In the realm of farming equipment, a comprehensive overview of the various elements that contribute to optimal functionality is essential. This section aims to elucidate the intricacies of essential machinery components, facilitating a deeper understanding for users and enthusiasts alike.

Exploring the configuration and relationships among these crucial elements can enhance maintenance practices and improve overall efficiency. By dissecting the assembly, individuals can identify potential issues and streamline repairs, ensuring the longevity of their equipment.

Whether for troubleshooting or enhancement, familiarizing oneself with the arrangement and roles of these components empowers operators to make informed decisions. The knowledge gained here serves as a valuable resource for both novice and experienced users seeking to maximize the performance of their agricultural machinery.

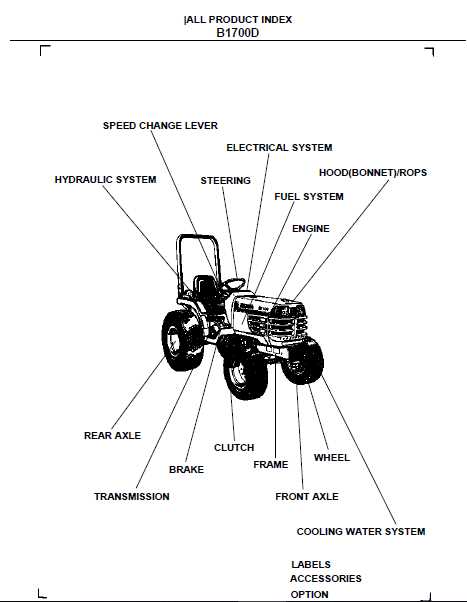

Kubota Tractor Parts Overview

This section provides an insightful examination of essential components found in agricultural machinery, focusing on their functions and significance in enhancing performance and efficiency. Understanding these elements is crucial for maintenance and optimal operation, ensuring longevity and reliability in various tasks.

Key Components

Various integral elements contribute to the seamless functioning of agricultural machines. Among these, the engine plays a pivotal role, delivering power necessary for operation. Additionally, the hydraulic system facilitates critical movements and attachments, ensuring versatility and adaptability in different farming applications.

Maintenance Tips

Regular upkeep is vital for sustaining the efficiency of these machines. It is recommended to routinely check fluid levels, inspect belts for wear, and ensure that all connections are secure. Proper maintenance not only extends the life of components but also enhances overall productivity in the field.

Understanding Basic Component Functions

This section explores the fundamental roles played by various elements within a machine’s structure. Understanding these functions is crucial for effective maintenance and troubleshooting, allowing operators to maximize efficiency and performance.

Core Elements and Their Roles

Each component within the assembly serves a specific purpose, contributing to the overall functionality of the system. Recognizing these individual responsibilities can enhance user proficiency and lead to better operational outcomes.

| Component | Function |

|---|---|

| Engine | Generates power by converting fuel into mechanical energy. |

| Transmission | Transmits power from the engine to the wheels, allowing for speed variation. |

| Hydraulic System | Powers various attachments and implements through fluid pressure. |

| Chassis | Provides structural support and stability to the entire assembly. |

Importance of Regular Maintenance

Regular upkeep of these essential elements ensures optimal performance and extends the lifespan of the machine. Familiarity with their functions can help in identifying potential issues early, thus avoiding costly repairs and downtime.

Commonly Replaced Tractor Parts

Maintenance is essential for ensuring the longevity and efficiency of agricultural machinery. Certain components often require replacement due to wear and tear, making it crucial for operators to be familiar with these frequently serviced items.

Filters play a vital role in maintaining optimal performance. Air, fuel, and oil filters should be inspected regularly and replaced to prevent contaminants from affecting engine functionality.

Batteries are another critical element that may need replacement over time. A reliable power source is essential for starting the engine and powering various electronic systems.

Belts and hoses are prone to degradation from heat and exposure to elements. Regular checks can help identify cracks or wear, preventing potential breakdowns during operation.

Fluids, including oil and coolant, require routine changes to ensure smooth operation. Regularly monitoring and replenishing these fluids can prevent overheating and engine damage.

Understanding these commonly replaced components helps operators maintain their machinery effectively, minimizing downtime and enhancing productivity.

Importance of Quality Replacement Parts

Using high-quality components in machinery maintenance is crucial for ensuring optimal performance and longevity. When equipment requires servicing, the choice of replacements can significantly influence functionality and reliability. Opting for superior alternatives minimizes the risk of malfunctions and enhances overall efficiency.

Enhanced Performance

Utilizing premium replacements ensures that the machinery operates smoothly, maintaining its intended power and precision. Quality components are engineered to meet stringent specifications, which helps avoid unnecessary wear and tear. This results in improved efficiency and productivity, allowing users to achieve their tasks effectively.

Cost-Effectiveness

While investing in high-quality alternatives may seem more expensive initially, it often proves to be more economical in the long run. Durable components reduce the frequency of repairs and replacements, leading to lower overall maintenance costs. Moreover, enhanced reliability decreases downtime, ensuring consistent operation and profitability.

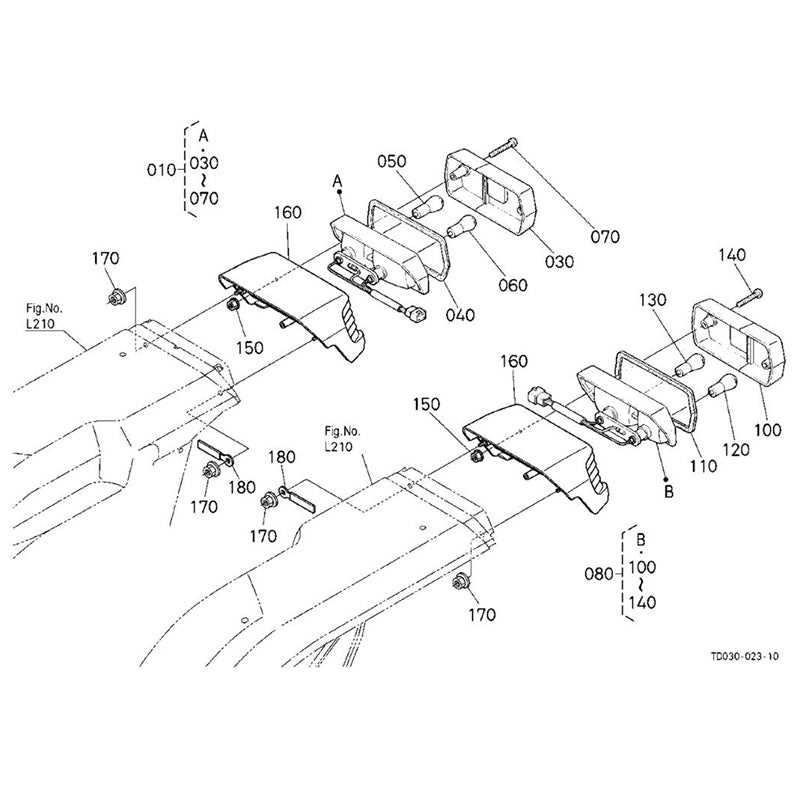

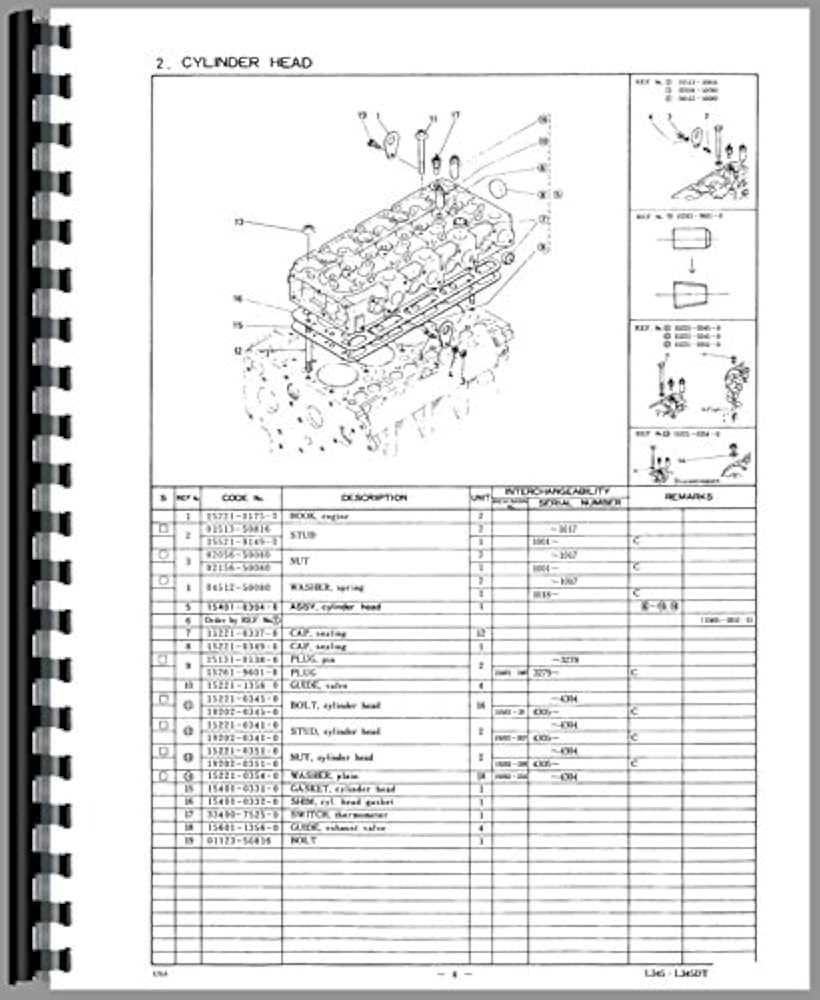

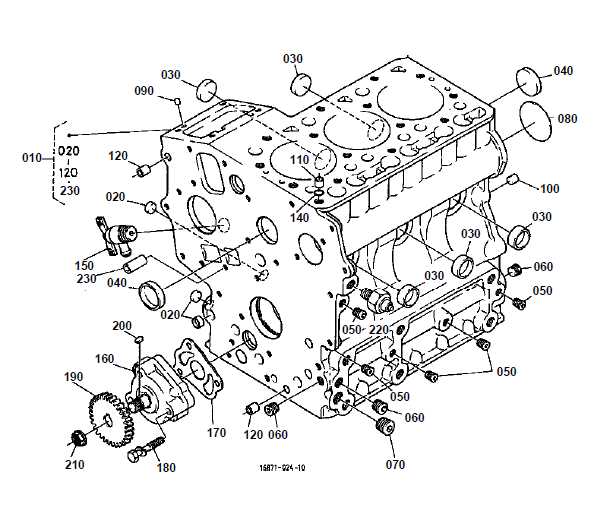

How to Read Parts Diagrams

Understanding visual representations of components is essential for efficient assembly and maintenance. These illustrations provide a detailed overview of how individual elements fit together and interact within a larger system. Mastering the art of interpreting these visuals can significantly enhance your troubleshooting and repair skills.

Begin by familiarizing yourself with the overall layout. Identify key sections that categorize various components. Typically, these visuals will include labeled areas for easier navigation. Look for legend sections that explain symbols or color codes used throughout the representation.

| Symbol | Description |

|---|---|

| Bolt | |

| Nut | |

| ⚙️ | Gear |

| Link |

Next, pay attention to the connections depicted. Lines often indicate relationships between components, showing how one part interacts with another. Understanding these relationships is crucial for effective repair or replacement.

Finally, take your time to analyze each element’s details, including measurements and orientations. This careful examination will empower you to execute tasks more accurately and efficiently.

Tools for Parts Identification

Accurately identifying components is essential for efficient maintenance and repairs. Utilizing the right tools can significantly streamline the process, ensuring that you find the correct items needed for your equipment.

Essential Tools

Several instruments can aid in recognizing and cataloging the various elements involved. Here are a few that are particularly useful:

| Tool | Description |

|---|---|

| Parts Catalog | A comprehensive reference guide detailing various components and their specifications. |

| Identification Apps | Mobile applications designed to help users identify and locate specific components using images and descriptions. |

| Digital Manuals | Online resources providing detailed instructions and diagrams for assembly and disassembly processes. |

Best Practices

To ensure the best results, keep a consistent inventory of tools and always refer to reliable sources when identifying items. Documenting findings can also aid in future maintenance tasks.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the long-lasting performance of your machinery. Regular attention not only enhances efficiency but also minimizes the risk of unexpected breakdowns. Implementing a systematic approach to maintenance can significantly extend the lifespan of your equipment.

Regular Inspections

- Conduct routine checks to identify wear and tear early.

- Examine fluid levels, filters, and belts to ensure optimal operation.

- Inspect tires for proper inflation and tread wear.

Proper Cleaning

- Clean the exterior regularly to prevent dirt accumulation.

- Remove debris from critical components to enhance airflow.

- Use appropriate cleaning solutions that do not harm surfaces.

By following these simple guidelines, you can foster reliability and performance in your equipment, ensuring it serves you well for years to come.

Where to Find Genuine Parts

Locating authentic components for your machinery is crucial for ensuring optimal performance and longevity. Reliable sources not only guarantee quality but also provide peace of mind regarding compatibility and durability. Here are some avenues to explore when seeking genuine replacements for your equipment.

Authorized Dealers

One of the best options for sourcing authentic components is through authorized dealers. These establishments typically have a comprehensive inventory and trained staff who can assist in finding the correct items for your needs. Additionally, purchasing from authorized vendors often ensures that you receive the latest updates and genuine items directly from the manufacturer.

Online Retailers

The internet offers a plethora of platforms for obtaining authentic components. However, it’s important to select reputable online retailers that specialize in high-quality machinery supplies. Checking customer reviews and ratings can help ensure that you are purchasing from a trustworthy source.

| Source Type | Advantages |

|---|---|

| Authorized Dealers | Direct manufacturer inventory, expert assistance |

| Online Retailers | Convenience, wide selection, competitive pricing |

| Local Repair Shops | Expert advice, possible bulk discounts |

| Manufacturer’s Website | Latest products, promotional offers |

Aftermarket vs. OEM Components

The choice between alternative and original manufacturer components is a significant consideration for many operators. Each option presents distinct advantages and challenges that can impact both performance and maintenance costs. Understanding these differences can help in making informed decisions that align with specific needs and budgetary constraints.

Benefits of OEM Components

Original equipment manufacturer offerings are designed to meet specific standards set by the manufacturer. These components typically ensure compatibility and reliability, as they are engineered to fit precisely within the system. Furthermore, using OEM parts often helps in maintaining warranties and securing higher resale values.

Advantages of Aftermarket Options

In contrast, alternative components often come with lower price tags and a wider range of choices. Many aftermarket suppliers offer enhanced features or improved durability, appealing to users seeking upgrades or custom solutions. Additionally, the availability of these alternatives can reduce downtime, as they may be more readily accessible than their original counterparts.

Assembly Instructions for Common Parts

This section provides essential guidance for assembling frequently encountered components. Understanding the proper techniques and order of assembly ensures optimal functionality and longevity of the equipment.

Preparation Steps

- Gather all necessary tools and components before starting the assembly.

- Review the manual or any accompanying documentation for specific instructions related to the components.

- Ensure a clean workspace to avoid losing small parts during the process.

Assembly Process

- Begin by aligning the main components according to the design specifications.

- Secure each piece using the recommended fasteners, ensuring they are tightened appropriately.

- Double-check the alignment of all components to prevent operational issues.

- Once assembled, conduct a thorough inspection to ensure everything is in place and functioning correctly.

Frequently Asked Parts Questions

This section addresses common inquiries regarding components used in agricultural machinery. Understanding the intricacies of these elements can enhance maintenance and repair efforts, ensuring optimal performance.

- How do I identify the right components for my machine?

Check the model number and specifications provided in the manual. Online resources and forums can also offer guidance.

- What should I consider when purchasing replacements?

Evaluate quality, compatibility, and warranty options. It’s advisable to choose reputable suppliers.

- How often should I replace specific components?

Refer to the maintenance schedule outlined in the user manual. Regular inspections can help identify wear and tear.

- Are there any tips for installation?

Always follow the manufacturer’s instructions. Using the correct tools and techniques is essential for effective installation.

- What is the best way to maintain these elements?

Regular cleaning, timely inspections, and lubrication can significantly extend the lifespan of your equipment.

Resources for Further Research

For those seeking to deepen their understanding of machinery components and their functionality, numerous resources are available to aid in comprehensive study. Exploring specialized literature, online platforms, and community forums can provide invaluable insights into the intricacies of various models and systems.

Books and Manuals: Look for specialized books that cover the operational principles and maintenance procedures of specific equipment. Manuals often include detailed instructions and schematics that can enhance your knowledge.

Online Forums: Engaging with online communities dedicated to machinery enthusiasts can be beneficial. These platforms allow users to share experiences, troubleshooting tips, and expert advice.

Manufacturer Websites: Many manufacturers offer extensive resources, including technical specifications and maintenance guides. These resources can be critical for understanding the design and functionality of equipment.

YouTube Channels: Educational channels provide visual demonstrations and tutorials that can help clarify complex concepts. Watching these videos can supplement theoretical knowledge with practical insights.

Utilizing these resources can significantly enhance your expertise and understanding of machinery components and their applications.