The efficient operation of agricultural machinery relies heavily on the intricate design and functionality of its various elements. Each component plays a vital role, contributing to the overall performance and durability of the equipment. Familiarity with these elements not only aids in maintenance but also enhances the operator’s ability to troubleshoot and resolve issues effectively.

To maximize the potential of heavy-duty machinery, one must explore the relationship between each segment and how they interact to form a cohesive unit. This exploration includes a detailed look at how these components are structured and function within the machinery, providing insights that can lead to improved productivity and reduced downtime.

For those engaged in the agricultural sector, understanding these intricate relationships is crucial. Proper knowledge equips operators with the tools needed to maintain their machinery in optimal condition, ensuring that every job is completed efficiently and effectively.

This section provides a comprehensive look into the essential components of agricultural machinery that has become synonymous with efficiency and reliability. Understanding these elements is crucial for optimal functionality and maintenance, ensuring the longevity of the equipment.

The following key aspects are explored in this overview:

- Historical Background: A brief insight into the evolution of agricultural machinery and its impact on farming practices.

- Core Components: An overview of significant elements that contribute to the overall performance and capability of the machinery.

- Maintenance Importance: The necessity of regular upkeep to ensure smooth operations and prevent breakdowns.

- Innovation and Technology: How advancements in technology have enhanced machinery efficiency and user experience.

- Common Issues and Solutions: Typical challenges faced by users and effective strategies for troubleshooting.

This structured approach aims to provide a thorough understanding of the various elements that contribute to the effectiveness of this essential agricultural equipment.

Importance of Understanding Tractor Components

Grasping the functionality of agricultural machinery is essential for effective operation and maintenance. A comprehensive knowledge of the various elements that constitute the equipment empowers operators to optimize performance, enhance longevity, and ensure safety. Recognizing how each section contributes to the overall efficiency can prevent costly repairs and downtime.

Key reasons for familiarizing oneself with these elements include:

- Operational Efficiency: Understanding how different components interact helps in maximizing productivity.

- Preventive Maintenance: Regularly checking and understanding the role of each part can lead to early detection of issues.

- Cost Savings: Knowledge of machinery can reduce repair expenses by allowing for timely interventions.

- Safety Assurance: Familiarity with the equipment ensures safer handling and reduces the risk of accidents.

Moreover, being well-versed in the specific functionalities can aid in troubleshooting problems more effectively. Operators who can quickly identify malfunctions are better equipped to address issues without relying solely on external assistance, leading to increased confidence and skill in managing their machinery.

In conclusion, a thorough understanding of each component is vital for anyone involved in the operation or upkeep of agricultural machines. This foundational knowledge not only improves efficiency and safety but also fosters a proactive approach to maintenance.

Parts Identification and Functionality

Understanding the components and their roles in machinery is crucial for efficient operation and maintenance. Each element serves a specific purpose, contributing to the overall performance of the equipment. Identifying these components accurately can enhance troubleshooting, repairs, and routine upkeep, ensuring optimal functionality.

Key Components and Their Roles

- Engine: The powerhouse that converts fuel into mechanical energy, driving the entire system.

- Transmission: Facilitates the transfer of power from the engine to the wheels, allowing for speed and torque adjustments.

- Hydraulic System: Provides the necessary force for lifting and controlling attachments through fluid power.

- Chassis: The framework that supports all other components, ensuring stability and durability.

- Wheels: Essential for mobility, they enable the machinery to traverse various terrains.

Identifying Components for Maintenance

Routine checks and maintenance can prevent unexpected breakdowns and extend the lifespan of the equipment. Here are some tips for identifying and maintaining key components:

- Regularly inspect the engine for leaks and unusual noises.

- Check the fluid levels in the hydraulic system to ensure proper operation.

- Monitor the condition of the tires for wear and appropriate air pressure.

- Examine the transmission for any signs of fluid leaks or slipping.

- Keep the chassis clean and free of debris to prevent rust and damage.

Common Parts and Their Uses

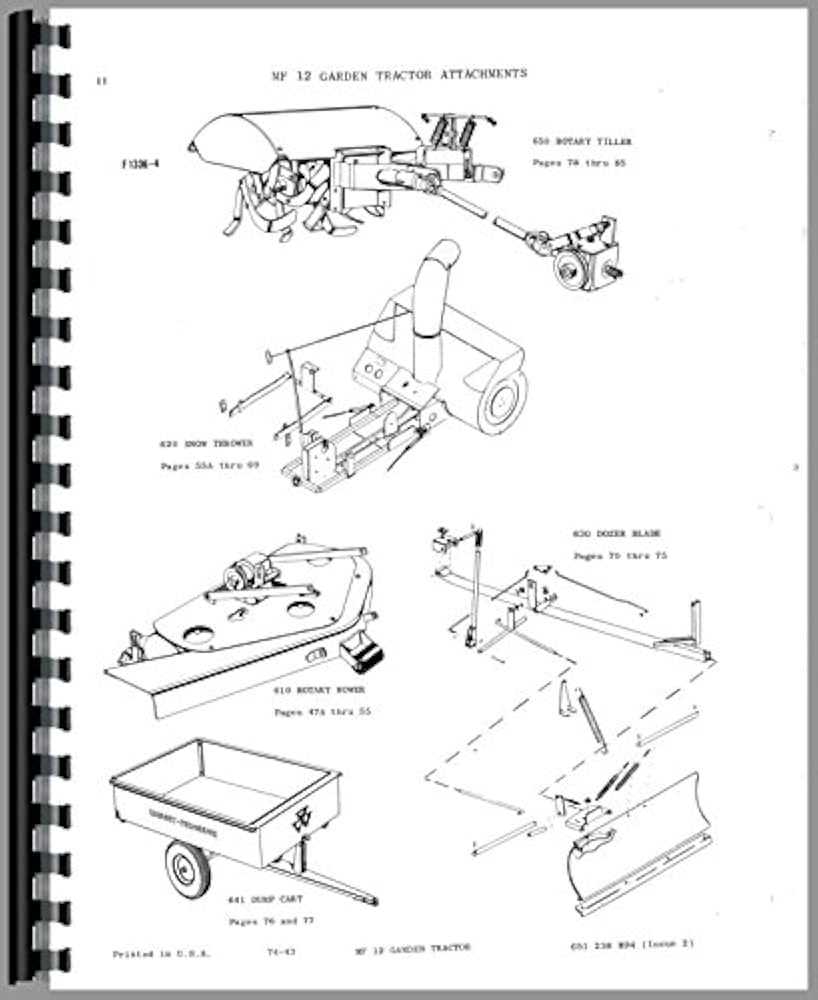

In agricultural machinery, understanding the various components and their functions is essential for efficient operation and maintenance. Each element plays a critical role in ensuring the overall performance of the equipment, contributing to productivity and durability.

Engine: The heart of the machine, the engine converts fuel into mechanical energy, enabling movement and operation of attached implements. Regular maintenance is crucial to ensure optimal performance and longevity.

Transmission: This system is responsible for transferring power from the engine to the wheels. Different types of transmissions, such as manual or automatic, offer varying levels of control and efficiency depending on the user’s needs.

Hydraulic System: This essential system utilizes fluid to operate various functions, including lifting and lowering attachments. Proper maintenance of hydraulic fluids and seals is vital to prevent leaks and ensure consistent operation.

Chassis: The framework provides structural support and houses various components, ensuring stability during operation. Regular inspections help identify any signs of wear or damage that could compromise safety.

Wheels and Tires: These components are crucial for traction and mobility across diverse terrains. Selecting the appropriate type of tire for specific conditions can significantly impact performance and efficiency.

Electrical System: This system powers lights, gauges, and starting mechanisms, playing a vital role in overall functionality. Keeping connections clean and checking for any signs of wear can prevent electrical failures.

Understanding these key components allows operators to perform timely maintenance, enhancing the machine’s reliability and extending its service life.

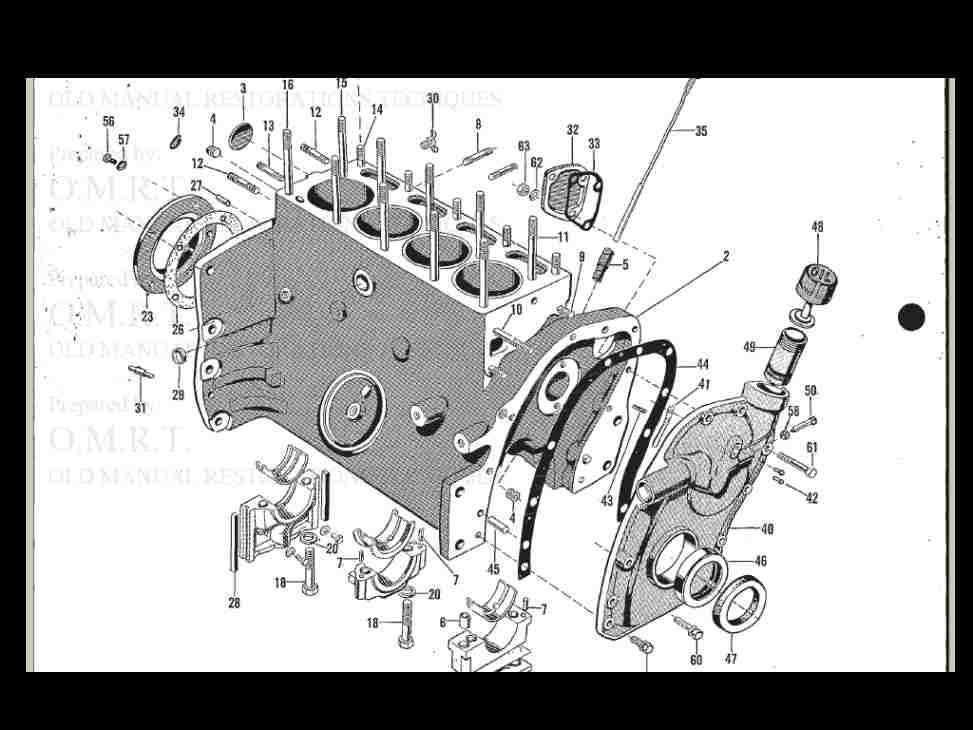

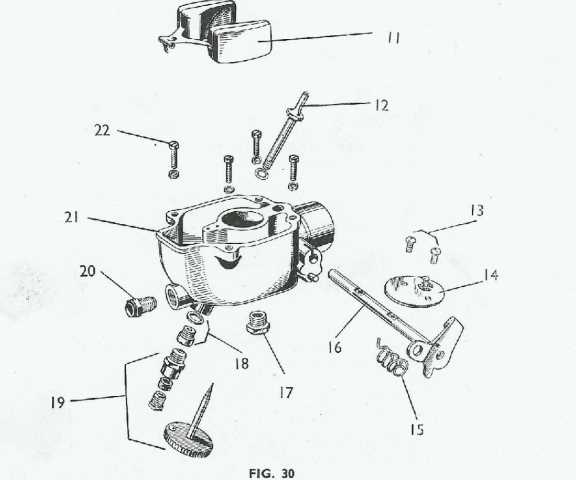

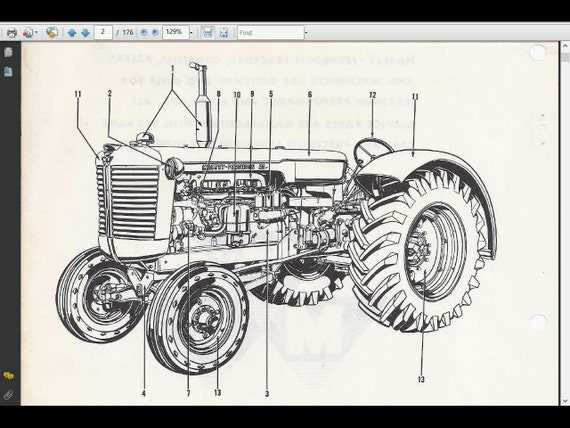

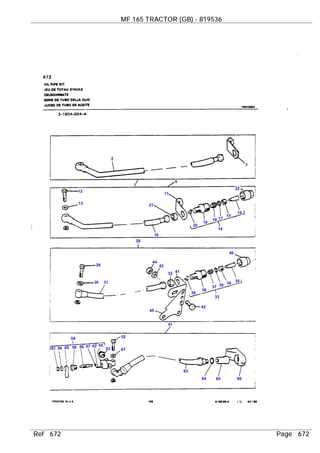

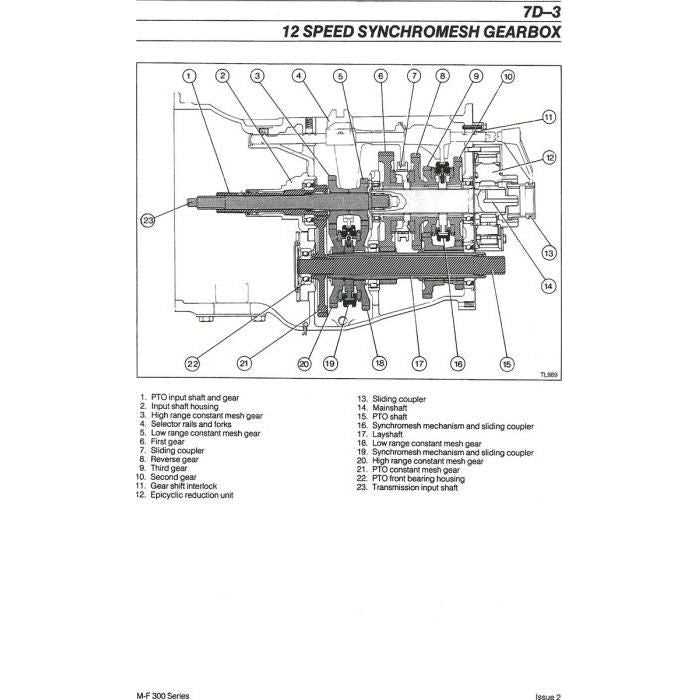

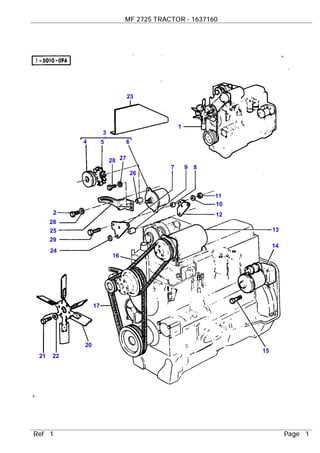

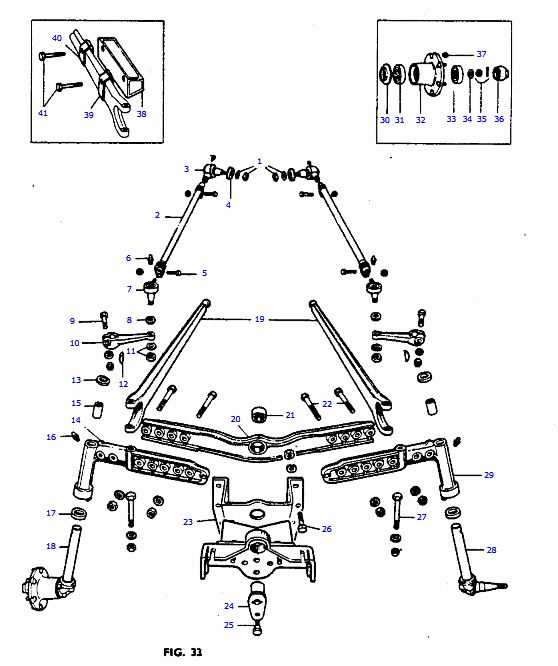

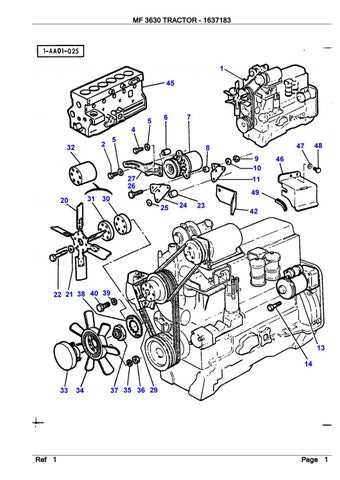

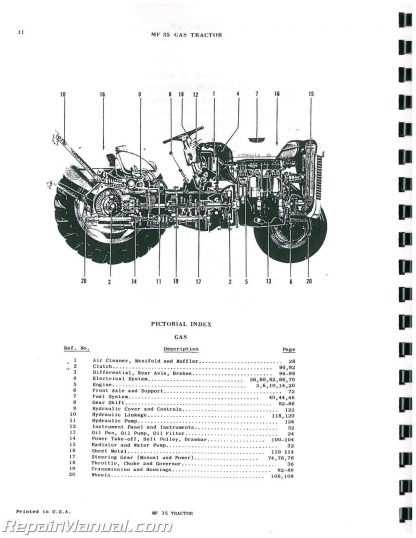

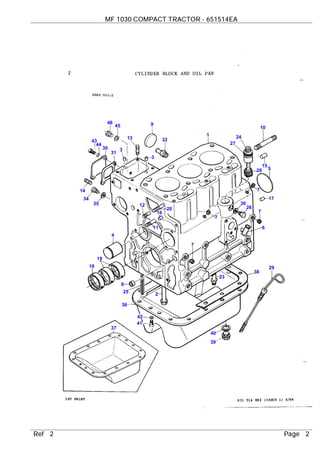

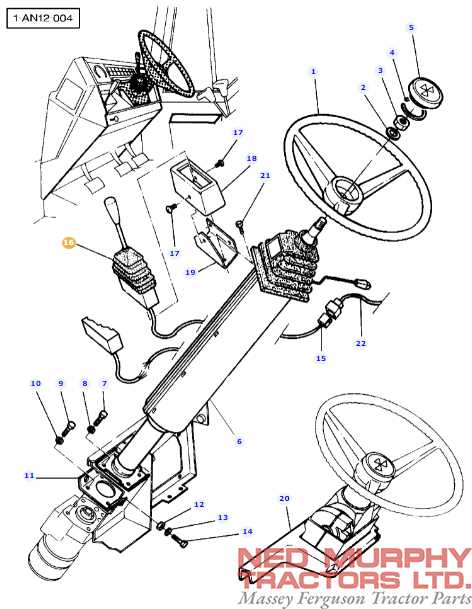

Understanding the Parts Diagram

Comprehending the assembly layout is crucial for effective maintenance and repair of agricultural machinery. It serves as a visual guide that illustrates the various components and their respective positions within the equipment. By familiarizing oneself with this layout, operators can quickly identify parts that require attention or replacement, ensuring optimal performance and longevity.

The Importance of Clarity

A clear representation of the components aids technicians in diagnosing issues efficiently. When each element is distinctly labeled, it reduces the likelihood of confusion during repairs. Understanding the arrangement not only streamlines the troubleshooting process but also enhances overall operational safety.

Navigating the Layout

To navigate the assembly schematic effectively, one must pay attention to the interconnectedness of the various elements. Each part interacts with others, creating a cohesive system. By understanding these relationships, users can make informed decisions when performing maintenance tasks or upgrading their equipment.

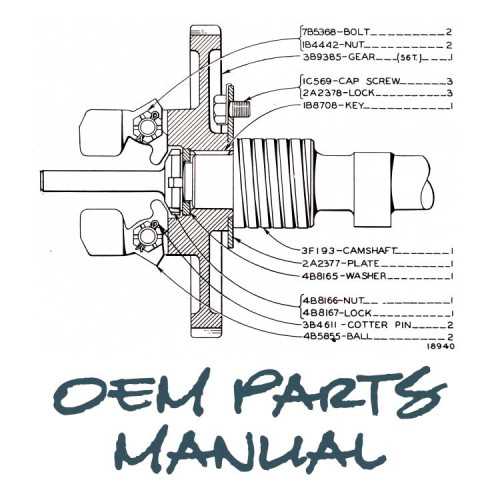

How to Read Parts Diagrams

Understanding how to interpret technical illustrations is crucial for anyone working with complex assemblies. These visual guides offer a detailed breakdown of individual components and their relationships, helping you identify, locate, and replace necessary items. Learning how to effectively navigate these images can save time and prevent errors during repairs or maintenance.

Key Elements of a Technical Illustration

Each illustration is composed of several essential elements that, when understood, make interpretation easier. These include labeled sections, numerical references, and a structured layout.

- Engine Variations: One of the primary

Aftermarket vs. OEM Parts

When it comes to replacing components in heavy-duty equipment, choosing between alternative suppliers and original manufacturers can be challenging. Both options offer unique advantages depending on the situation and specific requirements. This section explores the key differences and benefits of each, helping you make an informed decision.

- Original Manufacturer Components (OEM): These are produced by the original equipment maker, ensuring precise compatibility and reliability. They are often more expensive but provide assurance in terms of quality and long-term durability.

- Aftermarket Alternatives: These are parts created by third-party manufacturers, designed to

Resources for Tractor Repair

Finding reliable sources for machine maintenance and restoration can significantly enhance efficiency and reduce downtime. A range of guides, manuals, and technical information are available to assist operators and technicians in tackling common issues, helping ensure smooth and effective repairs.

Online Documentation and Guides

A wide variety of online platforms offer extensive resources, from step-by-step repair instructions to expert advice. These platforms provide access to service manuals, repair blogs, and community forums where professionals share valuable insights on keeping equipment in top condition.

Expert Consultation and Workshops

For more complex repairs, consulting with experts or attending specialized workshops can be invaluable. Professionals often provide hands-on training, troubleshooting tips, and practical knowledge, which can help resolve challenging mechanical problems efficiently.

Pro

Maintenance Tips for Tractor Components

Regular upkeep of essential mechanical systems ensures longevity and optimal performance. By following a systematic approach to care and inspection, you can prevent common issues and enhance the reliability of your equipment over time.

Lubrication and Cleaning

Proper lubrication of moving mechanisms is critical to reduce friction and wear. Ensure all joints, gears, and rotating elements are adequately greased. Additionally, routine cleaning helps remove debris that can cause damage or interfere with the functionality of key systems.

Inspection of Wear and Tear

Signs of Wear in Tractor Parts

Over time, key components in agricultural machinery are subject to wear due to constant use, exposure to harsh conditions, and mechanical stress. Identifying early signs of deterioration can help prevent costly breakdowns and ensure smooth operation.

Unusual Noises and Vibrations

If you notice unusual sounds such as grinding, squeaking, or rattling, it may indicate that certain elements are wearing out or misaligned. Similarly, excessive vibrations during operation often point to imbalances or loosened connections, which should be addressed promptly.

Ordering Replacement Parts Effectively

Ensuring the longevity and optimal performance of your machinery relies heavily on timely maintenance and replacing worn-out components. Having a well-thought-out approach when seeking substitutes for defective elements can significantly reduce downtime and enhance efficiency.

Identify the exact component that requires replacement. Carefully assess the condition of the faulty element and make sure you have a clear understanding of its function and compatibility with your equipment. A detailed inspection will help prevent purchasing errors.

Cross-reference available models and serial numbers to ensure the correct match for your system. Different machines often use components that

Where to Find Genuine Parts

When maintaining your agricultural machinery, it’s essential to ensure the use of high-quality, original components to guarantee longevity and optimal performance. Identifying the right places to purchase authentic elements can make a significant difference in the reliability of your equipment.

Specialized suppliers and authorized dealers are your best sources for finding original replacement items. These vendors ensure that the components meet manufacturer specifications, offering peace of mind and compatibility. Additionally, you can explore online platforms that partner with certified distributors, providing a convenient way to access genuine products.

Local dealerships

Comparison of Models and Parts

When analyzing various models, it becomes crucial to understand how their components differ in terms of functionality, durability, and design. Each series presents unique features that cater to different needs, making it essential to compare them carefully.