring Harness | A collection of wires that connect various electrical components. | Facilitates the flow of electricity between components, ensuring proper functionality. |

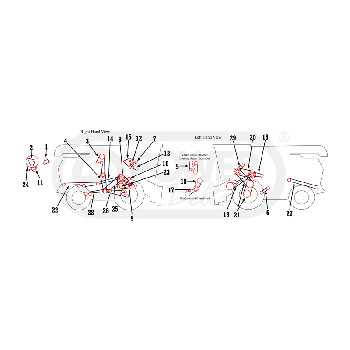

Understanding the Steering Mechanism

The steering system is a critical component that ensures maneuverability and control of agricultural machinery. This mechanism allows operators to navigate through various terrains efficiently, contributing to the overall functionality of the equipment. By comprehending how the steering operates, users can enhance their driving experience and maintain optimal performance.

Components of the Steering System

The steering mechanism comprises several key elements that work together seamlessly. These include the steering wheel, linkages, and the steering gearbox. The steering wheel serves as the primary control interface, allowing the operator to initiate directional changes. Linkages transfer the movement from the steering wheel to the gearbox, which ultimately dictates the angle of the wheels. Understanding these components is essential for troubleshooting and maintenance.

Importance of Regular Maintenance

Regular upkeep of the steering system is vital for ensuring safety and reliability. Over time, wear and tear can affect the responsiveness of the steering, leading to potential hazards during operation. Periodic inspections and adjustments can help identify any issues before they escalate, allowing for a smoother and safer driving experience. Additionally, maintaining proper lubrication in the moving parts is crucial for preventing corrosion and prolonging the lifespan of the mechanism.

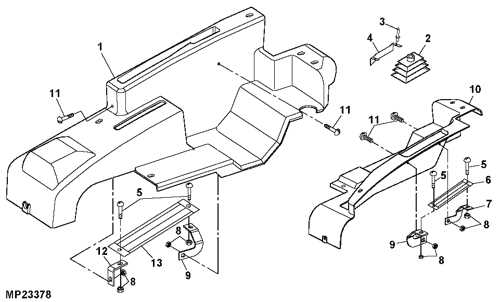

Parts that Ensure Smooth Navigation

Efficient movement and maneuverability in agricultural machinery rely heavily on various components designed to facilitate seamless operations. These elements work together to enhance control and responsiveness, ultimately contributing to the overall effectiveness of the equipment.

Key components involved in ensuring effortless navigation include steering systems, suspension elements, and drivetrain features. Each of these plays a crucial role in maintaining stability and direction during operation, allowing users to navigate diverse terrains with ease.

| Component | Description | Function |

|---|---|---|

| Steering Mechanism | A system that allows for precise direction control. | Enables accurate navigation and maneuvering in tight spaces. |

| Suspension System | A set of springs and dampers designed to absorb shocks. | Enhances comfort and stability during travel over uneven surfaces. |

| Drivetrain | Includes the transmission and axles that transfer power. | Facilitates smooth movement and power delivery to the wheels. |

Maintaining these components in optimal condition is essential for achieving reliable navigation performance. Regular inspections and timely replacements help ensure that machinery operates efficiently, reducing the likelihood of interruptions during critical tasks.

Exhaust and Muffler System Insights

The exhaust and muffler system plays a crucial role in the overall functionality and performance of any heavy machinery. This system is designed to manage the byproducts of combustion, ensuring that harmful emissions are effectively redirected while minimizing noise levels produced during operation.

Understanding the components of this system is essential for maintaining optimal performance. Key elements include:

- Exhaust Manifold: This component collects exhaust gases from the engine’s cylinders and directs them to the exhaust system.

- Muffler: Designed to reduce engine noise, the muffler contains internal chambers that dissipate sound waves.

- Exhaust Pipe: This pipe carries exhaust gases from the muffler to the atmosphere, ensuring proper ventilation.

- Catalytic Converter: A vital part of modern exhaust systems, it helps reduce harmful emissions by converting them into less harmful substances.

Regular inspection and maintenance of the exhaust and muffler system can lead to enhanced efficiency and performance. Here are some tips to consider:

- Check for leaks regularly to prevent harmful gases from escaping into the environment.

- Inspect the muffler for signs of rust or damage, as this can significantly affect sound reduction.

- Ensure that all connections and fittings are secure to avoid any exhaust backpressure issues.

- Replace any damaged components promptly to maintain system integrity.

By prioritizing the health of the exhaust and muffler system, operators can ensure smoother operation and longer lifespan for their machinery.

Components that Manage Emissions

Modern agricultural machinery incorporates various elements designed to minimize harmful emissions, ensuring compliance with environmental regulations. These components work collectively to enhance the efficiency of the engine while reducing the release of pollutants into the atmosphere. Understanding their roles is essential for maintaining optimal performance and sustainability in farming practices.

Key Elements

The following are some of the critical components responsible for managing emissions effectively:

| Component | Function |

|---|---|

| Exhaust Gas Recirculation (EGR) | Reintroduces a portion of the exhaust back into the combustion chamber to reduce nitrogen oxide emissions. |

| Catalytic Converter | Transforms harmful gases like carbon monoxide and hydrocarbons into less harmful emissions through chemical reactions. |

| Diesel Particulate Filter (DPF) | Catches and stores soot and other particulate matter from the exhaust before they are released into the environment. |

Importance of Maintenance

Regular inspection and maintenance of these emission management components are crucial. Ensuring their proper function not only helps in complying with legal standards but also improves fuel efficiency and prolongs the lifespan of the machinery.

Braking System Configuration

The braking mechanism is a crucial component of any vehicle, ensuring safe deceleration and stopping under various operating conditions. A well-designed braking system enhances overall performance and reliability, allowing operators to maintain control in different scenarios. This section provides an overview of the configuration of the braking system, detailing its primary elements and their functions.

| Component | Description |

|---|---|

| Brake Pedal | Acts as the primary control for initiating braking actions, allowing the operator to regulate speed effectively. |

| Brake Cylinder | Converts the force applied to the brake pedal into hydraulic pressure, enabling the braking action. |

| Brake Linings | Friction materials that engage with the braking surface to slow down the vehicle. |

| Brake Disc/Drum | Provides a surface for the brake linings to create friction, which is essential for effective deceleration. |

| Hydraulic Lines | Transmits hydraulic fluid between the brake cylinder and the brake assemblies, ensuring smooth operation. |

Understanding the configuration of the braking system is essential for maintenance and troubleshooting. Each component plays a vital role in the overall efficiency and safety of the machine. Regular inspections and timely replacements of worn parts will help ensure optimal performance and reliability during operation.